Gantry Option Available

KLR 2-Axis Horizontal Turning Series

Product highlights.

The Kent CNC 2-Axis slant bed lathe series combines proven machine design with advance technology in control and manufacturing. Reliability and stability make these a favorite among demanding job shops and in-house productions alike. The heavy duty turret and rigid machine body structure enable higher turning efficiency with better finish and longer tool life – resulting in greater productivity and profitability all around. Upgrade your global competitiveness today.

Up to 15″ 3-jaw chuck with 5.15″ bar capacity

Up to 35.4″ max turning diameter and 82″ max turning length

High speed / high accuracy 12 station turret

Induction hardened and precision ground box ways

45° slant bed with one piece Meehanite® casting for superior dampening and stability

High grade C3 precision ball screws and pretension for enhanced precision

Auto lubrication system metered check valves and piston distributor

Programmable spindle air blow tube

KLR-400 CNC Turning Center Overview

KLR Turning with Y-axis and Sub-spindle Demo

Specifications

Detailed information.

Kent CNC manufactures and sells more than its fair share of mill-turn lathes, machines that are increasingly indispensable to anyone supplying parts to the aerospace, medical, power generation, and other demanding industries. They reduce work-in-process, improve part quality, and if tooled properly, shorten overall setup times as well. But there are also many situations where a 2-axis CNC turning center is all you need.

Consider a simple job for several dozen washer-like spacers. Simple, right? But unless you enjoy boring repetitive work, that’s way too many parts for a manual lathe. It’s also, as I said, overkill for a mill-turn machine . This and countless other part examples fall into this category including flanges, adapters, fittings, bearing housings, and more. Even parts that have a couple cross-holes here or a pair of keyways there might be better suited for a two-axis CNC lathe, despite the fact that it will require a secondary operation and a fixture to hold them.

What do you look for in a basic two-axis CNC lathe?

- For starters, stay away from welded steel or light-duty construction—you want a machine with a single-piece, 45° slant bed Meehanite casting as its base.

- The ways should be wide enough to support heavy cutting, and precision-ground and hardened for long-term accuracy.

- You’ll also want a programmable tailstock, a fast, heavy-duty turret, an industry-leading CNC control, and because you’re going to be making lots of chips, be sure to choose a machine with a robust coolant system and a chip conveyor.

- Finally, look for a lathe with absolute encoders. They eliminate the need to home the machine, and prevent any mishaps. It’s a great feature that wasn’t available when CNCs first hit the market.

There’s definitely a place for mill-turn machines . In fact, Kent CNC gives customers the option of adding live-tools , a sub-spindle , and Y-axis milling to its KLR-series turning centers, machines that come standard with everything just described. We provide options for our CNC turning machines to match and scale depending on your part mix, the job quantities, and budget. Give us a call and find out whether a 2-axis horizontal turning center will suffice or if you need something more. Either way, we’re here to help.

- {{>productsMenu}} Products

- {{>trendsMenu}} News & Trends

- Machine-tools >

- Machining Center >

2-axis lathe

- My filters 2-axis Delete all

- What’s new?

Manufacturers

- 600 Group (1)

- Accuway Machinery (21)

- ACE DESIGNERS Limited (30)

- ACE Machine Tools Co., Ltd. (1)

- Akira Seiki Co., Ltd. (4)

- Alpha Additive LLC (1)

- Anyang Xinsheng Machine Tool Co.,Ltd (29)

- Bacci (2)

- Beijing No.1 Machine Tool Imp. & Exp. Corp. Ltd. (1)

- Benign Enterprise Co.Ltd. (3)

- Biglia (2)

- Bost Machine Tools Company S.L.U (2)

- Buffalo Machinery Co. Ltd. (1)

- CAZENEUVE (7)

- Centauro (2)

- Changzhou New District JinKang Precision Mechanism (1)

- CHEVALIER - Falcon Machine Tools (3)

- CITIZEN MACHINERY MIYANO CO.,LTD (8)

- Colchester-Harrison (12)

- Cormak (1)

- Craft Metalworking Machines (3)

- Dalian Haidi Machinery Co., Ltd. (3)

- DENN (1)

- Didelon (8)

- DN SOLUTIONS (14)

- Doosan Infracore Machine Tools (13)

- Ecotech Machinery, Inc. (1)

- EMAG GmbH & Co. KG (1)

- EMCO GmbH (4)

- EMISSA (1)

- ergomat (4)

- Frejoth International Ltd. (39)

- Guangzhou Dragon Diamond Technology Co., Ltd. (1)

- Haas Automation (22)

- HEINRICH GEORG GmbH (3)

- HELLER MAQUINA HERRAMIENTA, S.L. (6)

- Hercules Machinery Equipment Ltd. (3)

- HNK Machine Tool (1)

- HUISN CO., LTD. (4)

- Huracan Maquinarias S.L. (14)

- Hurco GmbH Werkzeugmaschinen (4)

- HURON (1)

- Hwacheon (10)

- IMT INTERMATO S.P.A. (10)

- INDEX Drehmaschinen (6)

- INDEX FRANCE (6)

- J.G. WEISSER SÖHNE (5)

- Jet Line Engineering (1)

- Jinan Blue Elephant CNC Machinery Co.,Ltd (1)

- JYOTI (6)

- KAAST Machine Tools Inc. (5)

- Kent Industrial (10)

- Knuth Machine Tools (14)

- KOVOSVIT MAS, a.s. (1)

- L & W Machine Tools, Inc. (4)

- Laguna tools (4)

- LEADWELL (12)

- LMW (28)

- LT Ultra-Precision Technology GmbH (4)

- LYMCO, BY LYWENTECH CO., LTD. (2)

- M Services (1)

- M.C.M. MADAR (7)

- Maschinen WAGNER Werkzeugmaschinen GmbH (6)

- Masteel America Corp. (2)

- Mazak (8)

- MECANUMERIC (1)

- Milltronics Manufacturing (8)

- Monforts Werkzeugmaschinen GmbH & Co. KG (2)

- Nakamura-Tome Precision Industry (3)

- NANTONG YIJI MACHINERY CO., LTD. (1)

- Nesto Machine Ltd. Co. (1)

- NEWAY CNC EQUIPMENT (SUZHOU) CO., LTD (3)

- Niles-Simmons Industrieanlagen (5)

- Ningbo GongTie Precision Machinery Co.,LTD (3)

- Ningbo gongtie smart technology co., ltd. (19)

- Oemak Machine (1)

- OKUMA EUROPE GMBH (5)

- PIETRO CARNAGHI (4)

- Pinacho Lathes (5)

- PORĘBA Machine Tools (8)

- PROTEM (1)

- Racer Machinery International USA Inc. (1)

- Rafamet (2)

- Romi (19)

- SALA s.r.l. (1)

- SCHAUBLIN MACHINES (4)

- Schuster Maschinenbau GmbH (1)

- Select Machining Technologies (1)

- Shibaura Machine (1)

- Sir Meccanica S.p.A. (2)

- SOMAB (9)

- SPINNER Werkzeugmaschinenfabrik GmbH (1)

- Starrag (1)

- Taiwan Trade Center, Chicago (27)

- Takumi USA (1)

- TOS a.s. (5)

- Toyoda Machine Works (3)

- Trens (21)

- Tsugami (5)

- TTGroup (8)

- Valmec (2)

- VICTOR (7)

- WEILER Werkzeugmaschinen (23)

- WIA (19)

- WMH Tool Group (1)

- Xi'an Huayue Machinery and Equipment Co., Ltd. (4)

- XYZ Machine Tools (10)

- YCM (Yeong Chin) (2)

- Zhejiang Yonglida Cnc Technology Co.,ltd. (3)

- ZMM Bulgaria Holding AD (38)

Control type

- CNC (599) NC

- conventional (126)

Spindle orientation

- horizontal (655)

- vertical (73)

Spindle speed

Number of axes.

- 2-axis (728)

- 3-axis (22)

- 4-axis (12)

Part diameter

Maximum part length, maximum cutting diameter, maximum cutting length, bar capacity, rapids on x, rapids on z, spindle mount.

- Camlock D1-6 (8)

- Camlock D1-4 (4)

Nominal power

Maximum torque, number of tool stations.

- 12 tools (151)

- 10 tools (25)

- 4 tools (24)

- 24 tools (6)

- 15 tools (1)

- 20 tools (1)

- 40 tools (1)

- 384 tools (1)

- 8 tools (1)

Coolant capacity

Drive system.

- belt drive (17)

- servo-driven (9)

Full load intensiy

Overall lenght, overall width, overall height, applications.

- heavy-duty (92)

- for large parts (46) for large workpieces for large-bore parts

- drilling (41) for deep drilling

- for metal (33) for aluminum

- for oil industry applications (17)

- for small parts production (15)

- for shaft machining (10)

- for bar machining (9)

- for long workpieces (9)

- for wheels (8) for aluminum wheels

- for aerospace applications (7)

- for automotive applications (7)

- for tube threading (5)

- for brake discs (4)

- for heavy turning (3)

- for mass production (3)

- for crankshafts (3)

- for brake disk facing (1)

- for production lines (1)

- for the plastics industry (1)

- for production (1)

- brake drum (1)

- for valves and flanges (1)

Other characteristics

- number of spindles/turrets (272) with turret 1-spindle double-spindle double-turret multi-spindle three-turret 4-spindle

- universal (96)

- for complex parts (5)

- portable (2)

- orbital (2)

& reach your clients in one place, all year round

{{product.productLabel}} {{product.model}}

{{#each product.specData:i}} {{name}} : {{value}} {{#i!=(product.specData.length-1)}} {{/end}} {{/each}}

{{{product.idpText}}}

NC lathe Charly4T

Diameter : 100 mm Spindle speed : 1,500 rpm

The simplicity for the turning of prototypes and small series, the technology for the performance The strengths • ISO programming, industry standard. • Allows the main turning operations (trimming, turning grooving, boring, drilling, ...

CNC lathe ST-15

Diameter : 419 mm Spindle speed : 4,000 rpm Axe X : 200 mm

The Haas ST Series high-performance turning centers were designed from the ground up to provide setup flexibility, extreme rigidity, and high thermal stability. The ST-15 is an extra-small footprint, big-bore lathe ...

CNC turning center ST-15LY

Diameter : 419 mm Spindle speed : 4,000 rpm Bar capacity : 64 mm

... long-bed, big-bore turning center that provides double the Z- axis travel and turning length of the standard ST-15Y for machining longer parts, while maintaining superior cutting performance, ...

CNC turning center ST-10

Diameter : 419 mm Spindle speed : 6,000 rpm Axe X : 200 mm

The Haas ST Series high-performance turning centers were designed from the ground up to provide setup flexibility, extreme rigidity, and high thermal stability. The ST-10 has an extra-small footprint, yet provides a generous ...

CNC lathe S65

Spindle speed : 0 rpm - 4,200 rpm Part diameter : 310 mm Maximum part length : 520 mm

Extremely solid machine bed, highest thermostability Top processing precision State-of-the-art control technology with Sinumerik 828D or Fanuc Oi TD with ShopTurn and ManualGuide i Made in the Heart of Europe

CNC lathe S45

Spindle speed : 0 rpm - 6,300 rpm Part diameter : 170 mm Maximum part length : 310 mm

CNC turning machine CONCEPT TURN 260

Spindle speed : 0 rpm - 6,300 rpm Maximum part length : 255 mm Maximum cutting diameter : 85 mm

... head stock with high drive power and C axis / 12 x tool magazine with up to 6 driven tools / Synchronized main spindle / Programmable part collecting device / Various clamping device and tool holder packages / Easy 2 control ...

universal turning machine B400

Diameter : 315 mm Spindle speed : 0 rpm - 4,000 rpm Maximum part length : 750 mm

... boring bars. The components Main spindle Holding brake for indexing the axis Star turret and compound slide setup / Disc turret Machining possible up to 70 mm below turning center 6,000 rpm, 8.8 kW, ...

universal turning machine B500

Diameter : 400 mm Spindle speed : 0 rpm - 3,150 rpm Maximum part length : 1,200, 750 mm

... 45° block design for high accuracy Work spindle with belt drive for high torques NC tailstock with electrically controlled axis Already included: the operating system iXpanel i4.0 ready with 18.5” touch screen - based ...

production turning machine C200

Diameter : 160 mm Spindle speed : 3,500, 6,000 rpm Bar capacity : 65, 90 mm

... large-sized working area for complete machining of workpieces. The kinematics The vertical design of the machine bed guarantees optimum chip removal and ready access. 2 x Y axes on the main-spindle ...

CNC lathe LabTurn 2028

Diameter : 200 mm Spindle speed : 100 rpm - 3,000 rpm Maximum part length : 280 mm

The LabTurn is suitable for CNC training as well as for the production of small workpieces. The compact and mobile CNC lathe represents the full range of functions of a large production machine. The 8-station tool turret ...

conventional lathe Turnado 230/2000

Diameter : 460 mm Spindle speed : 12 rpm - 2,000 rpm Maximum part length : 2,000 mm

The machines of the Turnado series are the modern version of the classic lathe . They are characterized by robust construction, a powerful motor and high level of versatility. With the extensive range of standard accessories ...

conventional lathe Turnado 230/2000 V const

Diameter : 460 mm Spindle speed : 30 rpm - 3,000 rpm Maximum part length : 2,000 mm

The turning machines of the Turnado series are characterized by their robust construction, powerful motor and versatility. For more than 20 years they have been among the tried and tested bestsellers of our conventional ...

CNC turning center SLANT TURN 500

Diameter : 1,040 mm Spindle speed : 1,600 rpm Rapids on X : 20,000 mm/min

... available spindle bores: φ185, φ275, φ320, and φ375mm The maximum available size steady rest is φ410mm - largest for this turning center class. Chucker version is also available. The MAZATROL SmoothC CNC sytem, ...

Diameter : 315 mm Spindle speed : 4,000 rpm Maximum part length : 750 mm

... drive for high torques Bar capacity dia. 82 mm, chuck up to dia. 315 mm Orthogonal, linear Y- axis for high accuracy NC tailstock with electrically controlled axis Already included: ...

Diameter : 400 mm Spindle speed : 3,150 rpm Maximum part length : 750, 1,200 mm

... drive for high torques Bar capacity dia. 102 mm, chuck up to dia. 400 mm Orthogonal, linear Y- axis for high accuracy NC tailstock with electrically controlled axis Also available ...

CNC turning machine ABC

Diameter : 65 mm Spindle speed : 6,000 rpm Bar capacity : 65 mm

Y axis -functionality for surface milling and off-center drilling Compact design and high performance with minimal floor space requirements Spindle clearance up to 65 mm Reduced cycle time through dynamic performance ...

2-axis turning machine XP 600

Portable facing & boring units Technical description: The SERCO machines are positioned and locked by means of a column / arm system fixed on the outer part of the flange to be machined. This clamping principle allows to perform internal ...

portable lathe Top 200

Diameter : 0 mm - 200 mm

Created to carry out internal and external surface operations and facing operations on the ends of non-rotating fixed tubular bodies, unable to be operated by the conventional machine tools. Suitable for the all the severals, complex ...

portable lathe TOP 400

Diameter : 0 mm - 400 mm Spindle speed : 0 rpm - 143 rpm Axe Z : 200, 320 mm

CNC turning center AC series

Diameter : 2,400, 3,200, 2,000, 1,600, 2,800 mm Spindle speed : 200 rpm - 6,000 rpm Maximum cutting diameter : 1,250 mm - 3,000 mm

The Pietro Carnaghi vertical turning centre model AC is designed and built in a compact form, with an extremely rigid thermo symmetrical structure, having the column mounted to the table base. All these elements are ...

double-column turning center AC series

Diameter : 3,600 mm - 6,500 mm Spindle speed : 60 rpm - 6,000 rpm Axe Z : 1,250 mm - 3,000 mm

The Pietro Carnaghi vertical turning centre model AC is designed and built in a compact form, with an extremely rigid thermo symmetrical structure, having two columns mounted to the table base. All these elements are ...

CNC lathe AP series

Diameter : 7,000 mm - 14,000 mm Spindle speed : 35 rpm - 6,000 rpm Axe Z : 2,000, 2,500, 3,000, 3,500, 4,000 mm

Model AP is characterized by a structure with 2 columns, designed for large parts, up to 14 meters (45.9 ft) of part diameter. The structure of the machine is a “formation” having the columns mounted to the table base, ...

CNC lathe Smart series

Diameter : 2,000 mm - 6,300 mm Axe Z : 2,000, 1,500, 1,200 mm Rapids on X : 10,000 mm/min

Table diameter mm 1.600/ 2 .000/ 2 .500/3.000 Maximum load kg 10.000/15.000/20.000/30.000 Table speed min-¹ 300/ 220/ 176/ 150 Standard turning height mm 1.600/ 2 .000/ 2 .400 Option ...

CNC lathe VTH series

Diameter : 10,000 mm Spindle speed : 5,000, 4,500 rpm Axe Z : 3,500, 3,000 mm

Table diameter mm 8.000 Maximum load kg 350.000 Table speed min-¹ 50 Standard turning height mm 5.000 Option of different turning heights mm 5.500 / 6.000 RAM section mm x mm 560 X 560 Min. RAM bore size mm 600 Milling power kW 63 60

CNC turning machine ELECNC-0508

Diameter : 300, 800 mm Spindle speed : 0 rpm - 24,000 rpm Axe X : 500 mm

Wood CNC Lathe is also called CNC Turning Machine, now it is for sale at the best price. Wood CNC Lathe machine is suitable for processing workpieces with large diameter and a short length. Features 1. ...

conventional lathe CR2870

Diameter : 280 mm Spindle speed : 150 rpm - 2,000 rpm Bar capacity : 26 mm

... Mode • Splashguard (Rear Safety Guard) • Emergency Stop Button • Chip tray • CE Standard Standard Accessories • 3 jaw lathe chuck Ø125 mm • Fixed Center • Travelling Center • Change Gear ...

conventional lathe CR3290

Diameter : 430, 320 mm Spindle speed : 65 rpm - 1,800 rpm Bar capacity : 38 mm

... Safety Guard for Lathe Chuck with micro switch • Emergency Stop Button • Siemens Electrical System • Lathe Foot Brake • Protective Chuck and Tool Holder Shields • Coolant System • CE Standard Standard ...

conventional lathe CB8020

Diameter : 800 mm Spindle speed : 30 rpm - 1,400 rpm Bar capacity : 320 mm

... Equipped with joystick featuring practical easy use • Machine lamp • Lathe Foot Brake • Coolant System • CE Standard Standard Accessories • 3 jaw lathe chuck Ø315 mm • 4 ...

Diameter : 152 mm - 304 mm Maximum part length : max 1016.0 mm Nominal power : 2 ch

... within the subtractive industry. Our CNC Lathe can be customized to the parameters and needs of your specific project. Standard with: - 6062 Extrusion Aluminum - Ballscrew Motion System - 2 hp ...

CNC lathe SUA 63 Numeric

Diameter : 655 mm Spindle speed : 5 rpm - 1,400 rpm

... jerky movements at low-speed feeds. Lathe SUA 63, NUMERIC is machine with automatic cycle control and it may be fitted with control system of companies Fagor, Heidenhain and Siemens. Lead of longitudinal feed - Z axis ...

CNC lathe SUA 80 Numeric

Diameter : 840 mm Spindle speed : 5 rpm - 1,250 rpm

... jerky movements at low-speed feeds. Lathe SUA 80, NUMERIC is machine with automatic cycle control and it may be fitted with control system of companies Fagor, Heidenhain and Siemens. Lead of longitudinal feed - Z axis ...

CNC lathe SUA 100 Numeric

Diameter : 1,050 mm Spindle speed : 4 rpm - 630 rpm

... - X axis is is realised by servo-drive directly to ball bolt. Measurement of both feeds is realised by rotating sensors located on servo-drives. In machines with longer turning lengths the Z axis - longitudinal ...

CNC lathe OPTIMAB 250

Diameter : 350 mm Spindle speed : 5,000 rpm Bar capacity : 54 mm

... tailstock (manual, pneumatic or hydraulic) Automatic turret Grinded ballscrews and double nut Digital drives Sliding and adjustable console EQUIPMENT Chuck with 3 concentric jaws Tailstock ...

CNC lathe OPTIMAB 450

Diameter : 500 mm Spindle speed : 4,500 rpm Bar capacity : 73 mm

... reconstituted granite on monobloc base Two prismatic guides on longitudinal and transverse axis Digital motorisation of axes with absolute encoders Y axis (option) Cartridge spindle with super ...

CNC turning machine DELTAMAB 800

Diameter : 560 mm Axe X : 360 mm Axe Z : 970, 2,290, 1,910 mm

CNC lathe XS series

Diameter : 350, 400, 460, 554 mm Spindle speed : 1 rpm - 3,500 rpm

... continuous threading Rigid tapping Constant surface speed/direct rpm programming Menu programming format with operator prompts 2 axes linear and circular interpolation Sequence number search Sequence ...

CNC turning center DX 200

Diameter : 250 mm Spindle speed : 50 rpm - 4,500 rpm Maximum part length : 500 mm

The DX 200 two- axis turning centre is ideal for the production of parts in a single setup. Particularly flexible and equipped with a turret with tools for drilling, boring and turning operations, the DX 200 turning centre ...

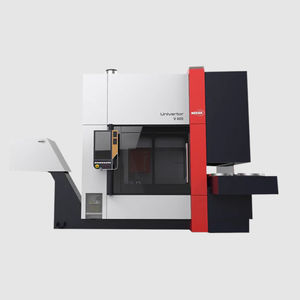

CNC turning center UNIVERTOR V

Diameter : 350 mm Spindle speed : 1,050, 750, 4,500, 3,500 rpm Axe X : 1,400, 1,850 mm

Left and right machine variants possible Direct path measuring systems in all machining axes Additional storage space for tools and utensils directly on the machine The UNIVERTOR V offers outstanding manufacturing competence for ...

CNC turning center UNIVERTOR AC series

Diameter : 150 mm Spindle speed : 1,600 rpm Bar capacity : 90 mm

... integrated handling unit ( 2 - axis version with swivel unit) Main spindle A6 according to DIN 55026 Interface in tool turret VDI or Capto possible Integrated measuring probe possible Driven tools ...

CNC turning center UNIVERTOR AM

Diameter : 360, 450 mm Spindle speed : 3,500 rpm Bar capacity : 120 mm

... despite compact external machine dimensions Precision linear guide ways in horizontal and vertical direction The modularly designed vertical precision turning machines of the UNIVERTOR ...

conventional lathe 70 Mi-CF

Diameter : 130 mm Spindle speed : 100 rpm - 8,000 rpm Axe X : 65 mm

The SCHAUBLIN 70 lathe is a tried-and-tested product whose qualities and applications are recognized worldwide. This lathe is equipped with an integrated motor (Mi) which allows it to run at up to 8000 ...

conventional lathe 102N series

Diameter : 200 mm Spindle speed : 100 rpm - 5,000 rpm Axe X : 100 mm

The SCHAUBLIN 102 lathe is a proven product whose qualities and applications are recognized worldwide. Continuing this tradition, SCHAUBLIN MACHINES SA has improved performance and further simplified the use of 102N-CF ...

conventional lathe 102 MI-CF

Diameter : 200 mm Spindle speed : 100 rpm - 6,000 rpm Axe X : 100 mm

The SCHAUBLIN 102 lathe is a widely recognized and established product, known for its exceptional features and applications worldwide. With an integrated motor (Mi), this lathe offers a rotational capacity ...

CNC turning center F

... grinding, or gear cutting – with a selection of numerous applications, you’re always well equipped. This way you can make a CNC lathe into a flexible combination cell specifically adapted for your applications. EQUIPPED ...

CNC turning center

Diameter : 280 mm Spindle speed : 6,000 rpm Maximum part length : 100 mm

It is a very focused machine to produce a wide range of different designs, shaped furniture and joinery parts such as chair, table and sofa legs and many other types of standard or complex parts.

CNC lathe Lz-1516

Spindle speed : 700 rpm - 2,800 rpm

... vibrating stress relief,so the lathe body is stabilized and will not be deformed forever. 2 .Prodessional used for wood turning and wooden cylinder engraving,for table legs,stair railing(banisters),etc.wood ...

CNC lathe EMITURN.CH

Spindle speed : 6,000 rpm Axe X : 310 mm Axe Z : 150 mm

EMITURN.CH is a compact frontal lathe based on a simple and very efficient concept. Like the EMISSA SA machines, the concept is to have a standard base with a large number of machining possibilities. The customization ...

CNC turning center YJ-CT350

Diameter : 600 mm Spindle speed : 30 rpm - 3,500 rpm Maximum cutting diameter : 400 mm

... With high-quality, high-precision linear guide. Fast feed rates of 20 and 24 m / min for the X and Z axes ensure efficient machining. High-precision C3 class player X, Z axis Ø32mm, Ø40mm. ...

Your suggestions for improvement:

Please specify:

Help us improve:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- 2-axis slotting machines

- 2-axis Swiss lathes

- 2-axis turning machining

- 2-axis milling-turning centers

- 2-axis transfer machines

- 2-axis copy routers

- 2-axis milling machines

- Machining services

- Haas 2-axis lathe

- Knuth Machine Tools 2-axis lathe

- SOMAB 2-axis lathe

- Mazak 2-axis lathe

- INDEX FRANCE 2-axis lathe

- TRAUB 2-axis lathe

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Understanding the Axes in CNC Machines: A Comprehensive Guide

Computer Numerical Control (CNC) machines come in different sizes, configurations, and technologies. Nonetheless, what these machines have in common is their use of axes, although the CNC machine axis count still varies from two to five. These axes typically include the linear axes as well as rotary axes. The CNC machine axes dictate the capabilities of the system, from the complexity to the size and shape of the part it can fabricate. The axes also influence the accuracy and precision of the machine.

In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

Table of Contents

Basics of CNC Machine Axes

Linear axes.

The Cartesian Coordinate System is a reference system widely used in mathematics and other areas such as computer-aided design (CAD) and manufacturing. It is within the domain of manufacturing that CNC machines fall. This system is based on the concept of three mutually perpendicular axes that intersect at the origin. We refer to these axes as the linear axes, and they include:

- X axis, which is the movement from left to right and vice versa (parallel to the cutting tool)

- Y axis, which is the movement from front to back and vice versa (perpendicular to the cutting tool)

- Z axis, which is the movement from top to bottom and vice versa (perpendicular to the cutting tool)

Rotary Axes

Indeed, we have grown used to the above-mentioned linear axes (X, Y, and Z) from our Math classes. However, when it comes to machining, a new class of axis – the rotary axes – enters the picture. Namely, the A axis, B axis, and C axis, these rotary axes help improve the accuracy and cycle times of fabrication processes. They do so by enabling the cutting tool to reach and work on a few more sides than would have been possible with linear axes. And as will be discussed in greater detail below, this is due to the part’s rotational shift in position.

Rotary axes get their name from their association with rotation. And given that these rotations always happen around one of the three linear axes, the relationship between rotary and linear axes becomes clearer. Typically, this relationship is as follows:

- A axis is the rotation or tilt around the X axis; the A axis is also known as the tilt axis

- B axis is the rotation around the Y axis

- C axis is the rotation around the Z axis

So, what is a rotary axis or rotary axes? The rotary axes relate to rotations around the linear axes by the rotary table that enable the cutting tool to access parts at different angles in order to machine features on the fourth or fifth side of the part.

Understanding Linear and Rotary Axes

You can think of a CNC machine axis as representative of the side from and dimension along which a feature on a workpiece can be machined. However, the term side does not necessarily mean the external face. Instead, and for simplicity, it can also refer to any internal surface that is parallel to the external face of a cube or cuboid.

Starting from the basics, if you encounter a term such as a 2-axis CNC machine, that means the system can only machine features on two sides of a workpiece at a time. As will be detailed below, these machines comprise a combination of two linear axes.

Similarly, if you come across the term 3-axis CNC machine, remember that such a machine performs the cutting action on three sides of the workpiece at a time. These sides will typically be the length (X axis), width (Y axis), and depth (Z axis), with the cutting or drilling tool traveling left to right (and vice versa), front to back (and vice versa), and top to bottom (and vice versa), respectively.

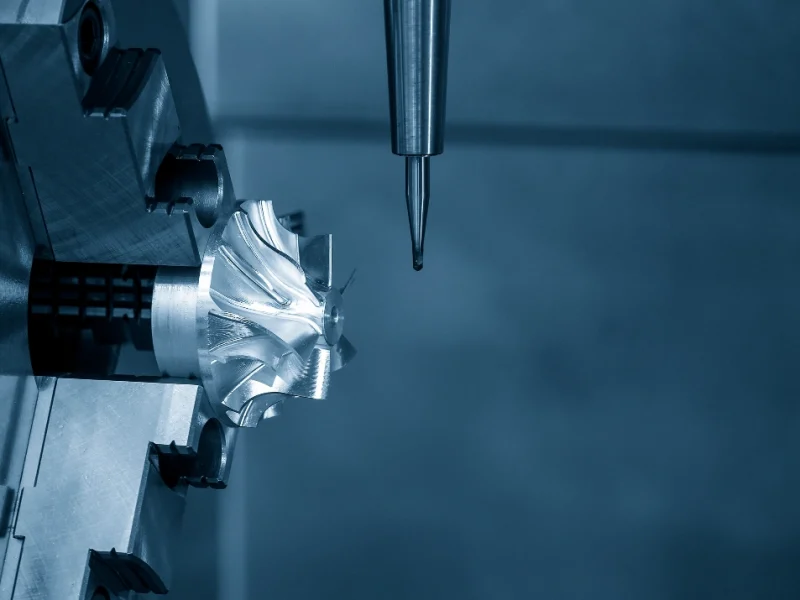

The introduction of the rotary axes gives rise to 4-axis and 5-axis CNC machines, also known as multi-axis machines. But following the same principle introduced above, a 4-axis machine can work on four sides of the part at a time. On the other hand, a 5-axis machine can manipulate and fabricate features on five sides of the part secured in the vise at a time. The multi-axis CNC machines’ additional capabilities, compared to the 2-axis and 3-axis machines, emanate from the ability of the cutting tool and rotary table (bed) to shift positions linearly and rotationally, respectively, which changes the part’s orientation relative to the cutting tool, exposing more sides.

2-Axis CNC Machines

As the name suggests, the 2-axis CNC machine has moving components that travel along two axes. Depending on the type of machine and the work envelope’s orientation (i.e., horizontal or vertical), these two axes can be a combination of the x-axis and y-axis, the x-axis and z-axis, or the y-axis and the z-axis.

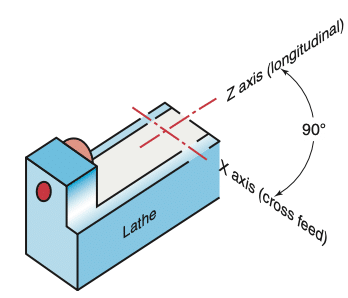

X and Z Axes in CNC Lathe Machine

CNC lathe machines and turning centers fall into this category. They mostly support movement along the x-axis and z-axis. These machines have a number of components, but in this article, we will focus on the chuck, which attaches to the main spindle and holds the workpiece in place, and the cutting tool. The chuck, for its part, rotates around the z-axis. On the other hand, the cutting tool moves along both the x-axis and z-axis.

As far as the cutting tool is concerned, the X axis relates to inward or outward movement. On the other hand, the Z-axis is associated with longitudinal movement (i.e., along the axis around which the chuck rotates). The movement of the cutting tool influences the classification of CNC lathe machines and turning centers as 2-axis CNC machines.

Multiple manufacturers, such as Haas with its ST-series turning centers and Knuth with its Forceturn series , produce and sell high-performance CNC lathe machines and turning centers. Some compact vertical milling machines and high-precision CNC grinding machines also fall into this category of 2-axis CNC machines.

3-Axis CNC Machines

The 3-axis CNC machine configuration is primarily found in CNC milling machines. In these machines, the workpiece is held in place by a vise. The vise, in turn, is fixed to a moving table. Designed to move, the table travels along the X and Y axes, while the drilling or milling tool travels along the Z axis. The combination of these movements means the CNC machine can simultaneously remove materials from the sides that correspond to the length, width, and depth.

This CNC machine axis configuration is ideal for machining simple parts with only a few features. These machines are also ideal for situations where the part does not require a lot of detailing. 3-axis CNC machines can also machine complex parts with numerous features. However, this will likely take longer than it would with systems that have more CNC machine axis configurations. More on this in the below section discussing whether more CNC machine axis configurations are better.

Examples of commercially available 3-axis CNC machines are EC-1600ZT , VF-1 , VF-2SS from Haas Automation, the BO 90 CNC and BO T CNC 110 series from Knuth, the VX8 from Huron, and the GENOS M series machines from Okuma.

4-Axis CNC Machines

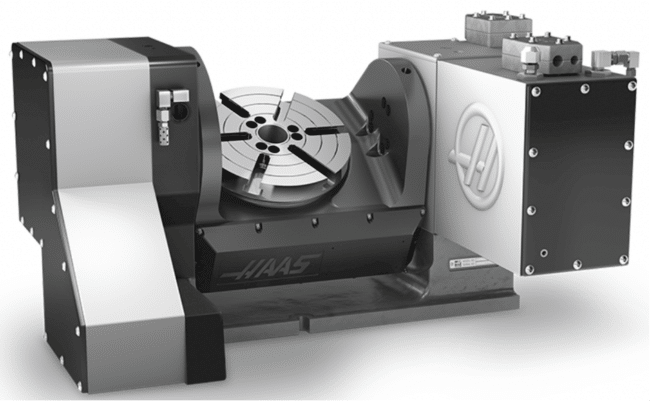

In 4-axis CNC machines, the axis count is 4. Such machines have the capabilities of a 3-axis machine, i.e., their cutting tool and/or table can move along the X, Y, and Z axes. However, they also support rotation around one of these linear axes. This rotation is thanks to their use of either 4th-axis (single-axis) rotary indexing tables or a 4th-axis swivel head.

Rotary indexing tables have built-in motion systems comprising, among others, fixed motors that link to a fixture plate that rotates around a single axis. They expose a new surface for machining. This process is technically known in manufacturing as indexing . Accordingly, the part clamped onto the fixture plate rotates based on the CNC program generated by the Computer-Aided Manufacturing (CAM) software.

Generally, 4th-axis rotary tables are available in right-hand, left-hand, or bottom configurations, with a bottom-, top-, side-, or back-mounted motor. They also come in different sizes to accommodate different sizes of parts or fixtures. These rotary tables are compatible with CNC machines that have a 4th-axis drive and firmware that supports full 4th-axis operations.

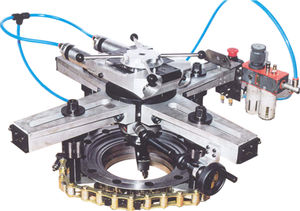

4th-Axis Rotary Table ( source )

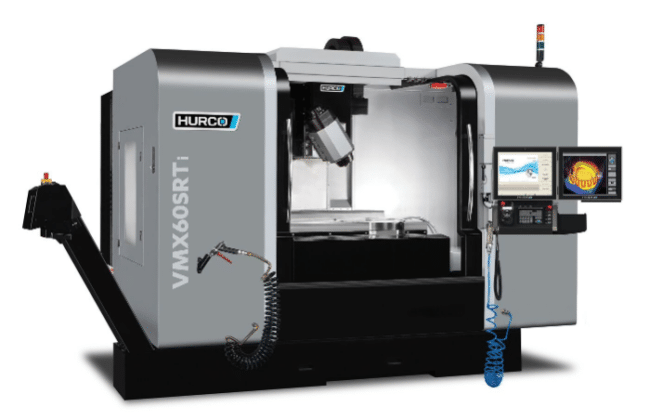

However, not all machines utilize rotary tables. Some have a swivel head paired with a non-rotating table that is nonetheless capable of traveling along the linear axes. The swivel action of the head introduces 4th-axis rotation. However, this is more accurately described as a tilt because the movement does not constitute a complete 360º rotation. Examples of 4-axis swivel-head machines are the VMX42SWi , VMX60SWi , and VMX84SWi from Hurco.

4-Axis Swivel Head Machine from Hurco ( source )

5-Axis CNC Machines

A 5-axis CNC machine has a CNC machine axis count of 5. This number includes the three main linear axes (X, Y, and Z) and any two rotary axes. This means that a 5-axis CNC machine includes the X, Y, and Z linear axes, along with two of the following rotational axes: A, B, or C. The additional two axes in the 5-axis CNC machines originate from two different mechanisms, resulting in two types of 5-axis CNC machines:

- Swivel-rotate-style 5-axis CNC machine

- Trunnion-style 5-axis CNC machine

Swivel-Rotate-Style 5-Axis CNC Machine

Also known as the swivel-head rotary table CNC machines, the swivel-rotate-style 5-axis CNC machines essentially have a swivel head that tilts around the B-axis, with a rotary table that rotates around either the A or C axis. This table supports the full 360º rotation, while the swivel head’s tilt is often less than 130º on either side of the vertical axis. It is worth mentioning that the tilt angle depends on the manufacturer. Hurco SRTi Series swivel-head rotary table machining centers support a maximum tilt of 92º on either side of the vertical axis, for example.

This type of 5-axis CNC machine is ideal for machining heavier parts. It is also less prone to tool interference issues. This is because the rotating table rarely interacts with the cutting tool, regardless of length. Moreover, the swivel-rotate-style machine offers flexibility and versatility. This is because it can machine both heavy and light parts.

Examples of swivel-rotate-style 5-axis CNC machines include the Hurco VMX60SRTi and VMX42SRTi .

Trunnion-Style 5-Axis CNC Machine

The trunnion-style 5-axis CNC machine introduces the rotary axes via dual-axis rotary tables and indexers. These dual-axis rotary tables orient the part to the cutting tool to take advantage of the cutter’s geometry. As a result, they expose as much as the part’s five sides to the cutter.

These tables tilt around the A or B axis by a specific angle on either side of the vertical axis. This angle typically depends on the manufacturer. CNC machines from Haas Automation support a maximum tilt of 120º each way. In contrast, those from Huron support a maximum of 110º. However, when it comes to the movement around the C axis, all rotary tables and machines support a full 360º rotation.

Haas TR200Y Trunnion-Style Rotary Table ( source )

However, these machines have a downside. Due to the rotary table’s continuous rotation and twisting of the part, the risk of tool interference significantly increases. Additionally, the rotation limits the weight of the part that the table can support. In this regard, trunnion-style machines are mostly ideal for machining light to medium-weight parts.

Some examples of Trunnion-Style 5-Axis CNC machines are the VC500i and VCX600iXP from Hurco, the VC-X350 from OKK, and the VR series and UMC series machines from Haas.

Multi-Axis CNC Machines

Multi-axis machines are those that have a CNC machine axis count that is greater than three. This means such machines have one or two rotary axes on top of the three linear axes. Compared to conventional CNC machines with two or three linear axes, multi-axis CNC machines offer several advantages:

- Multi-axis CNC machines require fewer setups as their cutting tools can access more sides than conventional machine’s cutters and mills

- The fewer setups translate to less cycle time, i.e., the amount of time spent machining a part with all designed feature

- These machines are more accurate because they eliminate the likelihood of human errors during setup – they have fewer setups and part-loading instances

As with all other machines, multi-axis CNC machines also have a few disadvantages, including:

- They are more expensive to purchase than conventional CNC machines

- Multi-axis CNC machines, particularly the trunnion-style 5-axis machines, are prone to collisions between the nose of the spindle of the machine and the side of the rotary table

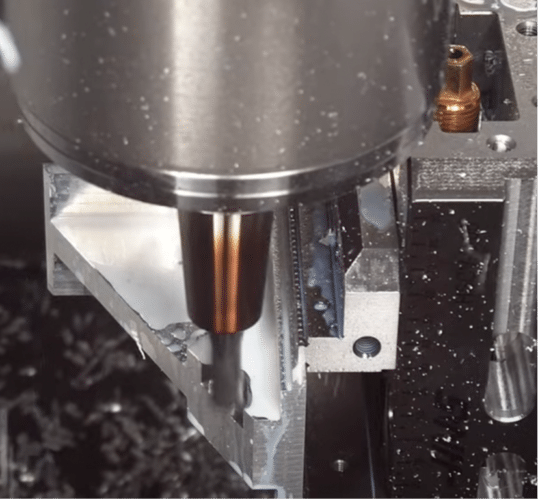

Image Showing Close Proximity of Spindle Nose to Side of Rotary Table ( source )

While the first disadvantage is unavoidable, measures can be taken to prevent the second. Running the machine slowly after loading the part can ensure safety and allow you to monitor the spindle nose’s proximity to the rotary table. If you establish that a collision is more than likely, there are two approaches you can take. First, you can use longer tools. Alternatively, you could attach your tools to an ER collet chuck to elongate them. That said, a few questions linger.

3-Axis CNC Machine vs. 5-Axis CNC Machine

Are higher CNC machine axis counts better? Are multi-axis CNC machines better than conventional CNC machines? To help answer the questions, Haas Automation conducted an analysis . In this analysis, a machinist separately created two identical parts using a 3-axis CNC machine and a 5-axis CNC machine. Though the analysis was not scientific, it offers insights that point to the fact that multi-axis CNC machines are better for machining parts with a high level of complexity.

This is because the use of the 5-axis CNC machine resulted in a 26.6% reduction in the cycle time. This implies that the machinist took less time to machine the part with the 5-axis machine compared to the 3-axis machine. Moreover, the former required just two setups or part loadings, compared to the latter’s five setups. The machinist also had to set the work offset during each setup. This means there were five different sets of work offsets in the 3-axis machine. In contrast, the 5-axis machine just required two. Furthermore, the fewer setups and work offsets because of using the latter dramatically reduced the chances of human error.

Another drawback of the 3-axis CNC machine that the analysis uncovered relates to tooling. The machinist had to constantly change the tool. And he did so even when that tool was required later to machine a feature on the part’s other sides. This added a few minutes to the cycle time. In contrast, the 5-axis machine would complete all machining operations required of the cutter by simply changing the part’s orientation. Only after the cutting tool had finished its job would it be changed. This helped reduce the cycle time.

Are Higher CNC Machine Axis Counts Better?

So, are more CNC machine axis counts better? Yes, they are. In fact, they are preferentially used in high-performance machine shops for pretty much this reason. However, multi-axis CNC machines may not be suitable for all types of machining jobs. This leads us conveniently to the next section, which discusses what goes into choosing the right number of axes.

Choosing the Right Number of Axes

There are numerous factors to consider when choosing a particular CNC machine axis count. These include:

- Part complexity

Future Plans

Different CNC machine systems come with varying costs. Naturally, 5-axis CNC machines are more expensive than 3-axis CNC machines. This is because you need to purchase additional accessories, e.g., the trunnion-style rotary table, longer tools, and collet chucks. However, industrial-grade, high-performance 2-axis CNC turning centers can also carry a high price tag. So, the cost may not always be the most crucial factor to consider when choosing the most appropriate CNC machine axis count for your machine shop.

Indeed, Haas Automation established that 5-axis CNC machines are inherently better than 3-axis machines at working on complex parts. However, multi-axis machines are not always ideal for all operations. In machining jobs that require 2-axis CNC machines, such as the CNC lathe or grinder, systems with more CNC machine axis counts will not cut it. Therefore, considering the intended function is crucial when selecting the appropriate number of axes.

Part Complexity

The complexity of a part increases the number of machining operations and tools to be used. And if the machined features are found on multiple sides of the part, then its orientation should be constantly changed. This is done to ensure the cutting tool accesses the different sides. Here, you can use a 3-axis system or a multi-axis system with a CNC machine axis count of 5. However, the former would require additional setups and sets of work offsets, which could compromise accuracy. In contrast, the latter would be a better option thanks to fewer setups and sets of offsets.

It is also important to consider your vision for your machine shop. This should be the case even when your current budget does not allow you to actualize this vision. Do you wish to scale up your operations? Are you looking to eventually reduce operational expenditure by lowering the cycle time? If the answer to both of these questions is an emphatic yes, you could initially purchase a machine whose capabilities can be upgraded later via the purchase of accessories. For instance, you can purchase a 3-axis CNC vertical milling machine that supports the fourth- and fifth-axis drives. You can then enhance your machine shop’s capabilities later by adding a trunnion-style rotary table.

Each CNC machine has a specific CNC machine axis count, depending on whether it employs only linear axes (X, Y, Z), or a combination of linear and rotary axes (A, B, C). While the CNC machine axis configuration is factory-imposed, you can increase the count for some types of machines by purchasing accessories such as a rotary table. All in all, the number of axes found in CNC machines influences their capabilities and functions. For example, while multi-axis machines are optimal for complex parts, 3-axis CNC milling machines are more suitable for simpler operations. Besides the function and part complexity, there are other factors you should consider when choosing the right number of axes. When choosing the right number of axes, consider factors such as function, part complexity, cost, and your machine shop’s future plans.

- Account Login

- CAD Tutorials

- CNC Tutorials

- Contact Support

- Help Articles

- CAD Answers

- Free DXF Files

- Convert Raster to Vector Online For Free

FROM THE BLOG

- Beyond 3D Printing: Mastering Additive Manufacturing Apr 14, 2024

- Decoding Model-Based Enterprise (MBE) in CAD Landscape Mar 26, 2024

- The Digital Thread: Weaving Through the CAD Industry Mar 13, 2024

IoT & Industry 4.0

Sales & Services

Machine Ecosystem

- Careers We Are Hiring

- SLC-16-LM-2S

- SLC-20-LM-2S

- CS-16-LM-200

- CS 2 -LM 400 / CS 2 – XL 400

- Jobber Junior

- Jobber LM/XL

- Super Jobber LM/XL

- Super Jobber 500 LM/XL

- JE 06 LM / XL / RG

- JE 08 LM / XL / RG

- SJE 06 LM / XL / RG

- SJE 08 LM / XL / RG

- SJE 10 LM / XL / RG

- Simpleturn 40100

- Simpleturn-5075 XL / 5075 – 6T XL

- Simpleturn-6075 XL / XL-6T

- Simpleturn-50125 XL/ XL-6T

- Simpleturn-50125 XL-SL

- SimpleTurn 60200 SL

- Simpleturn-60125 XL / XL-6T

- Simpleturn-50200 / 6T

- Simpleturn-60200 / 6T

- LT-20 C Classic

- LT-2 XL 500

- LT-2 XL 500 S

- LT-2 LM 500

- LT-2 LM 800

- LT-2 LM 1200

- LT-2 LM 1500

- LT-2-LM-500 Plus

- LT-16-300-LM

- LTP-2 LM 500

- Vantage 500 LM / XL

- Vantage 800 LM / XL

- Vantage 1000 LM / XL

- Vantage 1250 LM / XL

- Apollo Delta

- VTL-30 Plus

- VTL 300 XL L / R

- VTL-400 LM/XL

- LT-2 LM MSY

- LT-2 LM 500 MY

- LT-2 LM 500 MSY

- LT 2 XL / LM 500 M

- LT-2-XL / LM-500-MS

- LT-20 CLASSIC M

- LT 20 CLASSIC M / LM

- LT-30 1500-M

- LT 40 M 1000 / 2000 / 3000

- Vantage 800 MY

- Vantage 800 MSY

- Vantage 800 M / LM M

- Super Jobber 500 LM M

- SHA-20 Optima

- SHA-20 Magna

- SLC 16 LM G

- Cub LM Automation

- Colt LM Automation

- SLC-20 LM SPT

- 2TSL 12100 / M

- DTC-400L XL

- DTC-500L XL

- SUPER WINNER

- MCV-550L-50

- MCV-700N-50

- MCV-700N L-50

- Gemini Mini S

- Gemini Mini L

- Gemini Jr. XL

- LEADER-400XL

- CMH-500 XL-50

- MCH-500L-50

- Universal CNC Grinders

- Cylindrical CNC Grinders

- Centerless CNC Grinders

- Internal Grinders

- Special Purpose grinders

- TOYODA -Micromatic Grinders

- Crankshaft Grinders

- Manual/Semi-Automatic Cylindrical Grinder

- Hydraulic Cylindrical Grinders

- Hydraulic Centerless Grinders

- Auto Tool Wear Offset Correction and Automated SPC

- Machine Maintenance

- Process Parameters Monitoring

- Real Time OEE and Production Analytics

- eSHOPx – Digital Factory

- Visual Factory ANDON

- Track & Trace

Service Support

- Annual Maintenance Contracts

- Products, Subsystems, Kits & Spares

- Machine Calibration

- Machine Upgrades, Reconditioning & Retrofitting

- Value Added Services

- Tooled Up Solutions

Tech Centre

- Electronics

- General Engineering

- Pump & Motor

News & Media

- News Letters

- Case Studies

- Events & Webinars

- Privacy Policy

- Whistle Blower Policy

- Network List

2 Axes Horizontal Lathes

Compact Series

Compact series machines are 2-axes horizontal turning centres with a blend of precision & compact footprint. Cast bed with stepped-up construction, large swing over bed and thermally stabilised high speed spindle are some characteristics that make this machine compact with no compromise. Read more

Ace Designers Jobber series has been the benchmark for standard CNC lathes in India, with more than 10,000 + machines producing profits for satisfied owners. Over the years, using Jobber machines, numerous small and medium entrepreneurs have grown to become successful suppliers of turned parts to auto component, hydraulic, pumps & valves, general engineering and other industries. The enduring brand equity of the Jobber series is its world class reliability and accuracy through use of best in class inputs and standardized production and testing systems backed by years of experience of our strong team. The Jobber series machines are assembled on a conveyor line, in a lean environment, resulting in a highly efficient production system, to drive high volumes of machines with consistent quality, at optimal costs. Read more

The Jobber Evo, an evolutionary edition of the Jobber Series, has been specifically designed & developed taking inputs from our valued customers. These machines also feature a heavy duty hydraulic turret. With the option of Linear Motion guideways or Hardened & Ground box guideways, these machines have the versatility of fulfilling a wide range of your turning needs. From increased turning lengths to wiser chip collection area to increased swing diameter and more, the Jobber EVO offers better turning solutions to suit your needs. Read more

SimpleTurn Series

Simple Turn machines are designed to bridge the gap between manual and CNC turning lathes. These flatbed lathes are built on a wide, rigid double walled bed with robust headstock. The Z-axis in hardened & bolted on steel guideways for longer life. They are equipped with electronic hand wheels which impart flexibility and ease of handling to cut intricate parts without any additional effort or attachments. Simple Turn machines are ideal for tool room application and small batch production. Read more

Classic Series

The LT20-Classic machines are powerful, high precision turning centers suitable for medium sized components. Several premium features like robust ultra-precision spindle, safety clutches for both axes and high precision ball screws have been used. This machine is available with Hardened & Ground Box or Linear motion (LM) Guideways Read more

Heavy Duty Turning

These machines are robust high precision turning centres, ideal for large sized components. Their robust construction includes a high speed spindle with large bore capacity, safety clutches and a slant bed. LT- 25 , LT -30 and LT-40 machines are available with 3 different machining lengths. These machines are also available in the turnmill version. Read more

o The LT series is designed to provide customers with component specific solutions. o 2 Axes lathes can be configured with a wide range of customized solutions including Automation Featuring Tooling TPM features Process development Programming Read more

Vantage Series

Vertical turning lathes (VTL) are powerful, rigid and versatile with increased capacity. Wide access to the chuck zone, facilitates ease of loading and unloading of parts. Rapid traverse rates enable reduced cycle times and linear motion guideways on the X and Z axes ensure better positioning and repeatability. This machine is ideal for turning heavy and large diameter components. This machine occupies less floor space compared to a horizontal machine for similar sized components. Read more

CAT series are compact, high precision CNC 2 Axes Turning centers addressing the machining needs of small components. Productivity enhancements are possible with integration of Automation options. Read more

If you wish to receive up-to-date information about our products and services or would like us to contact you, please fill in the form below with your company address.

Choose Country (required) India Others

Select Product Service Support Training Spares Others

Select Turning Milling Grinding SPM IoT 3D Printer Laser cutting Foundry

- Online Manufacturing for Metal parts and Plastic Parts, XTJ Precision Mfg Ltd

Mobile: +86 17704021786

Email: [email protected]

2 Axis CNC Machining: The Ultimate Guide

- CNC Machining

Manufacturing requires a great deal of precision and detail when it comes to getting items exactly how they were planned. An industry that has taken precision to another level is CNC control and machining. When the machines are able to do the work without needing any kind of human intervention productivity increases and the best results are ensured for all of the items being produced.

The 2 axis control machine is an ideal solution for small and medium-scale precision manufacturing. It can be used in a variety of industries, including automotive, aerospace, medical, electronics, to create complex shapes with high accuracy. This type of machine will provide you with the ability to make precise cuts on any material that you choose. You can use it to produce components such as gears, bearings, and even complex assemblies like engines and more. The two-axis CNC lathe allows you to easily set up your own shop and start making parts right away.

We will provide throughout this article what exactly is a 2 axis cnc machine, its different types, the advantages and costs of owning and using this type of CNC machine tool, in addition to some general advice to consider before buying one.

Table of Contents

What Is a 2 Axis CNC Machine

A 2 axis CNC machine is a computer numerical control machine that has two axes of movement. The two axes are typically the x-axis and the y-axis, which correspond to the horizontal and vertical directions on a Cartesian coordinate plane. The machine can be used to create a variety of parts and objects with precise accuracy.

A two-axis CNC tool can do a lot of things. It can cut, drill, and machine parts. It can also be used for engraving a variety of materials, including wood, plastic, and metal. With this type of CNC lathe, you can create a lot of different parts and products, anything from simple ornaments to complex designs that make interesting and complex art.

Although this kind of machine is usually pretty expensive, it is worth the purchase and can be quite useful to manufacturers who are looking for something a little bit more precise.

The Different Types of 2 Axis CNC Machines

There are a few different types of 2 axis CNC machine tools. The three main types are vertical, horizontal, and gantry.

The vertical type is fairly rare because the machine will move along one axis and the head will move on the other axis, which usually isn’t going to give a lot of accurate cuts. This type of machine is more common in prototype work.

The horizontal machine has a table that moves along the x-axis and the head moves along the y-axis. This type of machine is going to give you the most accurate cuts and repeatability over time. However, this type of machine can have some issues with the parts becoming warped from being subject to too much vibration. This type of machine can also be the most expensive.

The gantry machine tool is the most commonly used by production facilities and manufacturers. Since it can move along two axes at once, the accuracy and repeatability of the cuts will almost always be higher than the other types of machines. It is also the most affordable of the three.

The Advantages of a 2 Axis CNC Machine

There are many advantages to having a CNC 2 axis machine in your workshop. Some of these advantages include:

1. Increased accuracy and precision in manufacturing.

A 2 axis lathe increases accuracy and precision in manufacturing by allowing for more precise control over the positioning of the tool in relation to the workpiece. This leads to a more consistent manufacturing process, with reduced variability in the final product. Additionally, a two-axis CNC machine can be used to produce more complex shapes and features than a traditional manual lathe or mill, making it a more versatile tool for manufacturing.

2. Reduced time to make complex parts

This type of CNC machine tools can quickly produce complex parts that would be difficult or impossible to create with traditional methods. This can save time and money, and improve productivity.

3. Increased repeatability of finished parts

A 2 axis CNC machine offers increased repeatability of finished parts due to the two linear axes of motion. This results in parts that are more consistent in terms of size and shape, which can be important for applications that require precise measurements.

4. Increased range of materials that can be cut

This is because they can move the cutting tool in two directions. This means that 2 axis machines can cut more complex shapes and are better suited for tasks such as engraving.

5. Faster removal of waste parts.

A CNC two-axis machine tool can quickly remove waste parts from a workpiece, which can speed up the manufacturing process.

The Costs of Owning and Operating a 2 Axis CNC Lathe

The cost of owning and operating a two-axis CNC machine can vary depending on the type of machine you choose, its size, its features, and the location in which it will be used and stored. Generally, the cost of owning and operating this type of CNC lathe will range from $1,000 to $10,000 per year.

How to Choose the Right 2 Axis CNC Machine

There are a few things you need to consider when choosing a two-axis machine. First, you need to think about what type of machines you want. This includes thinking about the types of CNC milling that your shop does and what is the capacity of the appliance. For a beginner, you will want to look for machines that are relatively small and simple.

Also, you might want to think about the location of the machine. If your shop is a large industrial space, you can try to look for machines that are heavy-duty, durable, and that can withstand the great elements in the shop.

An additional feature to consider is whether the machine can be stored. If so, you will want to look for machines that can hold onto the tooling they have on them and that can be stored easily.

The next thing you need to think about is the software and the device control options. It is recommended to look for options that give you a lot of customization options and that can be controlled with a joystick or a computer.

Finally, you will want to examine the price of the appliance. In general, these machines are more expensive than manual milling machines, but they are an excellent investment. They are durable and will last for many years. With the money you save on a manual milling tool , you will be able to buy yourself a couple of machines in no time at all.

What to look for in a basic two-axis CNC lathe

When looking for a basic two-axis lathe, there are a few things you should keep in mind.

1. A bed that is square to the ways and parallel to the spindle.

A bed that is square to the ways means that the bed is perpendicular to the ways. Meanwhile, a bed that is parallel to the spindle means that the bed is parallel to the spindle axis. This ensures that the workpiece is parallel to the spindle and results in accurate cuts.

2. A smooth table.

A basic two-axis CNC lathe should have a smooth table to provide a stable surface for the workpiece. The table should also be accurately machined to ensure that the workpiece is correctly positioned on the lathe.

3. A long spindle nose.

A long spindle nose is important for a two-axis CNC lathe because it allows the workpiece to be positioned further away from the machine’s headstock, which results in increased machining accuracy. It also allows for the use of larger tooling, which can improve the quality of the finished product.

4. At least four tool positions, though you’ll probably want an X-axis and a Y-axis if you do a lot of work that requires drilling or hole cutting.

A basic two-axis CNC lathe should have at least four tool positions. This will allow you to use a variety of tools to create different shapes and sizes. This way the appliance would be able to move the tools in multiple directions, so you can create even more intricate designs.

5. A good fence and a decent toolpost that allows you to position your work accurately.

A fence is important for holding workpieces securely in place while machining them. For the CNC lathe, a good toolpost is an essential component. A strong toolpost can hold the proper distance between the spindle and the workpiece for each different tool that you use.

The Complete Guide To The Different CNC machining Axis

Recent posts.

- How Does the Precipitation Hardening Process Work?

- What Does Clad Metal Mean?

- What is Types of Aluminum? Application for Aluminum CNC machining

- What is Tool Maintenance

- What is Motor Controllers and Drives

A Comprehensive Guide To 3 Axis CNC: Machine Specifications And Comparisons

GET IN TOUCH WITH XINTAINJIAN

Make the best product possible with the help of our international team of experts. When you’re ready for a project review, contact us for a free quote.

⇓ Catalogue Tour à commande numérique 2 axes

Tour à commande numérique 2 axes

Tournage 2 axes - jobber, sje, lt, vantage.

Découvrez les tours CN 2 axes ACE, très simples à manipuler et très fiables dans le temps. Robustes et abordables, ces tours d’usinage offrent un rapport qualité et prix très intéressant. De plus, ils s’adaptent à n’importe quel atelier avec des longueurs de tournage allant de 300 à 1200 mm et un ø max de 350 mm. Pour tous les modèles de tour CNC, vous aurez le choix entre des guidages linéaires (LM) ou prismatiques (XL), en commande numérique Fanuc ou Siemens.

Les points forts :

- Tourelle hydraulique bidirectionnelle, résistante à un usage intensif

- Vis à billes préchargée

- Puissant moteur de broche à courant alternatif

- Structure de l’axe Z renforcée

- Broche haute vitesse jusqu’à 4000 tr/min, stabilisée thermiquement

- Support de vis à billes précontraint

- Tous les axes sont calibrés au laser

- Réservoir de liquide de refroidissement séparé pour un entretien facile de la machine

N’hésitez pas à nous contacter pour plus d’informations.

- Rectification

- Machine de formage

- Forage mécanique profond

- Produits Heidenhain

- Services maintenance

- Formations CN

- Maintenance SAV

- C.B. Ferrari

- Tour Weiler

- ELB – ABA

- Meet Our Leadership Team

- Certifications

- Awards & Recognition

- Case Studies

- Aerospace & Defense

- Project Request

- Product Design & Development

- Advanced Manufacturing

- Support Activities

- Sustainability & Compliance

- Electrical & Electronics

- Industry Expertise

- Quality Services

- Empower QLM Software

- Quality Audits & Assessments

- Product Compliance & Sustainability

- Workforce Management

- Engineering

- Quality Lifecycle Management

The Latest News

- Company News

- Career Insight

- Infographic

What is CNC Machining? 3 Axis | 4 Axis | 5 Axis

CNC (computer numerical control) machining is a process in manufacturing where programmed computer software directs the motions of plant machinery and tools. The application can be used to automate a range of manufacturing techniques such as milling, water jet cutting, and laser cutting materials. Instructions are fed into the CNC machine through a CAD file and transposed into a precise set of sequential instructions. The CNC machine uses these programmed commands to operate automatically without a physical operator. Manufacturers accrue several benefits through the application of CNC machining such as expense reduction, improved speed, better accuracy, and enhanced productivity levels.

The reference to axes is used to describe CNC machines which operate along multiple axis points. CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth). The 4 th axis denotes the inclusion of an A axis (rotation around the X axis), and the 5 th axis denotes the B axis (rotation around the Y axis).

The number of axes on a CNC machine determines the type of work it can do, the level of detail it can cut, and the workpiece locations it can manipulate. So what does this all mean? The following provides a better explanation of the differences between a 3 axis, 4 axis, and 5 axis CNC machines.

3 Axis

3 axis machining implies that the workpiece remains in the same position while the cutting tool operates along the XYZ plane to trim away material. This is suitable for parts that don’t require a lot of depth and detailing. 3 axis machining is most commonly used to produce mechanical components and is best suited for:

- Automatic/interactive operation

- Milling slots

- Drilling holes

- Cutting sharp edges

4 axis machining implies that a workpiece is processed in the same way it would be with a 3 axis machine, but has an additional rotary movement around the X axis, which is named the A axis. This rotation allows the workpiece to be cut around the B axis. This method is beneficial when holes or cuts need to be made on the sides of a workpiece. The addition of a fourth axis (A axis) allows a workpiece to be automatically flipped over, so the machine can remove material from both sides. 4 axis machining is multifunctional and can be used for:

- Intermittent cutting

- Continuous cutting

- Engraving curved surfaces

5 Axis machining implies that a workpiece can be automatically manipulated from five sides at one time. In addition to automatic movements along the X, Y, and Z axes, 5 axis CNC machines can select two of the three rotational axes (A,B,C) to use. The A, B, and C axes perform a 180° rotation around the X, Y, and Z axes, correspondingly. This type of machining is used in the automobile, aerospace, and boating industries. Application is commonly favored for extremely complex components that are solid and would otherwise have to be cast. 5 axis machining requires greater CNC programming preparation time to accommodate complex rotatory movement, but allows one workpiece to be worked on all five sides during one operation. 5 axis machining is beneficial when components require a great deal of intricacy and quick precision. This includes:

- Feature accuracy

- Increased productivity

- Higher quality finishes

- Cutting intricate details

- Machining complex shapes

CNC machining has proven to be operationally beneficial across manufacturing intensive industries. Some advantages include improving product quality control, standardization, and precision. The adoption of CNC machining leverages CAD technology to automate the cutting and shaping of components. The numbers of axes determine what type of movement a CNC machine can conduct.

Axes Movements

- X axis – left to right

- Y axis – front to back

- Z axis – up and down

- A axis – 180° rotation around the X axis

- B axis – 180° rotation around the Y axis

- C axis - 180° rotation around the Z axis

Types of CNC Machines

- 3 Axis – X, Y, and Z axes

- 4 Axis – X, Y, Z, and A axes

- 5 Axis – X, Y, and Z axes and two out A, B, and C axes

About RGBSI

At RGBSI , we deliver business solutions that close the gap between strategy and execution for global organizations of all sizes. Our portfolio of solutions spans across the verticals of workforce management, engineering, quality lifecycle management (QLM), and information technology (IT).

With a strong engineering and IT backing, we work with global clients to deliver CNC programming & validation services in accordance with their business requirements.

Learn more about our engineering services .

Share this entry

You might also like.

Latest Posts

- Phone +1 248.589.1135

- Address 1200 Stephenson Hwy Troy, MI 48083

Connect with Us

Recent posts.

RGBSI © Copyright 2024

- Terms & Conditions

Budget 2-Axis CNC Build

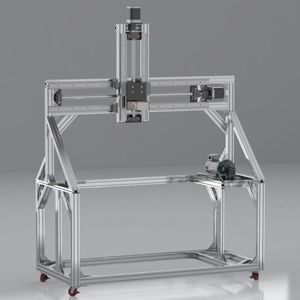

Introduction: Budget 2-Axis CNC Build

Hi, in this instructable I will go over how to create a 2-Axis CNC machine. This particular design utilizes parts which can be purchased at local hardware stores, reducing the price greatly. It also uses 3d printed parts which allow for customization and reduces the price even more. This design reduces the price of a typical 2-Axis laser cutter by approximately $100-$200 while maintaining similar quality.

Here are the supplies needed with costs relative to the amount used

- One roll of filament ($20)

- One 5/16 in x 36 in Threaded Rod ($4.36 from Home Depot)

- One 5/16 in x 72 in Round Rod ($14.93 from Home Depot)

- Fifteen 8x22x7 Bearings ($4.14 adjusted from a $13.79 50-pack on Amazon)

- Three Stepper Motor Couplings ($5.40 adjusted from an $8.99 5-pack on amazon)

- 16 in x 13.5 in wood board (Left over from IKEA furniture)

Screws, Nuts, and Bolts (~$5, Screws, nuts, and bolts were used from various screw kits already on hand)

- Sixteen #5 x 5/8 in wood screws

- Six 5/16-18 Hex Nuts

- Ten M3x20 Machine Screws

- Eight M3x16 Machine Screws

Electronics

- Arduino GRBL CNC kit - Includes End-stops, Cables, Arduino Uno, Stepper Motor Drivers, and Jumper Caps. ($20.99 by Keeyees on Amazon)

- Three Nema 17 Stepper Motors ($24.99 on Amazon)

- 5 amp 12 Volt power supply ($10.99 on Amazon)

Optional - I used a laser module for this build since I had one from a 2-in-one 3018 CNC, however, this CNC could be used with a drag knife or pen or make a cutter or a pen plotter respectively.

- Laser Module - The CNC I purchased the laser with was ~$50 more expensive than the other 3018 CNCs so I will use $50 as the approximate price for the laser.

Total costs

- Without the laser, the machine comes out to ~$110.80, adding the laser increases the price to ~$160.80. This price is much lower than the other laser engravers that could be bought on Amazon at the same power by about $150 or more for most laser engravers.

Step 1: Printing the Parts

I designed all the 3d printed parts in Onshape. I created the parts to have strong stability to prevent the machine from shaking or vibrating too much.

I printed the parts using 20% infill at a .25 layer height. Along with this, I used supports on the parts with overhangs.

Link to Thingiverse with STL files: 2-Axis CNC by Paragon427 - Thingiverse

Step 2: Cutting the Steel Rods

I used a Dremel rotary tool to cut the steel and threaded rods. This allowed me to buy larger rods to reduce the price as I could cut them down to any size I needed. A hacksaw will also work if you do not have a Dremel or similar rotary tool on hand.

First, I took the rolled round rods and cut four 12.5-in rods and two 9.75-in rods. Next, I cut the threaded rods into two 11.5-in rods and one 10.5-in rod.

You may have to adjust the length of the rods if you use a different sized wood board or different printed parts.

Step 3: Insert Bearing and Hex Nuts

Insert the 15 ball bearings and the 6 hex huts, using hot glue where needed. The bearings and hex nuts should not come loose from the printed parts.

Step 4: Attach the Stepper Motor Couplings to the Motors

Use the included hex screw key to attach the motor couplings to the motors.

Step 5: Insert Threaded Rods Into Steppers

Insert the three threaded rods into one stepper each. After they are inserted, tighter the hex nuts on the coupler to lock them into place.

Step 6: Mount the Stepper Motors

Using four M3x20 screws attach the motor with the shortest rod to the Y-axis carriage (The tall printed piece). After, use four M3x16 each to mount the other two steppers to the Y-axis stepper mounts. Keep in mind the orientation of the stepper motor wire connectors, as a motor cable will need to be attached and routed along the machine.

Step 7: Mount the Laser

Mount the laser or other module to the X-axis carriage using six M3x20 screws.

Step 8: Attach Endstops

Attach the two end-stops to the end-stop pads using hot glue on the printed parts. Make sure the end-stop arm is in a position where it will trigger if a carriage comes toward it.

Step 9: Assemble the X-axis

To assemble the X-Axis, you will need the two shorter round steel rods, the X-Carriage, and the two Y-Carriages. To start, screw the X-Carriage onto the Y-Carriage with the threaded rod. Do this until the X-Carriage is about halfway down the rod. Then slide the two steel rods through the bearings on the X-Carriage until they fit into the Y-Carriage. If they don't fit tightly, add some hot glue into the hole for the rods. Next, slide the other Y-Carriage onto all three rods, adding hot glue to only the round rods if they aren't tight. The threaded rod should turn easily in the bearing.

Step 10: Assemble the Y-Axis

Assembling the Y-Axis is similar to the X-Axis. Take one of the Y-Axis stepper mounts and screw the threaded rod through one of the Y-Axis carriages. Repeat this process with the other Y-Axis stepper mount and the other Y-Axis carriage. Screw the threaded rod until the carriages are about halfway down the rod. Try to keep the carriages relatively even as it will lower the stress on the X-Axis while assembling. After the threaded rods are inserted, slide two of the four remaining rods through the bearings on the Y-Axis carriage. Push them until they fit into the Y-Axis stepper mount, adding hot glue if necessary to keep them snug. Repeat this process with the other Y-axis stepper mount and Y-Axis carriage. Finally, slide the Y-Axis ends to the ends of the three rods, adding hot glue to the round rods if they don't fit snugly, and allowing the threaded rods to rotate easily.

Step 11: Connect the Machine to a Board

For this project, I had a spare 16" x 13.5" wood board from IKEA which I used as the base for this machine. You could use any size board but would have to adjust the rod lengths to fit your needs. To connect the machine to the base, simply line up the inner corners of the pieces on the machine with the outer corners on the board. The printed parts should fit flush against the wood. After lining it up, use sixteen #5 x 5/8 in wood screws to secure the machine to the base.

Step 12: Wiring the Controller Board

For the Controller Board, I went with a kit from KeeYees, which includes several parts, however, the ones we will need will be eleven jumper caps, three stepper motor cables, two end-stop cables, and three stepper motor drivers, an Arduino, and a GRBL Arduino shield. Start by lining the Arduino shield pins up with the Arduino's female headers and connect the two. Next, to enable micro-stepping, insert three jumper caps in the middle of where the X stepper driver would be. Repeat this with the Y and A stepper driver spots. To make the A axis duplicate the Y axis, on the side of the board near the power connections, insert two jumpers in the section labeled "Y". This makes the two steppers that move the Y axis operate in unison. Next, take the three stepper motor drivers and insert them into the "Y", "X", and "A" sections on the board, lining the "EN" pin on the driver with the "EN" on the board. Next, take the two end-stop cables and plug the first one into the "Y+" making near the edge of the board. Plug the red wire into the white header and the black wire into the black section. Leave the green wire unconnected. Repeat this with the other cable and the "X+" header. Finally, take the three stepper cables and connect them to the headers next to the three stepper drivers we used. the direction of the cable will change the direction the stepper motor spins but this can be easily changed later in software or by reversing the cable. For now, plug them all in the same direction.

Step 13: Optional - Connect Laser to Board

Whether you are using a spindle, laser, or another PWM-controlled device, you will need to connect it to the board. You can do this by connecting the PWM wire to the Z+ endstop header on the board.

Step 14: Plug in the Motors

Connect the wires from the control board to the three motors and the two endstops. The A and Y axis motor cables will connect to the two Y-Axis motors and the X-Axis motor cable will connect to the X-Axis motor. Next, connect the Y+ endstop cable to the endstop on the Y-Axis. Finally, attach the X+ endstop cable to the endstop on the X-Axis.

Step 15: Connect the Board to a Computer

Use the USB type B cable to plug the Arduino into a computer.

Step 16: Installing Grbl

To control the motors on the machine, we will need to give our arduino code to follow. Start by going to this link to download grbl: grbl link . Download it as a zip and extract the files. Next, utilizing the arduino ide, navigate to File > Examples > grbl > grblUpload. This will open a new sketch which will need to be uploaded to the arduino.

Step 17: Installing UGS

Now that the arduino has the code to control the machine, we need software to be able to communicate with the arduino. For this project, I used UGS or Universal G-code Sender. You can download it here .

Step 18: Connecting the Machine to UGS

After completing any following installation steps, you should reach this screen. This is the main screen for UGS. From here you will want to press plug shaped icon in the top left. This will connect the software the the machine. You may need to change the comm port if it does not connect properly. You can do this by clicking on the drop down box near the top left and selecting a different comm port. Along with this, make sure the firmware is set to GRBL and the baud is set to 115200.

Step 19: Setup Wizard

After connecting the machine to UGS, run set-up wizard by pressing "Machine" in the top left, then scrolling down to "Setup Wizard". This will allow you to change the settings of the machine easily in case your settings need to be different than mine. The settings I used are in the photos. Depending on the threaded rods used, you may need to change the step size. You can do this by following the instructions in the setup wizard which has you measure the actual distance traveled against the distance it should have traveled.

Step 20: Adding G-Code