ACGIH Digital Library

- Subscription Center

- Not a Subscriber?

ACGIH is a 501(c)(3) charitable scientific organization that advances occupational and environmental health.

- News Articles

- Copyright Policy

- ACGIH Copyright Permission Request

- Past Board of Directors & Annual Meeting Locations

- Scientific Committees

- Committee Operations Manuals

- Volunteer Spotlight

- 2021–2024 Strategic Plan

- ACGIH Sponsorship

- Organizational Subscriptions

- FIV On-The-Road

- Allied Industry Partners

- Collaborating Scientific Organizations

- Subscriptions

ACGIH advances the careers of professionals working in the occupational and environmental health, industrial hygiene, and safety communities interested in defining their science.

- Subscriber Benefits

- Emerging Career Professionals

- Awards Nominations Form

- Election Nominations Form

- John J. Bloomfield Award

- Robert T. Hughes Memorial Award

- Meritorious Achievement Award

- Philip R. Morey Memorial Award

- William Steiger Memorial Award

- Herbert E. Stokinger Award

- William D. Wagner Award

- Member Ethical Principles

This section has been established to help educate industry, government, and the public on what TLVs and BEIs are, and how TLVs and BEIs may best be used.

- Notice of Intended Changes

- Under Study

- Substances and Agents Listing

- Importance of TLV and BEI Documentation

- Compressed Schedule to TLV Development Process

- TLV/BEI Development Process

- TLV/BEI Policy Statement

- TLV/BEI Position Statement

- Conflict of Interest Policy

- Procedures for Commenting on TLVs and BEIs

- Guidelines and Services for Authors

- Career Development

ACGIH is committed to providing its members and other occupational and environmental health professionals with the training and education they need to excel in their profession.

- Access to ACGIH Online Learning

- Journal of Occupational and Environmental Hygiene

- Industrial Ventilation Resources

- In-Person Learning

- Noise Resources

- Learning Passes

- Submit 2024 Webinar Presentations

- Webinar Series Packages

- Professional Development Courses (PDCs)

- ACGIH Exhibits

- Submit a Job Posting

- Certification Resources

- Publications

ACGIH has publications in many different areas that fit your needs in your field.

- New Releases

- ACGIH Signature Publications

- Digital Publications

If you need to purchase the Digital Library, click here .

If you have purchased and need to access the Digital Library, click here .

- 2024 Documentation

- COVID-19 Resources

- Link to JOEH Articles

- The Action Level Program

The Foundation for Occupational Health & Safety (FOHS) is a 501(c)(3) corporation fostering the expanded establishment of occupational exposure values throughout the world.

- Board of Trustees

- FOHS Terms of Access

- Jeffrey S. Lee Lectureship Program

- Sustainable TLV/BEI Program

- Worldwide Outreach Program

TLV Chemical Substances Introduction

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec faucibus tempus eros eu fermentum.

Introduction to the Chemical Substances TLVs ®

General Information

The TLVs ® are guidelines to be used by professional industrial hygienists. The values presented in this book are intended for use only as guidelines or recommendations to assist in the evaluation and control of potential workplace health hazards and for no other use (e.g., neither for evaluating or controlling community air pollution; nor for estimating the toxic potential of continuous, uninterrupted exposures or other extended work periods; nor for proving or disproving an existing disease or physical condition in an individual). Further, these values are not fine lines between safe and dangerous conditions and should not be used by anyone who is not trained in the discipline of industrial hygiene. TLVs® are not regulatory or consensus standards.

Editor’s note: The approximate year that the current Documentation was last substantially reviewed and, where necessary, updated may be found following the CAS number for each of the adopted entries in the alphabetical listing, e.g., Chromium [7440-47-3] and inorganic compounds (2017). The reader is advised to refer to the “TLV ® Chronology” section in each Documentation for a brief history of the TLV ® recommendations and notations.

Definition of the TLVs ®

Threshold Limit Values (TLVs ® ) refer to airborne concentrations of chemical substances and represent conditions under which it is believed that nearly all workers may be repeatedly exposed, day after day, over a working lifetime, without adverse health effects.

Those who use the TLVs ® MUST consult the latest Documentation to ensure that they understand the basis for the TLV ® and the information used in its development. The amount and quality of the information that is available for each chemical substance varies over time.

Chemical substances with equivalent TLVs ® (i.e., same numerical values) cannot be assumed to have similar toxicologic effects or similar biologic potency. In this book, there are columns listing the TLVs ® for each chemical substance (that is, airborne concentrations in parts per million [ppm] or milligrams per cubic meter [mg/m 3 ]) and critical effects produced by the chemical substance. These critical effects form the basis of the TLV ® .

ACGIH ® recognizes that there will be considerable variation in the level of biological response to a particular chemical substance, regardless of the airborne concentration. Indeed, TLVs ® do not represent a fine line between a healthy versus an unhealthy work environment or the point at which material impairment of health will occur. TLVs ® will not adequately protect all workers. Some individuals may experience discomfort or even more serious adverse health effects when exposed to a chemical substance at the TLV ® or even at concentrations below the TLV ® . There are numerous possible reasons for increased susceptibility to a chemical substance, including age, gender, genetic factors (predisposition), lifestyle choices (e.g., diet, smoking, abuse of alcohol and other drugs), medications, and pre-existing medical conditions (e.g., aggravation of asthma or cardiovascular disease). Some individuals may become more responsive to one or more chemical substances following previous exposures (e.g., sensitized workers). Susceptibility to the effects of chemical substances may be altered during different periods of fetal development and throughout an individual’s reproductive lifetime. Some changes in susceptibility may also occur at different work levels (e.g., light versus heavy work) or at exercise — situations in which there is increased cardiopulmonary demand. Additionally, variations in temperature (e.g., extreme heat or cold) and relative humidity may alter an individual’s response to a toxicant. The Documentation for any given TLV ® must be reviewed, keeping in mind that other factors may modify biological responses.

Although TLVs ® refer to airborne levels of chemical exposure, dermal exposures may possibly occur in the workplace (see “Skin” on page 73 of the Definitions and Notations section).

Four categories of TLVs ® are specified: time-weighted average (TWA); short-term exposure limit (STEL); surface limit (SL); and ceiling (C). For most substances, a TWA alone or with a STEL is relevant. For some substances (e.g., irritant gases), only the TLV–STEL or TLV–C is applicable. If any of these TLV ® types are exceeded, a potential hazard from that substance is presumed to exist.

Threshold Limit Value–Time-Weighted Average (TLV–TWA)

The TWA concentration for a conventional 8-hour workday and a 40-hour workweek, to which it is believed that nearly all workers may be repeatedly exposed, day after day, for a working lifetime without adverse effect. Although calculating the average concentration for a workweek, rather than a workday, may be appropriate in some instances, ACGIH ® does not offer guidance regarding such exposures.

Threshold Limit Value–Short-Term Exposure Limit (TLV–STEL)

A 15-minute TWA exposure that should not be exceeded at any time during a workday, even if the 8-hour TWA is within the TLV–TWA. The TLV–STEL is the concentration to which it is believed that nearly all workers can be exposed continuously for a short period of time without suffering from 1) irritation, 2) chronic or irreversible tissue damage, 3) dose-rate-dependent toxic effects, or 4) narcosis of sufficient degree to increase the likelihood of accidental injury, impaired self-rescue, or materially reduced work efficiency. The TLV–STEL will not necessarily protect against these effects if the daily TLV–TWA is exceeded. The TLV–STEL usually supplements the TLV–TWA where there are recognized acute effects from a substance whose toxic effects are primarily of a chronic nature; however, the TLV–STEL may be a separate, independent exposure guideline. Exposures above the TLV–TWA up to the TLV–STEL (15-min TWA) should be less than 15 minutes, should occur no more than four times per day, and there should be at least 60 minutes between successive exposures in this range. An averaging period other than 15 minutes may be recommended when this is warranted by observed biological effects.

*Threshold Limit Value–Surface Limit (TLV–SL)

The concentration on workplace equipment and facility surfaces that is not likely to result in adverse effects following direct or indirect contact. The TLV–SL is intended to supplement airborne TLVs ® , especially those with Skin, DSEN and RSEN notations, to provide quantitative criteria for establishing acceptable surface concentrations expressed as mg/100 cm 2 . For systemic effects, consistent with the use of the Skin notation, the TLV–SL will often correspond to the dose permitted by the TLV–TWA over an 8-hour period, unless chemical-specific data are available linking adverse effects with surface sample results. For certain dermal sensitizers, the surface limit may be established using potency estimates from animal studies, such as the effective concentration causing a 3-fold increase in lymphocyte proliferation (EC3) and applying an appropriate adjustment factor (Naumann and Arnold, 2019). For other sensitizers, including some respiratory sensitizers that cause induction of sensitization via dermal exposure, professional judgment may be required to supplement available surface and airborne monitoring results.

Threshold Limit Value–Ceiling (TLV–C)

The concentration that should not be exceeded during any part of the working exposure. If instantaneous measurements are not available, sampling should be conducted for the minimum period of time sufficient to detect exposures at or above the ceiling value.

ACGIH ® believes that TLVs ® based on physical irritation should be considered no less binding than those based on physical impairment. There is increasing evidence that physical irritation may initiate, promote, or accelerate adverse health effects through interaction with other chemical or biologic agents or through other mechanisms.

Peak Exposures

The TLV ® Committee recommends consideration of a TLV–STEL if there are supporting data. For many substances with a TLV–TWA, there is no TLV–STEL. Nevertheless, short-term peak exposures above the TLV–TWA should be controlled, even where the 8-hour TLV–TWA is within recommended limits. Limiting short-term high exposures is intended to prevent rapidly occurring acute adverse health effects resulting from transient peak exposures during a workshift. Since these adverse effects may occur at some multiple of the 8-hour TWA, even if they have not yet been documented, it is prudent to limit peak exposures. Therefore, the following default short-term exposure limits apply to those TLV–TWAs that do not have a TLV–STEL:

Transient increases in workers’ exposure levels may exceed 3 times the value of the TLV–TWA level for no more than 15 minutes at a time, on no more than 4 occasions spaced 1 hour apart during a workday, and under no circumstances should they exceed 5 times the value of the TLV–TWA level when measured as a 15-min TWA. In addition, the 8-hour TWA is not to be exceeded for an 8-hour work period.

This guidance on limiting peak exposures above the value of the TLV–TWA is analogous to that for the TLV–STEL, and both represent 15-minute exposure limits. The consistency in approach is intended to encourage minimizing process variability and ensuring worker protection. Good design and industrial hygiene practice ensures that processes are controlled within acceptable ranges. Historically, guidance on peak exposures (formerly excursion limits) has been based purely on statistical considerations: if log-normally distributed, short-term exposure values for a well-controlled process have a geometric standard deviation of 2.0, then 5% of all values will exceed 3.13 times the geometric mean. Processes that display greater variability are not under good control, and efforts should be made to restore control. Higher exposure levels also increase the possibility that acute health effects may occur, which were probably not factored into the TLV–TWA if it was based on prevention of chronic effects. The maximum peak exposure factor of 5 also reflects this concern about undesirable health effects. Limiting peak exposures reduces the probability of exceeding the TLV–TWA. When initial samples indicate peak exposures beyond these recommendations, more careful assessment is needed, especially when dealing with unusual work schedules.

The so-called “3 by 5 Rule”, as described above, should be considered a rule of thumb, and a pragmatic precautionary approach. It is recognized that the geometric standard deviations of some common workplace exposures may exceed 2.0. If such distributions are known, and it can be shown that workers are not at increased risk of adverse health effects, recommended peak exposure guidelines may be modified based on workplace-specific and compound-specific health effects data. For example, consideration should be given to dose-rate effects and elimination half-times for the particular substance and for similar compounds. Special consideration should also be given to unusual work schedules and whether the peak exposure factors should be applied to the TLV–TWA (e.g., if concerns for acute health effects predominate) or the adjusted TWA (e.g., if the concern is with exceeding the adjusted TWA). The practicing hygienist must use judgment in applying this guidance on peak exposures. When a TLV–STEL or a TLV–C is available, this value takes precedence over the above guidance for peak exposures.

TWA and STEL versus Ceiling (C)

A substance may have certain toxicological properties that require the use of a TLV–C rather than a TLV–STEL or peak exposure guidance above a TLV–TWA. The amount by which the TLVs ® may be exceeded for short periods without injury to health depends upon a number of factors such as the nature of the contaminant, whether very high concentrations — even for short periods — produce acute poisoning, whether the effects are cumulative, the frequency with which high concentrations occur, and the duration of such periods. All factors must be taken into consideration in arriving at a decision as to whether a hazardous condition exists.

Although the TWA concentration provides the most satisfactory, practical way of monitoring airborne agents for compliance with the TLVs ® , there are certain substances for which it is inappropriate. In the latter group are substances that are predominantly fast-acting and whose TLV ® is more appropriately based on the concentration associated with this particular response. Substances with this type of response are best controlled by a TLV–C that should not be exceeded. It is implicit in these definitions that the manner of sampling to determine noncompliance with the TLVs® for each group must differ. Consequently, a single, brief sample that is applicable to a TLV–C is not appropriate to the TLV–TWA; here, a sufficient number of samples are needed to permit determination that the TLV-C is not exceeded at any time during a complete cycle of operation or throughout the workshift.

Whereas the TLV–C places a definite boundary that exposure concentrations should not be permitted to exceed, the TLV–TWA requires an explicit limit to the number and duration of peak exposures which are acceptable above the recommended TLV–TWAs.

Special consideration should also be given to the application of the TLVs ® in assessing the health hazards that may be associated with exposure to a mixture of two or more substances. A brief discussion of basic considerations involved in developing TLVs ® for mixtures and methods for their development, amplified by specific examples, is given in Appendix E.

Deviations in Work Conditions and Work Schedules

Application of TLVs ® to Unusual Ambient Conditions

When workers are exposed to air contaminants at temperatures and pressures substantially different than those at 25°C and 760 torr, care should be taken in comparing sampling results to the applicable TLVs ® . For aerosols, the TWA exposure concentration (calculated using sample volumes not adjusted to conditions at 25°C and 760 torr) should be compared directly to the applicable TLVs ® published in the TLVs ® and BEIs ® book . For gases and vapors, there are a number of options for comparing air-sampling results to the TLV ® , and these are discussed in detail by Stephenson and Lillquist (2001). One method that is simple in its conceptual approach is 1) to determine the exposure concentration, expressed in terms of mass per volume, at the sampling site using the sample volume not adjusted to conditions at 25°C and 760 torr, 2) if required, to convert the TLV ® to mg/m 3 (or other mass per volume measure) using a molar volume of 24.4 L/mole, and 3) to compare the exposure concentration to the TLV ® , both in units of mass per volume.

A number of assumptions are made when comparing sampling results obtained under unusual atmospheric conditions to the TLVs ® . One such assumption is that the volume of air inspired by the worker per workday is not appreciably different under moderate conditions of temperature and pressure as compared to those at 25°C and 760 torr (Stephenson and Lillquist, 2001). An additional assumption for gases and vapors is that absorbed dose is correlated to the partial pressure of the inhaled compound. Sampling results obtained under unusual conditions cannot easily be compared to the published TLVs ® , and extreme care should be exercised if workers are exposed to very high or low ambient pressures.

Unusual Work Schedules

Application of TLVs ® to work schedules markedly different from the conventional 8-hour day, 40-hour workweek requires particular judgment to provide protection for these workers equal to that provided to workers on conventional workshifts. Short workweeks can allow workers to have more than one job, perhaps with similar exposures, and may result in overexposure, even if neither job by itself entails overexposure.

Numerous mathematical models to adjust for unusual work schedules have been described. In terms of toxicologic principles, their general objective is to identify a dose that ensures that the daily peak body burden or weekly peak body burden does not exceed that which occurs during a normal 8-hour/day, 5-day/week shift. A comprehensive review of the approaches to adjusting occupational exposure limits for unusual work schedules is provided in Patty’s Industrial Hygiene (Paustenbach, 2000). Other selected readings on this topic include Lapare et al. (2003), Brodeur et al. (2001), Caldwell et al. (2001), Eide (2000), Verma (2000), Roach (1978), and Hickey and Reist (1977).

Another model that addresses unusual work schedules is the Brief and Scala model (1986), which is explained in detail in Patty’s Industrial Hygiene (Paustenbach, 2000). This model reduces the TLV ® proportionately for both increased exposure time and reduced recovery (i.e., non-exposure) time, and is generally intended to apply to work schedules longer than 8 hours/day or 40 hours/week. The model should not be used to justify very high exposures as “allowable” where the exposure periods are short (e.g., exposure to 8 times the TLV–TWA for 1 hour and zero exposure during the remainder of the shift). In this respect, the general limitations on peak exposures above the TLV–TWA and TLV–STELs should be applied to avoid inappropriate use of the model with very short exposure periods or shifts.

The Brief and Scala model is easier to use than some of the more complex models based on pharmacokinetic actions. The application of such models usually requires knowledge of the biological half-life of each substance, and some models require additional data. Another model developed by the University of Montreal and the Institute de Recherche en Sante et en Securite du Travail (IRSST) uses the Haber method to calculate adjusted exposure limits (Brodeur et al., 2001). This method generates values close to those obtained from physiologically based pharmacokinetic (PBPK) models.

Because adjusted TLVs ® do not have the benefit of historical use and long-time observation, medical supervision during initial use of adjusted TLVs ® is advised. Unnecessary exposure of workers should be avoided, even if a model shows such exposures to be “allowable.” Mathematical models should not be used to justify higher-than-necessary exposures.

TLV ® Units

TLVs ® are expressed in ppm, mg/m 3 or mg/100 cm 2 . An inhaled chemical substance may exist as a gas, vapor, or aerosol.

- A gas is a chemical substance whose molecules are moving freely within a space in which they are confined (e.g., cylinder/tank) at 25°C and 760 torr. Gases assume no shape or volume.

- A vapor is the gaseous phase of a chemical substance that exists as a liquid or a solid at 25°C and 760 torr. The amount of vapor given off by a chemical substance is expressed as the vapor pressure and is a function of temperature and pressure.

- An aerosol is a suspension of solid particles or liquid droplets in a gaseous medium. Other terms used to describe an aerosol include dust, mist, fume, fog, fiber, smoke, and smog. Aerosols may be characterized by their aerodynamic behavior and the site(s) of deposition in the human respiratory tract.

TLVs ® for aerosols are usually established in terms of mass of the chemical substance in air by volume. These TLVs ® are expressed in mg/m 3 .

TLVs ® for gases and vapors are established in terms of parts of vapor or gas per million parts of contaminated air by volume (ppm), but may also be expressed in mg/m 3 . For convenience to the user, these TLVs ® also reference molecular weights. Where 24.45 = molar volume of air in liters at 25°C and 760 torr, the conversion equations for gases and vapors [ppm:mg/m 3 ] are as follows:

When converting values for volatile forms of inorganic compounds (e.g., as Fe, as Ni), the molecular weight of the element should be used, not that of the entire compound.

In making conversions for substances with variable molecular weights, appropriate molecular weights should be estimated or assumed (see the TLV ® Documentation ).

User Information

Each TLV ® is supported by a comprehensive Documentation . It is imperative to consult the latest Documentation when applying the TLV ® .

Additional copies of the TLVs ® and BEIs ® book and the multi-volume Documentation of the Threshold Limit Values and Biological Exposure Indices , upon which this book is based, are available from ACGIH ® . Documentation of individual TLVs ® is also available. Consult the ACGIH ® website ( acgih.org/store ) for additional information and availability concerning these publications.

ACGIH ® disclaims liability with respect to the use of TLVs ® .

References and Selected Readings

- Brief RS; Scala RA: Occupational health aspects of unusual work schedules: a review of Exxon’s experiences. Am Ind Hyg Assoc J 47(4):199-202 (1986).

- Brodeur J; Vyskocil A; Tardif R; et al.: Adjustment of permissible exposure values to unusual work schedules. Am Ind Hyg Assoc J 62:584-594 (2001).

- Buringh E; Lanting R: Exposure variability in the workplace: its implications for the assessment of compliance. Am Ind Hyg Assoc J 52:6-13 (1991).

- Caldwell DJ; Armstrong TW; Barone NJ; et al.: Lessons learned while compiling a quantitative exposure database from the published literature. Appl Occup Environ Hyg 16(2):174-177 (2001).

- Eide I: The application of 8-hour occupational exposure limits to non-standard work schedules offshore. Ann Occup Hyg 34(1):13-17 (1990).

- Hickey JL; Reist PC: Application of occupational exposure limits to unusual work schedules. Am Ind Hyg Assoc J 38(11):613-621 (1977).

- Lapare S; Brodeur J; Tardif R: Contribution of toxicokinetic modeling to the adjustment of exposure limits to unusual work schedules. Am Ind Hyg Assoc J 64(1):17-23 (2003).

- Leidel NA; Busch KA; Crouse WE: Exposure measurement action level and occupational environmental variability. DHEW (NIOSH) Pub. No. 76-131; NTIS Pub. No. PB- 267-509. U.S. National Technical Information Service, Springfield, VA (December 1975).

- Paustenbach DJ: Pharmacokinetics and Unusual Work Schedules. In: Patty’s Industrial Hygiene, 5th ed., Vol. 3, Part VI, Law, Regulation, and Management, Chap. 40, pp. 1787-1901. RL Harris, Ed. John Wiley & Sons, Inc., New York (2000).

- Roach SA: Threshold limit values for extraordinary work schedules. Am Ind Hyg Assoc J 39(4):345-348 (1978).

- Stephenson DJ; Lillquist DR: The effects of temperature and pressure on airborne exposure concentrations when performing compliance evaluations using ACGIH TLVs and OSHA PELs. Appl Occup Environ Hyg 16(4):482-486 (2001).

- Verma DK: Adjustment of occupational exposure limits for unusual work schedules. Am Ind Hyg Assoc J 61(3):367-374 (2000).

Privacy Overview

What Are U.S. Standards and Regulations for Asbestos Levels?

- Learning Objectives

- Introduction

- Occupational Standards

- Environmental Standards

- Progress Check

Download Printer-Friendly Version [PDF – 843 KB]

Upon completion of this section, you will be able to

- Explain the Occupational Safety and Health Administration (OSHA) permissible exposure limit for asbestos and

- Explain the U.S. Environmental Protection Agency’s (EPA) maximum contaminant level for asbestos in drinking water.

The earliest evidence of asbestos-associated disease in workers was found in the 1930s by British studies [Lee and Selikoff 1979]. We now know that the toxic effects of asbestos depend on the nature and extent of exposure, particularly on the:

- Concentration of asbestos fibers involved in the exposure,

- Duration of exposure,

- Frequency of exposure,

- Type of asbestos fibers involved in the exposure, and

- Dimensions and durability of the asbestos fibers.

The Center for Disease Control and Prevention/National Institute for Occupational Safety and Health (NIOSH) and OSHA began establishing standards for asbestos in the 1970s. U.S. regulatory agencies such as EPA and OSHA recognize six asbestos and asbestiform minerals, i.e.,

- Actinolite asbestos,

- Amosite asbestos,

- Anthophyllite asbestos,

- Chrysotile asbestos,

- Crocidolite, and

- Tremolite asbestos

as legally regulated forms of asbestos out of the group of asbestiform minerals.

Asbestiform minerals are defined as crystal aggregates displaying these characteristics: groups of separable, long, thin, strong, and flexible fibers arranged in parallel [ATSDR 2001a].

Currently there is discussion underway to include asbestiform minerals that may have similar health effects to the previously mentioned forms of asbestos as regulated substances. However, nothing has been finalized at this time [OSHA 1992; NIOSH 2011a].

Currently, there are standards for asbestos in

- Drinking water,

- Some consumer products, and

- Workplace air.

In 1986, OSHA in Standard 29 CFR 1910.1001 established the current permissible exposure limit (PEL) for asbestos in the workplace: (0.1 fibers/cc of air as a time weighed average) [OSHA 2012]. PELs are allowable exposure levels in workplace air averaged over an 8-hour shift of a 40 hour workweek. There are also OSHA standards (29 CFR 1915.1001) for shipyards and construction (1926.1101).

Additionally, OSHA standards (1915.1001 and 1926.1101) requires employers of all workers whose work exposes them to asbestos above the PEL or excursion limit (1.0 f/cc over 30-minute period) to

- Provide training in the engineering controls, work practices, and proper use of personal protective equipment (PPE),

- Train workers in safety before beginning work and annually,

- Train workers regarding the health effects of asbestos exposure, and

- Inform workers of the relationship between smoking, asbestos exposure and increased risk of lung cancer.

In addition, OSHA requires employers of workers who are exposed to asbestos above the PEL and who are employed in certain asbestos industries to

- Provide and make sure of correct use of PPE (respirators, protective clothing like coveralls and goggles),

- To undergo medical surveillance in order to identify those with signs of asbestos-associated disease, remove them from further exposure,

- Comply with regulations requiring documentation for work-related injury claims, and

- Provide information to workers about where they can go for help to stop smoking.

Components of the required medical surveillance include

- Chest radiograph,

- Physical examination,

- Spirometric test, and

- Standard questionnaire.

Further information about OSHA requirements is available at http://www.osha.gov/SLTC/asbestos/standards.html .

For further information about protection guidelines, contact NIOSH via 1-800-CDC-INFO or via http://www.cdc.gov/niosh/contact/ .

ATSDR does not consider the use of OSHA’s PEL for workplace exposures to be appropriate for environmentally exposed populations since residential and/or environmental exposures are 24 hours a day year round, much longer than the typical 8-hour day and 40-hour workweek exposures of workers. Children and the elderly, who are not typically exposed in the workplace, may be more susceptible to exposure.

EPA has established a maximum contaminant level (MCL) for asbestos in drinking water of 7 MFL (million fibers per liter > 10 µm in length) in drinking water [EPA 2011]. Asbestos in drinking water comes from two main sources:

- Decay of water mains constructed of asbestos-containing cement, and

- Erosions of naturally occurring asbestos deposits into watersheds [EPA 2012a].

In addition, EPA has

- Banned spraying of asbestos in building interiors (for fireproofing and ceilings),

- Developed guidelines for proper treatment of in-place asbestos in old buildings,

- Recommended “no visible emissions” of asbestos,

- Regulated demolition of buildings with asbestos (NESHAP rules), and

- Regulated uses of asbestos in industrial products and construction.

More information on EPA rules and regulations regarding asbestos is available at http://www2.epa.gov/asbestos/asbestos-laws-and-regulations

The Asbestos Hazard Emergency Response Act of 1982 (CFR 40, Part 763, Subpart E) requires that local education agencies

- Inspect schools for asbestos-containing material using certified inspectors,

- Analyze these materials for asbestos content,

- Post results and notify parents and employees if asbestos is found,

- Test air levels following clean-up,

- Develop appropriate management plans,

- Communicate openly about any asbestos abatement needed, and

- Maintain appropriate records [EPA 2012c].

EPA also warned school authorities that power buffing and power stripping of asbestos-tile floors in schools produces significant airborne asbestos levels. Floor maintenance must be performed by hand to prevent release of asbestos fibers.

- OSHA’s PEL for asbestos in the workplace is 0.1 fibers/cc of air (8-hour TWA).

- OSHA requires all asbestos-exposed workers to be trained in PPE; they must undergo medical surveillance if exposed above the PEL.

- EPA’s MCL for asbestos in drinking water is 7 MFL greater than 10um in length (million fibers per liter) of drinking water.

- Local education agencies must inspect schools and analyze friable material for asbestos content, communicate results, and maintain records.

- Case Studies in Environmental Medicine

- Grand Rounds in Environmental Medicine

- Pediatric Environmental Health Training

- Patient Education

- Community Education

Exit Notification / Disclaimer Policy

- The Centers for Disease Control and Prevention (CDC) cannot attest to the accuracy of a non-federal website.

- Linking to a non-federal website does not constitute an endorsement by CDC or any of its employees of the sponsors or the information and products presented on the website.

- You will be subject to the destination website's privacy policy when you follow the link.

- CDC is not responsible for Section 508 compliance (accessibility) on other federal or private website.

Dashpivot article – OSHA asbestos exposure limits

OSHA Asbestos exposure limits

Asbestos, a fibrous mineral once widely used for its heat resistance and insulating properties, has been identified as a significant health hazard, causing diseases such as mesothelioma, lung cancer, and asbestosis.

Understanding and adhering to OSHA asbestos exposure limits is critical in ensuring the safety and health of workers across various industries.

This article delves into OSHA's regulations and the importance of maintaining these stringent exposure limits in the workplace.

OSHA's Role in Asbestos Regulation

OSHA, a regulatory body under the U.S. Department of Labor, is tasked with ensuring safe and healthful working conditions by setting and enforcing standards.

The administration's regulations on asbestos are geared towards minimizing employee exposure to asbestos fibers in the workplace.

Read more on OSHA Asbestos regulations here .

OSHA Asbestos Exposure Limits

Permissible exposure limits (pels).

OSHA's primary tool for regulating asbestos exposure is through its PELs. The PEL for asbestos is set at 0.1 fibers per cubic centimeter of air (f/cc) averaged over an 8-hour work shift. This limit is designed to reduce the risk of employees developing asbestos-related diseases.

Excursion Limit (EL)

OSHA also establishes an excursion limit, which is a higher concentration of asbestos fibers that workers may be exposed to for a short duration. The EL is set at 1.0 f/cc over a 30-minute period. This limit is critical in situations where short-term exposure might exceed the PEL.

Implementation and Compliance

Employers are required to conduct exposure assessments in workplaces where asbestos is present.

If the levels exceed the PEL, employers must implement engineering controls, such as ventilation systems, and work practice controls to reduce airborne asbestos fibers.

Additionally, personal protective equipment (PPE) must be provided to workers.

Medical Surveillance and Training

OSHA mandates medical surveillance for workers who are exposed to asbestos at levels at or above the PEL or EL.

This includes periodic medical examinations and lung function tests.

Employers are also required to provide training to workers on asbestos hazards and safe handling practices.

Recordkeeping Requirements

Employers must maintain accurate records of asbestos exposure measurements and medical surveillance data for at least 30 years.

An OSHA asbestos inspection checklist can help keep track of what's been inspected and signed off on for compliance and safety purposes.

This requirement helps in tracking exposure levels and the long-term health of workers.

Challenges and Best Practices

One of the main challenges in regulating asbestos exposure is the latency of asbestos-related diseases, which can take decades to manifest.

Therefore, continuous monitoring and adherence to OSHA's limits are crucial.

Best practices include regular training, updating safety protocols, and using the latest technology for monitoring and minimizing exposure.

Global Standards and Comparison

OSHA's asbestos exposure limits are part of a global effort to control asbestos-related risks.

Different countries have varying standards, with some opting for complete bans on asbestos use.

The comparison with global standards highlights the importance of continually reviewing and updating regulations to ensure the highest level of worker protection.

Regular inspections can help mitigate potential risks from asbestos exposure.

See how you could use an OSHA asbestos inspection checklist to monitor OSHA asbestos exposure limits in the example below.

Keep track of OSHA asbestos exposure limits with this OSHA asbestos inspection checklist template

Standardise your osha asbestos inspections.

Regular asbestos inspections are crucial parts of ensuring OSHA compliance and monitoring of asbestos exposure limits.

This digital OSHA asbestos inspection checklist template makes it easier for your team to run asbestos inspections that meet your compliance needs.

The standardised form has sections for your project location, details and inspector and checklist for your asbestos inspection questions.

Customise the checklist with any extra items you need to maintain OSHA compliance.

Create processes around the recording and managing of OSHA asbestos inspections

Use this OSHA Asbestos Inspection app to help manage the process of requesting, running and signing off on asbestos inspections.

Keep track of your completed inspections in the chronological Timeline view, or a more detailed overview in the Register view which you can use to filter or sort by various metrics.

Analyse asbestos inspection performance in the Analytics Dashboard to review pass/fail ratio, the frequency of inspections and more broken down by team, project or location.

OSHA Pre-Task Plan template

Ensure your OSHA Pre-Task Plans are compliant by using this free digital template.

OSHA form 300 & 300a template

Maintain your log of injuries and illnesses and your 300a summary with this free template.

OSHA Incident Report form 301 template

Properly document your injury and illnesses on site with this OSHA Injury and Illness Incident Report form 301 template.

Sitemate builds best in class tools for built world companies.

About Nick Chernih

Nick is the Senior Marketing Manager at Sitemate. He wants more people in the Built World to see the potential of doing things a different way - just because things are done one way doesn't mean it's the best way for you.

Leave a Comment Cancel Reply

Save my name, email, and website in this browser for the next time I comment.

The Law Dictionary

Your Free Online Legal Dictionary • Featuring Black’s Law Dictionary, 2nd Ed.

EXCURSION LIMIT Definition & Legal Meaning

Definition & citations:.

Specified, time-bound (typically 30 minutes), restricted exposure allowed to something unhealthy, even deadly. Meaningful especially in health and safety regulations.

This article contains general legal information but does not constitute professional legal advice for your particular situation. The Law Dictionary is not a law firm, and this page does not create an attorney-client or legal adviser relationship. If you have specific questions, please consult a qualified attorney licensed in your jurisdiction.

Browse Legal Articles

Business Formation

Business Law

Child Custody & Support

Criminal Law

Employment & Labor Law

Estate Planning

Immigration

Intellectual Property

Landlord-Tenant

Motor Vehicle Accidents

Personal Injury

Real Estate & Property Law

Traffic Violations

Browse by Area of Law

Powered by Black’s Law Dictionary, Free 2nd ed., and The Law Dictionary .

About The Law Dictionary

Terms and Conditions

Privacy Policy

- Skip to primary navigation

- Skip to main content

- Skip to primary sidebar

- Skip to footer

A Legal Dictionary

Black’s Law Online Dictionary

What is EXCURSION LIMIT

Specified, time-bound (typically 30 minutes), restricted exposure allowed to something unhealthy, even deadly. Meaningful especially in health and safety regulations.

- Skip to main content

- Skip to site information

- Departments

Language selection

- Français

Scheduled maintenance - Thursday, July 12 at 5:00 PM EDT

We expect this update to take about an hour. Access to this website will be unavailable during this time.

Occupational Hygiene - Occupational Exposure Limits

On this page, what is occupational hygiene, what are the occupational exposure limits, are there different types of exposure limits, what if i am exposed to several chemical substances at the same time, what if i work more than eight hours per day or 40 hours per week.

The occupational hygiene is the branch of occupational health and safety which focuses on the prevention of the occupational diseases. The exposure to health hazards can lead to diseases and illnesses that can manifest either immediately or after a long period of time after the exposure has stopped. Since these diseases are a consequence of exposure to hazards present in the workplace, they are known as occupational diseases. Occupational hygiene uses the techniques of anticipation, identification, evaluation, and control to identify and evaluate exposure.

The goal is to identify solutions for eliminating or reducing the hazard, and monitoring to ensure no further harm occurs. Occupational exposure limits are one tool or method used in this process.

In general, the occupational exposure limit (OEL) indicates the level of admissible exposure, for a length of time (usually 8 hours), to a chemical or physical hazard that is not likely to affect the health of a worker.

These limits are set out by many professional organizations around the world, such as the American Conference of Governmental Industrial Hygienists (ACGIH) and the National Institute for Occupational Safety and Health (NIOSH) in the United States.

The OELs for chemical substances are established based on the chemical properties of the substance, experimental studies on animals and humans, toxicological and epidemiological data. Different organizations may use different terminology for the OEL. For example, the ACGIH term for OEL is "Threshold Limit Value" (TLV)®, while the NIOSH term is "recommended exposure limits" (REL).

The OELs for physical hazards are based on industrial experience and experimental human and animal studies.

A list of legislative references for Exposure Limits to Chemical and Biological Agents for Canadian jurisdictions is available. Please note that while you can see the list of legislation for free, you will need a subscription to view the actual documentation.

Remember! A legal limit or guideline (such as an occupational exposure limit) should never be viewed as a line between "safe" and "unsafe". The best approach is to always keep exposures or the risk of a hazard as low as possible.

As an example, carcinogens do not usually have exposure limits. With many carcinogens, it is difficult to say for certain that if exposure is below a set point, the agent is not likely to cause harm. For this reason, for carcinogens and other specific agents (such as allergens), the "As Low as Reasonably Practicable" (ALARA) principle should be applied. ALARA, in practical terms, means that exposure should be eliminated or reduced as much as possible.

For chemical substances , ACGIH (2021) defines four categories of threshold limit values:

Threshold Limit Value – Time-Weighted Average (TLV-TWA): the time-weighted average concentration of a hazardous substance in the air averaged over an 8-hour workday and a 40-hour workweek to which it is believed that workers may be repeatedly exposed, day after day, for a working lifetime without adverse effects.

The time-weighted average concentration calculation considers the variations of the concentration in the air of a hazardous substance and the exposure time to that concentration over an 8-hour workday.

t i is the period of time the worker was exposed to the concentration c i .

Threshold Limit Value – Short-term exposure (TLV-STEL): a 15-minute time- weighted average exposure that should not be exceeded at any time during a workday, even if the overall 8-hour TLV-TWA is below the TLV-TWA. Workers should not be exposed more than four times per day to concentrations above TLV-TWA up to TLV-STEL. There should be at least a 60 minute interval between exposures. The short-term exposure threshold has been adopted to account for the acute effects of substances that have primarily chronic effects.

Threshold Limit Value – Ceiling (TLV-C) : the concentration that should not be exceeded during any part of the working exposure.

Threshold Limit Value – Surface Limit (TLV-SL): the acceptable concentration of a substance on a surface that is not likely to result in adverse health effects if a person touches that surface. It supplements the airborne TLVs for substances for which the route of exposure is through the skin and those identified as skin and respiratory sensitizers.

Peak exposures should be always controlled. For substances that do not have TLV-STEL or TLV-C established, the maximum admissible peak concentrations may exceed three times the value of TLV-TWA for maximum 15 minutes, for a maximum of four occasions spaced at least one hour apart during a workday. The exposure should never exceed 5 times the TWA and the 8-hour TWA should not be exceeded for an 8-hour work period.

The units of measures for the TLV-TWAs, TLV-STEL and TLV-C are ppm and mg/m 3 . The TLVs for aerosols are usually expressed in mg/m 3 . The TLVs for gases and vapours are expressed in ppm or mg/m 3 .

The units of measure for TLV-SL is mg/100 cm 2 .

For physical hazards, ACGIH defines:

Threshold Limit Value – Time-Weighted Average (TLV-TWA)*: The time-weighted average exposure for an 8-hour workday and 40-hour workweek.

Threshold Limit Value-Ceiling (TLV-C)*: Exposure limit that should not be exceeded even instantaneously.

Adapted from: 2021TLVs® and BEIs® - Threshold Limit Values for Chemical Substances and Physical Agents and Biological Exposure Indices. Cincinnati: American Conference of Governmental Industrial Hygienists (ACGIH)

For more information about OELs for physical agents, visit our factsheets:

- Noise - Occupational Exposure Limits in Canada

- Ultraviolet Radiation

- Radiation - Quantities and Units of Ionizing Radiation

- Vibration - Measurement, Control and Standards

- Cold Environments - Working in the Cold

- Temperature Conditions - Hot

In the workplace, a worker may be exposed to several chemical substances at a time. If the toxicological effect of the substances is similar (e.g., each substance affects the same target organ or has a similar effect), it can be considered that the combined effect of the chemicals will be the sum of individual effects. A common example is exposure to several organic solvents.

In this case, ACGIH recommends the following calculation:

If the sum of:

C1/T1 + C2/T2 +….Cn/Tn

is higher than 1, the threshold limit of the mixture is exceeded.

(C is the concentration in the air of the substance and T is the threshold limit)

This formula should not be used for:

- mixtures of substances with toxicological effects are not additive (individual toxicological effects and target organs are different),

- mixtures of substances which inhibit each other's effect,

- substances that may have a synergistic effect,

- carcinogens (exposure to mixtures of carcinogens should be eliminated or as low as possible), and

- complex mixtures (e.g., diesel exhaust).

The threshold limit values apply for 8-hour workday and 40-hour workweek. When working shifts longer than eight hours, the exposure time is increased and the recovery period between exposures is decreased. In these situations, the threshold exposure limit should be so adjusted that, in the end, the peak body burden does not exceed the one that would occur during a normal eight hour shift.

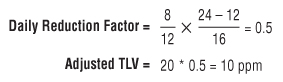

There are numerous mathematical models, some simple and some more complex, that can be used to adjust the TLV for chemical exposure to a different work schedule. ACGIH indicates that the Brief and Scala model is easier to use. This model reduces the TLV by a factor that considers the hours worked daily and the periods of rest between them. There are two reduction factors that can be used to calculate the adjusted TLV: one based on daily exposure, and one based on averaged weekly exposure.

Note: The daily reduction factor does not consider the number of days worked per week (e.g., where workers work 12-hour shifts, 5 days one week and 2 days the next week). The number of days worked in a week is factored in the weekly reduction factor (e.g., where a worker works 9 hours/day, seven days per week).

Both daily and weekly reduction factors should be calculated, and the most stringent result should be considered for use.

ACGIH recommends medical supervision during the initial use of the adjusted TLVs.

For example, the modified TLV-TWA for toluene (TLV-TWA = 20 ppm) for a 12-hr/day 14-day pattern shift (five workdays one week and two workdays the next week) will be:

Where a worker works 9 hours/day, seven days/week, the modified TLV-TWA for toluene may be:

The TLV adj = 16.65 ppm obtained using the daily adjustment formula should be considered as it is more protective.

One of the shortcomings of the Brief and Scala method is that the reduction factor for a certain amount of worked hours is identical for all chemicals regardless of their individual biological half-lives. This assumption may lead to an overestimation of the degree to which the limit should be lowered.

The formula is not applicable for:

- Work schedules with less than seven to eight hours per day or less than 40 hours per week.

- Work schedules that involve 24-hour continuous exposure (e.g., in submarines and space shuttles).

- Certain irritants.

- Fact sheet last revised: 2022-03-25

- Newsletter Signup

What is the PEL and How Does it Work?

By Safety Management Group

OSHA answers that question through what are known as Permissible Exposure Limits (or, more familiarly, PELs). PELs are legal limits for the degree to which workers may be exposed to chemicals and other hazards (such as noise) without suffering harm.

PELs are normally expressed in what are known as time-weighted averages (TWA), which describes the average exposure over a set period. In most cases, the TWA reflects a standard eight-hour shift, based upon a 40-hour workweek. In some cases, the chemical may also have short-term exposure limits (STELs) or ceiling limits. As the terms imply, those are the maximum levels to which workers may be exposed, even for a very short period of time.

When TWAs are used, it’s important to remember that they are averages. It’s entirely possible that a worker may be exposed to significantly higher levels of a chemical for a period of time during the eight hours. Those situations involve another term — the excursion limit — that normally describes situations in which workers are exposed to more than three times but less than five times the TWA PEL for no more than a total of 30 minutes during a shift.

If a worker is exposed to more of the chemical than allowed by the STEL or excursion limit, he is required to be completely removed from the hazard for at least an hour.

Another measurement created by the National Institute for Occupational Safety and Health is a level of a substance that is considered to be immediately dangerous to life or health (IDLH). NIOSH describes IDLH as an exposure “that is likely to cause death or immediate or delayed permanent adverse health effects or prevent escape from such an environment.”

The problem with PELs OSHA is responsible for determining PELs. Shortly after the agency was established in 1970, it set levels for nearly 500 chemicals. Unfortunately, legal disputes about the rulemaking process have kept OSHA from adopting any new PELs since then, and the agency has been unable to update its original PELs to reflect newer scientific data. In fact, OSHA has only been able to update fewer than three dozen of the PELs.

That creates two concerns for workers. First, PELs exist for only about 500 of the thousands of chemicals that may be found in American workplaces. Second, the vast majority of the PELs that do exist are nearly 50 years old. That has led many occupational safety experts to express concerns that the PELs provide inadequate protection of worker health and safety.

How can employers and safety professionals contend with that perceived shortfall? OSHA has suggested that employers use alternative exposure limits developed by other organizations, because those alternative measures generally allow less exposure than the PELs.

RELs, TLVs, and BELs One of the other measures is RELs, or Recommended Exposure Limits, developed by NIOSH. That agency evaluates all of the most current evidence about the chemical’s properties and effects upon workers before issuing RELs. Details of RELs appear in publications such as the well-known NIOSH Pocket Guide to Chemical Hazards.

A private scientific organization known as ACGIH (the American Conference of Governmental Industrial Hygienists) has developed a pair of health-based limits that may be useful to employers, although they should not be approached as legal standards for workplace safety. The first, Threshold Limit Values (TLVs), identifies the airborne concentrations of chemicals to which workers can be exposed on a daily basis without harmful effects. OSHA requires TLVs to be included on safety data sheets for chemicals.

The second measure, Biological Exposure Indices (BEIs), considers how much of the chemical may have been accumulated in the worker’s body, such as what can be detected in blood and urine. However, ACGIH does not believe these measures should be used for standards without considering other risk management-related factors such as technical and economic information.

Key information The NIOSH Pocket Guide provides well-organized information for nearly 700 common chemicals or types of substances that are commonly used on jobsites. It uses a table format to list the name of each chemical or substance, as well as its:

– chemical structure or formula – Chemical Abstracts Service registry number (CAS number) – Registry of Toxic Effects of Chemical Substances number (RTECS number) – U.S. Department of Transportation (DOT) identification and guide numbers – trade names and known synonyms for the chemical or substance – factors for converting measurements – NIOSH Recommended Exposure Limits (RELs), using a time-weighted average concentration – the short-term exposure limit (STEL)

By using the OSHA PEL (when available) as a starting point, and the NIOSH Pocket Guide as a reference, employers should be able to make reasonable decisions about the amount of exposure that’s acceptable on their worksites.

Latest Posts

- Staying Ahead: Tips for Regulatory Compliance and Effective Risk Assessments

- Safety in the Shadow: A Guide to Eclipse Preparedness on Construction Sites

- Safe Travels Under the Eclipse: Navigating Traffic During the 2024 Solar Eclipse

- Applying the Hierarchy of Controls to Different Types of Risks

- Utilizing Risk Matrices for Effective Hazard Evaluation and Prioritization

- Company News

- Construction Safety

- Contractor Management

- Environmental

- Healthcare & Pharm

- Higher Education

- Insights and Assessments

- Manufacturing

- Press Release

Industrial Hygiene in Construction

Entries tagged with “ excursion limit ”..

Fri 12 Oct 2012

Air Monitoring – Multiple samples throughout the day

Posted by admin under ACGIH , Air Monitoring , Chemical Exposure , Exposure , industrial hygienist , Management , PEL (Perm Exp Limit) , TWA Comments Off on Air Monitoring – Multiple samples throughout the day

When measuring by air sampling for a job task, or an employee’s personal exposure, how many samples should you take?

Sometimes it is easier to place one filter cassette (or media) on the employee for the duration of their day.  At the end of the shift, you collect your equipment, mail it to the lab, and they spit out a 8-hour time weighted average (8-hour TWA). This is simple and easy to understand.

However, if you have the time and resources, it is usually beneficial to obtain multiple samples throughout the day. Taking multiple samples allow you to:

- obtain peaks, lows, and anomalies.

- look at: set up & clean up activities (separate from daily tasks)

- measure multiple employees doing the same task (to better capture the job task)

- calculate your own time weighted average

- capture short term exposure levels (STELs), or excursion limits *

- choose appropriate PPE for short duration tasks

- determine if employees are “falsifying” the data (skewing the data high or low)

- reduce filter overloading (in some cases)

There are some reasons NOT to obtain multiple samples:

- collection limit constraints (sometimes the method of sampling does not allow for this type of multiple sampling)

- it can be costly

- it is very time consuming (and nearly impossible, if you have multiple pumps on multiple employees throughout the site)

- difficulty interpreting the data (the math, the inferences, etc)

If you are hiring an industrial hygienist to perform air monitoring, ask about multiple samples. It might be slightly more expensive, but the information and data might be worth the cost.

* ACGIH recommends that if the compound does not have a STEL, all airborne levels should not exceed 3x the 8-hour TWA as an excursion limit.

Tags: air monitoring , excursion limit , exposure assessment , industrial hygiene , safety , sampling , STEL

Book – Coming!!

- "A Safety Professional & Superintendent's Guide to Industrial Hygiene in Construction"....the actual title is not yet decided.

Email subscription

Your email:

- Admin Controls (42)

- Air Monitoring (67)

- Asbestos (29)

- Asphalt (4)

- Behavior Based (15)

- Bio Exposure Index (10)

- Biological Monitoring (19)

- Bloodborne Pathogens (3)

- Building Survey (17)

- Cadmium (3)

- Carbon Monoxide (2)

- Carcinogen (17)

- Chemical Exposure (17)

- Chlorinated Solvent (3)

- Combustible Dust (1)

- Concrete (18)

- confined space (6)

- Drywall (8)

- Engineering Controls (52)

- Exposure (53)

- Fall Protection (7)

- Federal OSHA (33)

- fit testing (9)

- Formaldehyde (5)

- Galvanized welding (2)

- Hazard Communication (50)

- Health & Wellness (4)

- Hearing Conservation (14)

- hearing protection (11)

- Heat Stress (1)

- Hexavalent chromium (12)

- hygienist (9)

- industrial hygienist (47)

- insulation (6)

- Ladders (6)

- lead in gasoline (3)

- Leaded Sheetrock (8)

- Management (82)

- Multi gas meter (3)

- occupational hygiene (26)

- odor thresholds (13)

- Olfactory (7)

- Paper Dust Masks (6)

- PEL (Perm Exp Limit) (30)

- Permit Required (5)

- Personal Protective Equip (PPE) (48)

- Phosgene (1)

- polybrominated diphenyl ether (1)

- Powder Actuated Tool (4)

- Presentation (10)

- Professional Profile (3)

- Proposition 65 (4)

- Radiation (3)

- Respirators (46)

- Return to work (1)

- safety (12)

- Safety Policies (25)

- Safety Programs (40)

- Sandblasting (3)

- Silica (39)

- software (2)

- Spray Booth (1)

- Spray Finishing (3)

- Stainless Steel (7)

- Tool Box Talk (4)

- Training (61)

- Uncategorized (55)

- ventilation (13)

- Welding (19)

- Entries feed

- Comments feed

- WordPress.org

- [Un]Subscribe to Posts

Industrial Hygiene in Construction is powered by WordPress 6.5.2 and delivered to you in 1.090 seconds using 33 queries. Theme: Connections Reloaded v2.1 by Ajay D'Souza . Derived from Connections .

ADVERTISEMENT

- POST a QUESTION or COMMENT about asbestos building material regulations, standards, & codes

This article provides definitions and actual numbers for recommended as well as regulated exposure limits to asbestos as provided by several U.S. agencies including the US EPA, NIOSH, and OSHA, by other countries' governments, and by professional associations such as ACGIH.

We also provide a more comprehensive INDEX to RELATED ARTICLES for this topic, but we recommend that you use the page top or bottom SEARCH BOX as a quick way to find information you need.

Definition of Asbestos Containing Material

In the U.S. and other countries, using the U.S. EPA guidelines, if either TEM or PLM analysis yields a result that the asbestos-suspect material contains greater than 1 percent asbestos , then the material must be considered ACM - "Asbestos-Containing-Material" and thus would merit appropriate protective measures depending on the material's friability, condition and location. - U.S. EPA, ASBESTOS FREQUENTLY ASKED QUESTIONS [PDF] cited in the REFERENCES section of this article.

Really? In the U.S. OSHA regulations and letters clarifying them also state that items or materials that do not contain >1% asbestos are covered to at least some extent by the Construction Asbestos Standard.

That is, in the workplace, OSHA 29 CFR 1926.1101 would apply even if neither asbestos permissible exposure limit (PEL) is exceeded 1.

The standard contains numerous work practice requirements and prohibitions which apply, regardless of the exposure levels.

However, only two of the requirements and three of the prohibitions must be observed in the case of work activities involving installed construction materials that do not contain >1% asbestos. Details from OSHA are given later in this article.

That same US EPA reference and many others also remark that

Asbestos that is in good condition and left undisturbed is unlikely to present a health risk. The risks from asbestos occur when it is damaged or disturbed where asbestos fibers become airborne and can be inhaled.

Managing asbestos in place and maintaining it in good repair is often the best approach.

Illustration above: health data from inhalation exposure to asbestos fibers in air, exposure limits from various sources, provided by the U.S. EPA cited just below. [Click to enlarge any image]

Summary Recommended Asbestos Exposure Limits

Asbestos toxicity or health risk value.

Health risk or RBC numbers are toxicological numbers from animal testing or risk assessment values developed by EPA.

- RBC (Cancer risk-based concentration)--a calculated concentration of a chemical in air to which continuous exposure over a lifetime is estimated to be associated with a risk of contracting cancer not greater than the specified probability (e.g., 1 in 1 million).

- Definition of RBC: Risk Based Concentration

- OSHA PEL --Occupational Safety and Health Administration's permissible exposure limit expressed as an 8-hour time-weighted average; the concentration of a substance to which most workers can be exposed without adverse effect averaged over a normal 8-h workday or a 40-h workweek.

- Definition of PEL : Permissible Exposure Limit: the legal limit (in the United States) for exposure of an employee to a chemical substance or physical agent (such as loud noise or particles of asbestos). PELs are set by OSHA, a U.S. government agency. OSHA PEL numbers are regulatory

- NIOSH REL --National Institute of Occupational Safety and Health's recommended exposure limit; NIOSH-recommended exposure limit for asbestos fibers >5 micrometers in length. Additionally, NIOSH considers asbestos to be a potential occupational carcinogen and recommends that exposures be reduced to the lowest feasible concentration.

- Definition of REL : Recommended Exposure Limit or recommended exposure limit (REL) is an occupational exposure limit that has been recommended by NIOSH the United States National Institute for Occupational Safety and Health to the Occupational Safety and Health Administration (OSHA) for adoption as a permissible exposure limit. NIOSH REL numbers are advisory.

- ACGIH TLV --American Conference of Governmental and Industrial Hygienists' threshold limit value expressed as a time-weighted average; the concentration of a substance to which most workers can be exposed without adverse effects.

- Definition of TLV : Threshold Limit Value of a chemical substance is believed to be a level to which a worker can be exposed day after day for a working lifetime without adverse effects. TLV is a reserved term of the American Conference of Governmental Industrial Hygienists (ACGIH). ACGIH TLV numbers are advisory.

Definition of Asbestos Regulatory Value vs Advisory Value for Asbestos Exposure Limits

References for permissible asbestos exposure limits.

1. Agency for Toxic Substances and Disease Registry (ATSDR). Toxicological Profile for Asbestos. Public Health Service, U.S. Department of Health and Human Services, Atlanta, GA. 2001. http://www.atsdr.cdc.gov/ToxProfiles/tp61.pdf

2. U.S. Environmental Protection Agency. Integrated Risk Information System (IRIS) on Asbestos. National Center for Environmental Assessment, Office of Research and Development, Washington, DC. Last revised 9/26/1988. http://www.epa.gov/iris

3. National Toxicology Program (NTP). Report on Carcinogens, Thirteenth Edition. Research Triangle Park, NC: U.S. Department of Health and Human Services, Public Health Service. 2014. http://ntp.niehs.nih.gov/pubhealth/roc/roc13/

4. International Agency for Research on Cancer (IARC). IARC Monographs on the Evaluation of Carcinogenic Risks to Humans: Arsenic, Metals, Fibres, and Dusts. Volume 100C. World Health Organization, Lyon, France. 2012. https://publications.iarc.fr/ENG/Monographs/vol100C/mono100C-11.pdf

5. National Institute for Occupational Safety and Health (NIOSH). Pocket Guide to Chemical Hazards. U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention. Cincinnati, OH. 2015. http://www.cdc.gov/niosh/npg/

6. Occupational Safety and Health Administration (OSHA). Occupational Safety and Health Standards, Toxic and Hazardous Substances. Code of Federal Regulations. 29 CFR 1910.1000. 1998. https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9 992&p_text_version=FALSE

7. American Conference of Governmental Industrial Hygienists (ACGIH). 2015 TLV's and BEIs. Threshold Limit Values for Chemical Substances and Physical Agents, Biological Exposure Indices. Cincinnati, OH.

OSHA Clarifications on Asbestos Handling & Exposure Regulations in Schools depending on the percentage of asbestos in a tested sample

Reply: Yes, those letters are correct although some requirements of the Construction Asbestos Standard, 29 CFR 1926.1101 were not addressed. 29 CFR 1926.1101 would apply even if neither asbestos permissible exposure limit (PEL) is exceeded1.

The standard contains numerous work practice requirements and prohibitions which apply, regardless of the exposure levels. However, only two of the requirements and three of the prohibitions must be observed in the case of work activities involving installed construction materials that do not contain >1% asbestos.

Those work practice requirements and prohibitions that must be observed regardless of the exposure levels and of the percentage of asbestos in the installed construction materials are:

29 CFR 1926.1101(g)(1)(ii), which requires: wet methods, or wetting agents, to control employee exposures during asbestos handling, mixing, removal, cutting, application, and cleanup, except where employers demonstrate that the use of wet methods is infeasible due to, for example, the creation of electrical hazards, equipment malfunction, and, in roofing, except as provided in paragraph (g)(8)(ii)2 of this section;

29 CFR 1926.1101(g)(1)(iii), which requires: prompt clean-up and disposal of wastes and debris contaminated with asbestos in leak-tight containers except in roofing operations, where the procedures specified in paragraph (g)(8)(ii)3 of this section apply;

29 CFR 1926.1101(g)(3)(ii), which prohibits: compressed air used to remove asbestos, or materials containing asbestos, unless the compressed air is used in conjunction with an enclosed ventilation system designed to capture the dust cloud created by the compressed air; and

29 CFR 1926.1101(g)(3)(iv), which prohibits: employee rotation as a means of reducing employee exposure to asbestos.

There are also some other provisions that apply to work activities involving installed construction materials even where the material does not contain >1% asbestos. However, if neither asbestos PEL is exceeded, only the following few provisions apply:

29 CFR 1926.1101(f)(2)(i), the provision for establishing that neither asbestos PEL is exceeded:

Each employer who has a workplace or work operation covered by this standard shall ensure that a "competent person" conducts an exposure assessment immediately before or at the initiation of the operation to ascertain expected exposures during that operation or workplace.

The assessment must be completed in time to comply with requirements which are triggered by exposure data or the lack of a "negative exposure assessment," and to provide information necessary to assure that all control systems planned are appropriate for that operation and will work properly;

29 CFR 1926.1101(f)(6)(i), a provision covering the observation of monitoring:

The employer shall provide affected employees and their designated representatives an opportunity to observe any monitoring of employee exposure to asbestos conducted in accordance with this section;

29 CFR 1926.1101(f)(5)(i), a provision covering employee notification of monitoring results:

The employer shall notify affected employees of the monitoring results that represent that employee's exposure as soon as possible following receipt of monitoring results;

29 CFR 1926.1101(f)(5)(ii), another provision covering employee notification of monitoring results:

he employer shall notify affected employees of the results of monitoring representing the employee's exposure in writing either individually or by posting at a centrally located place that is accessible to affected employees; and

There are numerous additional provisions of the standard that apply to work activities involving installed construction materials even where the material does not contain >1% asbestos if at least one of the asbestos PELs is exceeded.

Reader Comments, Questions & Answers About The Article Above

Reader q&a - also see recommended articles & faqs.

OPINION: where there is big money and liability involved, it's no surprise to run into a stone wall. It's cheaper for an institution or company to pay lawyers to fight until a plaintiff dies than to engage in a big settlement to cover that person's care and losses.

And to be a bit careful, while at-work exposure could indeed be a source of mesothelioma, it's not the only possible cause.

1920s - 1980s building materials that may have contained asbestos

Also, don't assume that only 1920s building materials contained asbestos. Asbestos was used in thousands of products up into the mid 1980s in the U.S. and still later in some other countries, as explain

at ASBESTOS MATERIAL REGULATIONS .

A few materials (I'll give an example below) can be reliably identified as asbestos-containing-material (ACM) from photos, while others can be reliably identified based on combination of age and appearance (such as asbestos cement board)

Still other asbestos-suspect materials would have had to be tested.

If also in historical records one could obtain photographs of the building interior taken during the time that you worked there, we could at least rule some materials or topics in or out as possible asbestos-containing-material (ACM).

- Floors : For example if we see 9x9 asphalt floor tile, virtual all of that will have contained asbestos, as did much 9x9 vinyl- and some 12x12- vinyl floor tile and some sheet flooring installed any time up to about 1986.

- Ceilings: Ceiling tiles are more-difficult to classify from photos alone as there were some brands that never used asbestos.

- Paints : Acoustic paints, textured paints, popcorn ceiling paint, and some fire-resistant materials certainly made wide use of asbestos.

- Insulation : Some pipe insulation such as on heating pipes, made of corrugated asbestos paper, is an example of a material that can be identified as virtually certain to have used asbestos as there were no non-asbestos look-alikes. See ASBESTOS PIPE INSULATION

- Window putty and other maintenance materials, sealants, etc. may have contained asbestos, again with a level of hazard that varies significantly depending on the material's location, condition, and disturbance.

at ASBESTOS PHOTO GUIDE to MATERIALS

and a near-exhaustive list

at ASBESTOS PRODUCING COMPANIES & TRUSTS

Exposure to asbestos in the building where you worked

The EPA has concluded that the presence of asbestos materials in the workplace can be a hazard to workers. But it's worth a cautious look and one should avoid panic - which itself is a health hazard.

Non-friable materials in good condition, such as floor tiles, even if they contained asbestos, would not be likely to explain asbestos-related illness unless they were damaged or demolished making a dusty mess without proper protective measures.

Even friable materials in good condition, such as asbestos pipe insulation, would not explain a high level of airborne asbestos dust in a building unless damaged similarly as I just noted.

If asbestos removal work or "abatements" were conducted improperly that could indeed create a hazard for building occupants.

Building conditions such as mechanical systems that circulate air, building maintenance and repair work (not just asbestos removal projects) and similar activities could also affect the condition of or cause damage to ACM.

Who investigates the history of asbestos in the building where you worked?

If your attorney is simply telling you to do the work then my opinion of that counsel is rather low. Rather than argue with such I'd find someone else.

I'd expect the attorney to also determine what legal notification of asbestos abatement would have been required (eg by OSHA and or the US EPA) to be provided to people working in the building during such activity.

If your workplace was in the United States, this link will illustrate what the US EPA and OSHA have to say

about WORKER NOTIFICATION of PRESENCE of ASBESTOS or ASBESTOS REMEDIATION - Building owners should inform occupants about the presence of ACM

On 2020-07-09 by (mod)- EPA recently concluded that current uses of asbestos in the U.S. pose a significant risk to workers and bystanders

Re-posting: The U.S. EPA recently concluded that current uses of asbestos in the U.S. pose a significant risk to workers and bystanders supporting the need for a ban on importing, exporting, manufacturing, and using all asbestos-containing materials. In March, EPA released its Draft Risk Evaluation for Asbestos under the Toxic Substances Control Act (TSCA) review of the current uses of asbestos in the U.S.

This action followed the prioritization of asbestos as one of the top 10 toxic substances to be reviewed under this new provision. As envisioned, this is a first step in implementing additional regulations or controls. However, the draft document has multiple deficiencies and is far from comprehensive in failing to account for all forms of asbestos, all uses of asbestos, and asbestos that is present in millions of homes, buildings and other structures. EPA indicated that they plan to address legacy uses of asbestos and waste disposal in a separate document. Source: Occupational Knowledge International Newsletter, July 2020 Website: www.okinternational.org

Continue reading at ASBESTOS MATERIAL REGULATIONS or

- ASBESTOS DISPOSAL REGULATIONS

- ASBESTOS IDENTIFICATION IN BUILDINGS - home

- HISTORY & DATES OF ASBESTOS CONTAINING MATERIAL BANS & REGULATIONS

- COUNTRIES THAT BAN OR REGULATE THE USE OR PRODUCTION OF ASBESTOS

- DEFINITION OF & HANDLING RULES FOR SUSPECT ASBESTOS CONTAINING MATERIALS (SACM)

- DEFINITION OF & HANDLING RULES FOR PRESUMED ASBESTOS CONTAINING MATERIAL (PACM)

- ASBESTOS EXPOSURE LIMITS (PELS) TLVs RBCs & RELs

- MOST COMMON OCCURRENCES OF ASBESTOS IN BUILDING

- WORKER NOTIFICATION of PRESENCE of ASBESTOS or ASBESTOS REMEDIATION

- ASBESTOS REMOVAL, WETTING GUIDELINES

- ASBESTOS ROOF MATERIALS

- CANADA ASBESTOS REGULATIONS

- U.K. ASBESTOS REGULATIONS

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia