Welcome to ArcelorMittal Automotive space

This is your personal space on ArcelorMittal's global automotive website. You can keep your favorite ArcelorMittal automotive web pages and configurations in a safe place for later access on any device, anytime in the future.

In this space, you can find:

- Pages on this site you have saved as favorites

- The configurations that you have created in the 3D car configurator using ArcelorMittal’s best-in-class solutions

- Your e-alert preferences for ArcelorMittal’s latest automotive news

I'm not registered. Register now.

Registration

Sign up for Automotive and enjoy the benefits by receiving our newsletters, downloading software, saving your bookmarks, sending it to your colleagues and much more. If you have any questions you can contact us at [email protected] .

All fields with (*) are required

I'm already registered. Login now.

Tailor your ArcelorMittal Automotive web experience

If you want, you can tailor your web experience on this automotive website to your personal needs. By selecting your job profile and/or region (both optional) you enable us to personalize the content you see on this website. No matter which job profile or region you select, you will always have unlimited access to all the information on this website. The only thing that changes is that you will be offered more tailored content. As well as your profile and region, we also use your browsing history on this website to remember your personal preferences and identify the most appropriate content for you. We are confident that this will help you to find the inspiration you are looking for on the ArcelorMittal automotive website.

My ArcelorMittal Automotive space

This is your personal space on ArcelorMittal’s global automotive website. You can keep your favorite ArcelorMittal automotive web pages and documents in a safe place. In this space, you can find:

- Your personal version of ArcelorMittal’s global automotive product catalogue

- A list of the personal car configurations that you have created in our 3D car configurator using ArcelorMittal’s best-in-class solutions

By logging into this website, you help us to offer you the most personalized experience possible. No matter what device or browser you use, your personal preferences, saved documents and favorited pages will always be accessible. No pages require a login to view content. So there is absolutely no obligation to create a login for this website. All information on this website is available to every visitor, without limits.

Please also check our privacy message which explains how we comply with the EU’s general data protection regulation (GDPR) and other relevant privacy laws.

Customize your experience by creating an account

You can store your preferences, favorite ArcelorMittal automotive web pages and documents in a safe place, accessible at any time, from any device.

- Your personal version of ArcelorMittal’s global automotive steel product catalogue

- Access to the car configurations that you have created in the 3D car configurator using ArcelorMittal’s best-in-class solutions

By creating an account for this website, you help us to offer you the most personalized experience possible.

Register now Remind me later

Don't ask me again

Privacy policy

Log in to your ArcelorMittal automotive account

To avoid spam, we must be able to identify the sender of the e-mail. Therefore, we kindly ask you to sign in or make an account first.

Login to my account Create account

- Flat products - our global offer

- 1st Gen AHSS

- TRIP steels

TRIP (TRansformation Induced Plasticity) steels

Description.

TRIP steels offer an outstanding combination of strength and ductility as a result of their microstructure. They are thus suitable for structural and reinforcement parts in complex shapes. The microstructure of these steels consists of islands of hard residual austenite and carbide-free bainite dispersed in a ductile ferritic matrix. Austenite is transformed into martensite during plastic deformation (TRIP: TRansformation Induced Plasticity effect), enabling greater elongation to be achieved which endows these steels with their excellent combination of strength and ductility.

These steels have considerable strain hardening capacity which endows them with good aptitude for strain redistribution and hence excellent drawability.

In the course of the manufacturing stages of parts, the tensile strength of TRIP steel increases sharply compared to its reference value for flat metal, both under the effect of local stamping strains and BH (Bake Hardening) effect during the paint process. These effects can be used to optimise the design of the part, especially in terms of crash behaviour. See below.

Applications

As a result of their high energy absorption capacity and fatigue strength, TRIP steels are particularly well-suited for automotive structural and safety parts such as crossmembers, longitudinal beams, B-pillar reinforcements, sills and bumper reinforcements.

ArcelorMittal has extensive data on the forming and service properties of the TRIP family of steels. A team of experts is available to carry out specific studies based on modelling or laboratory tests to incorporate these steels at the design stage.

B-pillar reinforcement in CR450Y780T-TR-EG (thickness: 1.2 mm)

Bumper cross member in CR450Y780T-TR-EG (thickness: 1.6 mm)

Designation and standard

Cold rolled steel.

Uncoated (EN 10338: 2015): Steel grade name Electrogalvanized (EN 10338: 2015 + EN 10152: 2017): Steel grade name+ZE Galvannealed (EN 10346: 2015): Steel grade name+ZF Extragal ® (EN 10346: 2015): Steel grade name+Z

VDA 239-100

Uncoated: Steel grade name-UNC Electrogalvanised: Steel grade name-EG Galvannealed: Steel grade name-GA Extragal ® : Steel grade name-GI

Mechanical properties

A 80mm %: Percentage elongation after fracture using a specimen with gauge length L 0 = 80 mm (ISO 6892-1 type 2 (EN20x80)) A 50mm %: Percentage elongation after fracture using a specimen with gauge length L 0 = 50 mm (ISO 6892-1 type 1 (ASTM12.5x50) or type 3 (JIS25x50) A%: Percentage elongation after fracture using a proportional specimen with L 0 = 5.65 (So) 1/2 Ag %: Percentage plastic extension at maximum force BH 2 : Increase in yield strength between a reference condition after a 2% plastic pre-strain and the condition obtained after heat treatment (170°C-20minutes)

Typical CR450Y780T-TR-EG microstructure (residual austenite fraction approx. 18%)

Typical CR400Y690T-TR-GI microstructure (residual austenite fraction approx. 10%)

Chemical composition

Global availability.

- Global view

- Europe region

- North America region

- South America region

- South Africa region

Under development Customer trials Commercial unexposed only Commercial exposed and unexposed

Under development Customer trials Commercial unexposed only Commercial exposed and unexposed

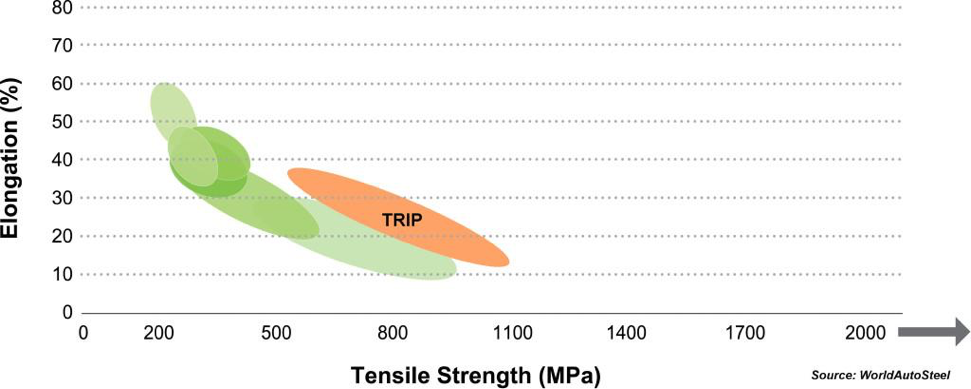

TRIP steels offer high ductility relative to their tensile strength. For example, CR450Y780T-TR boasts uniform elongation comparable to that of a type CR3 deep drawing grade.

The illustration below shows examples of forming limit curves for 1.5 mm thick CR400Y690T-TR and CR450Y780T-TR steels. Their formability is superior to that of a lower strength CR330Y590T-DP steel.

Forming limit curves for CR400Y690T-TR-GI and CR450Y780T-TR-EG (thickness: 1.5 mm) (ArcelorMittal model for Europe)

Forming limit curves for CR400Y690T-TR-GI and CR450Y780T-TR-EG (thickness: 1.5 mm) (Keeler model for North America)

Please contact us for more information on forming TRIP steels.

Resistance spot-welding

TRIP steels can be readily welded using conventional welding processes, provided the welding parameters are adjusted.

The table below gives examples (for information only) of spot welding parameters for CR400Y690T-TR-GI and CR450Y780T-TR-EG matching joints, in accordance with the ISO 18278-2 standard:

MAG arc welding

MAG (Metal Active Gas) arc welding employs a filler wire in a protective gas shield. It can be used for thicknesses greater than 0.8 mm. MAG weldability of CR450Y780T-TR has been assessed using CMOS (Welding Operating Procedure Characterisation based on standards EN 288 and EN 25817) for 1.5 mm thick butt joints. Heat input is of the order of 2 kJ/cm.

As a result of its chemical composition, CR450Y780T-TR typically has a relatively high carbon equivalent of the order of 0.50. However, no particular precautions are needed to prevent cold cracking. In actual fact, the reduced thicknesses employed (< 2 mm) minimise restraint stresses during welding.

The most appropriate combination for MAG welding of CR450Y780T-TR in a thickness range of approx. 1.5 mm is as follows:

- Filler: G3Si1 type in accordance with EN 440

- Shielding gas: Ar + 8% CO2

- (M21 in accordance with EN 439)

The CMOS evaluation shows satisfactory overall weld behaviour meeting the mechanical strength criteria set out in the standards, given that:

- Bends are acceptable up to 120° and crack on the reverse side at 180°;

- All tensile test failures occur in the base metal thanks to base metal/filler metal dilution, even with G3Si1 wire.

Laser welding

Laser welding tests have revealed no particular difficulties. Laser lap welding is particularly suitable for TRIP/TRIP joints.

Based on extensive shop-floor experience in characterising its products, ArcelorMittal is able to provide technical assistance in adjusting the welding parameters for all steels in the TRIP range.

Fatigue strength

Due to their high mechanical strength, TRIP grades boast significantly better fatigue properties than conventional steels.

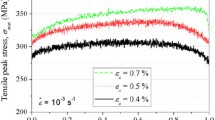

Examples of Wöhler curves for a variety TRIP grades are shown in the two graphs below. The curves plot maximum stress versus number of cycles to failure. They are calculated for two loading ratios: tension-compression R=-1 and tension-tension R=0.1.

The graph below shows the low-cycle fatigue or E-N curves for the same steels. The curves plot strain amplitude versus number of reversals to failure (one cycle equals two reversals). Other high and low cycle fatigue data can be provided on request.

ArcelorMittal can make a TRIP steel fatigue database available to its customers.

Impact strength

As a result of their very high tensile strength, TRIP steels are particularly suitable for parts designed to absorb energy in an impact.

TRIP steels have been characterised in dynamic axial compression tests using an omega structure with a spot-welded closure plate at an impact velocity of 56 km/h. These tests have demonstrated the very positive impact behaviour of these steels.

Weight-reduction potential compared to that of a CR340LA steel (reference)

These results are obtained for test pieces produced by bending. Strain-hardening during drawing enhances the energy absorption capacity of this grade. In order to fully exploit the potential of TRIP steels, the metal properties after forming (hardening) rather than those of the initial blank should be used in the design stage. Crush tests have shown a 9% gain in energy absorption of drawn parts compared to parts obtained by bending.

You may also be interested in

Explore our steel solutions for bev and ice vehicles, search our products.

By products

By strength, by product reference, by coatings, by applications, create your personal catalogue, get in touch with our experts.

Click here to see what we’re doing in Paris!

S-in-motion ® solutions

Innovation & sustainability, tailored blanks.

- Drawing steels

- HSLA steels

- Bake hardening steels

- Solid solution steels

- Dual Phase steels

- Complex Phase steels

- Ferrite-bainite steels

- Fortiform ®

- MartINsite ®

- Usibor ® and Ductibor ®

- Alusi ® -AS

- Extragal ® -GI

- Ultragal ® -GI

- Galvannealed-GA

- Zagnelis ® Protect-ZMP

- Zagnelis ® Surface-ZMS

- Electrogalvanized-EG

- Surface treatments

- Jetgal ® -ZV

- iCARe ® electrical steels

- iCARe ® Save

- iCARe ® 420 Save

- iCARe ® Torque

- iCARe ® Speed

- Coatings for iCARe ®

- High carbon steels

- Extragal ® double-side pure zinc galvanized steel

- Galvannealed zinc-iron alloy coated steels

- Zagnelis ® Protect Double-sided ZnMgAl galvanized steel

- Zagnelis ® Surface Double-sided ZnMgAl galvanized steel

- Galfan ® Steel coated with galfan zinc-aluminium alloy

- Steel coated with Alusi ®

- Electrogalvanized sheet coated on one or both sides

- Surface treatment

- Jetgal ® Cold stamping steel coated with zinc from an innovative & environmentally friendly process

Innovation & Sustainability

S-in motion ® solutions

- Advantages of laser welded blanks

- Applications for laser welded blanks

- Laser welded blanks for hot stamping

- Laser welded blanks for cold stamping

- Unwelded blanks – die cut blanks

- Unwelded blanks – laser cut blanks

- Patched blanks

- Multi Part Integration

- One-part rear H-frame

- Double door ring

- Ductibor ® / Usibor ®

- Laser ablation

- Nesting optimization

- Co-engineering

- Feasibility analysis

- Quality assurance

- Prototyping

Sustainability

News, events and stories

- an automotive engineer

- an automotive material purchaser

- an automotive top manager

- an automotive journalist

- an investor

- an influencer

- an ArcelorMittal colleague

- a student/professor

- an environmentalist

I am especially interested in information about automotive steel for…

This is your personal space on ArcelorMittal's global automotive website. You can keep your favorite ArcelorMittal automotive web pages and documents in a safe place

Configure this website

What are TRIP Steels?

WHAT ARE TRIP STEELS (Transformation Induced Plasticity Steels)?

TRIP Steels (Transformation Induced Plasticity Steel) are part of the Advanced High-Strength Steel (AHSS) family.

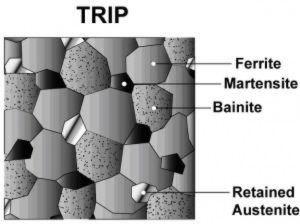

The microstructure of TRIP steels consists of at least five-volume percent of retained austenite, which is embedded in a primary ferrite matrix. The microstructure also contains hard phases like bainite and martensite in varying amounts.

TRIP steels are notable due to the higher carbon content than other members of the AHSS family, such as dual phase steels. They typically require the use of an isothermal hold at an intermediate temperature, which produces some bainite. Silicon and aluminum are added in order to both accelerate the ferrite and bainite formation process, as well as avoiding carbide buildup in the bainite region of the material.

Greater silicon, aluminum, and carbon content of TRIP steels result in large fractions of retained austenite in the material’s final microstructure. The increased carbon content also stabilizes the retained austenite phase below the usual ambient temperature.

Changing the carbon content helps to control the strain level at which the austenite begins to transform into martensite. At low carbon levels, the transformation of the retained austenite will begin almost immediately upon deformation, which will then improve the formability and work hardening rate during the stamping process.

At higher carbon content, the transformation will occur only at strain levels beyond those utilized during the forming processing. The retained austenite remains after the final stage of the forming process at these higher carbon levels – the transformation into martensite will occur only during subsequent deformation; in the case of automobiles, an example would be a crash event.

PROPERTIES OF TRIP STEELS

TRIP Steels can be produced as hot-rolled, cold-rolled, or hot dip galvanized, with a strength range from 500 MPa to 800 MPa.

TRIP Steels are highly sought after due to their high work hardening rate, which is created by the hard second phases that are dispersed in the soft ferrite during deformation. Despite the fact that initial work hardening rate of the material is lesser than that of, say, dual phase steels, TRIP steels sustain their hardening rate at much higher strain levels, where DP steel’s work hardening rate would deteriorate.

As a result of the high work hardening rates, TRIP steels also have substantial stretch forming properties.

The high strain hardening capacity and mechanical strength make these steels an excellent candidate for automotive parts that require a high energy absorption capacity. TRIP steels also have a strong bake hardening following deformation, which even further improves their crash performance.

To summarize TRIP steel’s properties:

- Work hardening – When compared to other advanced high-strength steels, TRIP steels exhibit and retain a higher work hardening rate at higher levels of strain.

- Formability – As a byproduct of the high work hardening rate, these steels have substantial stretch forming properties, and can be put through stamping processes in a relatively stable manner.

- Bake hardening – TRIP steels have a very high bake hardening capacity, and can by doing so can increase their yield strength by close to 70 MPa.

- Product mass reduction capacity – Due to the above characteristics, these steels are good candidates for weight reduction and part down gauging techniques.

APPLICATION OF TRIP STEELS IN AUTOMOBILES

TRIP steels are excellent for automotive parts that require high work hardening during crash deformation and large amounts of energy absorption.

They are also very well-suited for creatingcomplicated, hard-to-form parts, which is a result of their high formability and work hardening attributes. Thus, they are handy for complex reinforcement and structural parts.

Current production grades of TRIP steels and example automotive applications:

TRIP 350/600 Frame rails, rail reinforcements

TRIP 400/700 Side rail, crash box

TRIP 450/800 Dash panel, roof rails

TRIP 600/980 B-pillar upper, roof rail, engine cradle, front and rear rails, seat frame

TRIP 750/980

About National Material L.P. – National Material Limited Partnership and its affiliates have a long history of quality and service dating back to 1964. Since its founding, National Material L.P. has grown to over 30 business units and is now one of the largest suppliers of steel in America. The National Material group of industrial businesses consists of the Steel Group, Stainless and Alloys Group, Raw Material Trading Group, Aluminum Group, and Related Operations.

Visit National Material: https://www.nationalmaterial.com or call (U.S.) 847-806-7200.

Share This Story, Choose Your Platform!

Related posts.

Galvanized Steel for Solar Tracking: Applications and Capabilities

Processing Steel in the U.S. – Metal Forming 101

New Year, Great Outlook for Metals Processor National Material Company

Steel Tubing for Solar Trackers & Solar Applications

Aluminum for Electric Vehicles: Aluminum is The Future of Automotive

Cyclic Deformation of Advanced High-Strength Steels: Mechanical Behavior and Microstructural Analysis

- Published: 06 January 2009

- Volume 40 , pages 342–353, ( 2009 )

Cite this article

- Timothy B. Hilditch 1 ,

- Ilana B. Timokhina 1 ,

- Leigh T. Robertson 1 ,

- Elena V. Pereloma 2 &

- Peter D. Hodgson 1

1112 Accesses

61 Citations

Explore all metrics

The fatigue properties of multiphase steels are an important consideration in the automotive industry. The different microstructural phases present in these steels can influence the strain life and cyclic stabilized strength of the material due to the way in which these phases accommodate the applied cyclic strain. Fully reversed strain-controlled low-cycle fatigue tests have been used to determine the mechanical fatigue performance of a dual-phase (DP) 590 and transformation-induced plasticity (TRIP) 780 steel, with transmission electron microscopy (TEM) used to examine the deformed microstructures. It is shown that the higher strain life and cyclic stabilized strength of the TRIP steel can be attributed to an increased yield strength. Despite the presence of significant levels of retained austenite in the TRIP steel, both steels exhibited similar cyclic softening behavior at a range of strain amplitudes due to comparable ferrite volume fractions and yielding characteristics. Both steels formed low-energy dislocation structures in the ferrite during cyclic straining.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

The Effects of Pre-Straining Conditions on Austenite Stability during Fatigue of Multiphase Trip Steels

High-temperature low-cycle fatigue behavior and microstructural evolution of an improved austenitic ODS steel

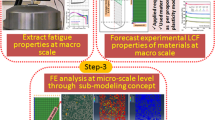

Predicting Macro- and Microscopic Responses of Dual-Phase Steels under Low Cycle Fatigue Based on Multi-scale Finite Element Methods

PHILIPS is a trademark of Philips Electronic Instruments Corp., Mahwah, NJ.

Y. Sakuma, O. Matsumura, H. Takechi: Metall. Trans. A , 1991, vol. 22A, pp. 489–98

ADS CAS Google Scholar

R.G. Davies: Metall. Trans. A , 1978, vol. 9A, pp. 41–52

M.S. Rashid: in Formable HSLA and Dual-Phase Steels , A.T. Davenport, ed., TMS AIME, Warrendale, PA, 1979, vol. 244, pp. 1–24

O. Matsumura, Y. Sakuma, H. Takechi: Scripta Metall ., 1987, vol. 21, pp. 1301–06

Article CAS Google Scholar

G.R. Speich, V.A. Demarest: Metall. Trans. A , 1981, vol. 12A, pp. 1419–28

ADS Google Scholar

W.W. Gerberich, P.L Hemmings, M.D. Merz, V.F. Zackay: Trans. ASM , 1968, vol. 61, pp. 834–47

Google Scholar

I. Tamura: Met. Sci ., 1982, vol. 16, pp. 245–53

CAS Google Scholar

V.F. Bhandarkar, V.F. Zackay, E.R. Parker: Metall. Trans ., 1972, vol. 3, pp. 2619–31

J. Johansson, M. Oden: Metall. Trans. A , 2000, vol. 31A, pp. 1557–70

B. Yan and D. Urban: “Characterization of Fatigue and Crash Performance of New Generation High Strength Steels for Automotive Applications (Phase I and Phase II),” AISI/DOE Technology Roadmap Program Report, AISI, Washington, DC, Jan. 2003.

T. Yokoi, M. Takahashi, and N. Ikenaga: SAE Technical Paper 2001-01-0042, SAE, Warrendale, PA, 2002

A.M. Sherman and R.G. Davies: Int. J. Fatigue , 1981, Jan., pp. 36–40

S.R. Mediratta, V. Ramaswamy, and P. Rama Rao: Int. J. Fatigue , 1985, Apr., pp. 101–06

H.J. Roven, E. Nes: Acta Metall. Mater ., 1991, vol. 39 (8), pp. 1719–33

T. Kruml, J. Polak: Mater. Sci. Eng ., 2001, vol. A319–A321, pp. 564–68

K. Basu, M. Das, D. Bhattacharjee, P.C. Chakraborti: Mater. Sci. Technol ., 2007, vol. 23 (11), pp. 1278–84

K. Sugimoto, M. Kobayashi, S. Yasuki, S. Hashimoto: Mater. Trans., JIM , 1995, vol. 36, pp. 632–38

K. Sugimoto, M. Kobayashi, H. Matsushima, S. Hashimoto: Trans. Jpn. Soc. Mech. Eng. A , 1995, vol. 61–581, pp. 80–86

I.B. Timokhina, P.D. Hodgson, E.V. Pereloma: Metall. Trans. A , 2004, vol. 35A, pp. 2331–41

B.D. Cullity: Elements of X-Ray Diffraction , Addison-Wesley Publishing Company, Inc., London, 1978, pp. 411–15

M. Onink, C.M. Brakman, F.D. Tichelaar, E.J. Mittemeijer, S. van der Zwaag, J.H. Root, N.B. Konyer: Scripta Metall. Mater. , 1993, vol. 29 (8), pp. 1011–16

P.B. Hirsch, R.B. Nicholson, A. Howie, D.W. Pashley, M.J. Whelan: Electron Microscopy of Thin Crystals , Butterworth and Co., London, 1965, pp. 51–54

P.M. Kelly: Met. Forum , 1982, vol. 5 (1), pp. 13–23

F.J. Humphreys, M. Hatherly: Recrystallization and Related Annealing Phenomena , Pergamon, Oxford, United Kingdom, 1996, p. 30

I. Alvarez-Armas, M.C. Marinelly, J.A. Malarria, S. Degallaix, A.F. Armas: Int. J. Fatigue , 2007, vol. 29, pp. 758–64

Z.Z. Hu, M.L. Ma, Y.Q. Liu, J.H. Liu: Int. J. Fatigue , 1997, vol. 19, pp. 641–46

Download references

Acknowledgments

The authors acknowledge the support of the ARC linkage and federation fellows programs.

Author information

Authors and affiliations.

Centre for Material and Fibre Innovation, Deakin University, Waurn Ponds, VIC, Australia, 3217

Timothy B. Hilditch ( Research Academic ), Ilana B. Timokhina ( Research Academic ), Leigh T. Robertson ( Postdoctoral Student ) & Peter D. Hodgson ( Professor )

School of Mechanical, Materials and Mechatronic Engineering, University of Wollongong, Wollongong, NSW, Australia, 2522

Elena V. Pereloma ( Professor )

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Timothy B. Hilditch .

Additional information

Manuscript submitted May 11, 2008.

Rights and permissions

Reprints and permissions

About this article

Hilditch, T.B., Timokhina, I.B., Robertson, L.T. et al. Cyclic Deformation of Advanced High-Strength Steels: Mechanical Behavior and Microstructural Analysis. Metall Mater Trans A 40 , 342–353 (2009). https://doi.org/10.1007/s11661-008-9732-x

Download citation

Published : 06 January 2009

Issue Date : February 2009

DOI : https://doi.org/10.1007/s11661-008-9732-x

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Strain Amplitude

- Find a journal

- Publish with us

- Track your research

- Deutsch Français Italiano

Stainless Steels

- Stainless Steel

- Stainless Steels Tube Pipe

- Stainless Steels Plate

- Stainless steel profile

- Stainless Steels Bras

- Seamless tube

- Square Steel Tube

- Boiler tube

Steel Profiles

- Cold roll flat bat

- Hot roll flat bar

Cold rolled/hot rolled

- Cold-rolled sheet / Coil

- Low Alloy Steel Plate

- Hot-rolled plate / Coil

- High tensile steel plate

- Ship steel plate

- Stainless steels wire

- Expansion alloy wire

- Magnetically soft alloy wire

Quality special steel

- Spring steels

- Mould & Die Steel

- Structural steel

- Cold-Drawn Steel

- Pinion steel

- Tool steels

- Free-cutting steel

- Steels of blade for steam turbine

- Alloy Structural Steel

- Shaped Steel

- High Speed Steel

Superalloy & High Temperature Alloy

- Ni-base superalloy

- Fe-Base Superalloy

- Cobalt-Base Superalloy

- Cast Superalloy

- Precise Alloy

- Carbon Steel

- Alloy Steel

- Mould Steel

- Structure Steel

- Tool Steel And Hard Alloy

- Special Steel

- Heat-Resistant Steel

- Boiler & Pressure Vessel Plate

- Valve Steel

- Special Alloy

- Tool Die Steels

- Superalloys

- Non-Magnetic Steel

- Specialsteel

- Steel Grades

- Find steel grades 200000+ Search for steel grades your needs with search features.

- Find Suppliers by Regions N+ Contact leading suppliers from around the world quickly and easily

- Find steel products N+ Find your interested products according to your different demands.

- Submit RFQ Get quotations from the most suitable suppliers

- TRIP780 / TRIP 780

China 首钢Q/SG TRIP780 冷轧相变诱导塑性钢钢板及钢带 and Mechanical Properties, Chemical Element, Cross Reference.

Chemical composition(mass fraction)(wt.%) of the TRIP 780

Mechanical properties of steel grade trip 780, physical properties of steel grade trip 780, heat treatment of steel grade trip 780.

Heat treated : 1823°C - 1486°C

Technological Curves of steel grade TRIP 780

Cross reference table (equivalent grade) of trip 780, available suppliers.

Jiangyou Longhai Special Steel Co.,Ltd.

Our main peoducts of steel are many kinds of special steel, like tool steel, mould steel, alloy steel, alloy constructural steel, heat-resistant steel, high speed tool steel,spring steel and bearing steel , stainless steel and so on, which have formed 12 series and more than 350 varieties with n...

- Do you supply this TRIP 780 ?

- List your company on S&G now? Join

- Non-paying users only

THE 10 CLOSEST Hotels to Museum and Exhibition Center

Hotels near museum and exhibition center, property types, distance from, traveller rating, hotel class.

- Best Value Properties ranked using exclusive Tripadvisor data, including traveller ratings, confirmed availability from our partners, prices, booking popularity and location, as well as personal user preferences and recently viewed hotels.

- Traveller Ranked Highest rated hotels on Tripadvisor, based on traveller reviews.

- Distance from Museum and Exhibition Center See properties located closest to the place of interest first with confirmed availability for your dates from our partners.

- Pavlovsky Posad Tourism

- Pavlovsky Posad Hotels

- Pavlovsky Posad Bed and Breakfast

- Flights to Pavlovsky Posad

- Pavlovsky Posad Restaurants

- Things to Do in Pavlovsky Posad

- Pavlovsky Posad Travel Forum

- Pavlovsky Posad Photos

- Pavlovsky Posad Map

- Pavlovsky Posad

- Things to Do

- Restaurants

- Vacation Rentals

- Travel Stories

- Rental Cars

- Add a Place

- Travel Forum

- Travelers' Choice

- Help Center

Photos of Pavlovsky Posad - Featured Images

- Europe

- Russia

- Central Russia

- Moscow Oblast

- Pavlovsky Posad

- Pavlovsky Posad Pictures

IMAGES

VIDEO

COMMENTS

TRIP steel are a class of high-strength steel alloys typically used in naval and marine ... These properties are exhibited because of a deformation-induced martensitic transformation from parent phase (FCC γ austenite) to the product phase (BCC α' martensite). ... (TRIP 780), identified by their minimum ultimate tensile strength expressed in ...

ArcelorMittal TRIP 780 Very High Strength Cold Rolled Steel. Description: TRIP steels offer an outstanding combination of strength and ductility as a result of their microstructure. They are thus suitable for structural and reinforcement parts of complex shape. The microstructure of these steels is composed of islands of hard residual austenite ...

Mechanical properties - Typical Test - Direction Yield strength (MPa) Ultimate tensile strength (MPa) Total elongation (%) Hot Roll DP590/600 JIS-T 400 630 27 Cold Roll/EG DP590/600 ASTM - L 370 635 24.5 DP690 ASTM - L 600 760 16.6 DP780 ASTM - L 480 830 18.2 DP980 - mid C ASTM - L 600 1030 13.8 DP980 - low C JIS - T 650 1030 14.7

The classical steel with tensile strengths of up to 800 MPa and exceptional deep-drawing properties. TRIP (transformation-induced plasticity) steels are part of the ahss classic product line of voestalpine in the field of ultralights. They maintain high ten-sile strength while achieving excellent deep-draw-ing properties through extraordinary ...

TRIP steels offer an outstanding combination of strength and ductility as a result of their microstructure. They are thus suitable for structural and reinforcement parts in complex shapes. The microstructure of these steels consists of islands of hard residual austenite and carbide-free bainite dispersed in a ductile ferritic matrix. Austenite is transformed into martensite during plastic ...

Download scientific diagram | Tensile properties of DP 780 and TRIP 780. from publication: Microstructural effects on the springback of advanced high-strength steel | The application of advanced ...

TRIP steels are excellent for automotive parts that require high work hardening during crash deformation and large amounts of energy absorption. They are also very well-suited for creatingcomplicated, hard-to-form parts, which is a result of their high formability and work hardening attributes. Thus, they are handy for complex reinforcement and ...

Abstract. As an industry-university cooperative project, an experimental research was conducted to develop a new cold-rolled transformation-induced plasticity (TRIP) steel with a tensile strength of 780 MPa and an elongation of 25% under the conditions that some processing parameters were preestablished according to the actual conditions of ...

Annealing of 0.18C-0.39Si-1.33Mn steel (A C1 = 721 °C) at 730 and 780 °C for 5 min led to formation of 25 and 75 % of ... The presented scheme is illustrating the potential impact on final microstructure and properties of TRIP steel manufactured on annealing and galvanizing lines featured by significant difference in possible holding time ...

Chemical compositions of the studied steel and TRIP 780 commercial steel (in wt%). Steel C Si Mn Al p Studied steel 0.21 0.82 1.87 0.43 0.03 TRIP 780 0.20 1.53 1.92 0.00 0.01 The ingot was hot forged at 1373 K (1100 C) by means of a hydraulic hammer, obtaining a billet of 18 mm 140 mm 1000 mm. Then, the billet was mechanized, obtaining samples ...

Product Characteristics. TRIP (TRansformation Induced Plasticity) steels are one of the newest family of advanced high strength steels (AHSS) developed for the automotive industry. The steels have a microstructure of soft ferrite grains with bainite and retained austenite. The retained austenite transforms into martensite (a hard phase) during ...

The optimum tensile properties of the 0.5% Si steel are better than those of 0% Si steel due to the solution hardening effec t of the Si and the higher stab ility of the retained austenite.

The first generation of AHSS includes some of the widely used grades such as dual phase (DP) [9, 10], transformation-induced plasticity (TRIP-assisted) [1], and complex phase (CP) steels [7].The second generation of AHSS with superior mechanical properties includes twinning-induced plasticity (TWIP) steels [11, 12], austenitic stainless steels (ASS) [13], and Al-added lightweight steels with ...

The investigated TRIP 780 steel was supplied in the form of 2.7 mm thick sheet. Table 1 gives the chemical composition of the TRIP 780 steel whereas Table 2 gives the exhibited mechanical properties. In addition, microstructural characterization and phase quantification were carried out by optical microscopy (OM) using an

2.1 Materials. The compositions of the commercially-produced uncoated DP 590 steel and TRIP 780 sheet steel are shown in Table I.Both steels had a nominal thickness of 2 mm. True stress-strain properties were determined using tensile tests conducted in accordance with AS 1391-1991 on a 100 kN screw-driven load frame at a constant crosshead velocity of 1.5 mm/min. Specimens had a nominal gage ...

Weldability of galvanized transformation induced plasticity (TRIP-780) steel is studied based on this process. Ultrasonic resistance welds showed nugget pullout failure mode and more ductility compared with conventional resistance spot welds. Optical and scanning electron microscopic analysis revealed the refined microstructure in the fusion ...

Mechanical Properties of steel grade TRIP 780. Yield R p0.2 (MPa) Tensile R m (MPa) Impact KV/Ku (J) Elongation A (%) Reduction in cross section on fracture Z (%) ... Heat Treatment of steel grade TRIP 780. Heat treated : 1319°C - 1185°C. Technological Curves of steel grade TRIP 780. No Curve. Cross Reference Table (Equivalent Grade) of TRIP 780.

Elektrostal Heavy Engineering Works, JSC is a designer and manufacturer of equipment for producing seamless hot-rolled, cold-rolled and welded steel materials and metallurgical equipment. MSZ, also known as Elemash, Russia's largest producer of fuel rod assemblies for nuclear power plants, which are exported to many countries in Europe.

Hotels near Museum and Exhibition Center, Elektrostal on Tripadvisor: Find 1,346 traveller reviews, 1,935 candid photos, and prices for 64 hotels near Museum and Exhibition Center in Elektrostal, Russia.

Electrogalvanized TRIP 780 steel with the thickness of 1.6 mm and a coated Zn layer of around 7 μm is used in this study. As a reference, the as-received TRIP steel contains allotriomorphic ferrite, blocky retained austenite, dispersed bainite and small amount of martensite, shown in Fig. 1.These steel sheets are provided by ArcelorMittal and corresponding chemical compositions are listed in ...

Alliance, Zheleznodorozhny: See traveler reviews, candid photos, and great deals for Alliance, ranked #1 of 2 B&Bs / inns in Zheleznodorozhny and rated 4 of 5 at Tripadvisor.

Pavlovsky Posad pictures: Check out Tripadvisor members' 709 candid photos and videos of landmarks, hotels, and attractions in Pavlovsky Posad.