Pre- and Post-Trip Inspection Dos and Don’ts

Minimizing over-the-road breakdowns and preventing out-of-service violations are two of the many benefits of pre- and post-trip inspections. Use this list of dos and don'ts to complete your inspections the right way.

Don't: Think they're optional.

They're the law. Federal Motor Carrier Safety Administration (FMCSA) regulation 392.7 requires pre-trip inspections, while regulation 396.11 mandates post-trip inspections.

Do: Know what to check.

For a pre-trip inspection, check:

- parking brakes

- service brakes

- tires and rims

- steering system

- fluid levels

- belts and hoses

- electrical and air lines

- coupling devices

- air brake warning system

- emergency kit

- lights, reflectors and signals

- all applicable paperwork

Check the same items for post-trip inspections minus the fluid checks — don't touch anything that might be hot!

Don't: Kick-check the tires.

Thump checks don't work, because a tire sounds empty only if it's nearly 100% out of air. Use a calibrated tire gauge instead. Also, make sure all tires have the proper tread depth and that all lug nuts are tight.

Do: Double-check the brakes.

More than 1 out of every 4 vehicle out-of-service violations in the U.S. during the 2023 Commercial Vehicle Safety Alliance's (CVSA's) International Roadcheck were due to brake system violations.

Don't: Do an inspection differently each time.

Instead, develop a routine, and go in the same order with each pre- and post-trip check. Consider starting at the cab, then inside the cab, the front of the vehicle, then around the truck starting at the driver's side.

Do: Take your time.

There's no rush. Budget 10-15 minutes for a proper pre-trip inspection.

Don't: Forget the interior.

A clean cab tells an inspector that the rest of the vehicle is in good shape. A dirty cab says the opposite.

Do: Check your wheels.

It's the best way to make sure your truck doesn't accidentally move when you're doing a pre- or post-trip check. Forgetting to do so could cause a serious injury — or worse.

Do: Keep accurate logs.

Whether you use electronic or paper logs, keep them updated regularly, and make sure all other paperwork (driver's license, inspection, insurance) is current.

Don't: Ignore potential problems.

If you spot something out of the ordinary during your post-trip inspection, report it to dispatch immediately.

Download and share a PDF of this Safety Bulletin with your drivers.

English Español Français

At this time the Penske website requires that you enable JavaScript in order to take advantage of our website features. Please enable JavaScript and retry.

For assistance with other Penske services, please use the numbers below.

Truck Rental

- Household Rentals: 1-800-GO-PENSKE

- Business Rentals: 1-844-906-3404

Used Trucks

- 1-866-309-1962

Truck Leasing

- 1-888-234-4201

Penske Logistics

- 1-800-529-6531

Join 100,000+ Drivers

- Sponsorship

- Thinking of Becoming a Truck Driver?

- Getting a CDL License

- Trucking Driving Jobs Guide

- Trucking Company Guide

- Trucker Life

- Paid CDL Training

- CDL Schools

- Professional Driving Skills + Knowledge

- Owner Operator

- Latest Articles

- Truck Driver Skills

The Pre-Trip Inspection: A Practical Guide For the Truck Driver

Updated February 24th, 2022

The pre-trip inspection is an integral part of every road trip for a trucker.

It’s probably the most disliked and most often overlooked part of the job of the professional truck driver in the trucking industry.

This inspection is meant to be a thorough check of the truck, trailer and load.

The check is to ensure that everything is in correct working order, prior to the truck and driver, departing on a trip.

Any damage or issues found during the pre-trip inspection which needs attention, must be addressed before departure.

CDL Test Pre-Trip Inspection

If you just came through the process of getting your CDL, you can breathe a sigh of relief.

You don’t have to check all 500 or so items that you had to memorize for the test every single day.

Out on the road, a thorough pre trip shouldn’t take more than 10 to 15 minutes.

DVIRs – Daily Vehicle Inspection Report

According to federal law ( FMCSR Section 396.11 ), every day, a driver must submit a Daily Vehicle Inspection Report (DVIR) for each power unit he operates. Multiple trailers can go in one report.

DVIRs are either paper or electronic.

Not every trucking company (ahem) enforces this policy, so some truck drivers can go months or years without submitting a DVIR.

Minimum DOT Pre-Trip Inspection Requirements

- Service brakes including trailer brake connections

- Parking brake

- Steering mechanism

- Lighting devices and reflectors

- Windshield wipers

- Rear vision mirrors

- Coupling devices

- Wheels and rims

- Emergency equipment

Your trucking company’s DVIR might be more thorough.

This is a thorough Q&A on DVIRs which you can refer to.

Inspecting a New Truck

When you are assigned a new truck (either daily or just once), there are a few additional things you need to check for on the pre-trip inspection.

Truck Compliance

- Cab card and book – This is a book containing the registration, inspection, permits, cab cards, IFTA paperwork, and any other important papers for the truck. Make sure it is in the truck and all the paperwork is up to date.

- Inspection sticker – This is outside the truck. Find it and make sure the truck is not overdue.

- IFTA stickers – These are the fuel tax compliance stickers. They are on both sides of the truck. Make sure the current year is displayed.

- Elog device – Most trucks are required to have a working elog device.

- Required permits – These are in the cab card book. The most common permits are Heavy Motor Vehicle Trip Permit (Oregon) and the Weight Distance Tax Permit (New Mexico).

- New York HUT sticker – This is usually on the front of your truck. It’s a type of permit.

- License plate – Make sure the license plates on the front and back of the truck match.

- FMCSA Safety Regulations and Hazardous Materials book – These will be given to you by your company. They must stay in your truck within arms reach from the driver’s seat.

- Paper logbook – If your e-log stops working, you must log your hours in a paper logbook, which must be kept in your truck.

- Medical card – You must keep your current medical card in your truck. Always have your CDL on you as well.

- Orange triangles – You must have 3 triangles for when you break down.

- Fire extinguisher – Must be charged and secured to the truck. No rolling around on the floor.

- Extra fuses – If your truck doesn’t use circuit breakers, you must have spare fuses.

- Load bars and/or straps

- Extra oil, coolant, and windshield washer fluid

- Line antifreeze and diesel anti-gel

- Chains and bungees

- Gladhand seals

- Hammer, wrench, wire cutters, cable cutters, knife with glass-breaker

The Class A Pre-Trip Inspection Process

Unless I have to bobtail to pick up my trailer, I inspect my truck and trailer together.

The best way to memorize a thorough pre trip is to do it the same way each time.

Your process will look different from mine, but as long as you are consistent, you will be less likely to miss anything.

I do the inspection first thing each morning as well as every time I swap trailers.

Paperwork and Trailer

- Check the paperwork. It should be the first thing checked when you get to your truck.

- Match the trailer number to your paperwork. If your trailer has a seal, make sure it matches too.

- Unsealed trailer. If your trailer does not have a seal, open it and confirm the product matches the bills. If you are picking up an empty trailer, open it and make sure it’s actually empty.

- Confirm your destination. Ensure the destination is the same as on your trip sheet or load assignment. If there is a discrepancy, call your dispatcher.

I personally like to start with checking under the hood of the rig. Not everyone does, but I do.

Under the Hood of the Truck

I walk around the front of the truck, making sure all the lights work. Then I open the hood.

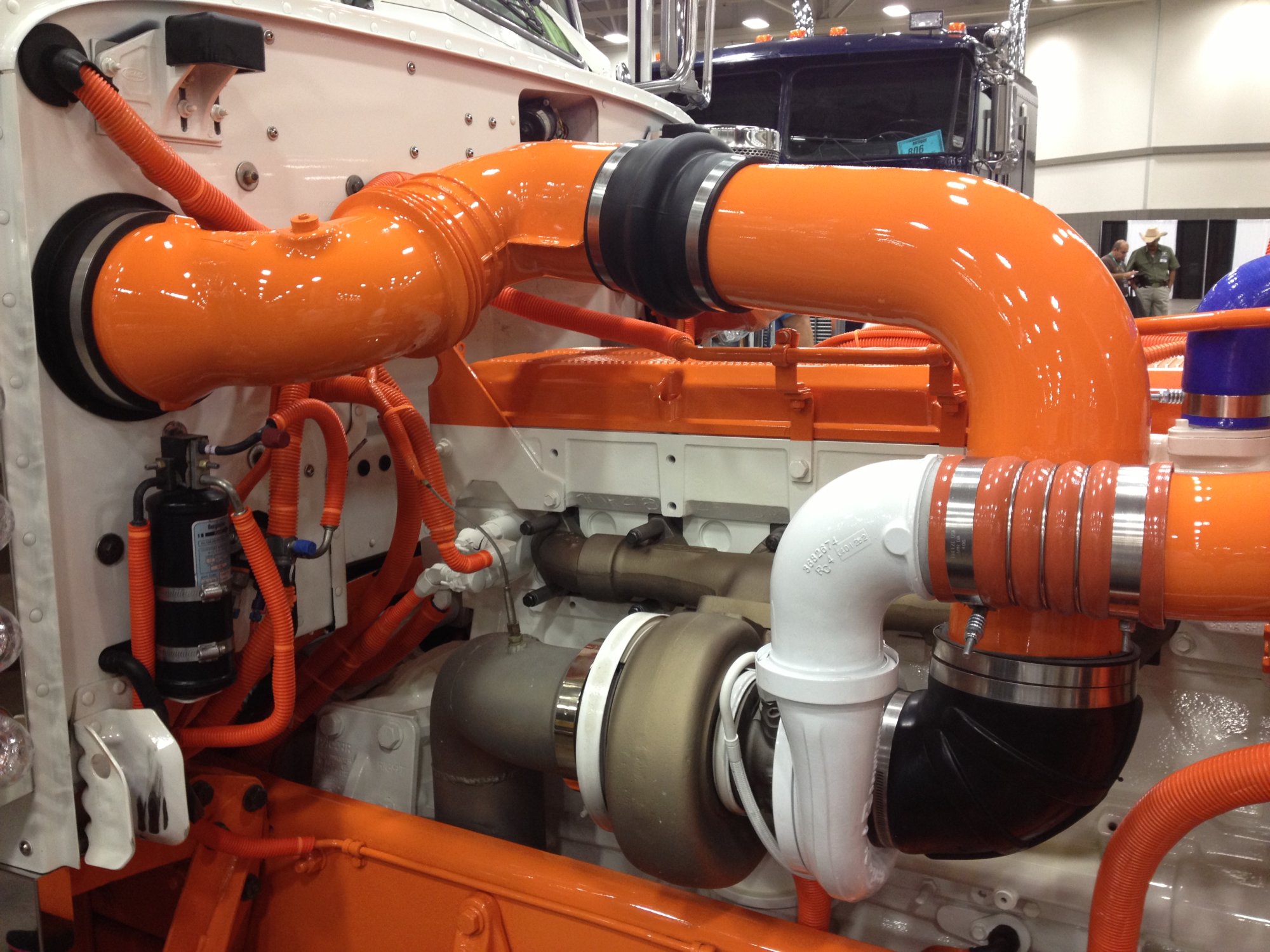

- Fluid levels – Check all fluids: coolant, oil, power steering fluid, and windshield washer fluid. Make sure caps are tight for the rad, oil filler, power steering fluid and the dip-stick is seated properly.

- Alternator, water pump, power steering pump –Make sure these are in good working order, and the belts are not worn or have too much slack.

- Observe at the engine block. Check for leaks, fluid running down the side of the engine. Check for wear, cracking or fraying. Inspect fan belts for proper tension and signs of wear.

- Hoses – Check all hoses for leaks, cracks, and tears.

- Wiring – Check wiring for wear.

- Steering linkage – Check linkage for worn or missing parts.

- Tires – Tires should be properly inflated and have decent tread. If there are flat spots on the tire, it needs to be replaced.

- Hub seal – Make sure it’s not leaking and wiped with oil if transparent.

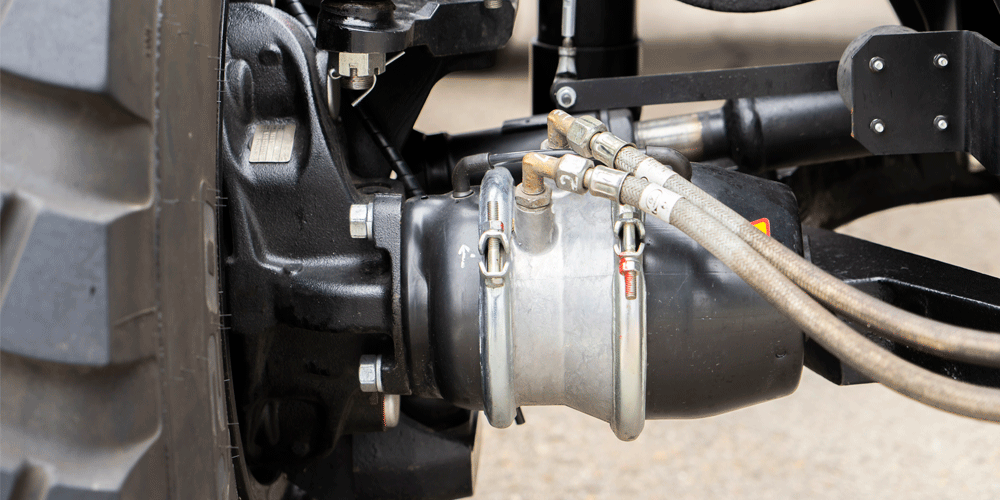

- Brakes – Brake chambers should not be out of round and should be free of grease. Shoes should not be worn down too much.

- Slack adjusters – Pull slack adjuster. If it travels more than an inch, it needs to be adjusted.

- Suspension – Shocks should be in good condition, and not covered in grease or oil.

Back of the Truck

Next, I check the back of my truck because it’s easier to check this before hooking to a trailer.

- Tires – Tires should be properly inflated and have decent tread. If the tires have flat spots, the tire needs to be replaced.

- Suspension – Shocks and airbags should be in good condition, and not covered in grease or oil.

- Drive shaft – Driveshaft should be undamaged and free of grease. Make sure there is no debris in the u-joints.

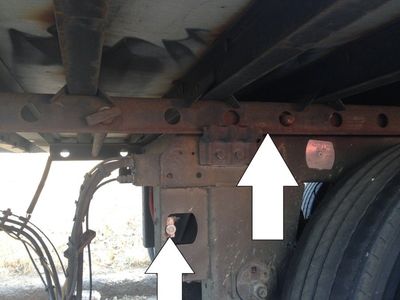

- Frame – The frame should not have any welds and not cracked or significantly rusted.

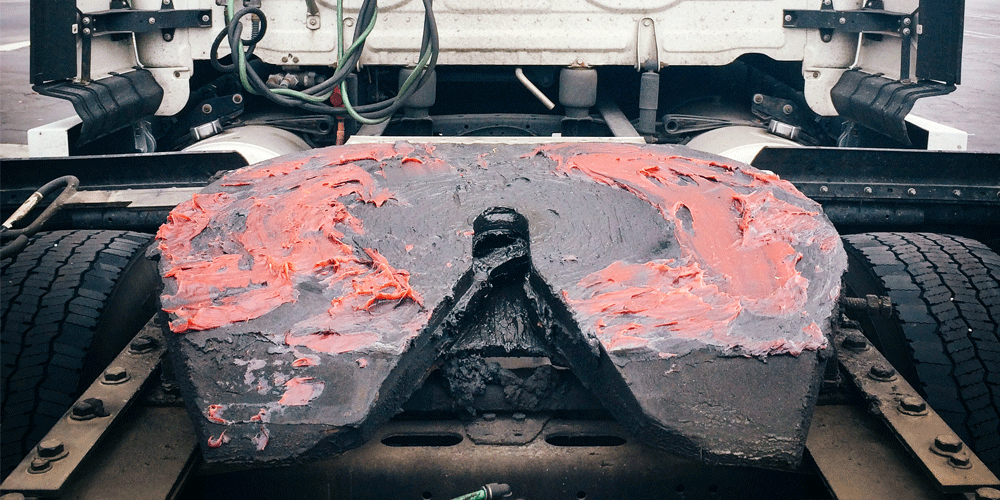

- Fifth wheel – The fifth wheel should be properly greased and not broken.

- Fuel tanks – Fuel tanks should not be leaking.

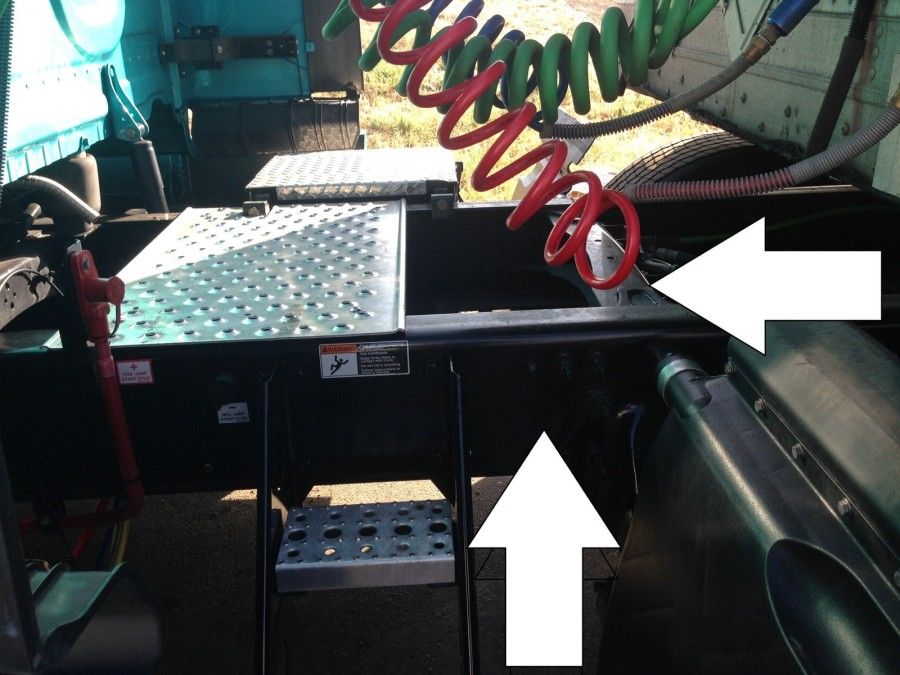

- Stairs and catwalk – Stairs and catwalk should be free of debris and not broken.

Tires should be checked with a tire gauge.

Tip . This is especially if you are slip seating. Tire thumpers aren’t very accurate. If you use a tire thumper, still check with a tire gauge from time to time.

Drives and tandems should be inflated to 100-110 psi and have a minimum tread or 2/32in. Steer tires should be inflated to 110-120 psi and have a minimum tread of 4/32in.

Tires under 50 psi should be replaced, as they can’t retain enough air pressure.

Flat spots can occur from dragging tandems in the winter or when trying to slide the tandems. Tires with flat spots should be replaced.

Check tires for damage, nails, and punctures.

Next, I jump in my cab and start my truck.

- Gauges – Make sure air, oil, and water temperature gauges rise to normal levels.

- Mirrors – Adjust mirrors before moving your truck.

- Windshield wipers – Make sure they work and sit flat against the windshield.

- Horn – Make sure the city and air horns both work.

- Heat and A/C – Check to see if heat and/or air conditioning is working.

- Seat belt – Seat belt should not be frayed and should move freely.

Coupling and Air Lines

This is what could happen if you don’t do the tug test.

The pre-trip inspection is a pretty important thing to do.

Learn your pre-trip procedure and do it when required.

This is why you should always do a tug test when picking up a trailer. The passenger side of the front of the trailer is resting on the frame of the truck and NOT hooked up to the 5th wheel.

The front left corner of the trailer is supported by retracted landing gear only. (Not good!)

The truck driver in this photo (hopefully) learned how critical a pre-trip is. Don’t end up in a pickle like this guy.

Next, I hook up to my trailer.

- Tug test – I back under my trailer until I hear a click, and then immediately do a tug test.

A tug test tests both your coupling and your brakes. If you pull away from your trailer, you aren’t hooked properly.

If you pull your trailer with you, your trailer brakes are out of adjustment. Be absolutely sure to write it up and have it corrected before departure.

- 4 Ways + Headlights. I also turn on my four-way flashers and headlights.

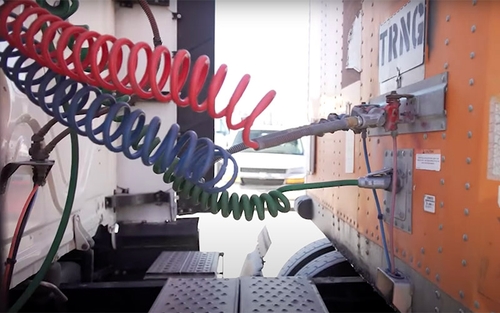

- Airlines and pigtails – Next, hook up airlines and pigtails (electrical connection). Inspect to make sure they aren’t leaking or ripped.

- Visual check of Fifth wheel – Look at the fifth wheel arm under the trailer to make sure it is coupled. The arm should be in.

- Landing gear – Raise the landing gear and check for damage.

Next, I check the bulkhead (front of the trailer).

- Wall – Make sure the wall is not damaged.

- Inspection sticker – Check the DOT inspection sticker to make sure it’s not out of date.

- Registration paperwork – Check the front trailer box to make sure the registration is good.

- Reefer unit – If you are pulling a reefer, select the pre trip function on the unit and run it. It should be completed by the time you are finished your pre trip inspection.

Next step for the pre-trip inspection is to check the side of the trailer and the tandems.

- Lights – Lights should be on and flashing.

- Suspension – springs or airbags should be in good condition, and not covered in oil or grease.

- Tandem pins – Tandem pins should be locked in position, and slider arm should be in its cradle.

- Cables – Make sure the tandem cables aren’t dragging on the ground.

- Underbelly – Make sure there are no damaged beams under the trailer. Check the entire length.

- Mudflaps – Mud flaps should not be torn and hanging.

Back of Trailer

Next, I check the back of the trailer.

- Doors – Doors and hinges should not be damaged.

- Door latches – Doors should be closed and secured.

- Seal – Seal should be intact and match paperwork.

- DOT bumper – DOT bumper should not be damaged

- License plate – Check for the license plate. They tend to wear out and fall off.

Passenger Side

Next, I check the passenger side.

- Brakes – Brake chambers should not be out of round and should be free of grease.

- Suspension – Springs or airbags should be in good condition, and not covered in grease or oil.

- Mudflaps – Mud flaps should not be torn.

Ready to Roll

Finally, I jump in my truck and double check my paperwork and destination.

I release my air brakes, roll forward, and push the service brake.

If everything is good, I’m ready to roll.

Post-Trip Inspection

When I’m done for the day, and every time I swap trailers, I do a post-trip inspection. If I am swapping trailers, I do a pre-trip on the new trailer as well.

A post-trip includes:

- lowering the landing gear

- removing the airlines

- uncoupling, and walking around the trailer checking tires, lights, seal, and mudflaps

Then I finish my paperwork and go home.

Slip Seating

If you slip seat (meaning you are in a different truck each shift), your pre- trip check should be more thorough than if you are permanently assigned a truck.

This also applies to the first inspection after being assigned a truck.

Please be courteous and write up any problems or issues found, so the next driver of the vehicle doesn’t have to deal with it.

Side Note: Clean out your truck and throw away any trash. Common courtesy goes a long way in trucking, between drivers.

Pre-Trip Inspection F.A.Q.

Most breakdowns can be avoided with proper preventative measures, such as daily inspections.

Thorough inspections should be done at the start of each shift. Inspections of trailers should be done every time you swap trailers.

Each driver should do a thorough pre-trip every time they swap drivers.

It should take about 10-15 minutes to perform a pre trip inspection.

The DOT. Make sure you stay in compliance so you don’t end up with hefty fines and an out of service.

The best way to memorize your pre trip inspection routine, is to do it the same way every time. That way you’re less likely to miss something. If you have questions, ask your safety team at your company.

Fluids in the engine, engine hoses and wires, brakes and suspension, mudflaps, trailer registration and inspection paperwork, and license plates.

A Few Trip Planning Tips

- Buy and learn to read a trucker’s atlas. It’s useful to plan routes and avoid restricted roads. I find this road atlas a necessity as a professional truck driver.

- Buy a decent trucking GPS , but don’t rely on it 100%. Use common sense.

- Don’t use the GPS in your elog device. It will put you in a lake.

Please note that minimum requirements for the inspection are established by the FMCSA.

But these may vary by state, trucking company, truck type, and trailer type.

It is your duty as a professional truck driver to perform a thorough pre-trip inspection before each trip and before you drive.

You’ll save yourself from headaches, fines and unnecessary accidents.

More Articles You May Like

- Trucking Terms – A Guide to Our Industry’s Lingo

- The 18 Wheeler – A Comprehensive Guide to Big Rigs

CDL Truck Driver Skills – Tips, Tricks + Knowledge to Kick Your CDL Skills Up a Notch!

- The D.O.T. Physical- A Guide For the Truck Driver

Everything You’ll Want To Know About Paid CDL Training

Custom Big Truck Sleepers Photo Gallery Collection

The Best Trucking Companies to Work For 2024 USA

5 Best GPS For Truckers – A Professional Driver’s Guide

Twice a month we email you the best tips and new articles to help you better navigate the trucking industry..

10 Truck Driving Safety Tips Every Professional Driver Should Follow

A veteran 40+ years truck driver shares 10 of the all time, tried and true truck driving safety tips ALL professional truckers should know AND follow! If every driver of EVERY vehicle on the road followed these safety tips, our roads would be SO much safer.

Trucker Tips Master Guide: Expert Advice From Experienced Truck Drivers

A collection of trucker tips from million milers and experienced drivers. These are gold nuggets for the new truck drivers!

Instruction, clear advice, videos and photos for truck driver skills, maneuvers and information for all professional truck drivers.

A practical guide to paid CDL training programs. Recommended Company Sponsored Schools, Requirements, pros + cons, what to expect from company-sponsored cdl training programs.

Is a Career As a Department of Defense Truck Driver For You?

As a Department of Defense (D.O.D.) truck driver, your role is integral to the logistics and supply chain operations of […]

Navigating Fair Truck Driver Pay: Are You Earning Enough?

Ready to take control of your truck driver pay? Discover key factors impacting your earnings and ensure you’re compensated appropriately […]

The Best Tanker Trucking Companies to Work, U.S., 2024

Top Tanker Trucking Companies in the US To Work For Tanker work typically falls to the ‘better carriers’. Tanker carriers […]

Best Flatbed Trucking Companies, US, 2024: Our Top Picks

There are over 1 million truck drivers working for flatbed trucking companies in the U.S. trucking industry. However, not all […]

Best Trucking Companies For New Drivers in the U.S., 2024

For new drivers entering the trucking industry, diving into the right pool can make all the difference. The foundation of […]

Follow Smart Trucking

- Free Practice Tests

Commercial Driving

- Introduction

Getting a CDL

- Fees and costs

CDL Types & Permits

Endorsements & Restrictions

CDL Exam Preparation

Written exams

Practical exams

- Skills test

- Pre-trip inspection

- TSA background check

- Retake policy

CDL Maintenance

ELDT Training & Certification

CDL how-to guides

Mastering the CDL Pre-Trip Inspection Exam: A Complete Guide

Learn how to conduct thorough pre-trip inspections with our guide, a critical component for commercial vehicle safety.

Written by Andrei Zakhareuski. With over 16 years of expertise, Andrei leads Driving-Tests.org, a top online resource for driver education. His leadership has established vital partnerships with over 2,600 libraries, educational bodies, and state agencies.

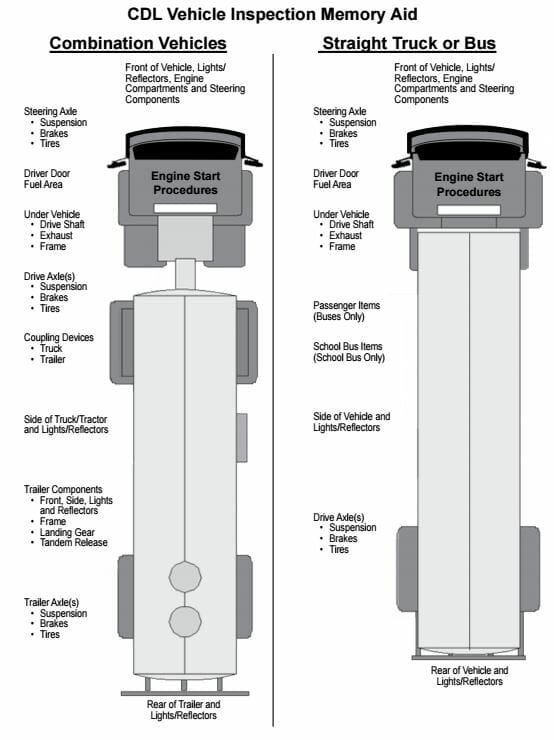

The CDL Pre-Trip Inspection Exam is an integral part of obtaining your commercial driver’s license. This guide covers Class A and Class B pre-trip inspections, provides a checklist, and offers tips for memorizing the inspection process.

Start a free Pre-Trip Inspection practice test:

- Alabama - AL - Alabama Pre-Trip Inspection Practice Test

- Alaska - AK - Alaska Pre-Trip Inspection Practice Test

- Arizona - AZ - Arizona Pre-Trip Inspection Practice Test

- Arkansas - AR - Arkansas Pre-Trip Inspection Practice Test

- California - CA - California Pre-Trip Inspection Practice Test

- Colorado - CO - Colorado Pre-Trip Inspection Practice Test

- Connecticut - CT - Connecticut Pre-Trip Inspection Practice Test

- Delaware - DE - Delaware Pre-Trip Inspection Practice Test

- District of Columbia - DC - District of Columbia Pre-Trip Inspection Practice Test

- Florida - FL - Florida Pre-Trip Inspection Practice Test

- Georgia - GA - Georgia Pre-Trip Inspection Practice Test

- Hawaii - HI - Hawaii Pre-Trip Inspection Practice Test

- Idaho - ID - Idaho Pre-Trip Inspection Practice Test

- Illinois - IL - Illinois Pre-Trip Inspection Practice Test

- Indiana - IN - Indiana Pre-Trip Inspection Practice Test

- Iowa - IA - Iowa Pre-Trip Inspection Practice Test

- Kansas - KS - Kansas Pre-Trip Inspection Practice Test

- Kentucky - KY - Kentucky Pre-Trip Inspection Practice Test

- Louisiana - LA - Louisiana Pre-Trip Inspection Practice Test

- Maine - ME - Maine Pre-Trip Inspection Practice Test

- Maryland - MD - Maryland Pre-Trip Inspection Practice Test

- Massachusetts - MA - Massachusetts Pre-Trip Inspection Practice Test

- Michigan - MI - Michigan Pre-Trip Inspection Practice Test

- Minnesota - MN - Minnesota Pre-Trip Inspection Practice Test

- Mississippi - MS - Mississippi Pre-Trip Inspection Practice Test

- Missouri - MO - Missouri Pre-Trip Inspection Practice Test

- Montana - MT - Montana Pre-Trip Inspection Practice Test

- Nebraska - NE - Nebraska Pre-Trip Inspection Practice Test

- Nevada - NV - Nevada Pre-Trip Inspection Practice Test

- New Hampshire - NH - New Hampshire Pre-Trip Inspection Practice Test

- New Jersey - NJ - New Jersey Pre-Trip Inspection Practice Test

- New Mexico - NM - New Mexico Pre-Trip Inspection Practice Test

- New York - NY - New York Pre-Trip Inspection Practice Test

- North Carolina - NC - North Carolina Pre-Trip Inspection Practice Test

- North Dakota - ND - North Dakota Pre-Trip Inspection Practice Test

- Ohio - OH - Ohio Pre-Trip Inspection Practice Test

- Oklahoma - OK - Oklahoma Pre-Trip Inspection Practice Test

- Oregon - OR - Oregon Pre-Trip Inspection Practice Test

- Pennsylvania - PA - Pennsylvania Pre-Trip Inspection Practice Test

- Rhode Island - RI - Rhode Island Pre-Trip Inspection Practice Test

- South Carolina - SC - South Carolina Pre-Trip Inspection Practice Test

- South Dakota - SD - South Dakota Pre-Trip Inspection Practice Test

- Tennessee - TN - Tennessee Pre-Trip Inspection Practice Test

- Texas - TX - Texas Pre-Trip Inspection Practice Test

- Utah - UT - Utah Pre-Trip Inspection Practice Test

- Vermont - VT - Vermont Pre-Trip Inspection Practice Test

- Virginia - VA - Virginia Pre-Trip Inspection Practice Test

- Washington - WA - Washington Pre-Trip Inspection Practice Test

- West Virginia - WV - West Virginia Pre-Trip Inspection Practice Test

- Wisconsin - WI - Wisconsin Pre-Trip Inspection Practice Test

- Wyoming - WY - Wyoming Pre-Trip Inspection Practice Test

CDL Class A Pre-Trip Inspection

Engine Compartment Inspection

Includes checking for leaks, belt tension, and the condition of hoses, among other components.

Cab Check/Engine Start

Involves inspecting the cab’s interior, gauges, and starting the engine to check for abnormalities.

Brake Check

Focuses on air brake systems, including air brake checks and the parking brake test.

CDL Class B Pre-Trip Inspection

Vehicle Overview

Begin with a general overview of the vehicle, checking for obvious signs of damage or issues.

External Inspection

Inspect all external components, including tires, lights, and mirrors.

Internal Inspection

Check all internal controls, ensuring everything is functional and within reach.

Pre-Trip Inspection Checklist

- Lights and reflector s: Ensure all are clean and functional.

- Engine oil and coolant levels : Check for adequate levels.

- Steering mechanism : Ensure it’s secure and functioning.

- Horn : Test for functionality.

- Windshield wipers : Check for operability and condition.

- Mirror s: Adjust for optimal visibility.

- Emergency equipment : Ensure presence and accessibility.

- Air brake system : Test for leaks and proper pressure.

Tips for Memorizing the Pre-Trip Inspection for CDL

- Create a Routine : Develop a consistent order in which to conduct your inspection.

- Use Mnemonics : Create acronyms or phrases to help remember the steps.

- Practice Regularly : Hands-on practice is the most effective way to memorize the inspection process.

- Visual Aids : Use diagrams or checklists as visual reminders.

Pro Tip : Practice the pre-trip inspection in a real-world setting. The more you perform the inspection in a practical environment, the more natural it will become.

Remember, the pre-trip inspection is not just a test requirement – it’s a fundamental safety practice every commercial driver should master. For more resources and detailed guides, visit Driving-Tests.org .

Secure your CDL with confidence!

Our exclusive CDL Premium program offers comprehensive online training with an ELDT certificate, authentic exam questions, and a solid Pass Guarantee, starting at only $49. Ideal for first-time applicants, seasoned drivers, and those new to the U.S. road rules.

Explore CDL Premium

Was this page helpful?

- Start a free Pre-Trip Inspection practice test:

- CDL Class A Pre-Trip Inspection

- CDL Class B Pre-Trip Inspection

- Pre-Trip Inspection Checklist

- Tips for Memorizing the Pre-Trip Inspection for CDL

PGT Trucking’s Guide to Pre- and Post-Trip Inspections

A proper pre- and post-trip inspection is what separates the average truck driver from a true professional! Federal law requires that a driver of a commercial motor vehicle completes an inspection every day on each vehicle operated (truck and/or trailer). More importantly, a thorough truck and trailer inspection helps truck drivers keep their equipment in safe working order, protecting everyone out on the road. Don’t skip your pre-trip! Follow PGT Trucking’s guide to pre- and post-trip inspections.

What is a pre-trip inspection?

A pre-trip inspection is a thorough check of the vehicle to ensure everything is in working order before you take off down the road. Flatbed truck drivers should check their tires, brakes, lights, engine fluid levels, securement (if loaded) and more. By completing a general observation of all equipment before leaving, flatbed truck drivers know their truck and trailer are safely ready for the day ahead.

When should I do a vehicle inspection?

Flatbed truck drivers at PGT are required to complete an inspection on their truck and trailer at the start of their day, at the end of their day, and any time they drop or hook to a different trailer. Walk around inspections and load checks should also be completed at every change of duty status (fueling, 30-minute break, loading, unloading, etc.).

Why should I do post-trip inspection?

A post-trip inspection will help a flatbed truck driver identify any defects that may have occurred since the pre-trip inspection. Any repairs that are needed can be addressed immediately instead of delaying the start of a driver’s next trip. For flatbed truck drivers who drop and hook, a post-trip inspection is common courtesy – don’t leave issues for the next driver to find. It’s not safe!

How long should a pre/post-trip inspection take?

A thorough pre/post-trip inspection should take about 15 minutes to complete. It doesn’t take long, but it will save a flatbed truck driver valuable time in the long run. Don’t be stuck on the side of the road with a blown-out tire. Get any problems quickly addressed during the pre/post-trip inspection.

What is the goal of a pre/post-trip inspection?

The purpose of a pre/post-trip inspection is safety ! When equipment fails over the road, it places the truck driver and other motorists at risk. By examining the vehicle at the start and end of a trip, flatbed truck drivers can catch any defects before they cause a bigger problem over the road.

If I find something wrong during my pre/post-trip inspection, what should I do?

Any defects in the truck or trailer must be noted on the Driver Vehicle Inspection Report (DVIR), and flatbed truck drivers should call the PGT maintenance hotline and their Fleet Manager . Any item considered out-of-service by the Department of Transportation (DOT) must be repaired immediately before the vehicle can move. Any defect that is not considered an out-of-service DOT violation must be repaired before that truck or trailer can be dispatched on another load. Drivers should not operate the vehicle if they feel it is in an unsafe condition or has any out-of-service defects!

What are the most common defects found during a pre/post-trip inspection?

At PGT, the most noted defects during a pre/post-trip inspection are related to the tires, brakes or lights. While all equipment should be reviewed for possible safety concerns, flatbed truck drivers should pay extra attention to these problem areas.

Do I need to wear any personal protective equipment (PPE) while doing a pre/post-trip inspection?

Yes! You should have your safety vest, gloves, appropriate footwear, goggles, and hard hat on while performing safety functions. Other tools for the inspection include a flashlight, tire depth gauge and tire pressure gauge.

Should I do a pre-trip inspection on my personal vehicle?

Yes! While it’s not legally required to do a pre-trip inspection, all non-commercial vehicles should still be routinely checked to confirm they are in good operating condition. It’s a great habit to get into, and for flatbed truck drivers, practice makes perfect. Do a pre-trip on every vehicle, every time!

How to Complete a Truck and Trailer Inspection

Step 1: Front of the Tractor

- Complete a visual inspection. Are all numbers and stickers present and clearly visible? Is there any damage or visible leaks?

- Open the hood and check all fluid levels and belt tension.

Step 2: Cab

- Enter the cab and start the engine. Test the horns, inspect the windshield (is it dirty? – clean it!), check the seatbelt and fire extinguisher.

- Is your ELD tablet securely mounted on the dash? Do you have all required documentation in the cab and readily accessible?

Step 3: Air and Lights

- Turn the engine off. Press and hold the brakes, listening for any air leaks or drop in pressure.

- Start the light check and observe all lights during your truck and trailer walk around.

Step 4: Left Front and Right Front Tractor

- Check the tires, brakes, and hub oil levels and look for exhaust leaks.

- When checking tires, check the air pressure, tread depth, sidewall, rims and lug nuts.

- When checking brakes, look for any extreme wear, cracks, soaked/contaminated oil, broken springs or anything out of adjustment.

Step 5: Front of Trailer and Mid Tractor

- Check the fuel cap.

- Look at the catwalk, headache rack, and bulkhead. Is everything clear of debris? Is all equipment properly secured? Remember, bungee cords have no working load limit and should never be used to secure tarps, chains, binders, lumber or pipe stakes.

Step 6: Right Forward and Rear Drive Wheel Ends

- Check both the inside and outside tires. Inspect the brakes, shocks and air lines.

Step 7: Rear of Tractor

- Check the rear light panel.

- Inspect the mud flaps.

- Confirm the fifth wheel jaws are fully closed.

Step 8: Trailer Right Mid Inspection

- Check the dolly legs, winches and straps.

- Check the lights down the trailer.

- Check your load securement!

Step 9: Trailer Right Forward and Rear Wheel Ends

- Check hub oil and grease levels.

- Look at the inside and outside rims and tires.

- Check the brakes, shocks and air lines.

- Drain trailer air tanks.

Step 10: Rear of Trailer

- Check the lights and mud flaps.

- Confirm the DOT tape is visible.

- Look for any damages to the ICC bumper.

Step 11: Trailer Left Forward and Rear Wheel Ends

Step 12: Trailer Left Mid Inspection

- Confirm the inspection, registration and insurance.

Step 13: Tractor Left Forward and Rear Driver Wheel

Step 14: Tractor Left Mid and Trailer Front

- Check the driver stairs.

- Inspect the bulkhead and headache rack.

- Drain the tractor air tanks.

Note: This list is meant to be a guideline only and is not fully comprehensive. Contact your Safety Manager, Fleet Manager or Training Department if you have any questions or need clarification.

Safety is Everyone’s Job – All the Time

PGT Trucking is committed to being a safe and reliable carrier , driven by the best flatbed truck drivers in the industry. We want our Proud Professionals to get home safely after every trip, and that starts with thorough trip inspections. PGT understands that details matter, and we provide multiple resources to equip our flatbed truck drivers with the tools they need to do the job well.

Want to join the company that values your safety above all else? Apply to PGT today !

We have Company Flatbed Truck Driver positions available, averaging $84,000 in gross pay a year. Other benefits include medical, dental, and vision insurance, 401(k) retirement plan, company-paid life insurance, vacation time, and paid holidays. Find out what makes PGT Trucking a 2023 Best Fleets to Drive For® Top 20 Company .

Do you want to haul freight at competitive rates while maintaining your independence? PGT is partnering with experienced Owner-Operators and has one of the best Lease Purchase Programs in the industry. Apply now !

Related posts

When to transition to an owner-operator

Considering a career as an owner-operator/independent contractor? With the ever

Flatbed Trucking Jobs – A Guide for Truckers

With the national truck driver shortage, the demand for truck drivers is at an a

Million Mile Driver Spotlight #8

PGT Trucking introduces our new Million Mile Drivers this year, celebrating thei

- Skip to main content

- Skip to primary sidebar

- Skip to footer

Truckers Training

Everything you need to know to become a truck driver

The Importance of Doing a Thorough Pre and Post Trip Inspection

by Geoff Craig, MBA

Keeping your drivers, customers and the public safe is one of the most important parts of a transport business. This is especially the case when the business involves putting drivers in one of your vehicles on the public roads.

Modern vehicles have so many mechanical parts that require maintenance and care. They also have many electronic components that can potentially go wrong. As a result, the role of keeping a vehicle safe for everyone is a vital commitment. It should not in any way be undermined or underestimated.

Just because a vehicle is safe to drive one day, does not mean that it is safe to drive another day. And just because a vehicle has been returned safely with no obvious mechanical or structural issues, does not mean that the vehicle is safe to drive the next day.

This means that the role of pre-trip and post-trip inspections is absolutely vital. Vehicles accrue not only miles but potential issues that can make them dangerous for drivers and put your business in a precarious situation. This is true both from the point of view of the safety of the vehicles that are going out. It is also true in terms of protecting the business from potential lawsuits or financial losses through negligence or loss of trade.

Taking Inspections Seriously

A vital part of fleet management, therefore, is taking pre-trip and post-trip inspections seriously. Many fleet managers will know a driver or drivers in their fleet who don’t tend to take these inspections seriously, as they take up time and rarely flag up a serious problem. However, they are a vital part of the successful running of a fleet and the safety of all involved. There is also a wide range of factors that should be considered.

Staying Legal

For any successful business, legal compliance is a key issue that should always be at the forefront of planning and execution. Fleet managers should make sure that they are aware of any national or local legislation or regulations that exist with regards to pre-trip or post-trip inspections.

Legislation may be general, or it may be specific to different industries. For example, a vehicle that carries passengers is required to do a post-trip inspection at the end of the working day. This follows a particular format and with a fresh report generated for each vehicle.

Although this could be considered by some to be an onerous task, it effectively generates a paper trail that can tell the story of a particular vehicle. It also enables the business to keep on top of both any individual problems the vehicle occasionally has but also any persistent issues that occur.

These end of day inspections will typically include:

- A test of the braking system

- A test of all vehicle lights

- A test of the windshield wipers

- An inspection of emergency equipment

- A test of tire condition

- A test of the steering

- A test of any coupling equipment

A quick glance at this list and it is obvious that these are daily tests of the most important equipment on the vehicle in terms of safety.

Failure to do these daily tests and log them in the appropriate manner could be detrimental for the business. This is in terms of legal issues and compliance as well as opening up the business to potentially damaging lawsuits in cases of an accident. More importantly, failure to conduct these checks could lead to an unsafe vehicle being on the road and injury or loss of life as a result of such negligence.

Driver Education

A major part of fleet management is not just about managing the vehicles but about managing the personnel. It’s about managing one of the most important resources in the business, that is, the drivers.

Many drivers will be confident in the safety of their vehicles. However, they may not immediately understand the importance of pre-trip and post-trip inspections on a daily basis. This is certainly the case if the inspections can seem time-consuming either at the beginning or the end of the day.

It is important, then, to educate drivers on the importance of these inspections, although not just for legal compliance. It is also important for reassuring them of the safety of the vehicles and the safety of the business for passengers and the drivers.

Safety checks are something that can easily lapse over time as people get lazy or forget to do them. Therefore, it is important that regular education of drivers takes place regularly. Whether through training sessions, mock inspections, and check-ups of drivers’ inspections. This ensures that everyone is on the same page in terms of the importance of regular pre-trip and post-trip inspections.

Educating Staff

As well as educating drivers, it is also vital to educate workers who work in-house about these inspections. They need to understand:

- How important the inspections are, and

- How important the results of the inspections are, and that those results need to be taken seriously.

In the aviation industry, if an inspection indicated that a problem existed on an aircraft, however small, that inspection would be taken seriously, examined, and fixed. Exactly the same should be the case within the automotive industry.

Staff should take all inspection reports seriously. They should also act on the results of any inspections seriously and without prejudice. If not carefully managed, small issues can easily become large issues if they are not taken care of.

Good channels of communication between drivers, fleet managers, and the shop workers will help to keep these processes running smoothly. It will also help the fleet run more smoothly.

What is a Pre-Trip Inspection?

Although both kinds of inspection are important, both serve a slightly different purpose. Arguably the pre-trip inspection is the more important of the two. This is for the reason that it decides whether the vehicle is in a fit or safe enough condition to be driven that day.

As a result of this, the inspection should be considered very seriously and should not be taken lightly. The impact of a careless or cursory pre-trip inspection could be to send a vehicle on the roads that are not safe for use. This could result in loss of life, injury, or damage to the reputation of the business.

What Will A Pre-Trip Inspection Cover?

It will cover a number of important items that will involve determining whether a vehicle is safe to take out onto the roads that day. This is broadly the same as the list produced earlier, but also considering any damage to the vehicle.

A business will need to consider a number of factors:

- How is the pre-trip inspection conducted?

- Who conducts the pre-trip inspection?

- In what format is the pre-trip inspection report produced – for example, on paper, using a tablet, or an app?

- How are the reports to be accessed – for example by those in the shop who may need to work on the vehicle should there be any problems?

A pre-trip inspection will neither be effective nor efficient if the information is not readily available to those who will need to examine it. That is, drivers, fleet managers, in-house staff, etc.

Any problems that may be spotted during the inspection, for example, problems with seat belts, tires, windshield wipers, brakes, etc., should be reported in a standard way.

Many businesses that use pre-trip inspections will have standard forms. These can be particularly valuable for marking external issues, perhaps on a 2D top-down model of the car. Additionally, a similar system will need to be in use also for internal issues.

Mutual Understanding

Whatever terminology is used, or whatever reporting method is used, it is important that all members of the team are on the same page. In that, there is a common understanding of how problems are defined and described. This will help those who are working on the vehicle for repairs to have as clear an understanding as possible as to what problems need fixing. This may require regular training or refreshers on what is required.

Reducing Liability

There also needs to be an understanding of what may be considered a minor problem. A minor problem that needs reporting but the vehicle can go out that day and be repaired at a convenient point, and a major problem that requires immediate repairs.

For example, a minor problem such as a small dent on the side of the, as long as it is noted and scheduled to be repaired, need not stop that vehicle being used that day. However, a noted failure in the operation of the brakes, the windshield wipers, or the tires would be considered more major problems. These problems will require immediate repair before the vehicle can be used safely to transport goods or passengers.

The pre-trip inspection is therefore seeking to answer the question, ‘Is this vehicle safe to take out today, right now?

What is a Post-Trip Inspection?

By contrast, the post-trip inspection is seeking to answer a different condition:

‘Does this vehicle have any damage or failures to its operation that means it needs repairs before the vehicle is taken out again’?

This may be damage caused as a result of it being out for operation that day. For example, a crash or if there has been a problem during the day in operating the vehicle. Examples could also be a broken windshield wiper or punctured tire. Or, general wear and tear on the vehicle over time that has now become noticeable.

As post-trip inspections are undertaken at the end, rather than the beginning of the day, they raise the issue of any vehicles that need remedial work done on them before they are taken out again.

Post-trip inspections and reporting procedures are also important as the vehicle may not be driven by the same drivers on two consecutive days. Efficient reporting methods in relation to these post-trip inspections mean that all drivers and relevant staff can be aware of any issues relating to particular vehicles. Drivers then taking up a vehicle for the day can be assured of good and constant checking procedures on that vehicle over time.

As with the pre-trip inspections, post-trip inspections may flag up issues that need resolving before that vehicle can be used again. This allows fleet managers to manage the vehicles available to their drivers over time. At the same time, they will then be aware of which vehicles are currently off the road for maintenance or repair.

Other Considerations

The question is sometimes asked as to whether it would be adequate to have only pre-trip inspections. However, the answer from a safety and fleet management perspective is a resounding no.

Pre-trip inspections will only flag up a potential issue with a vehicle at the last possible moment and may not give enough time for a repair to take place. There also may not be an available vehicle at such short notice. This can result in a loss of trade, profit, and reputation for the business.

Having both pre-and post-trip inspections doubles the number of eyes on the vehicle and allows for potential problems to be flagged up ahead of time. This makes it easier to arrange alternative transport and minimize loss of trade, profit, or reputation for the business.

Businesses may also consider where they park their vehicles. Vehicles awaiting maintenance or repair could be parked in a different area from those that are waiting to go out. This will help the fleet to run more efficiently and minimize the possibility of a vehicle awaiting repair accidentally being taken out on a job.

Successful pre-and post-trip inspection processes ensure that the appropriate vehicles are on the road. With clear reporting methods used consistently by all, regular training for those who need to inspect and report can increase the efficiency of the vehicle fleet. Vehicles requiring maintenance and repair are well documented and returned to the fleet in good time. This maximizes the efficiency of the business whilst keeping customers and the general public as safe as possible.

Geoff Craig, MBA

Geoff is a freelance writer at TruckersTraining.com with 20+ years of experience driving trucks and buses, dispatching, supervising, and training commercial driving teams. His expertise is writing topics on the transportation and trucking industry, and information technology trends.

- Geoff Craig, MBA https://www.truckerstraining.com/author/geoffcraig/ How to Become a Walmart Truck Driver

- Geoff Craig, MBA https://www.truckerstraining.com/author/geoffcraig/ Best Semi Trucks of the Future Revealed

- Geoff Craig, MBA https://www.truckerstraining.com/author/geoffcraig/ Can You Get a CDL License Without Going to School?

- Geoff Craig, MBA https://www.truckerstraining.com/author/geoffcraig/ Top 10 Highest Paid CDL Jobs

- How to become Truck Driver

- CDL Training

- Best CDL Schools by State

- Truck Driver Salary Guide

- CDL Scholarships Guide

- Paid CDL Training

- Veterans Grant

- Trade Adjustment Assistance (TAA) Grant

- Privacy Overview

- Strictly Necessary Cookies

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

- Register / Login

- Trucker's Forum

- Paid CDL Training

- Truck Driving Jobs

- CDL Practice Tests

- High Road Training

Pre-Trip Inspection Study Guide

Our Pre-Trip Inspection Study Guide has everything you need to prepare for the Class A CDL Pre-Trip Inspection Exam . Our study guide will cover the pre-trip inspection terminology as well as a thorough list of all of the parts you will be inspecting on the vehicle. For each part you will be inspecting there will also be a list of items you will be checking for. Our study guide is broken down into the following sections:

- What You Need to Know About Pre-Trip Inspection

Pre-Trip Inspection Practice Questions

- Pre-Trip Inspection Checklist

Pre-Trip Inspection Videos

Pre-trip inspection printable resources, what you need to know about the pre-trip inspection.

The Pre-Trip Inspection is a thorough inspection of the vehicle and all of its major systems. Inspecting the vehicle before driving each day is a Federal requirement and normally takes about 15 minutes. It must be logged in your logbook as "on duty not driving."

You will have to do thorough safety inspections of the coupling system, the vehicle lights, engine compartment, tires and brakes, the chassis, the fuel tanks, and an in-cab inspection.

The following information is a brief summary of Daniel's Complete Pre-Trip Inspection taken from our oustanding free PDF download:

Engine Compartment

You will be checking the engine compartment for any sort of leaks. You will also be checking to see if all components are properly mounted and secured. None of the mounts must be cracked, bent, or broken.

You will be checking all hoses to make sure they aren't leaking, frayed, or sliced and the fluid levels including the oil level, the coolant, and the power steering fluid.

You must check the components like the water pump, the power steering pump, and the alternator to make sure nothing is leaking, the belts are not frayed, and that everything is properly mounted and secured.

From inside the engine compartment you will also find the steering system, the front suspension system, and the front brake system. All components of these systems must be properly mounted and secured without anything being cracked, bent, or broken. Finally you will be checking the tires, rims, and axle seals to make sure the tires are properly inflated, the rim isn't bent or cracked, and the axle seals are not leaking.

Fuel Tank And Battery Area

You will be standing along the side of the tractor doing a series of checks on the mirrors, fuel tanks, batteries, exhaust system, and more. You will check to make sure nothing is bent, cracked, broken, or leaking.

Check the mirrors, door hinges, door handle to make sure nothing is cracked, bent, or broken. Check to make sure there is no fuel leaking and that the fuel cap is secured and the gasket is not missing.

Check the exhaust system to make sure nothing is cracked, bent, or broken. Check the driveshaft, cat walk, and steps to make sure nothing is cracked, bent, or broken.

Check the frame and crossmembers for structural integrity. Check the air lines going to the trailer to make sure they're properly connected and that there are no abrasions, bulges, or cuts. Make sure the gaskets are present.

Check the suspension system and brakes on the drive axles, making sure nothing is cracked, bent, or broken. Make sure the brake linings are the proper thickness and that the air bags and properly inflated. Inspect the brake chambers, slack adjusters, and pushrods are properly mounted and secure. Not Cracked, Bent, or Broken. With the brakes released and pulled by hand, the Push Rod should not move more than 1 inch.

Check the rims, tires, and axle seals of the drive tires for proper inflation, no leaks around the seal, and the lugs are all present and secured.

Coupling System

You will be standing where the tractor and trailer are connected and you'll start by checking the electrical line and air lines to make sure they're properly mounted and secure at both ends. No abrasions, bulges or cuts. Not leaking air. Make sure the electrical line has no wires exposed. Check the gladhands to make sure the seals are in good condition, no cracks or signs of dry rotting. Not leaking air.

Check the skid plate of the fifth wheel and the apron of the trailer to make sure there is no debris and nothing is cracked, bent, or broken. Make sure the fifth wheel is properly greased. Also make sure there is no gap in between the fifth wheel and the trailer apron once the tractor and trailer are coupled. Make sure the kingpin of the trailer is properly mounted and not cracked, bent, or broken and that the locking jaws of the fifth wheel are properly secured when the tractor and trailer are coupled.

Check the mounting bolts where the fifth wheel attaches to the tractor frame. Make sure there are no missing bolts and that everything is secured properly. Check the locking pin if you having a sliding fifth wheel to make sure it's properly locked into place.

Make sure that there is the proper clearance space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

You will start inspecting the trailer at the head board, which is the front wall of the trailer. Make sure there are no holes or missing rivets. Check the landing gear to make sure it is properly mounted and secure. Not cracked, bent, or broken. Make sure the fully raised and the handle is secure in the cradle when the tractor and trailer are coupled.

Check the frame and crossmembers under the trailer to make sure they're not cracked, bent, or broken. Check the tandem frame and release pins to make sure the frame is in good condition and the release handle and locking pins are in the fully locked position.

You will check the entire suspension and brake system for the trailer tandems the same way you did for the drive axles of the tractor. You will also make sure the mudflaps are properly secured. For dual tires check to see that there is proper space between the tires and there is nothing stuck between the tires.

Check the rear door and hinges to make sure they are properly mounted and nothing is cracked, bent, or broken. Make sure the door seals are not worn, torn, or dry rotted.

Light Check

You will be checking all of the lights and reflectors on both the tractor and the trailer. Check the reflectors and reflective tape to make sure they are properly mounted and secure, not cracked, bent, or broken, and clean and illuminated. Check that you have the proper color of amber to the front and sides, and red to the rear.

Start by turning on your marker lights and headlights. Now walk around the entire truck and trailer and point out the lights. Give the function of the light and the location. You should then ask your examiner to help you check your five functions.

While you're sitting in the drivers seat, the examiner will stand to the front of the truck, then behind the trailer. He will then check your Turn Signals, Four Way Flashers and Brake Lights. You must do each function at every location.

The five locations that you must check your lights:

- Front of the Truck

- Both sides of the Truck

- Rear of the Truck

- Both sides of the Trailer

- Rear of the Trailer

The Five Functions you are checking for:

- Left Turn Signal

- Right Turn Signal

- Four Way Flashers

- High Beams/Low Beams

- Brake Lights

In-Cab Inspection

The in-cab inspection and air brake check will cover the various gauges and systems inside the cab along with several tests to make sure you air brake system is working properly.

You will start by checking the following:

- Seat Belt- Properly Mounted and Secure. Not ripped or frayed Adjusts and latches properly.

- Fire Extinguisher- Properly Mounted and Secure. Fully charged

- Three Red Reflective Triangles- My three red reflective triangles are GIVE LOCATION

- Spare Electrical Fuses- My spare electrical fuses are GIVE LOCATION

- Volmeter, Oil Pressure Gauge, Water Temperature Gauge, and Air Pressure Gauge all show proper operation

- City horn and air horn functioning properly

- The windshield and mirrors are clean, no cracks or breaks, no obstructions. The mirrors are in proper adjustment.

- Windshield Wipers and Washers - Demonstrate that the washers work by spraying the windshield. The Wipers are: Properly Mounted and Secure and operate smoothly. The blades aren't cracked or dry rotten.

- Heater and Defroster - Demonstrate that both the Heater and Defroster are working properly.

- Lighting Indicators - Left Turn, Right Turn, Four Way Flashers, and High Beams.

Trailer Parking Brakes - Set the Trailer Brake, release the tractor brake, and then tug lightly on the trailer.

Tractor Parking Brakes- Then set the Tractor Brake, release the trailer brake, and then tug lightly on the tractor.

Service Brake Check - Release both Tractor and Trailer Brakes. Now drive at idle speed. Apply the Service Brake to make sure you come to a complete stop, and that it doesn't pull to the left or right when applying the brakes.

Air Brake Test

The air brake test will consist of a leakdown test to make sure your air brakes aren't leaking air and losing pressure. It will also test the warning lights and buzzer to make sure the driver gets the proper warning if the air pressure drops too low.

There are three stages to an Air Brake Test

#1: Applied Pressure Test

#2: Warning Light and Buzzer

#3 Tractor/Trailer Protection Valve Pop Out

Applied Pressure Test: Build the air pressure to governor cut out. Put the truck in the lowest gear. Then turn off the engine Immediately turn the engine back on. Push in both the tractor and trailer valves. (This will release the parking brakes.) Push and hold the Brake pedal fully. Allow the gauges to stabilize. Announce the gauges have stabilized and the Primary and Secondary PSI. With the Brakes fully pressed, you should not lose more than 4 PSI in one minute. Announce that you are listening for air leaks during that minute.

Warning Light and Buzzer Test: Pump down on the Brake pedal until the warning light and buzzer comes on, at or before 60 PSI.

Tractor/Trailer Protection Valve Pop Out Test: Pump down on the brake pedal until both the tractor and trailer protection valves pop out. They should both pop out between 40 and 20 PSI.

We have a ton of Pre-Trip Inspection Practice Questions along with the answers and a complete scoring system in our Free Online CDL Practice Tests :

The Engine Compartment Section will include questions about checking the oil level and coolant levels, inspecting belt-driven engine components (like the water pump, alternator, and air compressor), and the safety devices required in the cab. There will also be questions regarding the windshield wipers and free play in the steering wheel.

The Lights And Brakes Section will include questions about dashboard indicator lights, inspecting the parking brakes, and doing a leakdown test on the air brakes. It will also include questions about the low air pressure warning signal and testing your air horn and city horn.

The Suspension And Steering Section will include questions about the tractor protection valve, inspecting the steering box, and inspecting many suspension system parts. It will also include questions about welds being present on tire rims and the minimum tread depth required on steering axle tires.

The Tires And Coupling Devices Section will include questions about shiny trails or rusty threads on lug nuts, inspecting the battery box and cover, and inspecting electrical lines. It will also contain questions about inspecting the coupling devices and the fifth wheel skid plate.

The Emergency Equipment And Fifth Wheel Section will include questions about additional emergeny equipment required by school buses, inspecting the gap between the kingpin apron and the fifth wheel skid plate, and the landing gear securement. It will also contain questions about inspecting driver mirrors and the trailer frame.

Pre-Trip Inspection Checklist - Class A

Our pre-trip inspection checklist covers every part of the truck from front to back, both inside and outside of the truck. It covers the air brakes, suspension parts, steering components, wheels and rims, fuel tanks, batteries, lights, and more. It also covers the air brake tug test and checks for everything under the hood including alternator, water pump, fuel pump, fluids, and more.

This is a super handy checklist to study anytime you have a few minutes to spare:

Pre-Trip Inspection Checklist - Free Word Document Download (Editable Version)

Pre-Trip Inspection Checklist - Free PDF Download (Print Version)

Pre-Trip Inspection Video By Apex CDL Institute

Jeff from Apex Institute does an in-depth explanation of the entire pre-trip inspection process. This video is loaded with tips that go beyond the CDL test to help drivers really understand how to identify problems.

Pretrip Inspection Self-Test By CDL College

The Pretrip Inspection Self-Test By CDL College is really unique. It's a silent video which will show you the part you're inspecting and then gives you a few seconds to figure out what you should be checking for before giving you the answer. Definitely check this one out. Great for practicing before the CDL exam.

Pre-Trip Inspection Video By Averitt Express

This is a complete back to front pre-trip inspection of a truck and trailer by Averitt mainentance associate Kevin Breeding. This thorough pre-trip inspection covers all inportant points of inside the cab, lights, engine, the tractor itself and the trailer.

We have included two print versions of the pre-trip inspection process from Daniel. The first is the entire pre-trip inspection and the second is an abbreviated checklist for the inspection.

- PDF: Daniel's Pre-trip Inspection (Print Version)

- PDF: Daniel's Pre-trip Inspection Checklist (Print Version)

Why Join Trucking Truth?

- The High Road Training Program

- The High Road Article Series

- The Friendliest Trucker's Forum Ever!

- Email Updates When New Articles Are Posted

Apply For Paid CDL Training Through TruckingTruth

Did you know you can fill out one quick form here on TruckingTruth and apply to several companies at once for paid CDL training? Seriously! The application only takes one minute. You will speak with recruiters today. There is no obligation whatsoever. Learn more and apply here:

- Privacy Policy

- Fleet Training

- CDL Training

- Insurance Discount

- Court Diversion

- Our Courses

- What is the SPIDER Method?

Pre-Trip Inspection: An Essential Guide for Commercial Drivers

Why are pre trip inspections essential, and how can they make a difference in the daily lives of truck drivers? With safety, regulatory compliance, and preventative maintenance on the line, pre trip inspections are a crucial aspect of ensuring smooth and efficient operations on the road. In this blog post, we dive into the critical components of pre trip inspection and provide valuable tips and resources to help drivers stay ahead of potential hazards and costly repairs.

- Pre-trip inspections are essential for promoting safety, compliance, and cost savings while on the road.

- The pre-trip inspection process should take approximately 10–15 minutes and include items such as braking systems, steering & suspension systems, emergency equipment & engine compartment.

- Establishing a routine for pre-trip inspections with sufficient time to check all components is key to ensuring vehicle safety and regulatory compliance. Accurate records must also be kept.

The Importance of Pre-Trip Inspections

- Lessen accident risks

- Comply with regulations

- Maintain the vehicle’s condition

- Avert expensive repairs and downtime

Frequent inspections, such as periodic inspection, are important for maintaining safety and preventing costly issues.

The benefits of conducting pre-trip inspections include:

- Ensuring safety and compliance with regulations like DOT inspections

- Preventing fines, penalties, and potential harm to the driver’s or company’s reputation

- Acting as preventative maintenance, catching minor issues before they escalate

- Saving time, reducing repair costs, and minimizing downtime

Safety Concerns

Ensuring the vehicle’s safety is of paramount importance when conducting pre-trip inspections. A thorough examination of various components is necessary, including:

- Fire extinguishers

- Brake lights

This enables drivers to spot potential hazards and affirm the vehicle’s operational readiness, ultimately reducing the risk of accidents, in line with the goals of the Commercial Vehicle Safety Alliance.

However, the consequences of neglecting a thorough pre-trip inspection can be severe. Overlooking potential hazards may render the vehicle unfit for operation, increasing the risk of collisions. An inspection focused solely on the vehicle can spot these hazards and confirm the vehicle’s safety, underlining the significance of a thorough pre-trip inspection.

Regulatory Compliance

The Federal Motor Carrier Safety Administration mandates pre-trip inspections as part of DOT inspections for commercial motor vehicles, requiring drivers to acknowledge and certify that appropriate repairs have been made before commencing a trip. Non-compliance with pre-trip inspection regulations can result in fines, penalties, and harm to a driver’s or company’s reputation. Conducting periodic inspections can help maintain compliance and ensure the vehicle’s safety.

A Driver Vehicle Inspection Report (DVIR) is an essential tool to guarantee regulatory adherence. Watching a pre-trip inspection video can help drivers understand the process and ensure they follow the correct procedures, further emphasizing the need for thorough pre-trip inspections.

Preventative Maintenance

Preventative maintenance is an essential aspect of vehicle upkeep, aiming to prolong the lifespan of corporate assets, equipment, and infrastructure. By inspecting, cleaning, lubricating, adjusting, and replacing parts as necessary, drivers can detect minor issues before they escalate into major problems, saving time and money on repairs and reducing downtime.

The advantages of preventative maintenance include enhanced safety, increased efficiency, and minimized downtime. By incorporating pre-trip inspections into a regular maintenance routine, drivers can ensure their vehicles remain in optimal condition and avoid unexpected breakdowns or costly repairs.

Pre-Trip Inspection Process

Conducting pre-trip inspections at the start of each shift and each time a trailer swap occurs is integral. Such regularity aids in upholding the vehicle’s safety, roadworthiness, and regulatory compliance while also acting as preventative maintenance. The average inspection should last between 10-15 minutes, allowing enough time for a thorough examination of all components.

Engine Compartment

Inspecting the engine compartment is a critical part of the pre-trip inspection process. Drivers should examine the engine for leaks, fluid levels, belts, hoses, and other critical components to ensure optimal performance and prevent breakdowns. This includes checking the water pump, power steering pump, and alternator for any signs of leakage, fraying of belts, and ensuring that all components are securely mounted.

Additionally, drivers should verify the location of the dipstick and the appropriate oil level, as well as inspect the coolant system for proper levels, hose conditions, and secure mounting at both ends. By carefully examining each part of the engine compartment, drivers can maintain their vehicle’s performance and avoid unexpected issues on the road.

Exterior and Tires

A thorough inspection of the vehicle’s exterior and tires is crucial for ensuring its safety and roadworthiness. This includes checking the lights, reflectors, fuel tank, battery, and tires for any damage or wear that could impact safety or performance. Tires should be inspected for adequate tread, cuts, bubbles, or gouges, and to make sure there are no foreign objects, such as stones or large debris, between the wheels and no space between tires and rims.

Moreover, it is vital to check and maintain the appropriate air pressure in the tires to ensure optimal performance and prevent tire-related accidents. By carefully inspecting the exterior and tires, drivers can guarantee a safer and more efficient driving experience.

cabin and Controls

The cabin and controls of a commercial vehicle play a crucial role in the driver’s safety and comfort on the road. During a pre-trip inspection, drivers should examine the cabin for proper functioning of:

- other essential equipment

They should also ensure the availability of emergency equipment.

In addition to checking seatbelts, mirrors, seat position, steering wheel, pedals, windshield, lights, turn signals, ABS lights, gauges, windshield wipers, and horns, it’s essential to verify that all required emergency equipment, such as fire extinguishers, warning devices, and first aid kits, are present and in good working condition.

By thoroughly inspecting the cabin and controls, drivers can ensure a safe and comfortable driving experience.

Essential Items on a Pre-Trip Inspection Checklist

In addition to the aforementioned items, a pre-trip inspection checklist should also include the engine compartment, exterior and tires, and cabin and controls, as previously discussed. Combining all these components in a well-structured checklist ensures a thorough and effective pre-trip inspection that promotes safety and compliance.

Braking System

The braking system is a vital component of any vehicle, and a thorough inspection is necessary to ensure proper functionality and safety. During a pre-trip inspection, drivers should examine all components of the braking system, including air brakes, parking brakes, and hydraulic systems.

Specifically, drivers should inspect the following parts of the service brake system for any signs of wear or damage:

- Brake chamber

- Slack adjuster

By carefully examining each part, drivers can guarantee the vehicle’s safe operation and prevent potential accidents due to brake failure.

Steering and Suspension

A vehicle’s steering and suspension systems play a significant role in ensuring proper handling and a smooth ride. During a pre-trip inspection, drivers should inspect the steering components, suspension system, and wheel alignment to guarantee the vehicle’s optimal performance.

Specifically, drivers should examine the following components of the steering and suspension systems:

- Ball joints

- Tie rod ends

- Strut mounts or shock towers

- Steering effort for both manual and power systems

By thoroughly inspecting these components, drivers can maintain the vehicle’s handling capabilities and provide a comfortable driving experience.

Emergency Equipment

Ensuring the presence and proper functioning of emergency equipment is a crucial part of a pre-trip inspection. Drivers should verify that all required emergency equipment, such as fire extinguishers, warning devices, and first aid kits, are present and in good working condition.

In addition to these items, drivers should also be familiar with the location and operation of any other emergency equipment required by law or their specific company. By confirming the availability and functionality of emergency equipment, drivers can be prepared for unforeseen situations and enhance the overall safety of their vehicle.

Digital Tools and Resources for Pre-Trip Inspections

- Mobile apps that provide checklists and guides for conducting pre-trip inspections

- Online videos and tutorials that demonstrate best practices for inspecting different parts of the truck

- Websites and forums where drivers can stay updated with the latest regulations and requirements for pre-trip inspections

By leveraging these digital tools, truck drivers can enhance their knowledge and efficiency when it comes to pre-trip inspections.

These digital resources not only simplify the pre-trip inspection process but also help drivers maintain compliance with regulations and support preventative maintenance efforts. By leveraging technology, drivers can enhance their pre-trip inspections and promote safety and efficiency on the road.

Mobile Apps

Mobile apps designed for pre-trip inspections can greatly benefit truck drivers by creating checklists, tracking progress, and storing records digitally for easy access and compliance. Some popular mobile apps for pre-trip inspections include iAuditor, Whip Around DVIR software, Teletrac Navman Pre-trip Checklist tool, and Titan GPS Digital Pre-trip Inspection.

By utilizing these apps, drivers can:

- Generate checklists tailored to their specific vehicle and requirements

- Monitor their progress throughout the inspection

- Maintain digital records for future reference and compliance purposes

This not only simplifies the driver only inspection process but also ensures that drivers are following a thorough and effective routine.

Online Videos and Tutorials

Online videos and tutorials serve as valuable resources for truck drivers looking to enhance their pre-trip inspection skills and knowledge. By accessing these resources, drivers can learn best practices for conducting pre-trip inspections and stay updated on regulations and requirements.

Drivers can find online resources on websites, YouTube channels, and other digital platforms that provide informative and instructional content on pre-trip inspections. By staying informed and utilizing these resources, drivers can ensure they are conducting thorough and effective pre-trip inspections that promote safety and compliance.

Tips for a Successful Pre-Trip Inspection

To ensure a thorough and effective pre-trip inspection, truck drivers should establish a routine, take their time, and keep accurate records. Following these tips allows drivers to boost safety, comply with regulations, and bolster preventative maintenance efforts.

Adopting a consistent routine for pre-trip inspections helps ensure that all components are checked and nothing is overlooked. Here are some tips to follow:

- Allow sufficient time for a thorough inspection, typically between 15-30 minutes, to prevent missed issues and potential safety hazards.

- Check all essential components, including tires, brakes, lights, mirrors, and fluid levels.

- Keep detailed records of the inspections, including any issues identified and actions taken.

Regularly review and update your inspection checklist to ensure it covers all necessary items. By following these tips and maintaining a consistent pre-trip inspection routine, you can demonstrate compliance and support preventative maintenance efforts.

Establish a Routine

Developing a consistent routine for conducting pre-trip inspections is crucial for ensuring all components are checked and nothing is overlooked. Adhering to a systematic process lets drivers ensure the vehicle’s safety, roadworthiness, and regulatory compliance.

Some recommended components to include in a pre-trip inspection routine are:

- The engine compartment

- Exterior and tires

- Cabin and controls

- Braking system

- Steering and suspension

- Emergency equipment

By incorporating all of these components into a well-structured routine, drivers can guarantee a thorough and effective pre-trip inspection.

Take Your Time

Allowing sufficient time for a thorough pre-trip inspection is essential to prevent missed issues and potential safety hazards. An average inspection should last between 15-30 minutes, giving drivers enough time to examine all components in detail and ensure the vehicle’s safety and roadworthiness.