- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

Why (and How) to Take a Plant Tour

- David M. Upton

- Stephen E. Macadam

By adopting a systematic approach to plant tours, visitors can uncover and communicate a wealth of strategic and operating information.

In recent years, managers have recognized how manufacturing capabilities contribute to a company’s overall strategic strength. The ability to respond quickly to customers’ orders, to customize products to match customers’ exact requirements, or to ramp up production rapidly can be a powerful and difficult-to-imitate competitive weapon. But many corporate managers identify their plants’ capabilities only by accident—as a result of chance conversations with plant managers or operations specialists. Consequently, many managers do not have the information necessary to cultivate, shape, and exploit their company’s manufacturing capabilities. As plants develop, however, they need guidance to build capabilities that meet current and future needs. Plant tours can be a powerful way of providing factories with that kind of direction.

- David M. Upton is the American Standard Companies Professor of Operations Management at the University of Oxford’s Saïd Business School.

- SM Stephen E. Macadam is a principal at McKinsey & Company’s Charlotte, North Carolina, office.

Partner Center

Site Visit or Plant Tour: How to Maximize Its Effectiveness

- December 3, 2018

- Supplier Assessment , Supplier Sourcing

We’ve talked about why and how you should do a site visit before. Even though you know a site visit is of great importance in assuring you the quality and the consistency of your future products, you may still find it hard to put it to effective use. This is all the more true if you or your team have limited experience in conducting site visits or plant tours.

For some, especially those who are looking for overseas suppliers, site visits are both time and money consuming. Especially when you don’t have a local team to help you with that.

So what can you do to ensure an effective site visit? How can you maximize the effectiveness of the plant tours?

We’ve broken the whole site visit into the following 3 parts, so you’ll have a better idea of what to do in each phase of the site visit so as to make it effective as you hope.

Before the visit

Before going straight forward to the supplier, there are things that you can do to save time for the both parties. Such preparations are of utmost important in that they set the tone for the rest of the tasks that follow.

Prioritize your goals for the site visit

First, you need to know for sure why you want to do the site visit, what accomplishments you want to achieve, who do you think you should talk to if you want to get the problem solved.

Without knowing where to focus the time and effort, it’s almost unlikely that you will see a promising outcome for the site visit.

The last thing you want to do is to make the site visit just a day tour to the factory, only to discover that the site visit is but a tiring and non-effective waste of time.

Gather the right resources

Once you’ve set the goals for your site visit, it shouldn’t be hard for you to gather the right resources to actually going to the site.

For example, you should include a quality engineer in your site visit team if one of your priorities is product quality. And you should definitely include a sourcing professional if you want to make sure the product price is not off the chart.

It is, of course, very natural for you to include as many people who have site visiting experience as you can. Because the more site visits one has done, the easier for them to maximize the effectiveness of the tours. However, with the clear goals and structure set, it’s easy for even the young, in-experienced engineers to get the most out of site visits.

Do a joint preparation

When you have the goals and team set, the next thing you do is to start preparing for the visit. And we suggest doing a joint preparation, i.e. a joint meeting between you and the potential supplier.

In this way, you won’t have to explain to your supplier what exactly are you looking for at the site and waste the precious visiting time. And your supplier can prepare the required information such as data, numbers, figures when you ask for it at the site.

In addition, you can settle down on the detail schedule for the visit and propose changes to items that are of little importance to your visit goals.

During the visit

We’ve covered in the post Select the Ideal Supplier With a Site Visit about what questions you should as during a site visit.

Here is just a screen shot for your reference. Feel free to give it a read if you’re interested in knowing more.

After the visit

When the visit ends, it’s crucial that you summarize the visit into a form of report and then send feedback to your potential supplier.

On the one hand, the site visit report is a good way to tell how well you and your team have achieved the goals you set before the visit. In addition, the report provides an objective insight of whether the visited supplier is a good fit for your product.

On the other hand, your potential supplier could use the feedback to improve their expertise and capabilities. Even though the supplier won’t be your choice at the end, it’s still good for your business to maintain a nice, friendly relationship with more potential suppliers.

If site visits are almost impossible…

There are many cases where site visits are almost impossible to be done. For example, when your potential suppliers are located somewhere across the world; when you don’t have the right resources to assess the potential suppliers at site; when the suppliers refuse any chance of site visiting from you…

If you’re still bothered by the above problems, feel free to reach out to us, and we’d be more than happy to fix the problem for you.

We have a team of engineers with decades of experience in field; we’re located in Asia so it’s easier for us to get around; we have great relationships with hundreds of suppliers in almost any industries… In a nutshell, we’ve got you covered.

Feel free to let us know what’s bothering you, and we’ll see what we can do to help.

Leave a Reply Cancel reply

Recent posts.

Glass Types and Manufacturing Process

On The E-Cigarette and Vaping Chinese Supply Chain

Brief on China Smart Home Industry Supply Chain

On Microsoft’s Accusation of Foxconn IP Infringement

On The Folding Phone Screen’s Supply Chain

E-scooter Business is Zooming, How Can Chinese Supply Chain Help?

Move Manufacturing Production to Malaysia From China?

Mexico, The Next Destination for Manufacturing?

Discover more from insight solutions global.

Subscribe now to keep reading and get access to the full archive.

Type your email…

Continue reading

- Browse Archive

Published August 6, 2015 and updated July 22, 2021

How to Give a Successful Plant Tour

If you work in manufacturing, plant tours are likely a part of your everyday job. While it might not seem like a process that requires much attention to detail, there are actually dozens, if not hundreds, of different factors to consider during a plant tour. This is especially true when it comes to safety and communication.

Whether you’re trying to teach a plant visitor about workflow process or impress a potential client, giving a quality plant tour is essential in vetting new business and maintaining current business. What is one of the biggest challenges of successful plant tours? Noise.

At Sonetics , we know all about that. So, allow us to break down the ins and outs of plant tours and show you why efficient, clear communication is so important. We’ll also provide you with other tips and advice for giving an all-around successful plant tour.

Know Your Visitors’ Objectives

First and foremost, you should know the objective of your group’s visit to your plant. Knowing this will help you understand where they will be directing most of their attention during the tour, letting you plan ahead for the specific features and details you might want to point out, and can help you anticipate potential questions.

Will your guests be checking to make sure the quality of your plant is up to par? Probably. Are they looking to outsource the manufacturing of their product to your plant? Maybe. Are they investors looking to back one of your current clients? It’s possible. This article will give you a better idea of what visitors might be looking for when they visit your plant and can help you plan the flow and highlights of your tour.

No matter their objectives, you should do your best to make sure you provide your guests with a quality experience. The easiest way to do that is to make effective communication your top priority.

Prepare for Effective Plant Tour Communication

Most plant tour directors know when they should or shouldn’t speak to their groups during the tour of their facility. Likely, there are quieter hallways or corridors where the tour guide talks to the group, explains where they’re headed, and allows for questions before heading into a high-noise environment. Sounds familiar, right? While this practice is considered a standard operating procedure, it’s not all that safe or efficient for your tour group.

Lapses in communication mean lapses in safety. To solve this problem, you need a comprehensive wireless communications system. Sonetics’ variety of products can level up your plant tour by allowing your guests to hear clearly as they move about your facility and learn about your manufacturing site. This will improve your tour group’s experience at your plant and the entire safety of your process.

In addition, your group might have immediate questions or concerns that need to be answered or addressed immediately. Whether it’s an important question about a piece of equipment, or a comment about your processes, being able to talk in real-time is key to running a successful operation. By the end of a tour, your visitors might feel a bit overwhelmed. Being able to take feedback and concerns in-the-moment is a definite advantage.

While operations like the Chocolate World Tour at the Hershey Plant may have the luxury of not needing two-way communication devices, if you’re running a real manufacturing plant, your situation is different. The solution is simple: use two-way headsets to allow for efficient communication.

Show Off Your Professionalism

We know that safety is the main reason to use plant tour headsets, however, there are a few more reasons to value advanced, two-way communication systems like those from Sonetics.

If you’re already using a clear communication system for your team, why not use it for your plant tours, too? This gives your visitors a more realistic experience and shows them what it’s like to communicate on the floor of the plant day-in and day-out. They’ll get a firsthand perspective on the operations of your facility.

If your visitors are checking for quality and safety, or are vetting your company for a particular investment or deal, being transparent about your safe and effective communications will help in the long run. You’re already showing off your state-of-the-art manufacturing facility, why not show off the state-of-the-art tools and technology you’re using to make it happen, too? Next thing you know, your tour might be the next Boeing plant tour.

Another great benefit of using wireless communication devices is the opportunity to make introductions on the plant floor in real-time. Rather than waiting until the end of a plant tour to gather people into an office or room for a formal meeting, you can introduce people organically, when it makes sense. This helps with the overall flow of your tour and will help your clients put a name with a face sooner.

So, are you ready to take the leap into safe, efficient, communication with plant tour headsets? Your manufacturing business will thank you. Check out what we offer and don’t hesitate to contact us with your questions or specific needs.

We Use Cookies

By continuing to use our site, you agree to the use of cookies and other similar technologies. For details, read our Cookie Notice .

- One-Key Overview

- Accessible Construction Software

- Tool and Equipment Tracking

- Connected Smart Tools & Devices

- Data and Integrations

- All One-Key Products

- Drills & Drivers

- Hydraulic Tools

- Power Tools

- Rivets and Press Tools

- Tags & Trackers

- Connectivity Blog

- Success Stories

- Release Notes

- Quiz: How Well Do You Know One-Key?

- One-Key Support

- Request Support

- Inventory Management

- Connected Tools & Devices

- Crew Management

- Places Management

- Tool Tracking

- General Support

- Integrations

The Surprising Power of a Factory Tour

It’s not just about marketing; it’s about engaging people in solutions to real problems.

Can something as simple as a factory tour play a role in solving some of the macro-level problems that plague the construction industry? The short answer may well be “Yes.”

As the industry looks to its future, a number of issues sit in its metaphorical in-box waiting to be addressed: the labor shortage continues, with the number of job openings continuing on its increasing trend and reaching over 300,000 per month in mid-2021; productivity growth has continued to lag that of other industries ; and despite continuing adoption of sustainable construction practices, more improvement is necessary .

The good news is that there is a clear path to progress on each of these fronts, and that path entails increased use of prefab and modular construction methods. Yet many firms are setting foot on that path only hesitantly; while a reported three-fourths of firms have used prefab to one extent or another , for any individual firm that extent has not been great; only two in ten make use of prefab on half of their projects or more.

While legitimate concerns about the state of prefab and modular construction technologies have been expressed, it’s also clear that, as often as not, misperceptions about these techniques among firms, customers, and communities are the reason they’re not being used more.

Use Factory Tours to Build Engagement

The need, however, goes beyond education; it requires a real sense of engagement on the part of all stakeholders. It can be a challenge to generate and sustain that feeling of engagement in the bigger picture when people have day-in and day-out problems they need to solve. If you surveyed those who work in construction and related fields, the majority would almost certainly tell you they’d like to learn more. And that’s where a tour of a facility that manufactures prefab or modular units can be surprisingly effective. There’s no better way for any industry, or industry sub-sector, to build a sense of engagement than to make those stakeholders feel like insiders, to give them a peek behind the curtain in the form of a formal manufacturing center tour. And that benefits both the manufacturer and the customer alike.

There are a lot of ways tours can be designed to enhance the experience. Engaging all the senses makes everything more memorable. So does giving participants the chance to get a feel for the final product. At the Louisville Slugger factory tour, participants can handle the wooden rods that will soon become baseball bats, and in the process they’ll “smell the wood, and see the wood chips fly. ” The Harley-Davidson museum tour ends with participants being given a chance to settle into the saddle of a brand new motorcycle.

But while the effectiveness of the tour’s script will be enhanced by any of these additions, the tour guide’s words are still the most important source of engagement. Those words should be written keeping in mind a simple idea from author Simon Sinek: “People don’t buy what you do; they buy why you do it.” And while your customers already know what you do, and any tour makes it more clear how you do it, the real benefit of a tour for both parties is to deeply and compellingly communicate why you do it.

Well, why do you do it? The answer is different for each company, but the answer must involve solving the customer’s problems.

What problems can use of prefab or modular construction components solve?

Using prefab and modular components can not only increase labor productivity, it can result in improved scheduling, quality control, safety, and costs .

Using modular components can enhance sustainability by reducing waste, reducing disruption of the local community during construction, and reducing energy use during operation .

Modular construction does not result in “cookie-cutter” building design, and does not in fact have to reduce architectural creativity in any way.

This list of problems solvable through use of prefab/modular components actually looks a lot like the list of industry-wide “big picture” problems discussed above.

Use Tour Guide Headsets to Improve Communication

But there’s still one other critical consideration: none of this will work if the manufacturing floor is too noisy for the tour guide to be heard. Here the solution is straightforward: a wireless tour guide system that equips everyone involved with a comfortable headset and receiver/transceiver combination. The headsets are equipped with noise-reduction features, allowing the speaker’s voice to be heard clearly, right in the listener’s ears at normal conversational volume. And that creates the sense that the speaker’s words are directed at each person individually, almost more so than the group as a whole, which enhances the sense of engagement on everyone’s part.

Ultimately, the only truly effective marketing programs are those that communicate a solution to the customer’s problem. By ensuring that the message is heard, a wireless tour guide system empowers the client to use the company’s products to solve problems – not just day-to-day problems, but industry-wide issues as well.

This is a guest post written by Rick Farrell, President of Plant-Tours.com .

About the Author

Related Content

Subscribe to our blog.

Sign up to receive ONE-KEY™ news and updates.

Recent Articles

How construction professionals can stay ahead of evolving regulations for safer and more efficient construction practices.

Editorial Note : This article was brought to you courtesy of Rose Morrison, managing editor of ...

Plumber Shortage: Trade Education and Technology Needed to Fill the Gap

February 2024: construction industry news roundup.

A lot has happened in the industry since our last news roundup.

- Workforce Development

Four tips to help organize a fantastic factory tour

With good planning, people should be able to organize a memorable factory tour for all visitors..

If someone is looking for a way to draw in new customers or investors, a factory tour might be just what someone needs. It’s an excellent opportunity to show off facilities and equipment and introduce the staff. On top of that, a good company tour will emphasize professionalism and help build a stronger bond with clients.

All that is only possible if the factory tour is successful. And factories typically aren’t particularly suitable for tours — they tend to be loud and full of activity. In such conditions, it can be difficult to deliver a good presentation and ensure that everyone in the audience hears it.

Still, there are ways to organize fantastic factory tours that clients and investors will remember for years. Not sure how to do that? Consider these four tips for making a memorable tour.

1. Try to understand factory tour visitors’ goals

In order to organize a successful tour, start by understanding the visitors. If a company knows what they want to see and hear, they’ll have an easier time satisfying the visitors, and they’ll leave feeling their time was well spent. Ultimately, that’s exactly what is wanted.

Of course, someone can’t be sure what each and every member of the visiting group wants to hear. But someone can understand the whole group’s goals. Both investors and clients will probably want to see that the factory is up to par and the product quality is top-notch. But some of their other objectives might not be the same.

For instance, investors are more likely to be interested in a company’s efficiency and financial performance. After all, they are here to decide whether they should invest their money or not. On the other hand, if the visitors are potential clients, they’ll want to know more about the production process, cleanliness and inventory.

Take that into consideration when planning a tour. And of course, if someone doesn’t manage to answer all of the visitors’ questions, give them an opportunity to ask.

2. Use a wireless factory tour guide system

Factories aren’t exactly quiet — machines and people working with them tend to make a lot of noise. Thus, they don’t make a great setting for giving presentations or tours . After all, what’s the point of showing visitors around if they can’t even hear?

And, of course, someone can’t stop all activity as they’re showing visitors around. That wouldn’t only be a waste of money and time but also counterproductive to the tour. The audience wants to see how the company operates on a regular day, not an empty factory that’s not working.

So, how does someone resolve the noise issue then? Well, someone could use a wireless tour guide system during the presentation. These systems contain earpieces and microphones, allowing everyone to communicate even in less than ideal conditions. So, no matter how noisy it is, the presenter doesn’t have to raise their voice. Just speak as one would normally, and everyone will still hear.

Wireless systems usually come in two forms — one- and two-way systems. If a company chooses a two-way one, their visitors will also be able to talk to the company. Depending on the kind of tour, that may be a good idea. Someone might want to hear the audience’s feedback or allow them to ask questions even as they are being shown around.

3. Warn employees in advance

While the goal is to show visitors a regular day at the company, measures should still be taken to ensure everything goes smoothly. One such measure is telling employees an important tour is coming up and instructing them on what to do. For instance, tell them to be quieter or make more room for the group at a specific time.

Warning employees about the tour also gives them enough time to plan their activities with that in mind. Thus, they can postpone anything that may get in the way of the factory tour, as well as any projects a tour might interrupt. So, let them know at least two weeks before the big day — that way, they won’t feel blindsided.

If someone wants any of their employees to talk to visitors and share their experiences, make sure to let them know on time. They ought to prepare themselves for the part they will play in the presentation. For example, they might need time to gather and organize some information the visitors could ask them to provide. And even the most eloquent people can sometimes get tongue-tied if they are suddenly put on the spot. That is why it is best to notify employees well in advance.

4. Prepare information booklets

If someone wants their visitors to remember their factory tour longer, prepare information booklets for them. Hand them out at the start of the tour or give them as gifts at the very end. That way, the company will come off even more professional and prepared, and this good impression will linger for a while.

People can choose all kinds of information to put in a booklet, of course. But in most cases, someone should include some basic information about the company, financial stats and details about the products and services. Adding a few pictures might be a good idea, too — it’ll make a booklet that much more engaging.

RTS is a CFE Media content partner.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.

Privacy Overview

- Joining, Mounting & Bonding

- Medical Device Attachment

- Sealing & Gasketing

- Thermal Management

- Surface Protection

- EMI RFI Shielding

- Vibration Control & Sound Dampening

- Labeling & Identification

- Die Cutting

- Automated Assembly

- Rotary Die Cutting

- Flexo & Digital Printing

- Flat Bed Die Cutting

- Laser Die Cutting

- Tool Free Digital Converting

- Laminating Multiple Materials

- Clean Room Die Cutting

- 3M™ VHB™ Tape

- Adhesive Films

- Medical Tape

- Fastener Tape

- Optically Clear Adhesive

- Paper Adhesive Tape

- Foil Adhesive

- Thermal Interface Materials

- Industrial Packing Tape

- Transfer Tapes

- Masking Tape

- Medical Tape Converting

- Military & Defense

- Consumer Goods

- Renewable Energy

- Design & Construction

- Electronics

- Learning Center

- Capabilities

Touring Your Manufacturer’s Facility: What are the Benefits?

A few weeks ago, I was in Washington, D.C., for the Cherry Blossom Festival, and my friend and I thought we’d stop and get cold drinks from a nearby food truck.

I didn’t think much of it when I ordered mango tea, but as the man began pouring me a cup of plain coffee creamer, I realized we’d made a terrible mistake.

Thinking back to the incident, I can now spot the dozens of warning signs I’d ignored. For starters, every other truck had a long line, while this ice cream truck was empty. However, in the simmering heat, I trusted them simply because they’d written “TEA” on the side in big, bold letters.

Ordering from a flexible material converter without seeing the facility is like buying food from a mysterious food truck: you’ll get something, but it might not be exactly what’s written on the menu.

Facility tours can be a priceless opportunity to see the machines up close and listen to your converter explain how they use different processes. At Strouse, tours are critical to fostering customer relationships by demonstrating our existing capabilities.

Knowing the benefits of touring your manufacturer’s facility will allow you to determine when facility tours are necessary and how to get the most out of future tours.

5 Benefits of Touring Your Manufacturer’s Facility

Touring your manufacturer’s facility is more than just establishing trust in their capabilities, it’s also a way to further your connections and generate future project ideas.

These benefits of touring a manufacturing facility will demonstrate whether it’s worth the cost to your company:

BENEFIT #1: VERIFY MACHINES AND EQUIPMENT

“Yeah, we can make that for you,” says some guy you met online.

For all you know, this contact operates a single die cut machine out of his garage. Yet, when you invest in another company for your critical projects, you’ll want to have the utmost faith in their ability to deliver on time.

There’s a considerable difference between owning a single rotary die cut press versus multiple, and depending on where you are in the process, your project requires different capability levels. Not to mention, many businesses plan to scale up their production early.

Will you know whether the equipment they’re showing you is up-to-date rather than over a decade old? If you want to inspect a converter’s equipment, send one of your technical experts to check.

The company members you send on the tour will likely depend on where you are in the cycle. For example, if you’re designing for current projects, it could be helpful to bring your technical team. Meanwhile, if you already have a product planned, you might want to include your logistics or purchasing team.

Verifying the machines and equipment of a converter is the first step to checking their capability claims and building trust in the legitimacy of their business.

BENEFIT #2: OBSERVE THE STATE OF THEIR FACTORY

Nobody wants their parts built in filthy conditions, yet many people order from manufacturers without ever seeing the inside of their factory.

For certain products, cleanliness is a much higher priority than for others. For instance, medical tape, bandages, and other products should be produced and stored in a sterile environment.

When walking through the factory, consider overall cleanliness, organization, material storage, safety measures, and waste disposal. Observe the condition of their factory, including their inventory, to determine whether your contact can safely store your materials and products.

Supply chain issues are commonplace in the manufacturing industry, and your converter might be unable to compete if it can’t order and store enough material to minimize the impact of supply chain disruptions.

Lastly, ask if your converter has immediate expansion plans. It could be a good sign if they’re building, renovating their facilities, or actively adding members to their team. If your converter is steadily progressing as a company and becoming a leader in their respective field, this has positive implications for the work they’ll be doing for you.

BENEFIT #3: MEET WITH YOUR CONTACTS

Meeting your contacts establishes trust between your companies and lets you witness how they operate and meet in the middle of your processes.

Are they taking your project seriously? How have they handled the information you’ve presented them with so far? Do they ask questions about your current work and personalize the tour?

You can gauge a great deal about a company's culture based on the employees’ willingness to offer clear, insightful answers to your questions. In addition, it’s worth considering who you come into contact with on tour.

Are you directly communicating with somebody who can answer your more technical questions, or do they leave you hanging?

Touring a facility also lets you observe a company’s work environment and how the workflow is set up. While this might seem like a minor detail, it provides insight into their operations and inspires questions related to inter-team coordination.

Understanding how a potential partner operates may alter the way you coordinate, so it’s worth noting how the different teams are spread out.

Is the factory located in a separate building? You may need to confirm whether this business is the one responsible for building your part or if they’re outsourcing engineering and labor.

BENEFIT #4: INSPECT THEIR PRODUCT LEGITIMACY

Receiving samples in the mail is all well and good, but it’s different from seeing a converter build parts in real-time.

Watching rolls of material become products as part of a 1-pass production process will confirm that the machines are operational and that a converter knows how to set them up (which is arguably one of the most difficult aspects of flexible material converting) and build parts daily.

BENEFIT #5: REFLECT ON YOUR OWN PROJECT

Touring a manufacturing facility causes customers to reflect on their own project needs.

Firstly, you can rest assured that any product information you reveal will be strictly confidential if your converter suggests a mutual NDA .

Strouse insists upon a mutual NDA before anyone enters our facilities to preserve the confidentiality of our processes and protect the details of any product, process, or material information you wish to discuss.

At the end of the day, the question is: what are YOU hoping to get out of this? If you’re willing to travel to see our facility, we want to make sure you get to speak with whomever you’re hoping and see what you’d like.

Secondly, if you’re hoping to make the most of your tour, it’s useful to warn your converter and let them know more about your project or the capabilities you want to see.

You might be worried that mentioning a specific ability will narrow a converter’s focus too much. From our perspective , it simply gives us a more precise idea of what to show you and how to frame our conversations to make them more useful to you.

Even if your tour guide focuses on specific capabilities, sometimes just seeing the other machines and hearing about your options can spark ideas for your product or manufacturing process.

Should I Tour My Manufacturer’s Facility?

No matter the outcome, you’ll always have a better idea of whether you should work with a particular manufacturer after touring their facility.

In fact, even if you’ve been to a facility before, it can be beneficial to return again every few years to discuss your current projects, witness the changes they’ve undergone, and guarantee your converter still follows good manufacturing practices.

The main downside to touring a manufacturer’s facility is figuring out when a tour is necessary and potentially wasting time and travel costs to visit a nonviable option.

If the cost of travel is too much, or you don’t have enough time, there are other ways to qualify the legitimacy of a converter. For instance, you could look online at reviews to see what other people are saying or utilize Google street view to observe the appearance of their address and scope out its size.

There are three main outcomes of taking a factory tour:

- The manufacturer has your desired equipment and capabilities

- They DON’T have your desired equipment and capabilities

- There are some capabilities, but you want to find a better fit

If you can afford the travel costs, and you’re at the point of asking the question, “Should I tour this facility?” the answer is probably yes, you should request a tour.

Every manufacturer has limitations, and touring their facility is a straightforward way to visit, ask questions, and better understand where they focus primarily and how they’re expanding in the current market.

Are you interested in witnessing Strouse’s manufacturing capabilities up-close and personal? Contact us to schedule a tour.

Lee K. House

Related articles.

- Automotive Coatings

- Aerospace Coatings

- Infrastructure

- Residential

- Restoration & Repair

- Performance

- Resilient Construction

- Energy & Resources

- Wood Coatings

- Architectural Coatings

- Marine & ACE

- Industrial Coatings

- Plastics & Rubber

- Functional Packaging

- Flexible Packaging

- Paper & Paperboard

- Digital Inks

- Paper Coatings

5 reasons to ask a supplier for a plant tour

How much do you really know about your supplier's processes and practices the best way to find out is to go inside, watch: 5 things to look for when visiting a supplier, 1. confirm their safety process.

Safety is important all along the value chain, down to the end consumer, explains Christina Tarola, Account Manager, BASF. "If we're keeping our people safe, you can bet that we want to make sure that your people are safe when they're handling the products and using them. The people that encounter the product every step of the way need to know that they are touching something that's safe and that we deem it safe."

And a plant tour is the quickest way to assess whether or not a supplier complies 100 percent with its principles of the Responsible Care program.

"You get the sense of the adherence to responsible care, how well the plant is in terms of cleanliness, how well it is organized," explains Roger Haigh, Sales Manager, BASF Printing, Packaging and Adhesives. "You would see a clean, spacious plant where everything is hung up, everything is labeled." Any sign of an unkempt or cluttered plant is a red flag.

Look for how materials flow from railcar or truck, how they move through the plant and how they are stored along the way—all good indicators of safety, Haigh advises.

All hoses in these areas should be properly labeled and stored neatly to prevent tripping hazards. Ask about the safety measures to control or address leaks that might occur from the hoses or transfer pipes.

2. Efficiency

Moreover, how materials flow from railcar or truck—and how they move through the plant and are stored along the way—and not only good indicators of safety, but efficiency, Haigh adds.

Essentially, you'll get a solid grasp of "how good they are at doing what they're going to do." A plant that is run efficiently—and this probably goes without saying—translates to on-time deliveries, consistent product quality, and minimized time and financial waste.

Tip : Look for state-of-the-art control systems and tightly controlled processes that help ensure consistent product quality.

3. Build a stronger relationship to get a fast response to the next 'big ask'

Meeting face-to-face at a supplier's plant creates an opportunity to build a relationship that will result in quick and relevant action when a situation occurs that requires immediate attention.

"You get to know their plant people, you get to know more people in the organization. That gives you an opportunity to build a relationship," explains Haigh. "Bad things happen, and when they do, you can go to them and ask, 'Hey, could you schedule a bulk truck a day or two earlier, because I'm out of material?'"

"Hopefully they feel comfortable," says Tom Turnbull, BASF Production Manager. "If they have an issue or a concern, they can pick up the phone and give us a call. We're willing to talk to them and do what we can to satisfy their concerns. I think that's always easier to do after you've met and established a relationship."

It's a two-way street, however. Sharing the subtleties and nuances of business with a supplier truly makes hard questions easier to ask. If they understand your operations better, you don't have to waste time defining the problem when a solution is needed immediately.

It's a good idea to be prepared for a supplier's questions and be willing to share more than you might expect about your own operation. The more suppliers know about customers, the more they can shape solutions to the customers' benefit. Which brings us to...

4. Information exchange

"We can learn from each other," says Holly Johnson, Production Team Leader, Wyandotte Dispersions and Resins.

Talking openly with each other about what each party buys and sells can open up opportunities to suggest changes that will improve both business processes. Quite simply, the more detailed and informative the answers to those questions, the more you're going to get out of it in the long run.

"I like visiting other manufacturing facilities," says Turnbull. "If you're a manufacturing person, any time you visit somebody else's plant you can always get ideas that you can take back to your facility."

5. People, pride, and cultural alignment

The people you meet on a tour are a litmus test for those you don't meet. "Something I've observed fairly consistently is that the way a leader acts, the way that they conduct themselves—whether it be in business or personal life—tends to trickle down to their people," shares Gabriel McDonald, Continuous Improvement Specialist, Wyandotte Dispersions and Resins.

"If you're going on a plant tour and you have a very difficult time finding people or you can see that they're actively avoiding you, that would be a red flag to me—not necessarily in terms of what do they have to hide, but why would they feel like they can't speak with me? Is this reflection of their leadership? Is this the culture that's been created?"

Culture and how plant personnel behave can also signify product quality. "If I see operators yelling or not seeming very happy, it would seem to me that maybe they don't take pride in their work—is that going to impact quality downstream?" asks Johnson.

It's worth looking and listening for openness and a willingness to invest extra time. Those qualities can reveal a positive company culture that inspires confidence. And it will help assure that the supplier will deliver accurately and consistently—especially when challenges arise.

"When we really think about a company, a business is nothing but people," sums up McDonald. "It's just a group of people who have a common goal. All the capital in the world isn't going to produce anything without people."

1. Give plenty of notice. Being sensitive to supplier schedules is important, for example knowing dates for annual shutdowns before asking for a visit.

2. Draft a preferred timetable and agenda. Ensure expectations of both parties are aligned. Detailed objectives shared in advance make for more effective tours.

3. Share information. Check that the host supplier is up to date with latest developments in your business, especially if it's been more than three months since the last meeting with a sales person.

4. The NDA is your friend. Many large suppliers will ask for a Non-Disclosure Agreement (NDA) before a visit. The NDA can easily be treated as mutual, enabling the customer to provide information that will improve the supplier's learnings from the visit and the quality of service provided afterwards.

Recent Articles

- 6 Areas Every Buyer Should Check During a Factory Visit

Manufacturing and Quality Control blog

By Maegan Burkhart 2 Jul 2019

Many importers use factory visits as an opportunity to strengthen their relationship with a supplier and evaluate their capabilities. Productive factory visits can lead to improved product quality, smoother communication and fewer production delays.

And preparing before your visit helps ensure you get the maximum benefit and insight from your trip. If you’re not prepared, your factory contact might rush you through a brief tour of parts of the facility before you have a chance to see any issues or ask any questions.

There’s no substitute for a formal audit of a supplier’s facilities. But visiting the factory is a valuable opportunity for you to informally evaluate the factory for yourself. Whether your factory is in China, Vietnam, India or elsewhere, here are six areas to check during your next visit.

1. Factory organization

You often don’t need a black belt in Six Sigma to spot serious organizational issues during a factory visit.

Poor organization can cause many problems—from order delays to wasteful production processes, poor quality and even safety issues ( related: Factory Efficiency: 5 Common Examples of Poor Factory Layout & Process Setup ).

5S is a workplace organization method originating from Japan as part of the “just-in-time” manufacturing methodology. The rough English translation of each of the five S’s is:

- Sort : Sort through all items in a factory area and remove unnecessary tools, parts and instructions

- Set in order : Organize remaining items and arrange for easy use

- Shine : Clean the factory area on a regular basis

- Standardize : Schedule regular cleaning and maintenance

- Sustain : Train employees to make 5S a habit and monitor implementation

While you might see 5S posters when touring factories, it’s rare to see small- and medium-sized factories that actually implement the 5S method.

Here are a few questions you can ask yourself when visiting a factory to evaluate its organization:

- Do employees seem to be walking far from one production area to another? Moving long distances to transport materials can cause bottlenecks and slow down production.

- Are parts or semi-finished goods stacked neatly in an accessible location ? Disorganized items could be damaged or lost between production stages.

- Are materials and components labeled clearly and accurately? You should be able to spot signs and labels next to materials, even if you can’t read the local language.

2. Factory capacity: Production planning board

A supplier will often tell you their production capacity exceeds your order quantity to convince you to place an order. You can often validate this claim for yourself while visiting the factory.

- Increased production and shipping delays

- Misunderstandings regarding your quality requirements

- Limited social or other compliance oversight

A good factory takes steps to plan well for disruptions, whether they’re using sub-suppliers or not. Otherwise, they could constantly be playing catch up, especially around January or February when Lunar New Year affects manufacturing .

Every factory should be prepared year-round for potential material or labor shortages and equipment failures.

To validate a supplier’s production capacity, look for any visual boards on the production floor during your next visit. Do they list the day’s production targets and current progress? Is there a plan for the whole week? Month? These details can reveal the supplier’s true capacity and ability to track and manage orders.

Rushing production is rarely a good idea. And confirming your supplier plans for disruptions helps you rest assured that quality won’t slip during busy seasons.

3. Factory working conditions and instructions

A social compliance audit is often necessary to thoroughly assess your supplier’s working conditions. But the average buyer can still often tell the difference between a safe and unsafe working environment through a few basic checks during a factory visit:

- Are workers wearing any required protective gear to prevent injuries?

- Are workshops properly ventilated where required?

- Can you spot any safety hazards? Puddles of water, unlabeled chemicals and poor lighting are all cause for concern.

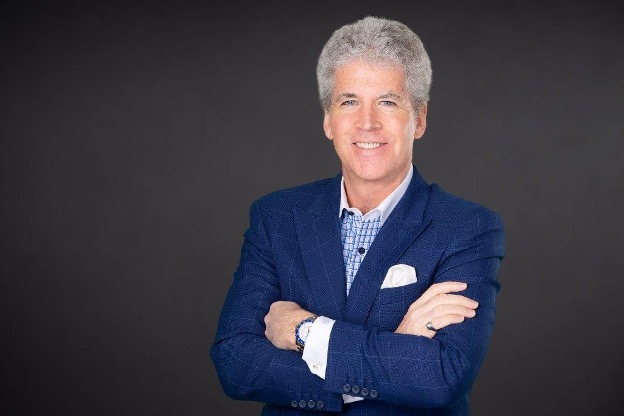

Detailed work instructions are another sign of a factory that takes working conditions and production quality seriously.

What are work instructions? You can think of them as the user instructions you reference when assembling a new piece of furniture. Assembly line workers should also have clear instructions, so they can safely and accurately complete production steps, like the below example:

Work instructions should generally be:

- Relatively simple with visual examples included to illustrate procedures

- Highly visible and clear, typically posted at each production station

You don’t need to be able to read and understand the local language to get a basic sense of how effective these work instructions are. Those that appear excessively long, poorly organized, inaccessible or hard to reference for specific information quickly can probably be improved.

4. Production equipment at the factory

Factories will generally cover the up-front cost of purchasing any necessary production equipment. But many factory owners don’t like to invest in the cost of regularly maintaining equipment.

Tools or machines that aren’t maintained or recalibrated periodically can lead to product defects , non-conforming products and inconsistent production runs.

Understanding what equipment your factory has on site can also help you set achievable quality standards based on your supplier’s available resources. You might be surprised to learn which production processes for your product are automated and which may require manual labor that can cause quality variance.

Some relevant questions to ask during your next factory visit regarding equipment include:

- Is equipment regularly inspected and in good condition? The factory should label equipment with maintenance information and log it in organized records. These records should note who performed the inspection and the inspection date.

- Does all equipment needed to manufacture your product appear to be available on site? A factory that doesn’t have all the necessary equipment might be outsourcing production.

- Does the factory have professional lab testing equipment available on site? Suppliers often claim to be able to test your products in their on-site lab but might lack essential equipment and personnel.

5. Warehouse and material inventory

Degraded raw materials used in mass production can cause quality issues in finished products, requiring extensive rework or replacement. A good factory usually conducts incoming inspections to verify raw materials before use in production.

Proper storage of finished products before shipment is also important for preserving product quality. Temperature, lighting and humidity, for instance, can affect certain products and packaging materials ( related : 3 Reasons Your Product Won’t Reach Customers in the Right Condition ).

Be sure to check the factory’s storage area for the following during your factory visit:

- Material storage time : A good factory should be able to provide records of incoming materials, including the date they were received.

- Cleanliness and orderliness of storage conditions : Materials can change or degrade if stored for long periods in improper conditions.

- Volume : Warehouse volume can indicate your factory’s capacity. You might even be able to see whether your supplier is working with your competitors by looking at carton labels.

6. Production samples

Many importers choose to plan a factory visit once the supplier has had time to manufacture a production sample. For example, you might plan your visit among other sourcing activities as follows:

- Identify and qualify a potential supplier

- Request quotation

- Place purchase order

- Factory prepares sample

- Visit factory and review sample on site

Reviewing a product sample on site often speeds up a process that can otherwise take days or weeks.

Reviewing samples on site lets you give direct feedback and point out any nonconformities immediately. The founders of Need/Want said this opportunity was invaluable for their importing company:

Immediately, we noticed a few issues with the product… Had we not been there, it would have taken a few weeks to catch them. This alone made it worthwhile for us to fly out there. The entire trip was all worth it just to catch this one mistake.

It’s still a good idea to have your supplier ship another sample after your visit to ensure they’ve corrected any nonconformities. But you can significantly speed up the process by providing clear feedback on site.

Gain more insight with a supplier visit report from a third party

Ultimately, there’s only so much information the average buyer can collect on site during a factory visit. Factory owners are often far more interested in “wining and dining” their customers than accurately representing their production capabilities ( related : 3 Cultural Barriers You Must Face for Effective China Quality Control ).

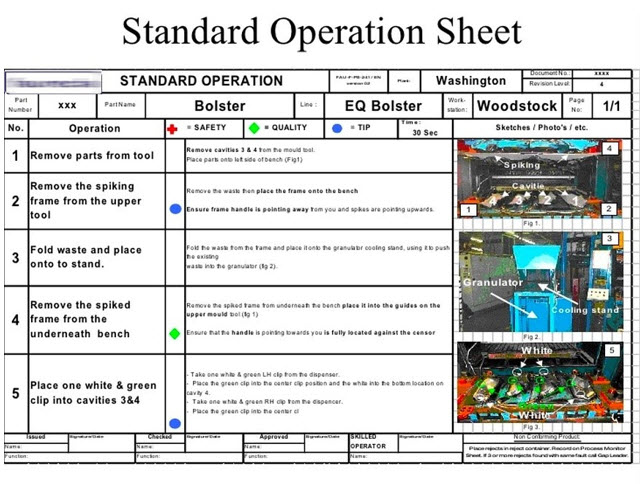

Sending an independent quality control professional to your factory can provide many benefits that an informal visit cannot. This sort of visit is commonly known as a supplier verification audit, or quality audit . The auditor typically follows a checklist based on international standards like ISO 9001 .

Professional auditors can use their industry expertise to objectively evaluate a supplier on even more areas than the six listed above. And a factory manager is less likely to influence an independent auditor that’s visiting the factory on your behalf.

How third-party supplier visit reports help you find a good factory

One of the main benefits of an independent audit is the supplier visit report you receive with results.

Quality control isn’t many buyers’ primary field of expertise, especially for purchasing managers and business owners . A third-party supplier visit report scores suppliers on objective criteria, making it easy to evaluate and compare suppliers.

- Quality management system : Evaluation of design controls, purchasing controls and production controls in compliance with ISO 9001 standards

- Quality control procedures : Evaluation of incoming, during and final product quality control procedures and use of acceptance sampling

- HR recruitment and training : Evaluations of records showing structured and frequent training programs and ethical recruitment practices

While auditors don’t typically review a production sample during an audit, you can usually ask the auditor to ship a sample to their local office for review. This can still speed up the sample review process by reducing shipment time and costs.

You can often accompany an auditor to observe the audit process for yourself. This might be a good option if you’re planning a visit but aren’t confident about your own ability to evaluate the supplier.

Every buyer should try to evaluate these six areas during each factory visit. Consider checking these factory areas as your main criteria for evaluating a supplier’s facility and capabilities.

You might also benefit from a more detailed supplier visit report from an independent auditor. A formal factory audit is especially relevant if you’re working with a factory for the first time, placing a large order or want to manage your supplier risk .

By gathering as much information as you can during a factory visit, your supply chain will be much better protected against potential disruptions.

What kinds of horror stories or other interesting discoveries have you made during a factory visit? Share them in the comments below!

POST A COMMENT

Stay updated on the latest in product inspection, auditing, and corporate responsibility weekly from the

InTouch Website

- Our Clients

- Privacy Policy

Retail Specific Compliance

- Apple Supplier Responsibility Compliance Services

- Costco Ethical Supply Chain Verification

- Nike Social Responsibility Assurance

- Sears & Kmart Vendor Conduct Adjustment Services

- Target Global Compliance Experts

- Tesco Ethical Trading Verification

- Walmart Ethical Sourcing Experts

- Product Specific Inspection

- Automotive Products

- Building Materials

- Commercial and Industrial Goods

- Cookware and Electrical Appliance

- Garment and Textile

- Jewelry, Clock, and Watch

- Juvenile Product and Toy

- Mobile Phone

- Mold and Tooling

- Sporting Goods, Fitness Equipment and Bicycle

Core Services

- Product Inspection Services

- Factory Audit China

- Pre-Production Inspections

- During Production (DUPRO) Inspection

- Final Pre Shipment Inspections in China

- Loading and Transportation Monitoring

No.1199 Heping Road, Jintian Building, Floor 9, Office 909, Luohu, Shenzhen, Guangdong, China 518010

中国广东深圳罗湖区和平路1199号金田大厦9楼909室,邮编:518010

China: +86 755-2220-0833 Europe: +33 6 43 27 34 46 North America: +1 617-274-8677 South America: +57 311 717 5792

across Asia

in 12 countries and regions

Accreditations

AQSIQ ID : 248

ISO 9001: 2015

& ISO 17020

of experience

A long history tells

Worldwide Sales Offices

America, Europe, Asia

Please contact

New business inquiries: [email protected] Existing customers: [email protected]

Our Global Service Coverage

Why and How to Conduct a Factory Tour

By Hale Foote, Scandic Springs

Reposted with permission of Springs magazine, a publication of the Spring Manufacturers Institute (www.smihq.org).

Should you consider opening the doors of your manufacturing facility to visitors? And if the answer is “yes,” how can you best conduct a tour of the plant?

Why Let the World In?

Having visitors come to your manufacturing facility offers a unique opportunity to present the business in a favorable way. When properly planned and executed, it is among our company’s most potent sales tools.

Most sales in a technical field like ours involve plenty of education. An engineer needs to learn whether your capabilities are suited to the project; a buyer wants to make sure your business processes are up to the task. Spending time together in the factory lets them learn all they need to satisfy their requirements, and the factory setting provides a much richer environment, compared to a meeting over lunch or most email or telephone interactions.

Even when the visitors don’t have a specific part they are trying to source, we look at factory tours as effective marketing. Many times I have had a visitor exclaim something like: “I knew you were a spring company, but I now see that you also do tooling and stamping. My project has a new stamping, too.” Seeing our wide range of processes very often leads to more work from an existing customer.

We host several different types of visitors who are not customers at all, or at least not yet. These long- range prospects include engineering students and their professors from Stanford and Berkeley; Scandic is now established as part of their engineering curriculum, helping with senior design projects and giving free samples of materials. I have been invited to lecture and to participate in roundtable programs there, which I think of as leveraging the marketing impact of the plant tour.

We have even invited Boy Scout troops and high school manufacturing clubs (start them young!) to tour our facility. Some of these kids are future engineers and customers, and I feel the exposure also gets the word out about manufacturing as a career choice. One of our most unusual tours was a Family Day for employees’ families, with all the machines running. I overheard one say “it’s the first time in 25 years that my family has seen what I do for a living,” and his pride was obvious.

I am often asked about confidentiality concerns regarding customer identities and their information. Like many manufacturers today, we have nondisclosure agreements with most of our customers. My advice is simply to keep prints and specs covered; if there is a particularly sensitive part or process running, shut it down beforehand and don’t dwell in that area of the plant. Before we start, I ask visitors to respect the privacy of the information, and remind them that their data will be treated the same.

How to Structure an Effective Tour

Manufacturing plants can be complex and overwhelming to a first-time visitor. I have learned the hard way that a little preparation can make all the difference in a tour. First, what time of day is best? Consider your production shift schedule; most visitors will want to see machines in action and observe how your operation works, which is difficult outside of production hours. But be very aware of both safety and cleanliness: safety because that is paramount for everyone, and housekeeping because a dirty restroom can spoil an otherwise positive impression. Keeping the plant in a visitor-ready state contributes to safety, too. And consider whether distributing safety glasses is prudent.

Spend some time to rehearse your presentation until you get comfortable. Think about the message you want to send: Are you trying to demonstrate overall competency, or do you need to show expertise in forming a kind of part that this particular visitor needs?

Who should conduct the tour? It depends on the type of visitor, and what you are trying to convey. An account manager often handles a general introductory tour. A visitor with a specific design challenge will benefit from an engineering-focused tour given by a sales engineer or engineering manager. These kinds of visitors might concentrate their time in the area of the plant which would produce the part under consideration.

Note that a quality audit is a very different kind of visit, primarily involving your QA staff and concentrating on documentation and process controls. Quality audits are usually driven by the visitor’s checklist.

Plan the direction of flow, and try walking it to see where you can stop to talk safely. In our plant, where jobs are constantly being setup and torn down, I find it useful to review the production area right before visitors arrive to know what is interesting today and what areas to avoid.

Starting and ending in the conference room is useful but not essential. But be sure to pass through your well-organized shipping area. I can tell visitors that we ship about one million parts every month, but it is more effective for them to see the bar-coded boxes lined up to ship to locations around the world.

Because Scandic has five production departments (coiling, tooling, fourslide, punch press, secondary ops) we point out synergies between departments, such as: “These parts are blanked on this waterjet, and you can see them being formed on the brake press over there.” This kind of narrative will help you from forgetting to mention an important area. But recognize that for a new visitor, some processes are sexier than others; I have to tear people away from watching the CNC wireforming machines!

If you have a large group, break into smaller teams. Generally four to six is the maximum workable size per team, at least in our plant. Even with small groups, remember that the tour guide should enunciate toward the visitors, not to the machine! You don’t need to stare at the loud punch press while you describe it: direct your voice towards the listeners, and be conscious of noise levels. One technique is to introduce a process while standing away from a noisy work center, then allow visitors to approach closer (if safe). It’s even more interesting to visitors if you can pass around a warm part fresh off the machine. Engineers especially love to hold a progression strip and figure out for themselves how the part is being stamped. If your parts are small, send visitors home with samples; it helps to prolong their experience.

Finally, remember that people are the company’s greatest ambassadors. Identify department supervisors and/or line workers who are good spokespeople, and let visitors speak with them directly. The best salesperson is never as convincing as the technician who has mastered a process. Some operators enjoy demonstrating their skill, and having them describe their area to visitors lets them shine. It also demonstrates the depth of knowledge throughout the company, and your visitors will remember that more than the “sales talk.”

In a time when most communication is electronic, an in-plant visit delivers a powerful message about what we have to offer. Tours by prospects, current customers, and even members of the community are a great way to market the business. Plant tours can showcase capabilities that even an existing customer might not know about, but planning and preparation are essential to make the visit worthwhile.

About the Author: Hale Foote is the President of Scandic Springs, Inc. Scandic is the largest spring and stamping company in Northern California, making custom metal parts for companies in the medical, automotive and aerospace fields worldwide. He has used Scandic to work with students and teachers at local schools and universities to promote careers in manufacturing. He is also on the board of directors of Manex and other nonprofits. Before joining Scandic, he practiced law in Washington, DC.

Best Universities in Luxembourg

Streamlining Student Management: The Power of Automated Systems

All You Need to Know about Scholarship to Study Abroad

International School Fees: Unveiling the True Value

Top 10 SEO company in Bangalore Specialized in SEO Educational Institute .

- Career & Jobs

- Career Guidance

- Study Abroad

- Personality Development

Industrial Visits and Production Tours- for Holistic Learning

- What are industrial visits?

- Importance of industrial visits for students

Industrial visits are now a part of the holistic educational process. Educational institutions are now realising the importance of industrial visits for college students.

So much so, the curriculum has now evolved to include industrial visits in the course syllabus.

What Are Industrial Visits and Why Industrial Visits Are Important?

Industrial visits are tours to manufacturing, production or business sites. They can be for a short duration of time lasting for just a few hours in a day, to long tours spreading over a few days.

The objectives of industrial visits are to establish a link between theory taught in a classroom and actual practical concepts .

The importance of industrial visits for college students cannot be undermined. Industrial visits contribute to the holistic learning development of students. Let’s look at some of the reasons why industrial visits are important.

1. Eliminates Misconceptions

Students may have certain pre-conceived notions based on what they see on television or hear through peer group stories. Having industrial tours can help students get the right perspective of the working of an industry.

2. First-Hand Experience

One of the reasons why industrial visits are important is because it gives first-hand experience of the work atmosphere in an industry.

Students can witness live events and activities in a business space through industrial visits.

3. Reduces the Learning Gap

A brick-and-mortar type of learning can offer only limited knowledge to students. Combining industrial visits and production tours with classroom teaching can fill the learning gap.

Students will be able to combine theoretical knowledge with practical experiences and use this additional knowledge to build their skills. This is why industrial visits for college students is important

4. Encourages Active Learning

Another importance of industrial visits for students is that it encourages active learning. Classroom learning requires sitting for long hours throughout the lecture.

However, on industrial visits students take tours of the different departments of the industry. Here, students walk and observe each department. Students become attentive and vigilant during industrial tours.

5. Improves Technical Know-How

One of the learning outcomes of industrial visits is that it improves technical know-how. Students can now observe the live working mechanisms of machinery and equipment.

Textbooks only provide a written procedure of the working of machines, but industrial visits can offer live demonstrations. These live demonstrations improve the technical knowledge of students.

6. Insight Into the Future

7. Encourages Students to Study

Believe it or not but one of the reasons why industrial visits are important is because it encourages students to study. This happens in two ways

- Some students are so mesmerised by the working of an industry that they too want to work in a similar place after college. This desire encourages them to study hard to get into an industry of their choice.

- Similarly, students are encouraged to study hard after an industrial visit because of the interest that the industrial visit has kindled in them. On an industrial visit, students learn a lot of practical concepts. These practical concepts can kindle the interest of students in certain subjects.

8. Answers Directly from The Horse’s Mouth

The importance of industrial visits for students can be seen in the fact that students can directly clear any concept doubts that they may have, directly from the management or the person in charge.

In a classroom, the teacher will clear doubts of students . However, this information is limited to textbook information.

On industrial visits, students can clear doubts from the people directly working on the concerned matter.

9. Easy Identification of The Area of Interest

An industry has many departments. Each department works in coordination with each other to fulfil the objectives of the business. Every business or industry has more or less the following departments

- Administration

Site visits demonstrate the working of all these departments. Students can get an idea about which department they would like to pursue a career in. They get a rough picture of their prospective job .

10. Witness Change in Policies

Different companies follow different company policies to achieve their goals . Through industrial visits, students can witness different policies of the companies and why they choose to follow these policies.

Industrial visits for college students is important because it shows students how to adopt the best company practices to achieve the company objectives.

11. Develops Critical Thinking Amongst Students

Another reason why industrial visits are important for students is that it develops critical thinking power amongst the students.

Many times industrial visits come with certain case studies. These case studies make students think critically to solve issues.

You May Also Like Creative Thinking Skills

12. Corporate Training Opportunities

Industrial visits are an opportunity for students to strike a conversation with the management and administration of companies.

When students are on good terms with the management, it gives them a better chance of receiving corporate training and jobs after college.

13. Change Is Good

Studying in a classroom atmosphere for long hours can be dull. Industrial visits are a welcome change from the daily routine . It is a good way for students to get a good break from the classroom atmosphere.

14. Working Conditions

When students go on business tours or industrial visits, they get exposure to the current working conditions.

Whether it is a labour centric industry or a white-collar type of company, students are exposed to the current working trends.

They can notice minute details like dress code , mannerisms of employees among other corporate trends.

15. Certification

Industrial visits are slowly becoming an integral part of the education system. Educators are now realising the importance of industrial visits for students.

Many schools and colleges have already adopted this system in their curriculum and are showing positive results.

You May Also Like Importance of Educational Excursion for Students

You Might Also Like

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Weekly Newsletter

subscribe to our latest blog and weekly newsletter

Popular News

Benefits & Importance of Having Hobbies for Students

- Advertisement -

- Certifications

Top Categories

Subscribe us, for quick admission assistance.

Sign in to your account

Username or Email Address

Remember Me

5 Key Benefits to Taking a Factory Tour

A factory tour? Thanks but no. You’re busy and have got better things to do than a factory tour – right?

Well, while you are busy and it’s easy to dismiss these events as a jolly, for us as interior architects & designers working on large-scale new build and refurbishment projects, continual professional development [CPD] is key to remaining on top of ever-changing design and technology developments in the industry.

Factory tours are one of the most valuable activities we undertake – and we’re always encouraging our clients to do the same.

If you’re a client developing a new hotel or new office project, it really does pay to visit your potential suppliers personally and find out more about their products and the way they work – and whether they are right for your project.

So what’s in it for you?

Well, to help you decide if you’ll accept your next supplier invite, we’ve compiled our list of the top 5 benefits of taking a factory tour with you and your busy diary in mind… take a look, discover what makes these visits so valuable and see for yourself the benefits they can bring to your project:

1. Relationships

Taking a factory tour is a wonderful way to build relationships with your suppliers and show them your serious about your project. Connecting personally and building great supplier relationships face to face leads to better service, better pricing and better outcomes for your project.

Earning your suppliers trust and involving them in your project from the earliest stages, ensures they become a strategic partner, vested in the project’s success.

2. Communication

Effective supplier relationships are all about excellent communication. Visiting your suppliers and seeing how they work is a crucial step in developing and agreeing on a communication style that leads to success for your project.

Moving from a purely transactional mindset and improving the way you connect and coordinate with your suppliers will lead to advantages in the speed and efficiencies of procuring products, reducing lead times and improving perfect orders.

3. Knowledge

Knowledge is power and Factory tours provide a powerful way to learn first hand how products come together.

Talking face to face with the experts, seeing the materials and activities that go into the manufacturing process and witnessing the final quality checks not only provides you with intimate knowledge of that particular product – the innovative manufacturing processes you witness may also inspire your thinking about your own working methods

4. Assesement

Evaluating a supplier and the products they produce from a distance is possible, but nothing will tell you the whole story like a factory tour.

You may already be familiar with the product range, but the benefit of a site visit to the factory and head office enables you to see – from the inside – the way the business works, how they manage their processes & production runs, what their quality management looks like and how sustainable and responsible their manufacturing is.

5. Negotiation

Strong negotiation can be the difference between a successful on budget project and a failed one. Where better to negotiate with a potential supplier than personally just after a factory tour?

As Ed Brodow, negotiation expert says “ Negotiators are detectives ” they ask the right questions and amass the right information to ensure they get the best deal. Knowing who you are dealing with and understanding their business personally will lead to smarter deals that benefit your project

A factory tour really is a great way to build balanced and sustainable supplier relationships that will truly benefit your projects. However, a visit is only as good as the planning and purpose you put into it, so before you go, organise your objectives and ask yourself a few key questions:

- Are you there to learn, to witness or to negotiate?

- Or is it all three?

- Are you looking to build relationships?

- Are you checking out capability or simply judging quality?

- What does a successful outcome look like for you?

Being clear on your objectives before your visit will ensure that you get the most out of the day and that your visit is productive and successful.

Find out more about our recent Hansgrohe Factory Tour and if you’re interested in taking some factory tours yourself, the RIBA CPD website is a great place to start.

Related articles

Ff&e and os&e explained, meet the design team – ii.

Meet the Team – Procurement

Sign up for our monthly newsletter

25 Best Factory Tours in America for Families Who Love to Go Behind the Scenes

Find out what it takes to construct a jellybean, giant plane and everything in between.

After a prolonged period of being stuck at home, some families are looking to travel again. And while the COVID-19 pandemic means that precautions still have to be taken, and not every destination is up and running at 100% capacity, there's still plenty of unique experiences out there that are once again open to the public.

The following factory tours and appropriate for kids, are well-reviewed by families and are currently open to visitors (or will be opening soon). But you might want to book ahead — some require timed tickets or reservations before you visit. But when you're done, you'll all know a little bit more about how the world around you is made.

Louisville Slugger Museum & Factory (Louisville, Kentucky)

Swing by to see how baseball bats are made — this company has been churning them out since 1884. Your family can walk through the factory production line and watch the wood chips fly! Everyone can try out bats from iconic players, like Babe Ruth and Derek Jeter. With plenty of photo ops (including your crew inside a giant baseball mitt) and a free mini bat souvenir for every guest, this tour will be a home run. Open daily; $ 18 for adults, $11 for ages 6 – 12, free for ages 5 and under

Jelly Belly Visitor Center & Factory (Fairfield, California)

From your perch above the production line, you’ll witness all the steps — slurry, steam bath, glossy application — it takes to create the gourmet jellybeans that have been a thing since the late 1800s. Video screens provide close-ups and fun facts (like it takes 1 – 2 weeks to make a jellybean). Feeling hungry? Stop at the café for a jellybean-shaped pizza. Open daily (but factory workers are typically there only on weekdays), $5 for adults, $2 for ages 2 and up, free for younger kids

The Kazoo Factory Tour Experience (Beaufort, South Carolina)

After learning the ins and outs of kazoo-making during a factory walk-through, everyone gets to create their own instrument to take home. A built-in souvenir is music to our ears! Open Monday to Friday, $9 for adults, $7 for ages 4 – 11, free for younger kids

MORE INFORMATION

PEZ Visitor Center (Orange, Connecticut)

The colorful facility dispenses equal parts nostalgia (it maintains well-organized vintage PEZ displays) and tech wizardry (you can see how the famous candy is packed). Be sure to snap your kid’s pic in front of the world’s largest PEZ dispenser, which looks like a person wearing a PEZ-themed baseball cap. Open daily; $5 for adults, $4 for ages 3 – 12, free for younger kids