Haas Alarm: 316 – X OVER TRAVEL RANGE

Haas Alarm: 316 X OVER TRAVEL RANGE – Commanded X-axis move would exceed the machine travel. Machine coordinates are in negative direction. This indicates either an error in the user’s program or improper offsets.

Videos by CNC Repairman

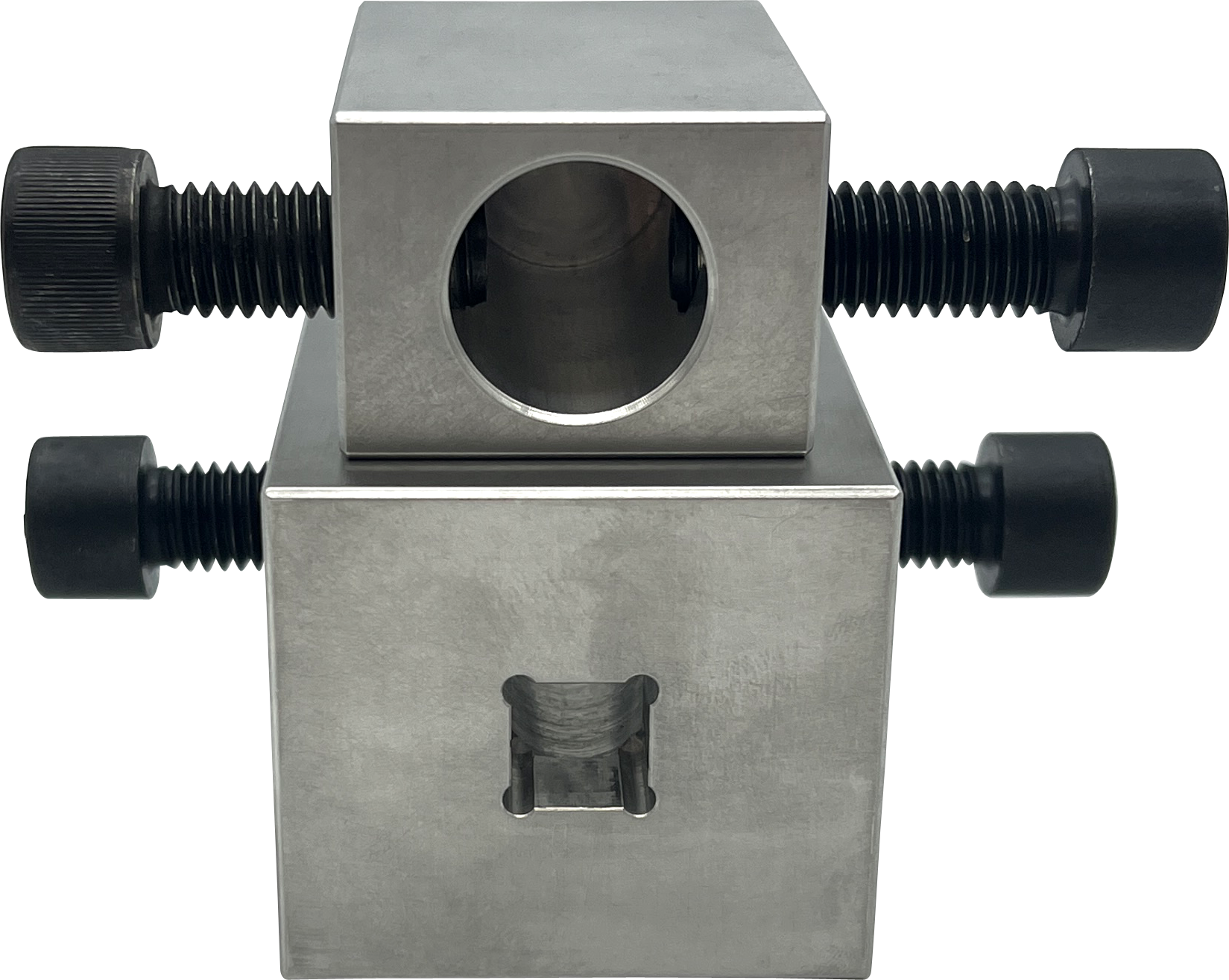

Ball Screw Lock tool 40 mm

$ 125.95

Easy Umbrella Removal Tool

Super Speed Draw Bar Tool

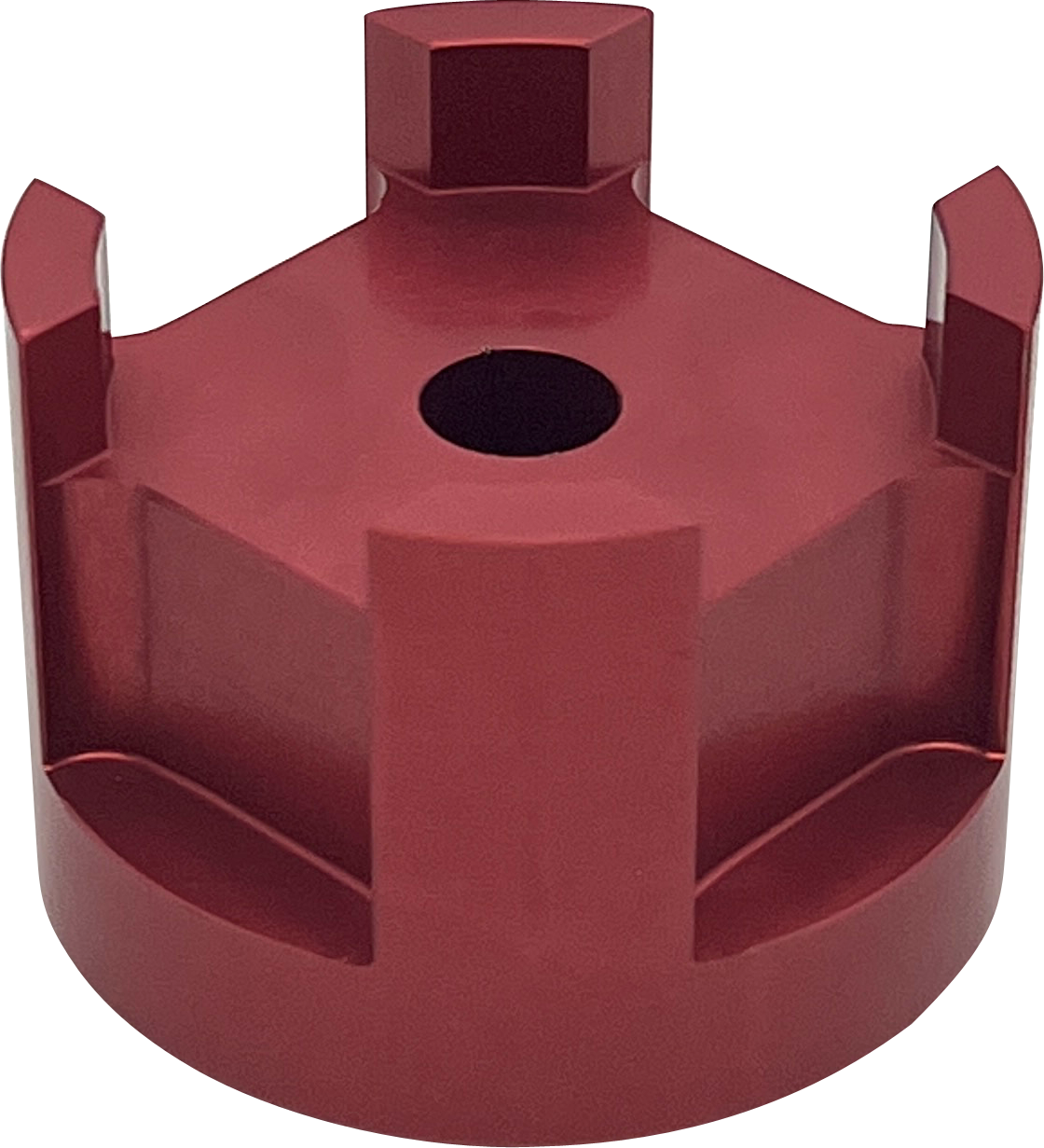

Spindle Drawbar Nut Removal Tool

$ 105.95

Molex Pin and Connector Kit

$ 355.95 – $ 455.95

Drawbar Force Gauge Rental

$ 55.00

ATC Double Arm Removal Tool

$ 75.95

Spindle Belt Tension Tool — Mill Spindle Belts

$ 45.95

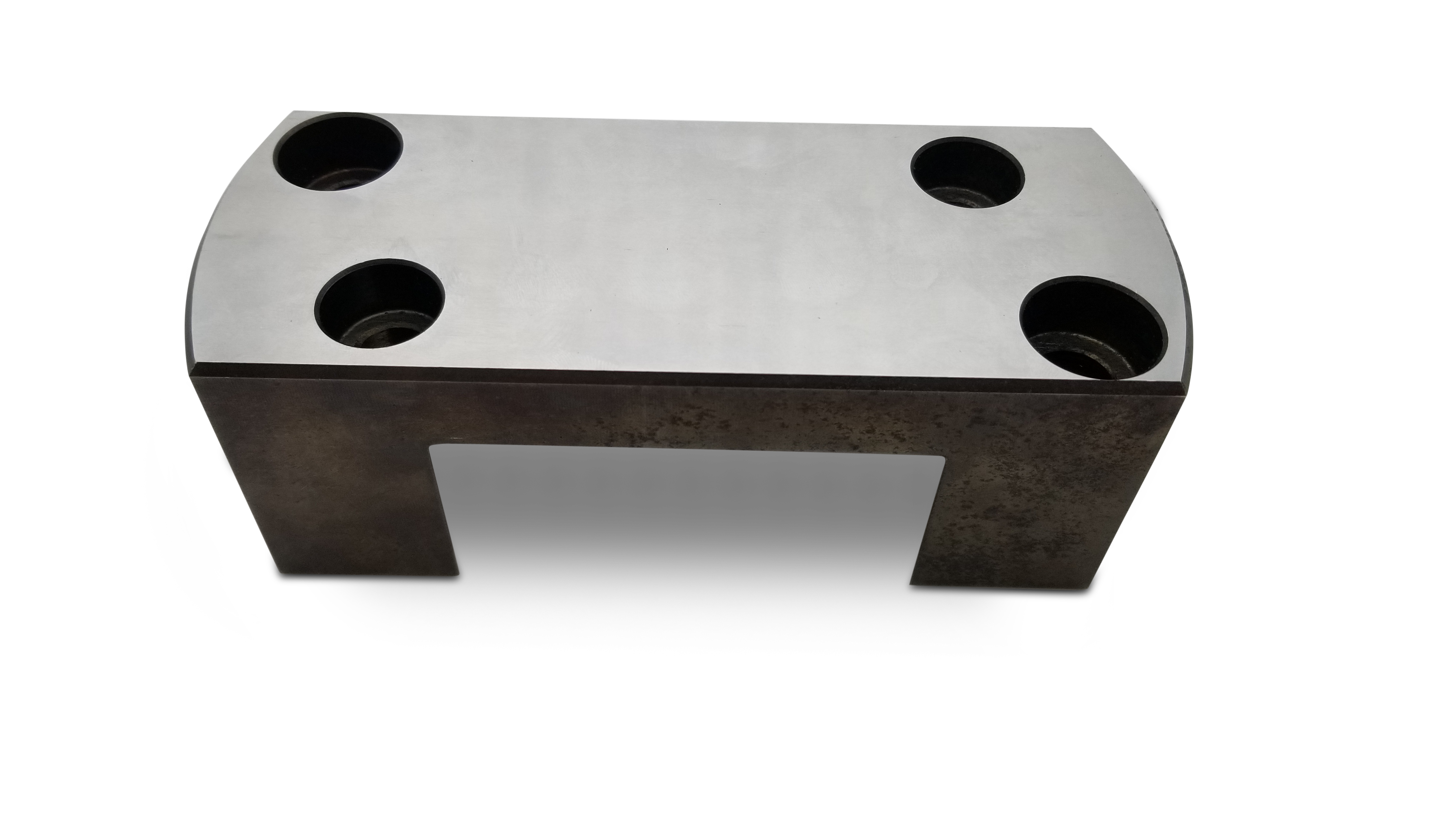

Wedge Alignment Bridge Tool (A-2-5 and A-2-6)

$ 650.00

Ball Screw Nut Removal Tool 32 mm

- Mechanical Engineer

- Industrial Designer

- Collaborator

- Electronics Engineer

- Learn & support

- Fusion Overview

- Machining Extension

- Simulation Extension

- Nesting & Fabrication Extension

- Generative Design Extension

- Product Design Extension

- Signal Integrity Extension

- Additive Build Extension

- Manage Extension

- Start free trial

- Forums Home

- Fusion Community

- Manufacture Forum

(03 Haas TL-01) Z Over Travel Range - Alarm

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Printer Friendly Page

- Back to Topic Listing

- Mark as New

Forums Links

- Getting started

- Contact Support & Downloads

- Autodesk Education Support

- Trial Support

Can't find what you're looking for? Ask the community or share your knowledge.

Post to forums

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Largest Manufacturing Technology Community on the Web

- Search Forum Discussions

- Search Entire Site

- Advanced Search

- Employer Products

- Employer Dashboard

- Job Seeker Dashboard

- REGISTER FREE

- Search forums

- Specific Machine Forums

Z Over Travel with -7.13 Tool Offset

- Thread starter magno_grail

- Start date Aug 17, 2017

- Views 5,816

magno_grail

- Aug 17, 2017

I was profiling a plate clamped to the table (top surface 0.75" above the table). It made one pass 0.050" then hit a 318 Z Over Travel. I changed to a long nose holder so the offset was about 1" higher. As soon as the Z1.0 move was started in the program the 318 error happened again. After trying different offset values I found whenever the tool offset is anything greater than -7.13 the 318 error occurs. Above that value the spindle travels down until is hits the Z stop. I tried re-homing and power down restart but the problem still occurs. I can manually move the tool down to where it is below the table surface. I checked the Z limit steps in the parameters and found it was set to the same value as the Y axis. I believe it should be the same as the X axis (20" travel). But that is not the cause of the 318 error. Any ideas? '91 VF-1

- Aug 18, 2017

did you update the H value?

Booze Daily

Post the chunk of code where its happening. The control reads a few lines ahead into the buffer. It won't necessarily alarm on the bad line, it could be that it read a bad line into the buffer.

Is there a z value left over in your fixture offset from the last job? That screws me up sometimes.

Not a program or tool length offset problem. Today I tried just the countersink, which worked before this, and it also came up with the 318 error when the line with the Z move was encountered. When the machine booted it had a motor interface board error which cleared with the reset. It appears something went south there.

Well that stinks.

Made more tests and it may not be the Motor Interface Board. I swapped the X-Z encoder inputs and X-Z outputs on the MOTIF board and also the X and Y servo cables then ran the countersink program. The X and Z positions going into the processor should be the same but using different paths through the MOTIF board. Same 318 Z error. If it was a chip in the Z axis path on the MOTIF board I would have expected an X over travel error. Now, the weird part: If I touch off the tool and set the offset, then reduce the steps/inch in the parameters to half the normal value, the tool will go down to the correct depth without the 318 Z error and do the drilling routine at the depth where the 318 error occurred. Of course, if I touch off the tool with the half step/inch value the position page shows twice the distance as expected. Hand cranking the Z axis with half the steps/inch moves the spindle half as far. Since the steps/inch value was changed after touching off the tool and before the program was run, the program must not be using the steps/inch for position, just travel limit. My friend thinks it might be the cable or encoder.

- Aug 20, 2017

Well, stupid error. Voltran had it right. The G54 Z value was way off. Normally I have this at -0.5 because I set my tools with a 1/2" pin. Somehow when setting the X and Y values I accidentally changed the Z to around -14.6.

Similar threads

- Mar 3, 2024

- Apr 17, 2024

- Aug 19, 2023

- Jan 28, 2024

- CNC Machining

- Madmatt1964

- Jun 26, 2023

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy . In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy . You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

G & M Codes

Mill programming, lathe programming, programming, m code tutorials, haas alarm: 319 a over travel range.

Alarm: 319 A OVER TRAVEL RANGE

Haas Alarm Description: Commanded A-axis move would exceed the machine travel. Machine coordinates are in negative direction. This indicates either an error in the user’s program or improper offsets.

- Haas Alarms PDF by Haas Automation, Inc.

COMMENTS

A Haas Factory Outlet (HFO) can answer your questions, and walk you through your best options. CONTACT YOUR DISTRIBUTOR > Options Main Menu. Spindles. ... Alarm 1.316 X-Axis Over Travel Range. DOWNLOAD AN INSTANT CUSTOM QUOTE FOR ANY HAAS MACHINE. GET QUOTE Alarm 1.316 X-Axis Over Travel Range.

HAAS Alarm 1.316 X over travel range. Thread starter motofish84; Start date Dec 2, 2021; Replies 9 Views 3,517 M. motofish84 Plastic. Joined Feb 22, 2021. ... With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest way to ...

On my 2004 mini mill I was putting an .003 in the offset tool #4 on the length wear offset. I see an rs232 pop up & now I get the X over travel on all programs. All x offsets in the work zero page are in the - range. But when I looked 1 offset X was 4.502 so I changed it to a -4.502. Still get...

Posted January 27, 2012. X5 MU1. Good Morning, Occasionally I get an over travel alarm and i get called in at all hours of the night. to get the cnc running. (this one say in the -x- negative) this program runs for 17 hours and has about 12 tools. My fix is to (drive in) and open file, reselect .mmd for that tool path group and. re-post the code.

Alarm: 316 X OVER TRAVEL RANGE Haas Alarm Description: Commanded X-axis move would exceed the machine travel. Machine coordinates are in negative direction. ≡ MENU. Home Fanuc Learn Examples Sinumerik Haas Reference Alarms Programming About. Haas Haas How To? Manuals Mill Manual Lathe Manual

0. There are a few way to get alarms 316 (X OVER TRAVEL RANGE), 317 (Y OVER TRAVEL RANGE), or 318 (Z OVER TRAVEL RANGE). 1) Work offsets are not properly set. Solution: follow steps in manual to adjust work offset. 2) The coordinate system used by the code does not match the setting of the machine.

There are a few way to get alarms 316 (X OVER TRAVEL RANGE), 317 (Y OVER TRAVEL RANGE), or 318 (Z OVER TRAVEL RANGE). 1) Work offsets are not properly set. Solution: follow steps in manual to adjust work offset. 2) The coordinate system used by the code does not match the setting of the machine.

Alarm 1.316 X-Axis Over Travel Range. DESCARGAR UNA COTIZACIÓN PERSONALIZADA INSTANTÁNEA PARA CUALQUIER MÁQUINA HAAS. PEDIR PRESUPUESTO Alarma 1.316 Por encima del rango de recorrido del eje X. ... Precio entregado por Haas. Este precio incluye el coste de envío, los aranceles de exportación e importación, el seguro y cualquier otro gasto ...

Ball Screw Nut Removal Tool 32 mm. $ 125.95. Haas Alarm: 316 X OVER TRAVEL RANGE - Commanded X-axis move would exceed the machine travel. Machine coordinates are in negative direction. This indicates.

Et Haas fabrikkutsalg (HFO) kan svare på spørsmålene dine, og ta deg gjennom de beste alternativene dine. CONTACT YOUR DISTRIBUTOR > Alternativer Main Menu. ... Alarm 1.316 X-Axis Over Travel Range. LAST NED ET ØYEBLIKKELIG SKREDDERSYDD PRISTILBUD FOR HVILKEN SOM HELST HAAS-MASKIN. FÅ PRISTILBUD Alarm 1.316 X-akse over kjøreområde.

Alarm Search Results: 1.316. X-Axis Over Travel Range. An axis was commanded to move outside of its travel limit. Use this list to help resolve the alarm: Make sure that the work offsets are correct. Check the G52 and G92 offsets. G52 and G92 offsets are used to shift all other work offsets. For most applications, these offsets should be zero.

constant over the full range of travel. 6. On newer EC-1600/2000 machines, X-axis pitch can be removed by adjusting the jacking screws under the base (one on each side - see illustration). Readjust-ment may be needed after heavy loads are placed on the table. For the EC-3000, use the outrigger screws for pitch adjustment by turning the screws ...

Haas VF-2 - 318 Z Axis Over Travel Range. Thread starter natemclain; Start date Jun 18, 2013; Replies 6 Views 37,588 N. natemclain Aluminum. Joined Jun 11, 2013 Location Houston, TX. Jun 18, 2013 #1 ... With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. ...

After all my offsets for tooling and origin (g54) are set and I attempt to run the code I get this "Z Over Travel Range - Alarm" right as it hits my first rapid to the starting location at N18. Here is the first bit of code. %. O0001 (SHIFT KNOB) N10 G98 G18. N11 G20. N12 G50 S2500. (Profile3) N13 T101.

VF-4. Every VF Series vertical machining center provides outstanding features at an excellent price, and features a wide range of available options to customize your machine to your exact needs. The VF-3 through VF-5 models feature larger work envelopes than the smaller VF-1 and VF-2 models. High-power, direct-drive spindles.

If the value is much too large then there might be a calibration problem.. To test the offset I used T1, called h1, and g00 x0. Y0. Z0., and it does go to the correct origin. The offset value is pretty large, as it reached across the tombstone, but definitely not out of reach of the tool, it's not z limiting because the tombstone is getting too ...

I am getting an 318 Z OVER TRAVEL RANGE on a known good program. The program worked yesterday and today I am getting this alarm. I double checked the offsets. Any ideas?-Park Similar Threads: Out of Range; Pay range; Alarm 317 Y over Travel Range? Need Help!-Lazy Cam not posting Fast Travel as Fast Travel; Mid-range first CNC

Alarm: 463 V OVER TRAVEL RANGE - Haas Lathe Haas Alarm Description: Commanded V-axis move would exceed allowed machine range.Coordinates are in the negativ ≡ MENU Home Fanuc Learn Examples Sinumerik Haas Reference Alarms Programming About

With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers.

Et Haas Factory Outlet (HFO) kan besvare dine spørgsmål og guide dig gennem de bedste valgmuligheder for dig. CONTACT YOUR DISTRIBUTOR > Ekstraudstyr Main Menu. ... Alarm 1.316 X-Axis Over Travel Range. DOWNLOAD ET SPECIALTILBUD MED DET SAMME PÅ ENHVER HAAS MASKINE. FÅ ET TILBUD Alarm 1.316 X-akse over vandrerækkevidde.

Alarm: 317 Y OVER TRAVEL RANGE - Haas Mill Haas Alarm Description: Commanded Y-axis move would exceed machine travel. Machine coordinates are in negative d

Alarm: 319 A OVER TRAVEL RANGE Haas Alarm Description: Commanded A-axis move would exceed the machine travel. Machine coordinates are in negative direction. ≡ MENU. Home Fanuc Learn Examples Sinumerik Haas Reference Alarms Programming About. Haas Haas How To? Manuals Mill Manual Lathe Manual

Din Haas-leverantör (HFO) kan besvara alla dina frågor och diskutera vilka lösningar som är bäst för dig. CONTACT YOUR DISTRIBUTOR > Alternativ Main Menu. ... Alarm 1.316 X-Axis Over Travel Range. LADDA NER EN NYSAMMANSTÄLLD OFFERT PÅ DIN HAAS-MASKIN. HÄMTA DIN OFFERT Larm 1.316 X-Axeln över rörelsesträcka.