- CruiseMapper

- Ships and Lines

Cruise Ship Design Construction Building

Information on cruise ship construction and design and how cruise ships are built. Learn what is the cost of building a cruise ship, where are cruise ships built, which are the major cruise shipbuilders/yards and building companies . Plus some other shipbuilding stuff and fun facts, like who built the Titanic ship, who built the most expensive cruise ship in the world, who built the most expensive yacht in the world, who is responsible for making the best cruise vessels of the world. This survey is integrated with our cruise ship engines-propulsion-fuel and cruise safety articles.

The actual cruise shipbuilding takes 2 to 3 years (the design plans are usually started a year ahead). Shipbuilding takes place in specialized facilities called shipyards. The cruise ship hull is designed by the shipyard, while the interiors and all the special features are designed by architects. Shipbuilders (also called shipwrights) do shipbuilding, as well as ship repairs, both services being also referred to as "naval engineering". The reverse process (dismantling of ships) is called ship breaking/demolition . The world's biggest ship-breaking scrap yards are in India (Alang) , Bangladesh (Chittagong) , Pakistan (Gadani) , and Turkey (Aliaga).

Cruise ship construction and design

The cruise shipbuilding process involves numerous complex research and testing procedures. The cruise ship design company (whose work is also called naval architecture) analyses and provides solutions to meet the Marine and Shipbuilding Industry's requirements, submitting the basic and detailed designs, ship equipment designs and production drawings to the shipbuilding company. The design firm also provides engineers with analysis, simulations, diagnosis, manufacture, repair and other data by using the latest CAE (Computer-Aided Engineering) technology. The ship cabins manufacturer is able to design and produce various types of ready-to-install ship cabins and bathrooms for virtually all passenger ships - big and small, luxury, ferries, Ro-Ros, research, etc. The shipbuilder also hires a company to provide the so-called "Lifecycle Services", pertaining mostly to the industry's rules and regulations. Some of these services are retrofitting and refurbishing and keeping regular updates regarding new rules and requirements.

It's a common modern practice big cruise ships to be built of pre-made huge sections. Entire multi-deck segments are built at another place, transported or slipway to the shipyard and lifted into place. The sections often feature even pre-installed equipment, cables, pipes, and other components - it saves a lot of shipbuilding time, and it surely saves lots of money. This technique was used for the first time in the construction of Cunard's Queen Mary 2 (2002-2004) by the French "Chantiers de l'Atlantique" company.

The next photo shows a pre-made section for the Symphony Of The Seas ship construction.

The ice-going cruise shipbuilding is so expensive as to hull strength and engine power, that the best option is to buy an unfinished vessel or to refit an existing Ice-class ship (often an ex-navy vessel), like the case of the Regent Seven Seas Navigator ship. Constructed as a naval support ship and strengthened for navigation in ice, the Navigator ship's hull was purchased from the former USSR (now Russia), while its superstructure was finished later at the T. Mariotti shipyards in Genoa, Italy.

The following YouTube timelapse video shows the Japan-made AIDAprima cruise ship construction process (shipyard Nagasaki Japan ). Next YouTube video shows the Aqua Mekong riverboat construction (time-lapse).

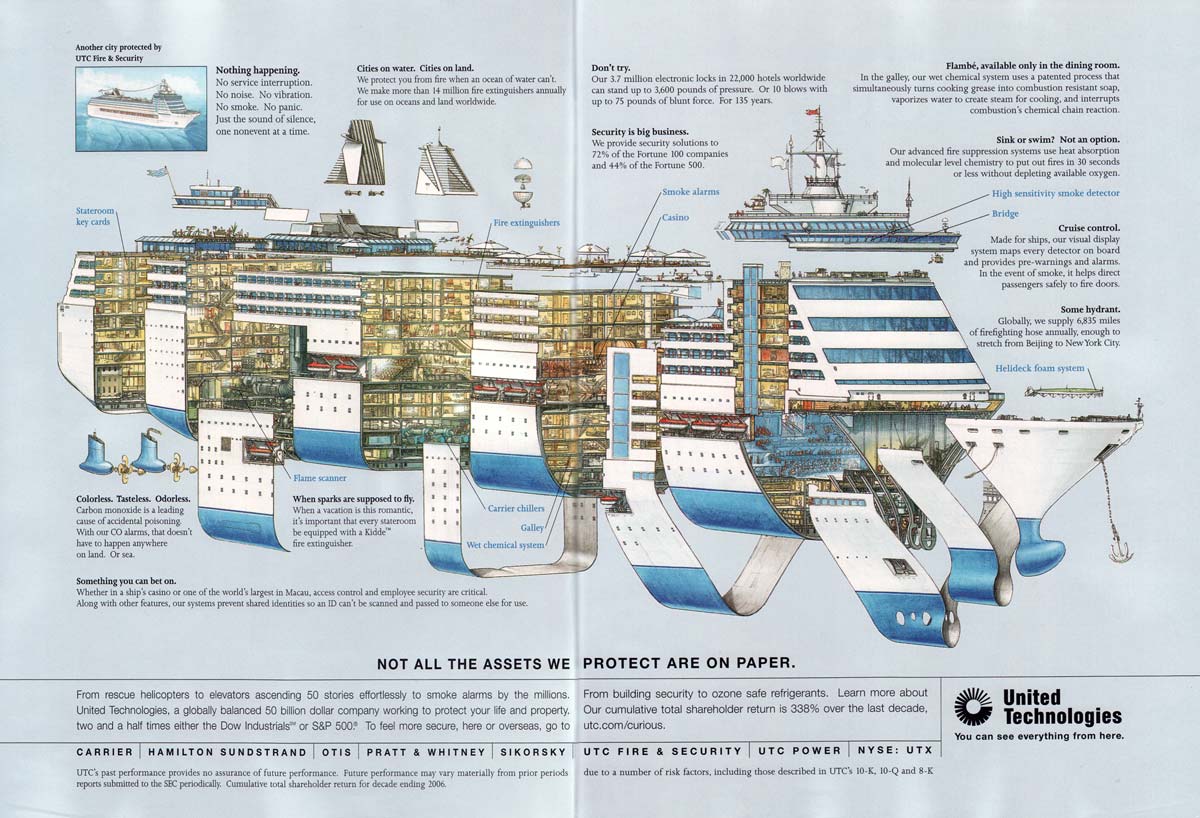

Cruise ship design

This is an amazingly detailed cruise ship design infographic showing what is what and where on a typical cruise passenger vessel. Note: Click on image to enlarge, backspace/back button to return to the article page.

Marine design solutions for cruise ships are truly amazing and unique, using the latest innovations, technologies, and materials to ensure difference from other existing passenger ships. Special onboard features, such as the Royal Caribbean ships' rock-climbing walls, ice-skating rinks, surf simulators, wave pools, and the 9-deck high Zip-line are an irresistible temptation and a true allure for all the ship vacation fun fans. As to the common features, all big-capacity passenger ships have a several decks-high Atrium, at least 3 huge swimming pools, a Spa-Fitness complex, a grand casino, a library, duty-free shops, 2 huge capacity main restaurants, grand theatre, disco nightclub, kids and teen areas, numerous bars and lounges, and all-new big ships feature an open wraparound Promenade.

Cruise ship interior design

What about cruise ship interior designs? An example is SMC Design, which was appointed by Cunard Line to lead the development of the interior spaces on RMS Queen Mary 2 in preparation for liner's drydock refit in 2016. Cunard's flagship had a multi-million 25-day extensive refurbishment (May 27-June 21, 2016) that boasted new interior designs. The most iconic liner in the world opened the next chapter in her illustrious career. The announcement of the designer company followed the news that QM2 will gain 15 brand new single cabins and an additional 30 Britannia Club rooms during the refit. The popular onboard kennels were expanded in order to cater to the high demand this extraordinary facility already attracts.

SMC Design was established in 1994. The London -based design consultancy specializes in the maritime sector. SMC Design's team has worked on many cruise vessels - from small yachts to some of the biggest ships ever built. It also has a working history with Cunard liners, leading previous refits of QE2, Cunard Princess and Cunard Countess, while also being involved in its current fleet design: Queen Victoria , Queen Elizabeth and Queen Mary 2. Andy Collier, SMC Managing Director, was part of the launch design team of QM2 at the beginning of the Century. She was then the first Atlantic liner being built for more than 35 years.

New Russian cruise ship designs

In August 2016, at Lotus shipyard (Astrakhan, Russian) part of ASC (United Shipbuilding Company), the keel was laid for the 1st Russian passenger cruise ship in decades. Support for the new class of even vessel is coming from Russian Federation president Vladimir Putin, who expressed hope that this will be the first but not the last of a series of such ships.

The Marine Engineering Bureau office engineers developed the Concept PV300VD cruise ship, the first of which is to be completed within 3 years. The project belongs to Saint Petersburg team of Marine Engineering Bureau SPb, which has been working in Russia for 16 years. Its other branch is in Odessa . Such vessels were not generally built in the old Soviet Union.

The last built in the USSR, 2 river cruise ships, Soviet Union and Lenin, were built at the Gorky plant in 1959-1960. Then, as with its ocean ships, the Soviet Union bought foreign-built river ships, until 1989-1990. However, these were not entirely foreign as they were created to Soviet order and developed for operation in Russian conditions. These vessels were built mainly in Austria, East Germany, and Czechoslovakia. After 1990, Russian riverboats were no longer built and the business was carried on for years utilizing old tonnage. The same happened with the Russian passenger fleet as they were banned in North America after Russia's invasion in Afghanistan.

Today, shipping conditions in Russia are different. The new ships are planned to be "river-sea" ships. This class is needed in order to navigate large lakes. Russian river cruise ships are much more powerful than typical Danube and Rhine vessels. Dimensions for the new 310-passenger ships will be 463 x 55 feet. The PV300VD concept emerged in 2010-2015 by the order of the Russian Federal Marine Agency. The program's state customer and coordinator is the Minister of Industry and Trade, and completion is scheduled for 2019. The cost of a ship varies between 2.5 to 3.5 billion rubles and the payback period is 5 to 20 years. 3 such ships are foreseen at the stage, though more could follow. The next photo shows the design of Vodohod's new river cruise ship project PV300VD.

The next photo combo shows the design of Mosturflot's new river cruise ship project PV300.

The routes foreseen for the new Russian ships are in season (May to October) between Moscow and Saint Petersburg, then taking travelers from Moscow to Samara and Rostov-on-Don, in the winter embarking in the Eastern Mediterranean and possibly the Red Sea: for example, Rostov-on-Don- Yalta- Odessa- Istanbul- Alexandria . There are talks about navigation in Crimea, Sevastopol, and Sochi, on more interesting routes in the Caspian sea.

The newbuilds could carry about 500,000 passengers annually, of which about 100,000 foreign tourists. The number of foreigners declined by nearly a half in 2014 as western tour operators cut Russian programs and westerners stayed away. According to the Ministry of Industry and trade, buyers of the new ship would be operators like Mosturflot (GK Sea and River shipping company), Vodohod and Orthodox. Given the high cost of the vessels, it is planned to lease them to operators. The main difference of this 4-deck ship is that it will be able to navigate not only rivers but seas as well. The vessels will also be more luxurious than past ships and will include western amenities, such as French balconies and comfortable large suites.

Next image shows a traditional European river cruise ship design (4-deck boat). All top-deck/sundeck structures (Wheelhouse, awnings, railings) are retractable and lowered when the boat passes under low bridges.

New expedition cruise ship designs

A new contract was awarded to the shipbuilder Uljanik (Croatia) for a 10,000-GT, 237-passenger ship ( Scenic Eclipse ) scheduled for delivery in 2018 but eventually postponed to 2019.

Based on these dimensions, the new ship was to be of the same general size as Ponant's fleet, the latest of which ( Le Lyrial ) was built at Fincantieri 's Shipyard Ancona Italy . Uljanik has not disclosed the identity of the purchaser, but new ships are also expected from Lindblad and Seabourn in 2018.

Next photos show other designs fitting the expedition vessel category.

The above is STX France's Project Ulysseas (145 m length, 200 passengers) was officially revealed in March 2015.

Next is the 2020-announced icebreaking cruise ship design developed by Knud E. Hansen.

The PC3 ice-classed vessel has deadweight/DWT 1965 tons, LOA length 144 m, beam 22 m, draught 7 m, max passenger capacity 300 (plus 150 crew) and 150 staterooms. Most cabins are with step-out balconies and interconnecting, featuring the company's "Flex Cabin System" which allows their walls to be reconfigured in order to convert a Suite into two separate cabins.

The newbuild has max cruising speed 17 knots (20 mph / 32 kph), can operate in solid ice (max thickness 1,8 m) and has diesel-electric propulsion (based on 2 azipods, total power output 15 MW), 6 electricity generators (dual-fuel / LNG and MDO-diesel) plus a lithium-ion battery pack (powers the ship while docked). The new passenger ship design features an Ice Bar, multi-purpose Lounge, a tender garage (for Zodiacs and other expedition equipment that can be launched via a portside shell door), an aft-located helicopter deck (where a helicopter is lowered into the hanger on the below deck).

The next design (by Aker Arctic) is of an expedition ship ordered by the UK-based company Polar Cruise Enterprises Ltd. The vessel has LOA length of 135.5 m, Beam 17.8 m, Draught 5.5 m, Propulsion 2x 3.5 MW azimuth thrusters, Engines 4x MAK 6M32C (2,88 MW each) allowing max cruising speed 13 knots (15 mph / 24 kph).

Knud E Hansen's expedition ship design is with 150 staterooms and heavy-duty, ice-rated hull.

The next video shows various passenger and research ship designs developed by Knud E Hansen (Danish marine engineering company established in 1937).

Next is the VARD-6 polar ship design on which are based the newbuilds of Ponant (Explorers-series), Hapag-Lloyd (Hanseatic-series), Viking Expeditions and Coral Expeditions (Australia).

Next images show expedition yacht cruise ship design by the Dutch shipbuilder Damen Group. The vessel is "Polar Class 6" (with ice-strengthened hull) and has endurance 30 days autonomous cruising.

The ship has approx 1100 m2 public space and 2500 m2 outdoor deck space. Max capacity is 115 passengers. Propulsion is a diesel-mechanical hybrid and encompasses IMO Tier 3 compliant medium speed engines.

Damen Shipyards new expedition cruise ship design

Damen's cruise vessel is "battery ready", which means it could be equipped with a battery system for peak-shaving (reducing peak demand), providing supplementary power for maneuvering or silent drive operations. The hybrid propulsion is the best fuel-efficient technology currently available, allowing service speed 16 knots (30 kph / 18 mph) and max speed 18 knots (33 kph / 21 mph). The next aft view image also shows the ship's marina platform.

SunStone's "World-Class" expedition cruise ship design

On March 16, 2017, SunStone Ships Inc (USA) signed an agreement with the Hong Kong-based "China Merchants Industry Holdings" (CMIH) for the construction of 4 units based on the "ULSTEIN CX103" design. SunStone is currently the world's largest (by GT tonnage) shipowner chartering exclusively expedition vessels to the cruise travel industry. The contract included the option for additional 6 units.

The ice-class 1A vessel has the following polar code specifications.

- Designer: SUNSTONE SHIPS INC

- Shipbuilder: (CMIH) CHINA MERCHANTS INDUSTRY HOLDINGS

- Passenger cabins: 80-95

- LOA Length: 104 m

- Beam / Width: 18 m

- Speed: 15 Kn / 17 mph / 28 kph

- Ice-Class: 1A

- Polar Class: PC 6 (highest)

The boat has a fleet of Zodiacs (20-22x aft-stored inflatable RIB boats) and features a dedicated Zodiac loading platform for easy boarding.

Charterers of these ships are the travel brand companies AQV-American Queen Voyages , Aurora Expeditions ( fleet ), Albatros Expeditions ( fleet ).

STX France "Ulysseas" cruise ship project

In March 2015, the major shipbuilder STX France unveiled a revolutionary new expedition ship design named "Ulysseas". It represents an innovative idea for a small cruise ship ( passenger capacity 200, ice-class hull, length 476 ft / 145 m, cruising speed 17 Kn / 20 mph / 31 kph) aimed at the expedition cruising market.

The main reason for the Ulysseas project is that currently, the expedition cruise market uses mostly second-hand vessels. Unique for this new ship design is the excessive usage of glass (in all public areas) and the French balconies (false balconies) on all passenger cabins. Every passenger-use facility on the new vessel features floor-ceiling windows. There will be a unique forward-located observation lounge for 360-degree views.

The Ulysseas ship's aft-section is an STX-patented design for saving energy. This is a movable duck-tail, which position depends on cruising speeds and weather conditions. The vessel is powered by two 2,5 MWT azipods (360-degree rotating thrusters), with 4x diesel-electric generators and 1x scrubber. This cruise ship design also features a helipad (helicopter landing pad), a helicopter storage space (inside the ship), zodiac boats for ship-to-shore operations.

(2018) "Silenseas" sailing cruise ship design by Chantiers de l’Atlantique (fka STX FRANCE)

In early March 2018, STX France revealed a carbon-free cruise vessel design (trademarked Silenseas) using wind as main power source. The new wind-power technology was trialed on Ponant 's yacht Le Ponant , on which one of the existing sails was replaced and the new technology tested.

STX France's project was something never done before. The carbon-free sailship design is an alternative to the popular hybrid-powered vessels. Hydrogen and fuel cells are still expensive, plus hydrogen is not available in most ports.

The technology uses the company's patented "SolidSail" concept. The sails (total size up to 1200 m2 / 12900 ft2) are mounted on masts but without any ropes or cables. The STX France design has 3 masts and 3 rigs, with masts rotating in order to adapt the sails to the wind. The new design also includes the latest hybrid propulsion technologies, combining wind with LNG, and potentially batteries, solar panels, and fuel cells.

The sailing ship can reach speeds of 12 knots (14 mph / 22 kph) under sail in 15 knots (17 mph / 28 kph) winds. In winds over 15 knots, the vessel's propellers will be used, acting as a turbine that draws power from the sails. On Caribbean Sea routes, the new technology could reduce propulsion energy by 60%.

STX France's sailship design was developed for 3 vessel sizes, the biggest being 15000 GT-ton with LOA length 190 m (620 ft) and 150 passenger staterooms. The French shipbuilding company started research in sail propulsion in 2009, Silenseas has technology patents (2009 and 2017) for the new sail. The unit is made from fiberglass, carbon and epoxy-resin panels.

SolidSail system debuted on October 31, 2018, on the yacht Le Ponant. The new Solid Sail (sized 300+ m2) was constructed at Chantiers de L'Atlantique ( Saint-Nazaire ) and installed in Marseille . The 3-masted Le Ponant departed from France to Cape Verde Islands, then embarked on a Transatlantic crossing to Cuba, testing the new sail for 1 year.

Similar is the concept of Peace Boat's new vessel Ecoship (built by Arctech Helsinki Shipyard in Helsinki, Finland ).

In December 2022 was announced the shipyard's first SolidSail with a carbon-fiber mast. The project was a collaboration with the Lorient -based companies Lorima (manufacturer of carbon fiber masts and spars), Avel Robotics (manufacturer of composite parts), CDK Technologies (boat building company) and Mulitplast ( Vannes -based shipbuilding company).

The carbon-fiber SolidSail mast has height 66 m/217 ft, width 2 m/7 ft and weight ~20 tons. It can carry a SolidSail sized ~1500 m2/16150 ft2.

Silenseas' SolidSail will propel the world's largest wind-powered/sailing cruise vessel - Accor's Orient Express Corinthian/fka Silenseas (2026).

Aeoldrive (rig comprising the mast and the SolidSail) is fully automated and 360-degree rotating, while the masts rotate/tilt up to 70 degrees (when the vessel passes under bridges).

(2019) "Wind Cruise Vessel" design by KNUD HANSEN

On June 19, 2019, KNUD HANSEN announced its medium-sized (LOA length 110,3 m / 361 ft) long "Wind Cruise Vessel" design. This sail-assisted ship has max passenger capacity 100, max speed 15 Kn (17 mph / 28 kph), operational range 6000 nm (6900 ml / 11100 km), draught 4,5 m (), TDW-deadweight tonnage 730 tons. The new sail-ship targets the expedition travel market and passengers who prefer destinations inaccessible by larger vessels.

The vessel is powered by 4x low-sulfur ULSD diesel engines (plus wind power) and also includes a large battery pack (for zero emissions while in port and protected marine zones). The rig is designed by Detlev Loll Ingenieurburo GmbH ( Peenemunde -based company) and comprised of 3x free-standing masts. Each mast is fitted with a fully-battened sail with adjustable flaps (wing devices that increase the max lift coefficient that a wing can generate). Ship's total sail area is 1910 m2 (20260 ft2). The sails are computer-controlled and designed for peak performance even in light winds.

The propulsion system is based on aft-located twin-screw propellers (fixed) and two fore-located tunnel thrusters (for better maneuverability in ports and anchorages). In sail-assisted mode, two fin stabilizers limit the ship's heel/listing to just 6 degrees.

Cabin decks house 48 passenger staterooms (46 cabins plus 2 suites) - all outside and many with balconies. Sea Lounge features underwater porthole windows. Deck 2 has a large tender boat garage for Zodiacs (rigid inflatable boats), jet skis, scuba diving gear, and other equipment. The ROV (remotely operated underwater vehicle) is fitted with HD camera equipment underwater observations at max depth 3 km ()9840 ft). Deck 3 is the Sun Deck featuring a swim platform with a ladder for easy water access. On Deck 4 are the restaurant (with outdoor terrace), bar, library, card room. On Deck 5 are the aft-located bar lounge and the bow-located observation area. Deck 6 has an open-air cafe and sun deck (sunbathing area with deckchairs and loungers).

Cruise ship building vs ship refurbishments

Unlike the scheduled cruise ship refurbishments , major refits may include even a cruise ship lengthening, like in the case of Royal Caribbean ship Enchantment of the Seas lengthened in 2005 (see the photo below). The Enchantment ship lengthening cost ~ US$55 million, it was a process of cutting the ship in two and inserting a whole new 73 ft (22 m) 3,500 tons midsection, pre-built at the Aker Finnyards.

The month-long dry-dock at the Keppel Verolme shipyards (Rotterdam, The Netherlands) resulted in adding 151 brand new cabins, a 50% bigger Pool Deck area, a new kids area, a teen centre, several new bars and lounges, an expanded main dining room, a new specialty restaurant. This "refurbishment cost" record was recently beaten by the CCL line and the US$155 million Carnival Destiny refit 2013 producing a brand new ship named Carnival Sunshine!

The average cost of building a cruise ship is around the US $450 for mid-sized vessels and up to $800 million for bigger cruise ships. These prices, along with the current economy status force many cruise lines to hold off from building new ships - the biggest expense of all. As a rule, all new cruise ships on order/currently under construction are by contracts signed years ago when the dollar had a good rate.

Cruise shipbuilding prices are high enough to not meet the return requirement. Even the mighty Carnival Corporation (the world's largest cruise shipowner) puts its shipbuilding plans on hold. Royal Caribbean is one of the few companies continuing to place orders for new ships - and not any ships, but the ever largest, the most innovative, the most expensive in the world. Still, most passenger ship lines are trying to keep their current fleet fresh and good looking. Two of the best examples are Holland America with its $450 million SOE program for ship renovations, and Carnival investing $250+ million to fully refit and refurbish 8 of its oldest vessels.

The next photo shows the construction of the world's largest cruise ship - Harmony of the Seas - at Saint-Nazaire (STX France) .

The following tag link lists all of CruiseMapper's news related to shipbuilding .

Streets of Monaco Superyacht

"Streets of Monaco Superyacht" is a futuristic project developed by Yacht Island Design. The vessel is modeled after the actual city and designed for billionaires to sail and play.

The 500-ft / 152-metre-long ship is lined with scaled-down versions of Monte Carlo's most famous buildings, including the Casino and its Grand Prix course (which on the yacht doubles as go-kart course). Among the most prominent amenities on this superyacht are swimming pools, cafes, full-service spa, full-size sports court (doubles as a helipad for private helicopters), library, interior parking for smaller boats, mini-submarine.

Staterooms (1VIP Suites) are sized 3800 ft2 (350 m2) each. There are also cabins for the 70 crew and staff members. The Superyacht cost about USD 1 billion.

Havyard's sightseeing cruise vessel design

In July 2019, Havyard Group ASA (Fosnavag Norway-based ship technology company) and SINTEF ( Trondheim Norway -based research company) started a project for designing a new environmentally friendly sightseeing cruise vessel specifically for touring the Norwegian Fjords, as well as a new Norwegian Coastal cruiseferry design. The project includes measuring energy consumption, hull optimization, developing new-generation equipment and using renewable energy sources.

These ships are designed with battery-power propulsion (zero-emission) and recharging in call port. The vessel has LOA length is 70 m (230 ft), max passenger capacity between 600-800, max speed 10-11 knots (20 kph / 13 mph), floor-ceiling and wall-to-wall windows throughout (for unobstructed fjord cruising experiences), wheelchair-friendly interior and exterior spaces. The new vessel's designer is Stig Magne Espeseth.

Passenger embarkations/debarkations are at floating hubs (platforms at sea) installed at the fjord's mouth and outside the itinerary's seaports. The hubs also double as charging stations for the smaller-sized vessels.

Building Cruise Ships: The Ultimate Guide

Since the introduction of the world’s first bona-fide cruise ship Prinzessin Victoria Luise in 1901, cruising has developed into a multi-billion-dollar industry.

There are currently over 320 cruise ships sailing worldwide, which represents only a tiny fraction of the estimated 99,800 cargo ships around the world.

2018 was the busiest year ever for the cruise market. An incredible 26.5 million passengers were carried across all the world’s cruise ships. Shortly after this, numbers plummeted due to the pandemic, but cruise lines are recovering. Many companies downsized their fleets in order to cut costs, selling off older and smaller vessels in favour of larger vessels capable of carrying more passengers.

While cruise ships have a fairly long lifespan – usually at least 25 years – there is a steady need to replace old ships and expand fleets, so shipyards still do good business in building new cruise ships.

Where are most ships built?

According to Statista , there are an estimated 283 shipyards around the world. Asia rules the world when it comes to shipbuilding. South Korea is the leading nation in shipbuilding by tonnage produced, closely followed by China and then Japan. These three nations are responsible for over 80% of new ships by tonnage.

Incredibly, of the 283 shipyards producing merchant ships, there are only four shipyards in the world capable of building modern cruise ships .

Fincantieri is the largest shipbuilder in Europe, and the fourth largest shipbuilder in the world. Arguably the leading shipyard for building cruise ships, Fincantieri is responsible for the construction of one third of the world’s cruise ship fleet.

STX Europe has operated under a number of different names, and now builds cruise ships solely in France. The world’s largest cruise ship by gross tonnage, Wonder of the Seas , was completed in their Saint-Nazaire shipyard in January 2022. In the past, STX Europe operated a yard in Finland which constructed ships for Royal Caribbean, TUI Cruises, Viking Line, and others.

Meyer Werft is a German shipbuilding company which has been owned by the Meyer family for seven generations. Their German yards are home to the largest roofed dry docks in the world. Unusually, due to the inland location of Meyer Werft’s shipyard in Papenburg, ships built there must make a 36-kilometre voyage up river Ems to reach open sea once launched. In 2014, Meyer Werft purchased a majority share of STX Europe’s Finnish shipyard.

Mitsubishi Heavy Industries is located in Japan and its Nagasaki shipyard has the smallest output of cruise ships among the four shipbuilders. In 2016, Mitsubishi announced that due to huge losses sustained on previous orders, it would no longer be taking orders for massive passenger ships, instead limiting itself to small and midsize cruise ships.

Cruise companies do not necessarily stick with the same shipyard to build all of their ships. They will opt for the yard which can offer them the best deal in both price and availability. Princess Cruises, for example, have had ships built by Fincantieri, STX Europe, and Mitsubishi.

How to build a cruise ship: a timeline

All cruise companies will have succession plans for each of their ships. These plans may be influenced by market trends and the success of the business, but they will have a general idea of when they intend to order new ships.

Once a company has decided that it wants to build a new cruise ship, it will begin the planning stage around 3-4 years before the ship’s intended launch date. This involves drawing up a rough design of the proposed vessel, with general details such as size, number of passengers, and unique features being decided upon.

The company will then open discussions with some or all of Fincantieri, STX Europe, Meyer Werft, and Mitsubishi to get an idea of the availability and rough price of each yard.

The build cost will vary as material costs in shipbuilding can fluctuate quite a lot. Steel, for example, has seen a large surge in price in the last 18 months. Even the location of the shipyard can incur extra costs – Mitsubishi attributes some of its past losses on building large cruise ships on the fact that it had to import so many parts from Europe to meet European passengers’ preferences.

You may find it surprising how quickly a cruise ship can be built. Considering their size and the attention to detail required in their interior design and finishes, it seems remarkable that a cruise ship can be fully constructed, launched, and ready for passengers in under 12 months . This is achieved by incredible efficiency in the build process.

Approximately 18 months before the planned launch date, the steel cutting ceremony takes place. Although called a ‘ceremony’, this is typically a low-key affair. At the ceremony, the very first plates of steel that will be used in the ship’s construction are cut into shape. After this point, it takes around six months for all of the ship’s steel to be cut into the correct size and shape, ready to be assembled.

Approximately 1 year before the planned launch date, the keel laying ceremony takes place. This is the first major ceremony in a ship’s life and will be attended by executives from the cruise company and the shipyard because this officially marks the exciting first day of the building project after many years of planning.

Traditionally, a keel laying ceremony involved the literal laying of the actual keel – the central piece of timber which made up the backbone of the vessel. In modern ship construction, vessels are built in many small sections which are fabricated and then transported to the dry dock to be welded together, so nowadays the keel laying ceremony will usually consist of the first prefabricated section being placed into the dry dock.

One major part of a cruise ship’s keel laying ceremony is the placing of the coin under the mast . This is the continuation of an ancient ceremony which is believed to date back to Ancient Greece, where the coin was intended to pay the ferryman Charon across the River Styx should the ship sink. These coins are usually placed where they will be visible to passengers, so if you are ever on a cruise ship have a look for it!

You may have noticed that there are a fair few ceremonies involved in the building of a ship. Considering the superstitious and traditional nature of seafaring, it’s not surprising that these ceremonies are still happening today.

After the keel laying ceremony, the ship’s construction really begins. Prefabricated sections of the ship’s hull and superstructure are constructed in yards away from the dry dock before being lifted into place on the keel blocks in the dock and then being welded together, one layer at a time.

As the decks are built up, essentially machinery is also installed. The engines and machinery in cruise ships’ engine rooms are absolutely massive, and this is the easiest way to get them into the belly of the ship, before decks are added above them.

One very important aspect of cruise ships is not installed until the shell of the entire ship is completed, however – the cabins .

All cruise ship cabins are constructed as individual units off-site. Carpet is laid, wardrobes, beds and tables added, and plumbing and wiring installed. Each cabin is in a self-contained metal box, which is crafted to specific measurements so that the cabins all sit flush to one another once installed.

Once constructed, each individual cabin is craned into place and slots into position, its magnetic walls helping it to sit firmly in place.

Once the shell of the ship is completed, it is time to complete the interior work. Public spaces such as atriums, theatres, and restaurants are all fitted out with their equipment before the focus turns to perfecting the aesthetics of the ship’s interior.

Once the exoskeleton of the ship is finished and all cabins are in place, the outside of the ship is painted and the ship’s name is added to the transom and to each side of the bow. Each cruise line has its own colour scheme for the outside of its ships, with AIDA, Norwegian Cruise Line, Cunard, and Holland America Line ships all being immediately recognisable simply from their exterior paintwork.

It is well known that most cruise ships are painted mostly white above the waterline. If you’d like to find out why, check out our video:

You may have noticed that all merchant ships, not just cruise ships, are painted a different colour below the waterline. Check out our video below to learn how using different paint below the waterline can save shipping companies millions of dollars over the lifetime of a ship:

External machinery such as rudders and propellers are also installed at this stage. There are many different types of propulsion used by cruise ships, and they all work in different ways. The fuel efficiency, manoeuvrability, and speed of a cruise ship can vary depending on which type of propulsion she has installed. To learn more about the different types of propulsion that a cruise ship can have, check out our article: Do Ships Have A Reverse Gear?

After over 130,000 hours of planning and 2,000,000 working hours in the shipyard (according to Fincantieri ), the ship will be ready to be put into the water for the first time. This is known as the launching ceremony .

In the past, this would be combined with the naming ceremony of the ship. However, cruise companies like to be able to stage these naming ceremonies in their preferred location for marketing and PR purposes, so it is more common for these ceremonies to be staged separately.

Once she is floated, she will undergo sea trials .

Sea trials involve up to three days of intense testing of the ship. Insurers, executives, surveyors, and essential navigational and engineering crew will all be onboard the ship as her manoeuvrability is tested to the limit.

The data collected from these sea trials will be collated and used to create a wheelhouse poster displaying the manoeuvring capabilities of the ship, including crash stop time and distance and turning circle at various speeds and rudder angles.

Once sea trials are complete, the ship’s first crew will come onboard and begin an intense period of familiarising themselves with the ship, drills, and training. If the ship has an identical sister ship already in the fleet, it is common for officers who are familiar with the sister ship to be assigned to the new ship to expedite the learning and training process.

Once the crew are all fully familiarised and the ship has been fully inspected and audited by its Flag State, it will sail to its home port for the biggest ceremony of all – the naming ceremony .

A cruise ship’s naming ceremony is a high-profile affair featuring celebrities, executives from the cruise company and shipyard, journalists, and often royalty. It is a long-standing naval tradition – not restricted to cruise ships – for a godmother to be appointed to the ship.

The ship’s godmother is responsible for smashing a bottle of champagne against the ship’s hull, which is said to bring good luck to the ship and those who sail on her. Conversely, it is said to bring bad luck to a ship if the champagne bottle does not smash on the first attempt.

Of course, that’s just a superstition. By the way, the bottle did not smash during the Costa Concordia’s naming ceremony…

Ships and their godmothers

A wide range of women have been asked to be godmothers to cruise ships in the past. Famous godmothers include Queen Elizabeth II (Queen Mary 2, Queen Elizabeth), Helen Mirren (Ventura), Julie Andrews (Crystal Serenity), and Sophia Loren (eight different MSC ships).

It is not always celebrities who are chosen to be godmothers to cruise ships, however. Some companies have used the title of godmother to honour women who have accomplished great things or who have overcome incredible hardships.

For example, Royal Caribbean chose Katherine Louise Calder to be godmother to the Freedom of the Seas . Katherine had fostered over 400 children with additional needs over three decades, and is certainly deserving of her recognition.

How do cruise ships last so long?

Because they are constantly in the public eye, cruise ships receive a lot more care and attention than most other merchant ships. They have a much higher budget for maintenance and paintwork, and they also go to dry dock more often than cargo ships.

Passenger ships are legally required to dry dock two times every 5 years, with a maximum period of 36 months between dry docks. It is a general rule that ships carrying passengers must adhere to the strictest legislation regarding their architecture, safety, stability, and maintenance.

In dry dock, the ship will undergo essential maintenance that is not possible with passengers onboard, some of which can only be done while the ship is out of the water.

Some of the major dry dock jobs include stripping all of the anti-foul paint off the hull and re-painting it. This not only makes the ship look better, but it also improves fuel efficiency by removing any marine life that had called the ship’s hull home.

Maintenance of major equipment such as the rudder and propeller shafts is undertaken. Anchors are paid out and their chains are re-painted and checked for corrosion. The condition of all the ship’s tanks is also inspected.

With proper planning and maintenance, regular dry docks can extend a cruise ship’s life beyond three decades. As long as the champagne bottle smashes on the first attempt…

How much does it cost to build a cruise ship?

Today's cruise ships are akin to floating resorts, so it's perhaps not surprising that building a ship can get pricey.

The newest vessels often feature multiple decks with numerous restaurants and bars, entertainment venues, various types of cabin configurations and every attraction you can imagine (such as roller coasters, zip lines and ice skating rinks). The price tag could be astronomical.

The cost of building a cruise ship can vary due to many factors, some of which include ship size, amenities, technology and design. If you're curious just how much money a cruise line needs to construct a new ship, here's everything you need to know.

For more cruise guides, news and tips, sign up for TPG's cruise newsletter .

On average, modern cruise ships cost between $500 million to over $900 million to build.

Cruise ship costs were much different back in the day. When the Titanic entered service in 1912, the 3,300-passenger ship was the world's largest and cost $7.5 million to build (almost $239 million by today's standards).

While we might think of the Titanic as a cruise ship, it was technically classified as an ocean liner. While its main purpose was transporting passengers across the Atlantic, it also carried mail and products. However, it was designed to offer passengers comfort and luxurious sea travel, making it similar to today's cruise ship experience.

Mardi Gras , the first ship in Carnival Cruise Line 's fleet, cost $5 million to renovate and carried 1,248 passengers when it launched in 1972. (The ship was the refurbished Empress of Canada, originally constructed in 1961.)

Carnival's cruise ships have certainly evolved over the years. The line's new Mardi Gras debuted in 2020, showcasing a seemingly endless list of attractions, including the first roller coaster at sea called BOLT: Ultimate Sea Coaster . The cost to build the 6,500-passenger ship was around $950 million.

Why do cruise ships cost so much to build?

Many components factor into cruise ship construction costs. The bigger the ship and the more passengers it holds, the more money it will cost to build. Also, the number of cabins and suites, as well as onboard features like restaurants, bars, spas, pools and ship attractions (water park, climbing walls, sports areas and the like) add to the final cost.

Additionally, new ships often employ cutting-edge technology and engineering, and cruise lines must pay for the teams of experts needed to turn design dreams into reality. The type of materials used can also drive up the cost, especially if sustainable or ultra-high-end products are used.

Where are cruise ships built?

The shipyards that build most modern-day cruise ships include the Meyer Werft shipyard in Germany, the Chantiers de l'Atlantique shipyard in France, the Meyer Turku shipyard in Finland and several Fincantieri shipyards in Italy.

At the shipyard, cruise ships are built in a special dry dock. The dry dock is an open dock area that's been drained. When construction is complete, the ship is launched into the water using a float-out technique — shipyard workers flood the dock with seawater, and the ship floats out. Interior work will continue even as the ship takes to the water for sea trials.

What is the most expensive cruise ship?

Size doesn't always matter when it comes to shipbuilding expenses. Ponant Cruises ' 245-passenger Le Commandant Charcot reportedly cost $430 million for a ship with just 123 rooms. Launched in 2021, the vessel is the first expedition cruise ship capable of reaching the North Pole.

Related: The most epic cruise ever? What it's like traveling to the North Pole on a luxury icebreaker

Royal Caribbean corners the market for building expensive cruise ships. Allure of the Seas , which debuted in 2010, is currently the world's most expensive cruise ship. It was constructed at the STX Europe Turku shipyard in Finland for a cost of around $1.43 billion.

The 18-deck, 8,454-passenger ship was the second vessel in the line's groundbreaking Oasis Class series. It's one of the world's largest. The ship is chock-full of amusements — multiple dining and drinking venues, a zip line, the FlowRider surf simulator, an ice skating rink and an AquaTheater.

Wonder of the Seas , the line's newest ship, is the second-most-expensive ship at a construction cost of approximately $1.35 billion. Built at the Chantiers de l'Atlantique shipyard in Saint-Naizaire, France, the 6,988-passenger vessel, which debuted in 2022, currently holds the title of the world's largest ship. As you can imagine, it also holds a dizzying array of diversions. Additionally, it's the first Oasis Class ship to feature a dedicated neighborhood of exclusive amenities for suite guests.

Set to debut in early 2024, Icon of the Seas might overtake the top spot in the list of most expensive cruise ships to build — just as it will surpass Wonder of the Seas as the largest cruise ship in the world.

Icon is Royal Caribbean's first ship in the line's all-new Icon Class, so its design and style will differ from previous vessels. The 7,600-passenger, 20-deck-tall ship will also be around 6% larger and about 10 feet longer than Wonder of the Seas. Early estimates have the construction cost at $2 billion.

Refurbishing older ships vs. building new ones

While it's more cost-effective to refurbish an older ship than to build a new one from the ground up, those enhancements don't come cheap. Sometimes, the renovations require a complete overhaul, including changing the ship's layout and adding cabins, restaurants and attractions.

For example, 17 years after it launched, Royal Caribbean's Navigator of the Seas received a glow-up in 2019 at a cost of $115 million. Improvements included everything from new furniture, carpeting and upholstery to expanded onboard amenities, entertainment and cabins.

Bottom line

The next time you board a cruise ship teeming with every diversion you can imagine, think about how much it cost to build that floating megaresort. It might give you new appreciation for just how much the cruise line has invested to create your ideal vacation at sea.

Planning a cruise? Start with these stories:

- The 5 most desirable cabin locations on any cruise ship

- A beginners guide to picking a cruise line

- The 8 worst cabin locations on any cruise ship

- The ultimate guide to what to pack for a cruise

- A quick guide to the most popular cruise lines

- 21 tips and tricks that will make your cruise go smoothly

- Top ways cruisers waste money

- The ultimate guide to choosing a cruise ship cabin

Building a Cruise Ship

If you build it, they will cruise, what it takes to build a ship..

By Kari Reinikainen

Have you ever looked around a cruise ship and wondered, “How in the world do they build this?” From the lighting and the plumbing to the logistics and the sheer size, it’s hard to imagine where one would even start. The construction of a major cruise ship is a technically demanding task, but it also requires highly skilled project and financial management teams.

The Business of Building Three European shipbuilding groups — Fincantieri in Italy, Meyer in Germany and Finland, and STX in France — dominate the market. Each has decades of experience in cruise ship building as well as the chains of suppliers and contractors in place who play a big role in the successful completion of today’s highly innovative cruise ships.

Meanwhile, six major cruise line companies— Carnival Corporation & plc, Royal Caribbean Cruises, Ltd. (RCCL); Norwegian Cruise Line Holdings (NCLH); Genting Hong Kong in the Far East; MSC Cruises, which is headquartered in Geneva; and TUI Cruises in Hamburg — dominate cruising’s newbuild order book.

The way ships are built has changed quite a bit over the past five decades. When the cruise industry was in its infancy in the late 1960s, nobody had much experience as to what kinds of ships should cater to middle America. Consequently, they relied on outside help. Knud E. Hansen, the Danish naval architects and consultants, designed the first duo of Norwegian ships, and Wartsila, the Finnish engineering group that, at the time, was also a shipbuilder, offered RCCL a design based on the 1967-built overnight ferry, Finlandia .

Today, everything is very different. The major cruise shipping groups know their customers. This means it is the cruise line, rather than the shipyard, that sets the pace in the design process and selection of equipment, although cooperation with the shipyard continues to play an important role.

The Construction Process The initial steps to building a cruise ship is when designers use software that enables them to produce three-dimensional drawings and images of the planned vessel. These digital drawings are also useful later on, when the ship comes due for a refit, as it’s easier to find….

This is an excerpt only. To read this article in its entirety, pick up an issue of Porthole Cruise Magazine , or check out our digital edition .

Photos: Royal Caribbean International

Porthole Cruise and Travel Magazine

Now in its 25th year, Porthole Cruise and Travel Magazine is published bi-monthly and available worldwide through digital subscription. It offers the latest news in cruise and travel, with in-depth features on voyages, new ships, the best destinations, readers' picks, onboard cuisine, entertainment, and more!

You may also like

Vitamin Sea: Best Bath Amenities

Get the low-down on cruising’s best bath amenities By Judi Cuervo The lovely young suite attendant

Jazz at Sea, Queen Mary 2

Grooving Across the Atlantic Enjoy the sounds of Jazz at Sea aboard Queen Mary 2 By Kim Foley MacKin

Like a Local: Fort Lauderdale

Finding Fort Lauderdale Close the guidebooks and let a local lead the way. By Jessica Chesler Fort L

Regent Seven Seas Cruises Launches 2025-2026 Exotic Edition Voyage Savings

Virgin Voyages’ Brilliant Lady Sets Sail in September 2025

Exclusive Insights with Belinda Hindmarsh on PONANT

Princess Cruises Announces 114-Day World Cruise

- Credit cards

- View all credit cards

- Banking guide

- Loans guide

- Insurance guide

- Personal finance

- View all personal finance

- Small business

- Small business guide

- View all taxes

You’re our first priority. Every time.

We believe everyone should be able to make financial decisions with confidence. And while our site doesn’t feature every company or financial product available on the market, we’re proud that the guidance we offer, the information we provide and the tools we create are objective, independent, straightforward — and free.

So how do we make money? Our partners compensate us. This may influence which products we review and write about (and where those products appear on the site), but it in no way affects our recommendations or advice, which are grounded in thousands of hours of research. Our partners cannot pay us to guarantee favorable reviews of their products or services. Here is a list of our partners .

How a New Cruise Ship Is Built

Many or all of the products featured here are from our partners who compensate us. This influences which products we write about and where and how the product appears on a page. However, this does not influence our evaluations. Our opinions are our own. Here is a list of our partners and here's how we make money .

Cruise ship construction is an enormous undertaking that involves thousands of decisions and logistical planning protocols that must be precisely set and coordinated in just the right order.

Watching a ship come together is a fascinating process, and I was able to witness it firsthand in Saint-Nazaire, France, where the Celebrity Apex was being built as the second in a series of five Celebrity Edge ships at the Chantiers de l’Atlantique shipyard.

The scope of building a ship

The ship is actually built in stages, often in different locations before being put together like a jigsaw puzzle or a game of Legos. It comes together as the result of 1,000 key steps, 200,000 different tasks, and the involvement of 500 subcontractors and suppliers. According to shipyard officials, each shipyard completes the process a bit differently.

For the Celebrity Apex, it has taken one year to go from having its first pieces of steel cut and prepared to seeing the final touches added before its March 2020 delivery to Celebrity Cruises.

More than 1.5 million manpower hours are involved in putting such a large ship together. In fact, the building of the ship begins even while engineering work is still going on; such is the large-scale nature of this process.

3D imagery and virtual reality are used in creating the mockups and models, which allow interior designers to take tours of the ship before it is built. They can decide where to most efficiently install electrical outlets or piping, as well as how the style of the interiors will come to life. No one wants a power outlet on the ceiling!

This process also allows designers to work on various parts of the ship simultaneously instead of needing to have each be ready before another can start.

» Learn more: Does cruise travel fit into your points and miles strategy?

Starting construction

It takes six months to build the outer structure of the ship, which is then stocked with passenger cabins, restaurants, public areas, bathrooms, and hundreds of miles of electrical wires and plumbing pipes.

Large cranes capable of lifting 1,400 tons at a time put each of the pieces together into what we recognize as a cruise ship.

Stacking cabins like Legos

For me, the most surprising element of ship construction was that most of it is actually built elsewhere. The ship as a whole consists of dozens of smaller parts, including cabins, which are each built at an assembly line.

The assembly line includes the installation of almost all passenger amenities — light fixtures, wiring, power outlets, furniture, TVs, beds, bathroom fixtures and even trash cans — so that when cabins are stacked into the ship, their electrical wires and plumbing can be instantly connected to the rest of the vessel. There is little additional work that needs to be done once the cabin is loaded onto the ship.

In fact, more than 3,000 miles of electrical wires come affixed to the cabin; some suites have even more due to their more spacious quarters. Everything must arrive to the ship at the right time and at the right place.

One installed in the ship, each cabin is furnished with decor and amenities in as few as 20 minutes, as staffers pass through installing facilities and cross-check one another's work.

If you think about it, the cabins must come furnished because large items like beds and sofas would not fit through many ship doorways or hallways. Once the cabins are stacked across the previously built hull, the steel sides are wrapped around the vessel. Designers had left cutouts where the windows and balconies belong.

Altogether, more than 40 individual blocks and 500 panels — each constructed off-site — are eventually integrated into the ship’s frame, which composes 250,000 steel parts representing 25,000 tons of steel.

» Learn more: Our family vacation: A Mexican cruise for 5

Wood, weight and 'wow factor'

Wood is not allowed in the construction of the ship because it can easily burn. Those walls in your room might be covered by wallpaper and artwork, but they are actually made from metal and steel.

The weight of the ship must be balanced and optimized, with a focus on keeping the center of gravity low to the waterline. Celebrity Cruises has a team that manages the weight of everything aboard the ship. Once designers choose what they want to install on the ship, a separate team of engineers gets involved to see if there are more lightweight options to use.

It is a balancing act to reduce weight while also maintaining the overall design aesthetic and “wow factor” of the ship.

Heavier materials are less efficient at the top of the ship; no one wants a top-heavy ocean liner. Thus, the Celebrity Apex uses a more eco-friendly material that looks just like glass for the transparent atrium in the Solarium — though it weighs only 1% of what glass would weigh. Other materials like lightweight carbon fiber help offset the weight of steel and fuel tanks.

Even the smallest details like room and public area signage is examined by a variety of teams from lawyers to marketing experts. To convey important messages, the cruise line wants to be informative without being stern.

For example, small placards by toilets in cabin bathrooms say, “Excuse me, only toilet paper please.” Throwing anything else into these vacuum toilets can cause plumbing stopups.

» Learn more: Should you insure your cruise?

What’s new on board

Adding new amenities for passengers can sometimes pose challenges for designers. New features like the Magic Carpet (also aboard sister ship the Celebrity Edge), required plenty of additional planning.

This cantilevered deck ascends the side of the ship between decks 2 and 16, allowing guests to dine or gather with panoramic views while more comfortably boarding smaller tender boats to go ashore when needed. It essentially is an external elevator on the side of the ship.

In the trilevel Grand Plaza area, the Martini Bar features over 700 LED lights in crystallized lenses designed to dance in coordinated fashion for dramatic effect. If lined up on the ground, these lights would span more than half a mile.

A Spa Thermal Suite adds eight different therapeutic experiences like a salt room, massaging Rainfall Water Therapy room, Iyashi Dome sauna (said to cleanse and detoxify the body), and new treatment tables. It also features the first F45 fitness classes at sea as well as a Kerastase Institute beauty salon.

Each of these elements requires significant plumbing and wiring design, which is different from the systematic approach found in cabins and must be integrated into the overall maze of pipes on the ship. The spa’s design, especially, requires unique setups for plumbing and piping.

A 23-foot 4K LED screen curving around the main theater stage is fitted with laser projectors for wraparound lighting during stage shows.

And Eden, a combined dining and lounge space, features a canopy of leaves, which are more than decorative — they shield the view of electronic equipment and lighting.

» Learn more: I survived a cruise — and you can too

The bottom line

On this ship, I found everything seemed to fit together with precision and often served to function both for internal use and passenger appreciation.

The next time you travel aboard a new cruise ship, look closely to appreciate the myriad details that came together to create it.

Photos courtesy of Celebrity Cruises and Ramsey Qubein.

How to maximize your rewards

You want a travel credit card that prioritizes what’s important to you. Here are our picks for the best travel credit cards of 2024 , including those best for:

Flexibility, point transfers and a large bonus: Chase Sapphire Preferred® Card

No annual fee: Bank of America® Travel Rewards credit card

Flat-rate travel rewards: Capital One Venture Rewards Credit Card

Bonus travel rewards and high-end perks: Chase Sapphire Reserve®

Luxury perks: The Platinum Card® from American Express

Business travelers: Ink Business Preferred® Credit Card

Planning a trip? Check out these articles for more inspiration and advice: Find the best travel credit card for you How to get the best deal on your next cruise Your money-saving guide to vacations

on Chase's website

1x-5x 5x on travel purchased through Chase Travel℠, 3x on dining, select streaming services and online groceries, 2x on all other travel purchases, 1x on all other purchases.

75,000 Earn 75,000 bonus points after you spend $4,000 on purchases in the first 3 months from account opening. That's over $900 when you redeem through Chase Travel℠.

on Bank of America's website

1.5x-2x Earn unlimited 2 points for every $1 spent on travel and dining purchases and unlimited 1.5 points for every $1 spent on all other purchases.

60,000 Receive 60,000 online bonus points - a $600 value - after you make at least $4,000 in purchases in the first 90 days of account opening.

Winter is here! Check out the winter wonderlands at these 5 amazing winter destinations in Montana

- Plan Your Trip

How They Build Cruise Ships

Published: December 7, 2023

Modified: December 28, 2023

by Beryle Gamache

- Sustainability

Introduction

Building a cruise ship is a marvel of engineering and design. These floating cities of luxury and entertainment require meticulous planning, skilled craftsmanship, and innovative technology to bring them to life. From the initial concept to the final launch, the process of constructing a cruise ship is a complex and fascinating endeavor.

In this article, we will take a closer look at how cruise ships are built, step by step. We’ll explore the initial design and planning stages, the construction of the shipyard itself, the fabrication of steel components, the assembly of ship sections, the installation of mechanical and electrical systems, the testing and safety checks performed, and the final finishing and certification processes.

So, join us on a virtual tour of the cruise ship construction process as we delve into the remarkable journey from blueprint to seafaring vessel. In each stage, we’ll uncover the careful attention to detail, the skilled labor, and the impressive technology that goes into creating these floating wonders of the sea.

Whether you’ve dreamt of cruising the open waters or are simply curious about how these magnificent ships come to be, this article will provide you with a behind-the-scenes look at the ingenuity and craftsmanship that shape the world of cruise ship construction.

Initial Design and Planning

The construction of a cruise ship begins long before the first steel plate is cut. It starts with the initial design and planning phase, where naval architects and designers collaborate to bring the vision of the ship to life.

During this stage, extensive research is conducted to identify market trends, customer preferences, and technological advancements. The ship’s size, layout, amenities, and features are carefully considered to ensure a balance between passenger comfort and operational efficiency.

Once the general concept is established, detailed engineering and architectural plans are created. These plans outline the structural framework, compartmentalization, propulsion systems, and safety measures of the ship. They also account for factors such as stability, maneuverability, and power requirements.

The design team also collaborates with interior architects and designers to create stunning and functional public spaces, staterooms, restaurants, entertainment venues, and facilities. The goal is to create a seamless and immersive experience for passengers, with careful consideration given to aesthetics, ergonomics, and the overall passenger flow.

In addition to the design aspect, the planning phase also involves sourcing and procurement of materials and equipment. This includes selecting the right suppliers for items such as engines, navigation systems, HVAC systems, and entertainment equipment.

Furthermore, environmental sustainability has become a major focus in recent years, and cruise ship design incorporates green technologies and practices to minimize the environmental impact. This includes advanced wastewater treatment systems, energy-efficient lighting, and the use of alternative fuels.

Once all the design and planning elements are finalized, the shipyard is ready to commence construction. The detailed plans serve as a roadmap throughout the entire building process, ensuring that every aspect of the cruise ship is meticulously executed.

The initial design and planning phase sets the foundation for a successful shipbuilding project. It combines the vision of the cruise line, the expertise of naval architects and interior designers, and the latest advancements in technology to create a blueprint for a remarkable and unforgettable floating experience.

Shipyard Construction

Before the actual construction of a cruise ship can take place, a shipyard capable of handling such a massive project must be established. The shipyard serves as the hub for all the construction activities and consists of various facilities and infrastructure dedicated to shipbuilding.

Building a shipyard involves careful planning, excavation, and construction of dry docks, slipways, workshops, and storage areas for materials and equipment. The size and capacity of the shipyard are determined based on the specifications of the cruise ship to be built.

Dry docks are one of the key components of a shipyard. These massive structures are flooded to allow the ship to be floated in and then drained to enable work to be carried out on the ship’s hull. Dry docks provide a controlled environment for construction, maintenance, and repairs.

Slipways are another critical element of the shipyard. These inclined ramps or platforms allow the ship to be launched into the water once it is completed. Slipways need to be properly engineered to accommodate the weight and dimensions of the ship, ensuring a smooth and safe launch.

In addition to the dry docks and slipways, shipyards also consist of workshops equipped with specialized machinery and equipment. These workshops house skilled craftsmen such as welders, carpenters, electricians, and plumbers who work on various aspects of ship construction.

Furthermore, shipyards have storage areas where materials and equipment are kept. This includes steel plates, pipes, electrical components, furniture, and fixtures. Having these items readily available at the shipyard eliminates delays and ensures a smooth construction process.

Health and safety are of utmost importance in shipyards. Strict regulations and protocols are in place to protect workers and prevent accidents. Safety measures include the use of personal protective equipment, regular inspections, and training programs to ensure a safe working environment.

Shipyard construction is a significant and resource-intensive undertaking. It requires the expertise of engineers, architects, and construction workers to build the necessary infrastructure to support the construction of cruise ships. Once the shipyard is ready, it becomes the bustling center where the actual construction of the cruise ship begins.

Steel Fabrication

Steel fabrication is a crucial stage in the construction of a cruise ship. It involves the shaping, cutting, and welding of steel plates and sections to build the ship’s structural framework. This process requires skilled craftsmen and specialized equipment to ensure precision and accuracy.

The first step in steel fabrication is the preparation of steel plates. These plates, which can weigh several tons each, are cut and shaped according to the specific dimensions and patterns provided in the ship’s design plans. Advanced cutting machines, such as plasma cutters or laser-cutting technology, are used to achieve clean and precise cuts.

Once the steel plates are cut, they are bent, formed, and shaped into various sections that make up the ship’s hull, decks, and bulkheads. These sections are known as “blocks” and are assembled together to form the structural framework of the ship.

The steel fabrication process also involves welding. Skilled welders use various welding techniques, such as arc welding or MIG welding, to join the steel sections together. Welding ensures the structural integrity of the ship and provides strength and durability against the forces encountered at sea.

Quality control plays a crucial role in steel fabrication. Inspections are conducted to ensure that the steel plates and sections meet the required specifications and industry standards. Non-destructive testing methods, such as x-ray or ultrasound, may be employed to detect any potential defects or weaknesses in the welds.

Environmental considerations have also led to the adoption of greener practices in steel fabrication. Shipyards are increasingly using recycled steel as raw materials, reducing the demand for new steel production. Additionally, energy-efficient machinery and processes are employed to minimize the environmental impact of steel fabrication.

Steel fabrication is a labor-intensive process that requires a high level of skill and precision. It forms the foundation of the cruise ship’s structure and sets the stage for the subsequent assembly and construction processes. Once the steel fabrication is complete, the ship begins to take shape as its various sections are assembled together in the shipyard.

Assembly of Ship Sections

Once the steel fabrication is complete, the various sections of the cruise ship are ready for assembly. This stage involves joining the individual blocks and components to form the complete structure of the vessel. It is a process that requires precision, coordination, and expertise.

The assembly begins with the alignment and joining of the pre-fabricated steel sections. Large cranes and specialized lifting equipment are used to maneuver and position the heavy sections into place. The shipyard becomes a symphony of activity as different teams work together to ensure each section is fitted accurately.

During the assembly process, the ship’s hull, superstructure, decks, and bulkheads are connected. This framework provides the necessary strength and stability for the vessel. The alignment of each section is vital to ensure a seamless integration and maintain the structural integrity of the ship.

As the ship begins to take shape, additional components and systems are integrated into the structure. This includes the installation of propulsion systems, grating and flooring, navigation equipment, HVAC systems, and plumbing networks. Skilled technicians and engineers work hand in hand to ensure that each component is properly installed and connected to the ship’s infrastructure.

The assembly of ship sections also encompasses the installation of windows, doors, and other openings. Care is taken to ensure proper sealing and insulation to ensure passenger comfort and comply with maritime safety regulations. These features play a significant role in providing natural light, ventilation, and access to different areas of the ship.

Throughout the assembly process, quality control measures are implemented to ensure the highest standards are maintained. Inspections and tests are conducted to verify the integrity of the connections, the functionality of the installed systems, and adherence to safety standards.

Interior Design and Furnishing

While the exterior of a cruise ship is an impressive sight to behold, it is the interior design and furnishing that truly enchants passengers. This stage of construction focuses on creating captivating and luxurious spaces that will delight and pamper those on board.

The interior design process begins with conceptualizing the overall theme and atmosphere of the ship. Interior architects work closely with the cruise line to create a cohesive and enticing design scheme that reflects the brand’s identity and appeals to the target demographic.

Meticulous attention is given to every detail, from the color schemes and materials to the furniture and lighting. The goal is to create a harmonious blend of aesthetics, functionality, and comfort, providing passengers with memorable experiences in every area of the ship.

The design team considers the flow and layout of public spaces, ensuring they are intuitive and inviting. These spaces may include grand atriums, elegant dining areas, relaxing lounges, vibrant entertainment venues, spa and wellness facilities, and children’s play areas.

The selection of materials and finishes is another crucial aspect of interior design. High-quality and durable materials are chosen to withstand the demands of a cruise ship environment, while also providing an opulent and refined ambiance. Fabrics, carpets, marble, wood, and glass are meticulously selected to create a sense of luxury and elegance throughout the ship.

Furnishing plays a vital role in bringing the design vision to life. Custom furniture pieces are crafted to fit seamlessly into the available spaces, maximizing functionality without compromising on style. From luxurious seating arrangements to bespoke cabinetry and fixtures, every furnishing element is carefully chosen to enhance the overall design concept.

The interior design process also considers accessibility, ensuring that all areas of the ship are inclusive and accommodating to passengers with disabilities. Various amenities, such as ramps, elevators, and adapted cabin features, are incorporated to ensure everyone can enjoy the facilities onboard.

Throughout the interior design and furnishing process, close collaboration takes place between the design team, shipyard, and various contractors and vendors. Rigorous quality control is implemented to maintain the highest standards of craftsmanship and ensure that the design concepts are executed flawlessly.

The result of this meticulous interior design and furnishing stage is a cruise ship that exudes elegance and grandeur, providing passengers with an unforgettable experience in every corner. Whether it’s a lavish suite, a stunning dining venue, or a cozy lounge, the interior spaces of a cruise ship are designed to create lasting memories for those who embark on the voyage.

Installation of Mechanical Systems

Beyond the luxurious interiors and captivating design, cruise ships are complex machines that rely on a wide array of mechanical systems to operate smoothly and efficiently. The installation of these systems is a critical phase in the construction process, ensuring that everything from propulsion to sanitation functions seamlessly.

One of the key mechanical systems installed in a cruise ship is the propulsion system. This could include diesel engines, gas turbines, or a combination of both. These powerful engines provide the thrust required to propel the ship through the water at varying speeds. The installation process involves carefully positioning and connecting the engines and their associated components, such as shafts and propellers.

In addition to propulsion, the installation of auxiliary systems is essential. These systems include HVAC (Heating, Ventilation, and Air Conditioning), plumbing, and sanitary systems. HVAC systems maintain comfortable temperatures and proper air circulation throughout the ship, while the plumbing and sanitary systems ensure the proper flow and treatment of water and wastewater on board.

The electrical system of a cruise ship is another critical installation. Large generators are installed to provide the necessary power for lighting, appliances, entertainment systems, and other electrical equipment. Highly skilled electricians work diligently to connect and integrate the electrical components, including wiring, circuit breakers, and control panels, throughout the ship.

Fire suppression and safety systems are also given utmost importance during the installation phase. This includes the installation of fire detection and alarm systems, automated sprinklers, and firefighting equipment strategically placed throughout the ship. These systems are crucial to ensure the safety and well-being of passengers and crew in the event of a fire or emergency.

Automation and control systems are implemented to monitor and manage various ship operations. These systems include computers, sensors, and programmable logic controllers (PLCs) that regulate the functioning of different mechanical and electrical systems. They provide real-time information and allow for efficient control and troubleshooting.

The installation process of mechanical systems requires close coordination between different teams, including engineers, technicians, and contractors. Each system needs to be integrated seamlessly with the ship’s structure and other systems, ensuring that everything functions harmoniously.

Throughout the installation phase, rigorous testing and inspections are conducted to verify the proper functioning and safety of the installed systems. These tests may include load testing, pressure testing, and control system checks to ensure that the ship is ready for operation.

The installation of mechanical systems is a complex and vital part of cruise ship construction. It ensures that the ship is equipped with the necessary functions and infrastructure to provide a safe, comfortable, and enjoyable experience for passengers throughout their journey at sea.

Electrical Wiring and Integration

Electrical wiring and integration are integral components of cruise ship construction, as they ensure the seamless functioning of various electrical systems and equipment on board. The installation of electrical wiring involves careful planning, precise execution, and thorough integration throughout the ship.

Electrical wiring is responsible for supplying power to lighting, appliances, entertainment systems, navigation equipment, and other electrical components on the ship. Skilled electricians work in coordination with the design team to ensure that wiring routes are strategically planned to reach every area of the ship.

During the installation process, different types of cables and wiring materials are used, depending on the specific requirements and regulations of the cruise ship. These cables are carefully routed, protected, and connected to provide a reliable and safe electrical infrastructure throughout the vessel.

Integration is a crucial aspect of electrical wiring, as it involves connecting various electrical systems and components to work cohesively. This includes the integration of switches, outlets, circuit breakers, and control panels to ensure proper distribution of power and efficient operation.

Automation and control systems are also integrated into the electrical wiring framework. These systems help monitor and regulate the ship’s electrical functions, providing real-time information, and allowing for efficient control and troubleshooting when necessary.

Throughout the installation process, rigorous testing and inspections are conducted to ensure the accuracy and safety of the electrical wiring. This includes continuity tests, insulation resistance tests, and grounding tests to validate the integrity of the installed electrical systems.

In addition to the primary electrical wiring, power generation and distribution systems are also integrated into the ship’s electrical infrastructure. Large generators, switchboards, and transformers are installed to provide the necessary power supply to different areas of the ship.

Safety is a top priority in electrical wiring and integration. Cruise ships adhere to strict regulations and standards to prevent electrical hazards. Ground fault circuit interrupters (GFCIs), surge protection devices, and insulation systems are implemented to minimize the risk of electrical shocks or fires.

Efficiency and sustainability are also considerations in electrical wiring and integration. Cruise ships now incorporate energy-saving technologies, such as LED lighting and energy management systems, to reduce power consumption and environmental impact.

By ensuring the proper installation and integration of electrical wiring and systems, the cruise ship can provide a comfortable and safe environment for passengers and crew. The seamless integration of electrical components ensures reliable power distribution and functionality throughout the vessel, enhancing the overall experience of those on board.

Testing and Safety Checks