Truck Drivers

In July 2023, DMV will introduce a new testing program for commercial truck drivers providing modernized protocols and helpful tools. See the CDL Modernization Guides for VI and BCS Tests for more information.

Driving a truck is no easy task, and very different from driving a regular vehicle. Keep reading for tips and information to help you drive with care, keep your vehicle in good condition, and ensure your cargo arrives safely at its destination.

Becoming a Commercial Driver Commercial Driver’s Handbook – English Commercial Driver’s Handbook – Spanish Commercial Driver Practice Test #1 Commercial Driver Practice Test #2 Vehicle Inspection Checklist CDL Modernization FAQs

Your License and Registration

You need a commercial driver’s license (CDL) to drive a truck. This section includes information about how to get a CDL, how license classes can affect the kind of trucks you can drive, how you can register your truck and trailers, and additional programs you might be eligible for.

Your CDL allows you to drive various kinds of trucks.

You must have a CDL to operate:

- Any single vehicle with a gross vehicle weight rating (GVWR) of 26,001 pounds or more.

- Any single vehicle with a GVWR less than 26,000 pounds which is designed, used, or maintained to transport more than 10 passengers (including the driver).

- A combination vehicle with a gross combination weight rating (GCWR) of 26,001 or more pounds, provided the GVWR of the vehicle(s) being towed is in excess of 10,000 pounds.

- Any vehicle that tows any vehicle with a GVWR of 10,001 pounds or more.

- Any vehicle that tows more than 1 vehicle or a trailer bus.

- Any size vehicle which requires hazardous material (HazMat) placards or carries material listed as a select agent or toxin in Code of Federal Regulations (CFR), Title 42, Part 73.

- Transports hazardous wastes ( California Health and Safety Code (CHSC) §§25115 and 25117).

Federal regulations through the Department of Homeland Security require a background check and fingerprinting for the hazardous materials endorsement.

To apply for a CDL, you:

- Must be 18 years of age.

- The DL is used to validate the CLP (CFR, Title 49 §§383.5, 383.25).

- May drive for hire within California if you are 18 years of age or older and you do not engage in interstate commerce activities.

- Must be at least 21 years old to drive a commercial motor vehicle (CMV) engaged in interstate commerce or to transport hazardous materials or wastes (intrastate or interstate commerce) ( California Vehicle Code [CVC] §12515).

Find out what you need to apply for a CDL, how much it will cost, and what special instructions you may need on the CDL page.

While your CDL allows you to drive a truck, the commercial class of your license (A, B, or C) determines the type and size of vehicle you can drive.

- Commercial Class A You can drive any legal combination of vehicles with a gross combination weight rating (GCWR) of 26,001 pounds or more, provided the GVWR of the vehicle(s) being towed is in more than 10,001 pounds.

- Commercial Class B You can drive any single vehicle with a GVWR of more than 26,000 pounds, or any vehicle towing a vehicle weighing no more than 10,000 pounds GVWR, or a 3-axle vehicle weighing over 6,000 pounds.

- Hazardous materials (HazMat)

- Passenger vehicle (PV)

- Tank vehicle (TV)

- All trailers are registered under the permanent trailer identification (PTI) program.

- Fifth-wheel trailers and camp trailers are registered as a trailer coach (not PTI) or camp trailer (PTI) based on the length, width, and size.

- However, you may want to register a tow/auxiliary dolly as PTI if you will tow it out of state, because other states’ registration requirements vary.

Any person or business entity that is paid to transport property in their motor vehicle regardless of vehicle size, type, or weight needs an MCP . Entities that transport property for compensation are deemed a ‘For-Hire’ motor carrier. (Example: If you are a courier service and your vehicle is a motorcycle, you are required to have an MCP.)

Additionally, you need an MCP if you operate:

- A CMV with a GVWR of 10,001 pounds or more, either for commercial or private use, hauling your own goods or property.

- Any vehicle or combination of vehicles transporting HazMat.

- A combination of motor truck and trailer, semitrailers, pole or pipe dollies, auxiliary dollies, and logging dollies, that exceeds forty feet in length when coupled together. For the purpose of an MCP, a “trailer” excludes camp trailers, utility trailers, and trailer coaches.

- Any motor vehicle or combination of motor vehicle and trailer for which the operation requires a CDL, except vehicle combinations including camp trailers, utility trailers, and trailer coaches.

To learn more about the Motor Carrier Program, including more information about who should apply and what the application process involves, in the Motor Carrier Services section.

International Registration Plan (IRP)

If you carry cargo among U.S. states and Canadian provinces, you might be eligible for the International Registration Plan (IRP). IRP member jurisdictions collect registration fees from their ‘home based’ interstate trucking companies on behalf of each member jurisdiction in which the companies operate and must register.

To learn more about how the IRP works and what vehicles qualify, visit the IRP landing page.

DMV is making it easier for military personnel trained in the operation of heavy vehicles to obtain a civilian CDL.

The Troops to Trucks program allows DMV to waive the CDL driving test for qualified military service members who are (or were) employed within the last year and in a military position requiring the operation of a military motor vehicle equivalent to a commercial motor vehicle on public roads and highways. Waiving the driving test requirement streamlines the CDL application process for service people and eliminates the need to provide a commercial motor vehicle (CMV).

The driving test will not be waived for a school bus and/or passenger endorsement.

Applicants must complete a Commercial Driver’s License application .

To meet the federal regulation requirements, an applicant must certify that, during the two-year period immediately prior to applying for a CDL, they have not had:

- More than one license (except for a military license).

- Any license suspended, revoked, or cancelled.

- Any alcohol or drug related offenses.

- Leaving the scene of an accident.

- Commission of a felony involving the use of a motor vehicle.

- Driving a CMV while your CDL is suspended, revoked, disqualified, or cancelled.

- Causing a fatality through the negligent operation of a CMV, including , but not limited to, manslaughter, homicide by motor vehicle, and negligent homicide.

- Use of a motor vehicle in a felony involving manufacturing, distribution, or dispensing of a controlled substance.

- Violation of state or local law relating to motor vehicle traffic control (other than a parking violation) arising in connection with any traffic accident and has no record of an accident in which they were at fault.

- Speeding in excess of 15 mph

- Reckless driving

- Making improper or erratic lane changes

- Following the vehicle ahead to closely

- A violation arising in connection with a fatal accident

- Driving a CMV without obtaining a CDL

- Driving a CMV without a CDL in possession

- Driving a CMV without the proper class or endorsement

- Violating a state or local law or ordinance prohibiting texting while driving

- Violating a state or local law or ordinance prohibiting the use of a hand held telephone while driving

An applicant must provide evidence and certify that they:

- Are regularly employed or were regularly employed within the last year in a military position requiring operation of a CMV.

- Were exempted from the CDL requirements in §383.3(c).

- While serving in the military, were operating a CMV equivalent to a civilian CMV, for at least 2 years immediately preceding discharge from the military.

Applicants can make these certifications by filling out the following forms:

- Commercial Military Waiver (DL 965)

To complete the application, applicants must submit the following documents to a DMV field office :

- Acceptable birth date / legal presence document

- Social Security Card, Medicare Card, or United States (U.S.) Armed Forces ID card

- DD 214 – Certificate of Release or Discharge from Active Duty (Veterans)

Tests and Inspections

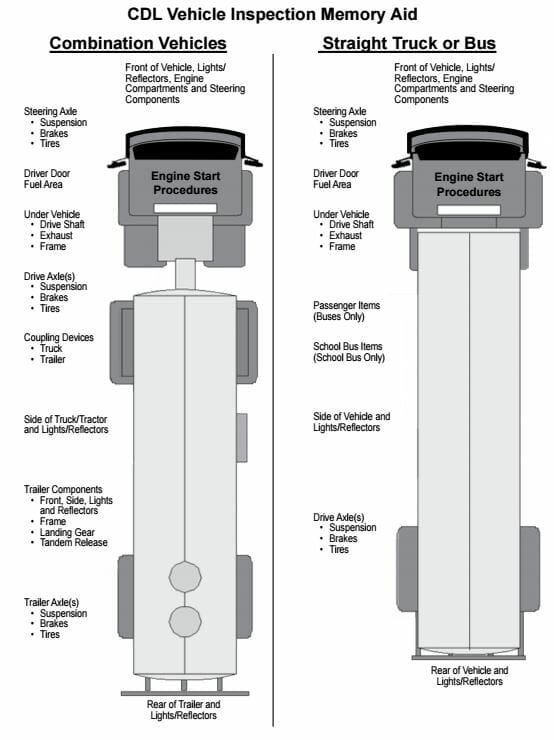

The vehicle inspection test is a skills test to see if you can identify which features and equipment on the test vehicle should be inspected before operating the vehicle. The entire vehicle inspection test must be conducted in the English language, as stated in CFR, Title 49 §§391.11(b)(2) and 383.133(c)(5).

During the vehicle inspection test, you must show that the vehicle is safe to drive. You will have to walk around the vehicle and point to or touch each item and explain to the examiner what you are checking and why. If any of these items do not work, the skills and road portions of the test will be postponed.

If you are applying for a Class B or Class C CDL, you will be required to perform a vehicle inspection in the vehicle you brought with you for testing. Tests include an engine start and in-cab inspection. Then, your test may require an inspection of the entire vehicle or only a portion of the vehicle which your CDL examiner will explain to you. You will also have to inspect any special features of your vehicle (for example, school or transit bus).

You can learn more about inspection tests and review a detailed checklist of inspection items in the Driver Education section.

The basic control skills text evaluates your skill in controlling your truck and judging its position and relation to other objects while maneuvering through various exercises. The judgement and skill required for each exercise can apply to many different driving situations.

If you refuse or fail to complete a basic control skills test exercise as instructed, this may result in an automatic failure.

You will be tested on a subset of the following exercises:

- Straight line backing.

- Offset back/right.

- Offset back/left.

- Parallel park (driver side).

- Parallel park (conventional).

- Alley dock.

Your performance on the basic control skills test is scored by the examiner. You will be scored for the following:

Encroachments The examiner will score the number of times you touch or cross over an exercise boundary line or cone with any portion of your vehicle. Each encroachment will count as an error.

Pull Ups When a driver stops and pulls forward to clear an encroachment or to get a better position, it is scored as a “pull up.” Stopping without changing direction does not count as a pull up. You will not be penalized for initial pull ups. However, an excessive number of pull ups will count as errors.

Outside Vehicle Observations (Looks) You may be permitted to safely stop and exit the vehicle to check the external position of your vehicle (look). When doing so, you must place the vehicle in neutral and set the parking brake(s). Then, when exiting the vehicle, you must do so safely by facing the vehicle and maintaining 3 points of contact with the vehicle at all times (when exiting a bus, maintain a firm grasp on the hand rail at all times). If you do not safely secure the vehicle or safely exit the vehicle, it may result in an automatic failure of the basic control skills test.

The maximum number of times that you may look to check the position of your vehicle is 2, except for the straight line backing exercise, which allows only 1 look. Each time you open the door, move from a seated position where in physical control of the vehicle or on a bus walk to the back of a bus to get a better view, it is scored as a “look.”

Final Position It is important that you finish each exercise exactly as the examiner has instructed you. If you do not maneuver the vehicle into its final position as described by the examiner, you will be penalized and could fail the basic skills test.

- Preparing for Your Commercial Driver’s Test (video)

In July 2023, the DMV will introduce a new testing program with modernized protocols for commercial truck drivers.

- Commercial Driver Information

- Modernization Supplement to CDL Handbook

- Vehicle Inspection Checklist

Q: Will jurisdictions need to change to the modernized version of the test? A: No. The current version (2014/2017) of the test system will remain valid. Jurisdictions can offer the current version, the modernized version or both. Both are FMCSA approved test systems.

Q: Can a jurisdiction do parts from both tests? A: Only one complete version of a test system can be offered. Test systems cannot be mixed or combined.

Q: When the new manual(s) comes out, will it have both the current and the modernized test systems? A: Yes. California will incorporate the addendum into the manuals.

Q: Is the modernized test easier? A: No. A third-party research entity evaluated the modernized test, it was found to be as effective as the current version in assessing the abilities of a novice commercial driver. Much of the modernized test is the same as the current version.

Q: For the Modernized Basic Control Skills (BCS) test, what is the area required? A: The BCS testing area is a minimum of 260 ft. long by 40 ft. wide to accommodate most combination vehicles with trailers up to 53 ft. in length. Longer combination vehicles will require additional length.

Q: Are there time restrictions for finishing Vehicle Inspection (VI) and BCS? A: No. Neither AAMVA versions stipulates a time restriction, time restrictions are up to the jurisdictions.

Q: Does driver still need to sound horn at end of each maneuver? A: Yes. They must still set their parking brake, shift to neutral and sound the horn.

Q: What is the passing score for VI? A: The maximum number of incorrect responses varies depending upon the vehicle type and configuration.

Q: For lighting, what does an applicant need to do to pass? A: The criteria for all lighting (e.g., lighting indicators, lights operation) is contained in the CDL addendum.

Q: Is the VI scoring different? A: The VI scoring is very similar, rather than adding up to the number correct, add the number missed to determine the applicant’s score. Making it easier to total the points and determine pass/fail.

Q: Was there a time difference needed to conduct the new VI? A: New Hampshire reported longer test times during initial implementation, but eventually test times were equal to or less than the current randomized test once applicants became accustomed to the modernized VI.

Q: Will CSTIMS have the modernized test? A: Yes. It is currently in progress.

Q: How was the modernized VI checklist developed? A: The modernized VI test and driver checklists more closely align with industry practices and focuses on safety critical items.

Q: To get credit for a component on the VI, will the applicant need to provide a rationale? A: No. Providing the rationale is not required. The applicant needs to name, touch or point to the item(s), and fully explain what they are inspecting each safety critical item for. The process is the same as the current test.

Q: Can applicants use a check list for the VI? A: Yes. AAMVA has developed checklist(s) for applicant use. Applicants will need to use the checklist to realize any time savings.

Q: Is the modernized vehicle inspection easier? A: No. It is a bit shorter but equal in level of difficulty to the current version.

Q: Will the new electric vehicles/autonomous vehicles be held to the same testing standards? A: Yes. The driver/vehicle will still be held to the same testing standards. The existing CDL VI test provides instructions regarding how to handle situations where equipment on a Commercial vehicle that is to be inspected does not exist. In those situations, the applicant is to be given credit for missing items. The electric and autonomous vehicles would be handled the same way. The applicant would receive credit for any inspectable item the is not on the electric or autonomous vehicle.

Q. Will a new CDL applicant be tested on the current 2005 test model? A: It depends on which CDL site location the CDL applicant goes to take the test. CA DMV will be converting 22 out of 25 CDL sites to the modernized testing model.

Q. When renewing a CDL, will the applicant be tested on the current 2005 test model or the modernized test model? A: It depends on which CDL site location the CDL applicant goes to take the test. CA DMV will be converting 22 out of 25 CDL sites to the modernized testing model. This applies to applicants requiring a classification upgrade or adding an endorsement requiring CDL skills testing.

Download the CDL Modernization FAQs .

To pass the road test portion of the CDL driving performance evaluation (DPE), you must make no more than 30 errors and no critical driving errors, which will result in an automatic failure. The entire road test must be conducted in the English language, according to CFR, Title 49 §391.11(b)(2) and 383.133(c)(5).

The road test requires you to drive over a test route that has a variety of traffic situations. At all times during the test, you must drive in a safe and responsible manner and:

- Wear your safety belt.

- Obey all traffic signs, signals, and laws.

- Complete the test without an accident or moving violation.

During the driving test, the examiner scores you on specific driving maneuvers as well as on your general driving behavior. The examiner will give you directions, so you will have plenty of time to do what they have asked.

You will not be asked to drive in an unsafe manner.

If your test route does not have certain traffic situations, you may be asked to simulate a traffic situation. You will do this by telling the examiner what you would do if you were in that traffic situation.

Remember : You are allowed a total of 3 attempts to pass the vehicle inspection, basic control skills, and road tests.

You will be tested on:

- Turns (right/left)

- Intersections

- Urban business

- Lane changes

- Expressway/highway

- Stop/starts

- Railroad crossings

- Bridges/overpasses/signs

- School bus – student discharge

- General driving behaviors (clutch usage, gear usage, brake usage, lane usage)

- Regular traffic checks

- Use of turn signals

A driver must be tested in a truck or bus (as those terms are defined in CFR, Title 49, §390.5), or other single unit vehicle with a GVWR of 26,001 or more, to satisfy the skills testing requirements for a Class B CDL.

Truck Driver Safety

It is important to stay safe on the road, especially when your days are long and you are trying to meet deadlines. Here are some safety tips to help you stay alert and manage difficult situations.

A vehicle inspection will help you find problems that could cause an accident or breakdown. Vehicle inspections should be done routinely before operating the vehicle.

Federal and state laws require that drivers inspect their vehicles, and federal and state inspectors may also randomly ask to inspect your vehicle. If they judge the vehicle to be unsafe, they will put it “out of service” until it is fixed, and you will not be able to drive it.

For safety during a trip, you should:

- Watch gauges for signs of trouble.

- Use your senses to check for problems (look, listen, smell, feel).

Check critical items when you stop:

- Tires, wheels, and rims.

- Lights and reflectors.

- Brake and electrical connections to trailer.

- Trailer coupling devices.

- Cargo securement devices.

You can review a detailed checklist of inspection items along with more information on how to perform inspections in the Driver Education section.

To drive a vehicle safely, you must be able to control its speed and direction. Safe operation of a commercial vehicle requires skill in:

- Accelerating

- Backing safely

Fasten your seatbelt when on the road. Apply the parking brake when you leave your vehicle.

Steering Hold the steering wheel firmly with both hands. Your hands should be on opposite sides of the wheel. If you hit a curb or a pothole (chuckhole), the wheel could pull away from your hands unless you have a firm hold.

Stopping Push the brake pedal down gradually. The amount of brake pressure you need to stop the vehicle will depend on the speed of the vehicle and how quickly you need to stop. Control the pressure so the vehicle comes to a smooth, safe stop. If you have a manual transmission, push the clutch in when the engine is close to idle.

Backing Up Safely Because you cannot see everything behind your vehicle, backing is always dangerous. Avoid backing whenever you can. When you park, try to park so you will be able to pull forward when you leave. When you have to back up, here are a few simple safety rules:

- Start in the proper position.

- Look at your path.

- Use the mirrors on both sides.

- Back slowly.

- Back and turn toward the driver’s side whenever possible.

- Use a helper whenever possible.

Backing Up with a Trailer When backing up a trailer, turn the steering wheel in the opposite direction. Once the trailer starts to turn, you must turn the wheel the other way to follow the trailer.

- Back up in a straight line. If you must back on a curved path, back toward the driver’s side so you can see. Back up slowly so you can make corrections before you get too far off course.

- Correct Drift Immediately . As soon as you see the trailer getting off the proper path, correct it by turning the steering wheel in the direction of the drift.

- Pull Forward . When backing, make pull-ups to reposition your vehicle when needed.

Shifting gears using double clutching requires practice. If you remain too long in neutral, you may have difficulty putting the vehicle into the next gear. If so, do not try to force it. Return to neutral, release the clutch, increase the engine speed to match the road speed, and try again.

Make sure you know the basic method for shifting up . Most heavy vehicles with manual transmissions require double clutching to change gears.

- Multi-speed rear axles and auxiliary transmissions are used on many vehicles to provide extra gears. You usually control them by a selector knob or switch on the gearshift lever of the main transmission. There are many different shift patterns. Learn the right way to shift gears in the vehicle you will drive.

- Some vehicles have automatic transmissions. You can select a low range to get greater engine braking when going down grades. The lower ranges prevent the transmission from shifting up beyond the selected gear (unless the governor rpm is exceeded). It is very important to use this braking effect when going down grades.

- Some vehicles have “retarders.” Retarders help slow a vehicle, reducing the need for using your brakes. They reduce brake wear and give you another way to slow down. Because these devices can be noisy, be sure you know where their use is permitted.

To be a safe driver you need to know what is going on all around your vehicle. Whether you are seeing what’s ahead of you or monitoring what is going on to the sides and rear of your vehicle, here are some tips to help keep you alert and safe.

- Make sure you always look far ahead, because stopping or changing lanes can take a lot of distance. Most good drivers look at least 12 to 15 seconds ahead. That means looking ahead the distance you will travel in 12 to 15 seconds.

- Always look for traffic coming onto the highway, shifting into your lane, or turning off the main road.

- Be sure to look for hills and curves, because you might have to slow down or change lanes.

- Pay attention to traffic signals and signs, because they may alert you to changing conditions where you may have to adjust your speed.

- Check your mirrors regularly and ensure they are properly adjusted.

- Make sure you can see the vehicles on either side of you and to the back of you. Watch for overtaking vehicles that might be hidden in your blind spot.

Communicating Other drivers cannot know what you are going to do until you tell them.

Signaling what you intend to do is important for safety. Here are some general rules for signaling.

- Signal early — Signal well before you turn. It is the best way to keep others from trying to pass you.

- Signal continuously — You need both hands on the wheel to turn safely. Do not cancel the signal until you have completed the turn.

- Cancel your signal — Do not forget to turn off your turn signal after you have turned (if you do not have self-canceling signals).

Other drivers may not notice your vehicle even when it is in plain sight. To help prevent accidents, let them know you are there. You can communicate your presence by tapping your horn:

- When passing vehicles, pedestrians, or bicyclists.

- When it is difficult to see in changing weather conditions or at daytime/night time.

- When you are parked at the ride of the road. Be sure to turn on your 4-way emergency flashers.

Driving too fast is a major cause of fatal accidents. You must adjust your speed depending on driving conditions. These include traction, curves, visibility, traffic, and hills.

- Stopping distance helps you estimate the distance ahead of you from the time when you begin braking until the time when you are able to come to a full stop. The faster you drive, the greater the impact or striking power of your vehicle and the longer stopping distance you will need. Also, the heavier your vehicle is, the harder the brakes must work to bring you to a full stop.

- Match your speed to the road surface. Make sure you always maintain traction, which is friction between the tires and the road. Certain road conditions reduce traction and call for lower speeds.

- Slow to a safe speed before you enter a curve. Braking in a curve is dangerous because it is easier to lock the wheels and cause a skid. Make sure you slow down as needed and do not ever exceed the posted speed limit for the curve. Put your vehicle in a gear that will let you accelerate slightly in the curve.

- Drive at the speed of the traffic, if you can do so without going at an illegal or unsafe speed. If you go faster than the speed of other traffic, you will have to keep passing other vehicles. This increases the chance of an accident. Moving with the flow of traffic is safer and easier.

- Watch your vehicle’s speed on downgrades. Gravity will cause your speed to increase on downgrades, so always follow maximum safe speed recommendations.

- Observe the posted speed limits at all times when approaching and driving through work zones. Speeding traffic is the number one cause of injury and death in roadway work zones.

- Do not overtake or pass another vehicle which is moving at less than 20 mph on a grade unless you can pass that vehicle at at least 10 mph faster than it is traveling.

You need to manage the space around your vehicle to make sure you have space to maneuver when something goes wrong. While this is true for all drivers, it is very important for large vehicles. They take up more space and require more space for stopping and turning.

- Space ahead – How much space should you keep in front of you? One good rule says you need at least 1 second for each 10 feet of vehicle length at speeds below 40 mph. At greater speeds, you must add 1 second for safety.

- Space behind – You cannot stop others from following you too closely, but you can make sure you stay to the right of the road, avoid quick changes, increase your following distance, and slow down in dangerous conditions.

- Space to the sides – Commercial vehicles are often wide and take up most of a lane. Safe drivers will manage what little space they have. You can do this by keeping your vehicle centered in your lane, and avoid driving alongside others.

- Space overhead – Hitting overhead objects is a danger. Make sure you always have overhead clearance. If you doubt you have safe space to pass under an object, go slowly. If you are not sure you can make it, take another route. Warnings are often posted on low bridges or underpasses, but sometimes they are not.

- Space below – Many drivers forget about the space under their vehicles. This space can be very small when a vehicle is heavily loaded. This is often a problem on dirt roads and in unpaved yards. Do not take a chance on getting hung up. Drainage channels across roads can cause the ends of some vehicles to drag. Cross such depressions carefully.

- Space for turns – The space around a truck or bus is important in turns. Large vehicles can hit other vehicles or objects during turns because of wide turning and off-tracking. Turn slowly to give you more time to avoid problems and watch out for vehicles coming toward you.

Distracted driving can describe anything that takes your attention away from driving. Whenever you are driving a vehicle and your full attention is not on the road, you are putting yourself, your passengers, other vehicles, and pedestrians in danger. Distracted driving can cause accidents, resulting in property damage, injury, or even death.

There are many causes of distractions, all with the potential to increase risk.

- Physical distractions – something that causes you to take your hands off the wheel or your eyes off the road, such as reaching for an object or checking your GPS.

- Mental distractions – activities that take your mind away from the road, such as engaging in conversation with a passenger or thinking about something that happened during the day.

- Both physical and mental distractions – together, these distractions form an even greater chance that an accident could happen. Examples include talking on a mobile phone, or sending/reading text messages.

CFR, Title 49, Part 383, 384, 390, 391 and 392 and the Hazardous Materials Regulations (HMR) restricts the use of hand-held mobile telephones by drivers of CMVs.

Your goal should be to eliminate all in-vehicle distractions before driving begins. You can do this by:

- Assessing all potential in-vehicle distractions before driving.

- Developing a preventative plan to reduce/eliminate possible distractions.

- Expecting distractions to occur and being aware.

- Discussing possible scenarios before getting behind the wheel.

Based on the assessment of potential distractions, you can develop a preventative plan to help you stay focused and attentive.

When you encounter something unexpected on the road, it is tempting to react quickly or to overcompensate in your reaction to a hazard. Here are some safe ways to react to driving emergencies that will help you remain in control of your rig.

Steering to avoid accidents – Stopping is not always the safest thing to do in an emergency. When you do not have enough room to stop, you may have to steer away from what is ahead. Remember, you can almost always turn to miss an obstacle more quickly than you can stop. However, top-heavy vehicles and tractors with multiple trailers may flip over.

Stop quickly and safely – You should brake in a way that will keep your vehicle in a straight line and allow you to turn if it becomes necessary. You can use the “controlled braking” method or the “stab braking” method. Do not jam on the brakes.

Brake failure – Brakes kept in good condition rarely fail. Most hydraulic brake failures occur for one of 2 reasons:

- Loss of hydraulic pressure – When the system will not build up pressure, the brake pedal will feel spongy or go to the floor.

- Brake fade on long hills – Going slow enough and braking properly will almost always prevent brake failure on long downgrades. Once the brakes have failed, however, you are going to have to look outside your vehicle for something to stop it. Your best hope is an escape ramp. If there is one, there will be signs telling you about it. Use it.

Tire failure – Tire failure, such as blowing a tire, can happen at any time on the road, so you should be aware of the telltale signs and react accordingly. Signs of a tire failure include:

- A loud sound (loud bang).

- Sensing vibration (if the vehicle thumps or vibrates heavily).

- Steering feels heavy. The best way to respond in this situation is to hold the steering wheel firmly, stay off the brake, come to a full stop, and check your tires.

When you brake hard on slippery surfaces in a vehicle without ABS, your wheels may lock up. When your wheels lock up, you lose steering control and you may skid, jackknife, or even spin the vehicle.

ABS helps you avoid wheel lock up and maintain control. You may or may not be able to stop faster with ABS, but you should be able to steer around an obstacle while braking, and avoid skids caused by over braking.

- Sensors detect potential wheel lock up. An electronic control unit (ECU) will then decrease brake pressure to avoid wheel lockup.

- Brake pressure is adjusted to provide the maximum braking without danger of lockup.

- ABS works far faster than the driver can respond to potential wheel lockup. At all other times the brake system will operate normally.

The Department of Transportation (DOT) requires that ABS be on:

- Truck tractors with air brakes built on or after March 1, 1997.

- Other air brake vehicles, (trucks, buses, trailers, and converter dollies) built on or after March 1, 1998.

- Hydraulically braked trucks and buses with a GVWR of 10,000 pounds or more built on or after March 1, 1999.

- Many commercial vehicles built before these dates have been voluntarily equipped with ABS.

All drivers should know something about HazMat. You must be able to recognize hazardous cargo, and know whether or not you can haul it without having a HazMat endorsement on your CDL.

Note: If you apply for an original or renewal HazMat endorsement, you must undergo a Transportation Security Administration (TSA) federal security threat assessment (background records check). For a list of TSA agent sites, go online at universalenroll.dhs.gov or call 1-855-347-8371.

Learn more about Federal Hazardous Materials Requirements .

Placards and Identification (ID) Numbers Placards warn others of hazardous materials. Placarded vehicles must have 4 identical placards clearly placed on the vehicle (front, rear, left, right).

- ID numbers are 4-digit codes used by first responders to identify hazardous materials. An ID number may be used to identify more than one chemical on shipping papers. The ID number will be preceded by the letters “NA” or “UN.” The U.S. DOT Emergency Response Guidebook (ERG) lists the chemicals and the ID numbers assigned to them.

- Not all vehicles carrying hazardous materials need to have placards. If you do not know if your vehicle needs placards, ask your employer. Never drive a vehicle needing placards unless you have the HazMat endorsement. To do so is a crime. When stopped, you will be cited and you will not be allowed to drive your truck. It will cost you time and money. A failure to placard when needed may risk your life and others if you have an accident. Emergency help will not know of your hazardous cargo.

Changing Driving Conditions

As a truck driver, you need to be prepared to handle a variety of changing road conditions when you’re driving a long haul. From nighttime driving to fog, snow, and extreme heat, there are many difficult and potentially dangerous conditions to prepare for so you can adapt and react accordingly.

You are at greater risk when you drive at night. Drivers cannot see hazards as quickly as in daylight, so they have less time to respond. Drivers caught by surprise are less able to avoid an accident. Driving at night can also lead to fatigue and a lack of alertness, which raises your risk of getting into an accident.

Poor Lighting In the daytime there is usually enough light to see well. This is not true at night. Some areas may have bright street lights, but many areas will have poor lighting. On most roads, you will probably have to depend entirely on your headlights. Be sure to drive more slowly when lighting is poor or confusing.

Your Vision Because seeing well is so critical to safe driving, you should have your eyes checked regularly by an eye specialist. You may never know you have poor vision unless your eyes are tested. If you need to wear glasses or contact lenses for driving, remember to:

- Always wear them when driving, even if driving short distances. If your DL says corrective lenses are required, it is illegal to move a vehicle without using corrective lenses.

- Keep an extra set of corrective lenses in your vehicle. If your normal corrective lenses are broken or lost, you can use the spare lenses to drive safely.

- Avoid using dark or tinted corrective lenses at night, even if you think they help with glare. Tinted lenses cut down the light that you need to see clearly under night driving conditions.

Glare Drivers can be blinded for a short time by bright lights, and it can take several seconds to recover from glare. Even 2 seconds of glare blindness can be dangerous. A vehicle going 55 mph will travel more than half the distance of a football field during that time.

Fatigue and Lack of Alertness Fatigue is physical or mental tiredness that can be caused by physical or mental strain, repetitive tasks, illness, or lack of sleep. Just like alcohol and drugs, it impairs your vision and judgment.

Fatigue causes errors related to speed and distance, increases your risk of being in an accident, causes you to not see and react to hazards as quickly, and affects your ability to make critical decisions. When you are fatigued, you could fall asleep behind the wheel and crash, injuring or killing yourself or others.

However, many people cannot tell if or when they are about to fall asleep. Here are some signs that should tell you to stop and rest:

- Difficulty focusing, frequent blinking, or heavy eyelids.

- Yawning repeatedly or rubbing eyes.

- Daydreaming, wandering, or disconnected thoughts.

- Trouble remembering the last few miles driven.

- Missing exits or traffic signs.

- Trouble keeping head up.

- Drifting from your lane, following too closely, or hitting a shoulder rumble strip.

- Feeling restless and irritable.

When you are tired, trying to “push on” is far more dangerous than most drivers realize. If you notice any signs of fatigue, stop driving and go to sleep for the night or take a 15 – 20 minute nap. Do not continue driving while fatigued.

Night Driving Procedures

- Pre-trip procedures – Make sure you are rested and alert. If you are drowsy, sleep before you drive! Even a nap can save your life or the lives of others. If you wear eyeglasses, make sure they are clean and unscratched. Do not wear sunglasses at night. Do a complete vehicle inspection of your vehicle. Pay attention to checking all lights and reflectors, and cleaning those you can reach.

- Avoid blinding others – Glare from your headlights can cause problems for drivers coming toward you. They can also bother drivers going in the same direction you are, when your lights shine in their rearview mirrors. Dim your lights within 500 feet of an oncoming vehicle and when following another vehicle within 500 feet.

- Avoid glare from oncoming vehicles – Do not look directly at the lights of oncoming vehicles. Look slightly to the right at a right lane or edge marking, if available. If other drivers do not put their low beams on, do not try to “get back at them” by putting your own high beams on. This increases glare for oncoming drivers and increases the chance of an accident.

- Use high beams when you can – Some drivers make the mistake of always using low beams. This seriously cuts down on their ability to see ahead. Use high beams when it is safe and legal to do so. Use them when you are not within 500 feet of an approaching vehicle. Also, do not let the inside of your cab get too bright. This makes it harder to see outside. Keep the interior light off, and adjust your instrument lights as low as you can to still be able to read the gauges.

- If you get sleepy, stop at the nearest safe place – People often do not realize how close they are to falling asleep even when their eyelids are drooping. If you feel sleepy, stop driving! You are in a very dangerous condition, and the only safe choice is to sleep.

You should not drive in fog if you do not have to. It is preferable that you pull off the road into a rest area or truck stop until visibility is better. If you must drive, be sure to consider the following:

- Obey all fog-related warning signs.

- Slow down before you enter fog.

- Use low-beam headlights and fog lights for best visibility even in daytime, and be alert for other drivers who may have forgotten to turn on their lights.

- Turn on your 4-way emergency flashers. This will give vehicles approaching you from behind a quicker opportunity to notice your vehicle.

- Watch for vehicles on the side of the roadway. Seeing taillights or headlights in front of you may not be a true indication of where the road is ahead of you. The vehicle may not be on the road at all.

- Use roadside highway reflectors as guides to determine how the road may curve ahead of you.

- Listen for traffic you cannot see.

- Avoid passing other vehicles.

- Do not stop along the side of the road, unless absolutely necessary.

Make sure your vehicle is ready before driving in winter weather. You should make a regular vehicle inspection each season so you can drive slowly and smoothly on slippery roads. If it is very slippery, you should not drive at all.

Here are some tips for driving in cold weather:

- Start gently and slowly – When first starting, get the feel of the road. Do not hurry.

- Check for ice – Check for ice on the road, especially bridges and overpasses. A lack of spray from other vehicles indicates ice has formed on the road. Also, check your mirrors and wiper blades for ice. If they have ice, the road most likely will be icy as well.

- Adjust turning and braking to conditions – Make turns as gently as possible. Do not brake any harder than necessary, and do not use the engine brake or speed retarder they can cause the driving wheels to skid on slippery surfaces.

- Adjust speed to conditions – Do not pass slower vehicles unless necessary. Go slowly and watch far enough ahead to keep a steady speed. Avoid having to slow down and speed up. Take curves at slower speeds and do not brake while in curves. Be aware that as the temperature rises to the point where ice begins to melt, the road becomes even more slippery. Slow down more.

- Adjust space to conditions – Do not drive alongside other vehicles. Keep a longer following distance. When you see a traffic jam ahead, slow down or stop to wait for it to clear. Try hard to anticipate stops early and slow down gradually. Watch for snowplows, as well as salt and sand trucks, and give them plenty of room.

- Wet brakes – When driving in heavy rain or deep standing water, your brakes will get wet. Water in the brakes can cause the brakes to be weak, to apply unevenly, or to grab. This can cause lack of braking power, wheel lockups, pulling to one side or the other, and jackknife if you pull a trailer.

When you’re driving in hot weather, you should go slowly to prevent overheating. You should also watch out for tar in the road pavement, as it can be very slippery.

To ensure your rig is in proper condition to drive in hot weather, you can perform a normal vehicle inspection and pay special attention to the following items.

- Tires – Air pressure increases with temperature. If a tire is hot, remain stopped until the tire cools off.

- Engine oil – This helps keep the engine cool, so make sure you have enough for your trip.

- Engine coolant – Make sure the system has enough water and coolant. Check the temperature of the water and coolant regularly, and add more if needed.

- Engine belts – Learn how to check v-belt tightness on your vehicle by pressing on the belts. Loose belts will not turn the water pump and/or fan properly. This will result in overheating. Also, check belts for cracking or other signs of wear.

- Hoses – Make sure coolant hoses are in good condition. A broken hose while driving can lead to engine failure and even fire.

In mountain driving, gravity plays a major role. On any upgrade, gravity slows you down. The steeper the grade, the longer the grade, and/or the heavier the load–the more you will have to use lower gears to climb hills or mountains. In coming down long, steep downgrades, gravity causes the speed of your vehicle to increase. There are three key ways to navigate downgrades:

Select a safe speed – Consider total weight of your vehicle and cargo, the length and steepness of the grade, road conditions, and weather.

Select the right gear before starting down the grade – Shift transmission into low gear. Don’t downshift after your speed has built up.

Practice braking techniques – The use of brakes on a long and/or steep downgrade is only a supplement to the braking effect of the engine. Once the vehicle is in the proper low gear, the following are the proper braking techniques:

- Apply the brakes just hard enough to feel a definite slowdown.

- When your speed has been reduced to approximately 5 mph below your “safe” speed, release the brakes. This brake application should last for about 3 seconds.

Watch out for brake fading or failure – Brakes are designed so brake shoes or pads rub against the brake drum or disks to slow the vehicle. Braking creates heat, but brakes are designed to take a lot of heat. However, brakes can fade or fail from excessive heat caused by using them too much and not relying on the engine braking effect.

A hazard is any road condition or other road user (driver, motorcyclist, bicyclist, and pedestrian) that is a possible danger. For example, if a car in front of you is headed toward the freeway exit and they begin braking hard, this could mean the driver is uncertain about taking the off ramp. They might suddenly return to the highway. This car is a hazard. If the driver of the car cuts in front of you, it is no longer just a hazard; it is an emergency.

Seeing hazards lets you be prepared – You will have more time to act if you see hazards before they become emergencies.

Move-over laws – Move-over laws have been enacted, which require drivers to slow and change lanes when approaching a roadside incident to lessen the problem. Signs are posted on roadways in states that have such laws.

Drivers who are hazards – In order to protect yourself and others, you must know when other drivers may do something hazardous.

To identify hazards, be aware of your surroundings. This includes cars that are driving quickly, weaving between lanes, frequently varying speed, and more:

- Confused drivers

- Slow drivers

- Drivers signaling a turn

- Drivers in a hurry

- Impaired drivers – sleepy, drunk, high

Make sure you are aware of the causes of fires and how to prevent them.

Here are some of the common causes of vehicle fires:

- After accidents – Spilled fuel, improper use of flares.

- Tires – Under-inflated tires and duals that touch.

- Electrical system – Short circuits due to damaged insulation, loose connections.

- Fuel – Driver smoking, improper fueling, loose fuel connections.

- Cargo – Flammable cargo, improperly sealed or loaded cargo, poor ventilation.

There are a number of things you can do to prevent fires, such as:

- Vehicle inspections – Make a complete inspection of the electrical, fuel, and exhaust systems, tires, and cargo. Be sure to check that the fire extinguisher is charged.

- En route inspections – Check the tires, wheels, and truck body for signs of heat whenever you stop during a trip.

- Following safe procedures – Follow correct safety procedures for fueling the vehicle, using brakes, handling flares, and other activities that can cause a fire. Carry a fire extinguisher with you in the cab.

- Regular monitoring – Check the instruments and gauges often for signs of overheating and use the mirrors to look for signs of smoke from tires or the vehicle.

- Using caution – Use normal caution in handling anything hot, electric, or flammable.

How to Fight Fires

Knowing how to fight fires is important. Learn how your fire extinguisher works. Study the instructions printed on the extinguisher before you need it. Here are some procedures to follow in case of fire.

The first step is to get the vehicle off the road and stop. When you do so:

- Park in an open area, away from buildings, trees, brush, other vehicles, or anything that might catch fire.

- Do not pull into a service station!

- Notify emergency services of your problem and your location.

Before trying to put out the fire, make sure that it does not spread any further.

- With an engine fire, turn off the engine as soon as you can. Do not open the hood if you can avoid it. Shoot foam through the louvers, radiator, or from the vehicle’s underside.

- For a cargo fire in a van or box trailer, keep the doors shut, especially if your cargo contains hazardous materials. Opening the van doors will supply the fire with oxygen and can cause it to burn very fast.

Make sure you fully extinguish the fire.

- When using the extinguisher, stay as far away from the fire as possible.

- Aim at the source or base of the fire, not up into the flames.

For more information, refer to California Code of Regulations (CCR) , Title 13 §1242.

Additional Information

Whether you need to look up traffic conditions or you need to contact a state or federal agency, here are some additional links that you might find useful. Occupational Licensing Driving School Complaint Office of Truck Services American Association of Motor Vehicle Administrators California Board of Equalization California Department of Food and Agriculture California Department of Health Services California Department of Transportation California Highway Patrol California Office of Traffic Safety Environmental Protection Agency Federal Motor Carrier Safety Administration Internal Revenue Service International Registration Plan, Inc. National Highway Traffic Safety Administration Public Utilities Commission Unified Carrier Registration

General Disclaimer

When interacting with the Department of Motor Vehicles (DMV) Virtual Assistant, please do not include any personal information.

When your chat is over, you can save the transcript. Use caution when using a public computer or device.

The DMV chatbot and live chat services use third-party vendors to provide machine translation. Machine translation is provided for purposes of information and convenience only. The DMV is unable to guarantee the accuracy of any translation provided by the third-party vendors and is therefore not liable for any inaccurate information or changes in the formatting of the content resulting from the use of the translation service.

The content currently in English is the official and accurate source for the program information and services DMV provides. Any discrepancies or differences created in the translation are not binding and have no legal effect for compliance or enforcement purposes. If any questions arise related to the information contained in the translated content, please refer to the English version.

Google™ Translate Disclaimer

The Department of Motor Vehicles (DMV) website uses Google™ Translate to provide automatic translation of its web pages. This translation application tool is provided for purposes of information and convenience only. Google™ Translate is a free third-party service, which is not controlled by the DMV. The DMV is unable to guarantee the accuracy of any translation provided by Google™ Translate and is therefore not liable for any inaccurate information or changes in the formatting of the pages resulting from the use of the translation application tool.

The web pages currently in English on the DMV website are the official and accurate source for the program information and services the DMV provides. Any discrepancies or differences created in the translation are not binding and have no legal effect for compliance or enforcement purposes. If any questions arise related to the information contained in the translated website, please refer to the English version.

The following pages provided on the DMV website cannot be translated using Google™ Translate:

- Publications

- Field Office Locations

- Online Applications

Please install the Google Toolbar

Google Translate is not support in your browser. To translate this page, please install the Google Toolbar (opens in new window) .

- Register / Login

- Trucker's Forum

- Paid CDL Training

- Truck Driving Jobs

- CDL Practice Tests

- High Road Training

Pre-Trip Inspection Study Guide

Our Pre-Trip Inspection Study Guide has everything you need to prepare for the Class A CDL Pre-Trip Inspection Exam . Our study guide will cover the pre-trip inspection terminology as well as a thorough list of all of the parts you will be inspecting on the vehicle. For each part you will be inspecting there will also be a list of items you will be checking for. Our study guide is broken down into the following sections:

- What You Need to Know About Pre-Trip Inspection

Pre-Trip Inspection Practice Questions

- Pre-Trip Inspection Checklist

Pre-Trip Inspection Videos

Pre-trip inspection printable resources, what you need to know about the pre-trip inspection.

The Pre-Trip Inspection is a thorough inspection of the vehicle and all of its major systems. Inspecting the vehicle before driving each day is a Federal requirement and normally takes about 15 minutes. It must be logged in your logbook as "on duty not driving."

You will have to do thorough safety inspections of the coupling system, the vehicle lights, engine compartment, tires and brakes, the chassis, the fuel tanks, and an in-cab inspection.

The following information is a brief summary of Daniel's Complete Pre-Trip Inspection taken from our oustanding free PDF download:

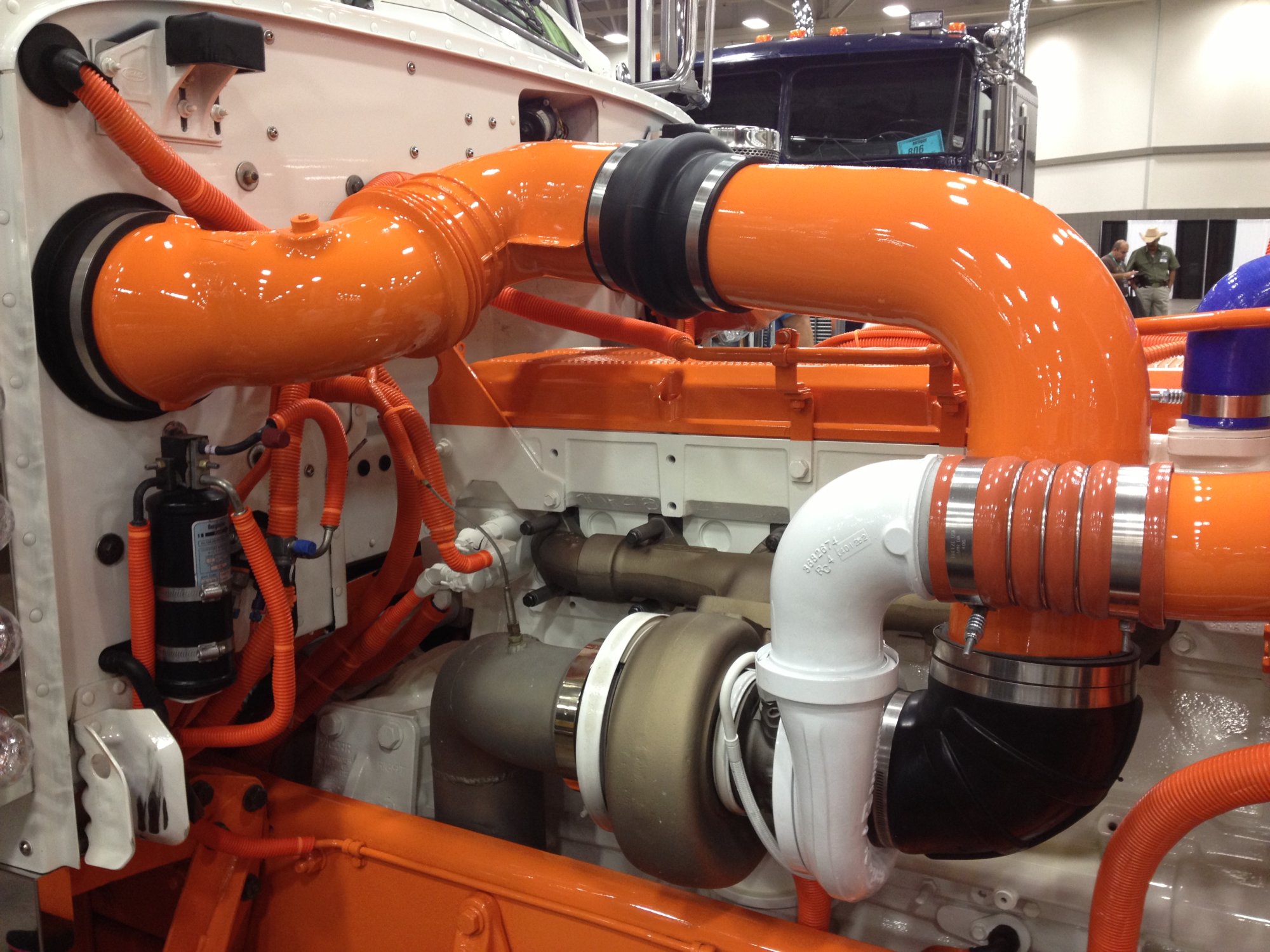

Engine Compartment

You will be checking the engine compartment for any sort of leaks. You will also be checking to see if all components are properly mounted and secured. None of the mounts must be cracked, bent, or broken.

You will be checking all hoses to make sure they aren't leaking, frayed, or sliced and the fluid levels including the oil level, the coolant, and the power steering fluid.

You must check the components like the water pump, the power steering pump, and the alternator to make sure nothing is leaking, the belts are not frayed, and that everything is properly mounted and secured.

From inside the engine compartment you will also find the steering system, the front suspension system, and the front brake system. All components of these systems must be properly mounted and secured without anything being cracked, bent, or broken. Finally you will be checking the tires, rims, and axle seals to make sure the tires are properly inflated, the rim isn't bent or cracked, and the axle seals are not leaking.

Fuel Tank And Battery Area

You will be standing along the side of the tractor doing a series of checks on the mirrors, fuel tanks, batteries, exhaust system, and more. You will check to make sure nothing is bent, cracked, broken, or leaking.

Check the mirrors, door hinges, door handle to make sure nothing is cracked, bent, or broken. Check to make sure there is no fuel leaking and that the fuel cap is secured and the gasket is not missing.

Check the exhaust system to make sure nothing is cracked, bent, or broken. Check the driveshaft, cat walk, and steps to make sure nothing is cracked, bent, or broken.

Check the frame and crossmembers for structural integrity. Check the air lines going to the trailer to make sure they're properly connected and that there are no abrasions, bulges, or cuts. Make sure the gaskets are present.

Check the suspension system and brakes on the drive axles, making sure nothing is cracked, bent, or broken. Make sure the brake linings are the proper thickness and that the air bags and properly inflated. Inspect the brake chambers, slack adjusters, and pushrods are properly mounted and secure. Not Cracked, Bent, or Broken. With the brakes released and pulled by hand, the Push Rod should not move more than 1 inch.

Check the rims, tires, and axle seals of the drive tires for proper inflation, no leaks around the seal, and the lugs are all present and secured.

Coupling System

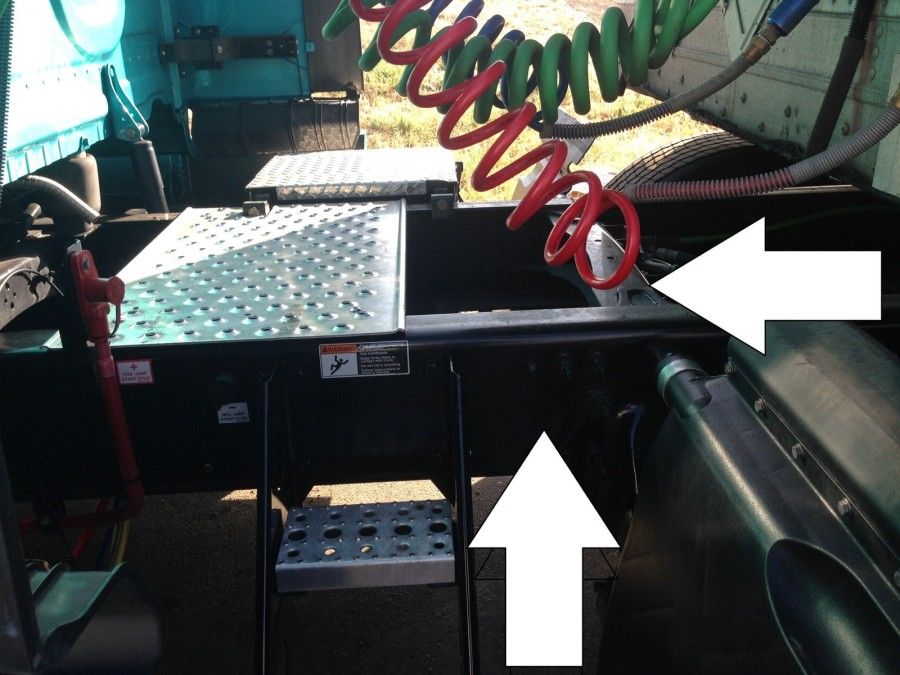

You will be standing where the tractor and trailer are connected and you'll start by checking the electrical line and air lines to make sure they're properly mounted and secure at both ends. No abrasions, bulges or cuts. Not leaking air. Make sure the electrical line has no wires exposed. Check the gladhands to make sure the seals are in good condition, no cracks or signs of dry rotting. Not leaking air.

Check the skid plate of the fifth wheel and the apron of the trailer to make sure there is no debris and nothing is cracked, bent, or broken. Make sure the fifth wheel is properly greased. Also make sure there is no gap in between the fifth wheel and the trailer apron once the tractor and trailer are coupled. Make sure the kingpin of the trailer is properly mounted and not cracked, bent, or broken and that the locking jaws of the fifth wheel are properly secured when the tractor and trailer are coupled.

Check the mounting bolts where the fifth wheel attaches to the tractor frame. Make sure there are no missing bolts and that everything is secured properly. Check the locking pin if you having a sliding fifth wheel to make sure it's properly locked into place.

Make sure that there is the proper clearance space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

You will start inspecting the trailer at the head board, which is the front wall of the trailer. Make sure there are no holes or missing rivets. Check the landing gear to make sure it is properly mounted and secure. Not cracked, bent, or broken. Make sure the fully raised and the handle is secure in the cradle when the tractor and trailer are coupled.

Check the frame and crossmembers under the trailer to make sure they're not cracked, bent, or broken. Check the tandem frame and release pins to make sure the frame is in good condition and the release handle and locking pins are in the fully locked position.

You will check the entire suspension and brake system for the trailer tandems the same way you did for the drive axles of the tractor. You will also make sure the mudflaps are properly secured. For dual tires check to see that there is proper space between the tires and there is nothing stuck between the tires.

Check the rear door and hinges to make sure they are properly mounted and nothing is cracked, bent, or broken. Make sure the door seals are not worn, torn, or dry rotted.

Light Check

You will be checking all of the lights and reflectors on both the tractor and the trailer. Check the reflectors and reflective tape to make sure they are properly mounted and secure, not cracked, bent, or broken, and clean and illuminated. Check that you have the proper color of amber to the front and sides, and red to the rear.

Start by turning on your marker lights and headlights. Now walk around the entire truck and trailer and point out the lights. Give the function of the light and the location. You should then ask your examiner to help you check your five functions.

While you're sitting in the drivers seat, the examiner will stand to the front of the truck, then behind the trailer. He will then check your Turn Signals, Four Way Flashers and Brake Lights. You must do each function at every location.

The five locations that you must check your lights:

- Front of the Truck

- Both sides of the Truck

- Rear of the Truck

- Both sides of the Trailer

- Rear of the Trailer

The Five Functions you are checking for:

- Left Turn Signal

- Right Turn Signal

- Four Way Flashers

- High Beams/Low Beams

- Brake Lights

In-Cab Inspection

The in-cab inspection and air brake check will cover the various gauges and systems inside the cab along with several tests to make sure you air brake system is working properly.

You will start by checking the following:

- Seat Belt- Properly Mounted and Secure. Not ripped or frayed Adjusts and latches properly.

- Fire Extinguisher- Properly Mounted and Secure. Fully charged

- Three Red Reflective Triangles- My three red reflective triangles are GIVE LOCATION

- Spare Electrical Fuses- My spare electrical fuses are GIVE LOCATION

- Volmeter, Oil Pressure Gauge, Water Temperature Gauge, and Air Pressure Gauge all show proper operation

- City horn and air horn functioning properly

- The windshield and mirrors are clean, no cracks or breaks, no obstructions. The mirrors are in proper adjustment.

- Windshield Wipers and Washers - Demonstrate that the washers work by spraying the windshield. The Wipers are: Properly Mounted and Secure and operate smoothly. The blades aren't cracked or dry rotten.

- Heater and Defroster - Demonstrate that both the Heater and Defroster are working properly.

- Lighting Indicators - Left Turn, Right Turn, Four Way Flashers, and High Beams.

Trailer Parking Brakes - Set the Trailer Brake, release the tractor brake, and then tug lightly on the trailer.

Tractor Parking Brakes- Then set the Tractor Brake, release the trailer brake, and then tug lightly on the tractor.

Service Brake Check - Release both Tractor and Trailer Brakes. Now drive at idle speed. Apply the Service Brake to make sure you come to a complete stop, and that it doesn't pull to the left or right when applying the brakes.

Air Brake Test

The air brake test will consist of a leakdown test to make sure your air brakes aren't leaking air and losing pressure. It will also test the warning lights and buzzer to make sure the driver gets the proper warning if the air pressure drops too low.

There are three stages to an Air Brake Test

#1: Applied Pressure Test

#2: Warning Light and Buzzer

#3 Tractor/Trailer Protection Valve Pop Out

Applied Pressure Test: Build the air pressure to governor cut out. Put the truck in the lowest gear. Then turn off the engine Immediately turn the engine back on. Push in both the tractor and trailer valves. (This will release the parking brakes.) Push and hold the Brake pedal fully. Allow the gauges to stabilize. Announce the gauges have stabilized and the Primary and Secondary PSI. With the Brakes fully pressed, you should not lose more than 4 PSI in one minute. Announce that you are listening for air leaks during that minute.

Warning Light and Buzzer Test: Pump down on the Brake pedal until the warning light and buzzer comes on, at or before 60 PSI.

Tractor/Trailer Protection Valve Pop Out Test: Pump down on the brake pedal until both the tractor and trailer protection valves pop out. They should both pop out between 40 and 20 PSI.

We have a ton of Pre-Trip Inspection Practice Questions along with the answers and a complete scoring system in our Free Online CDL Practice Tests :

The Engine Compartment Section will include questions about checking the oil level and coolant levels, inspecting belt-driven engine components (like the water pump, alternator, and air compressor), and the safety devices required in the cab. There will also be questions regarding the windshield wipers and free play in the steering wheel.

The Lights And Brakes Section will include questions about dashboard indicator lights, inspecting the parking brakes, and doing a leakdown test on the air brakes. It will also include questions about the low air pressure warning signal and testing your air horn and city horn.

The Suspension And Steering Section will include questions about the tractor protection valve, inspecting the steering box, and inspecting many suspension system parts. It will also include questions about welds being present on tire rims and the minimum tread depth required on steering axle tires.

The Tires And Coupling Devices Section will include questions about shiny trails or rusty threads on lug nuts, inspecting the battery box and cover, and inspecting electrical lines. It will also contain questions about inspecting the coupling devices and the fifth wheel skid plate.

The Emergency Equipment And Fifth Wheel Section will include questions about additional emergeny equipment required by school buses, inspecting the gap between the kingpin apron and the fifth wheel skid plate, and the landing gear securement. It will also contain questions about inspecting driver mirrors and the trailer frame.

Pre-Trip Inspection Checklist - Class A

Our pre-trip inspection checklist covers every part of the truck from front to back, both inside and outside of the truck. It covers the air brakes, suspension parts, steering components, wheels and rims, fuel tanks, batteries, lights, and more. It also covers the air brake tug test and checks for everything under the hood including alternator, water pump, fuel pump, fluids, and more.

This is a super handy checklist to study anytime you have a few minutes to spare:

Pre-Trip Inspection Checklist - Free Word Document Download (Editable Version)

Pre-Trip Inspection Checklist - Free PDF Download (Print Version)

Pre-Trip Inspection Video By Apex CDL Institute

Jeff from Apex Institute does an in-depth explanation of the entire pre-trip inspection process. This video is loaded with tips that go beyond the CDL test to help drivers really understand how to identify problems.

Pretrip Inspection Self-Test By CDL College

The Pretrip Inspection Self-Test By CDL College is really unique. It's a silent video which will show you the part you're inspecting and then gives you a few seconds to figure out what you should be checking for before giving you the answer. Definitely check this one out. Great for practicing before the CDL exam.

Pre-Trip Inspection Video By Averitt Express

This is a complete back to front pre-trip inspection of a truck and trailer by Averitt mainentance associate Kevin Breeding. This thorough pre-trip inspection covers all inportant points of inside the cab, lights, engine, the tractor itself and the trailer.

We have included two print versions of the pre-trip inspection process from Daniel. The first is the entire pre-trip inspection and the second is an abbreviated checklist for the inspection.

- PDF: Daniel's Pre-trip Inspection (Print Version)

- PDF: Daniel's Pre-trip Inspection Checklist (Print Version)

Why Join Trucking Truth?

- The High Road Training Program

- The High Road Article Series

- The Friendliest Trucker's Forum Ever!

- Email Updates When New Articles Are Posted

Apply For Paid CDL Training Through TruckingTruth

Did you know you can fill out one quick form here on TruckingTruth and apply to several companies at once for paid CDL training? Seriously! The application only takes one minute. You will speak with recruiters today. There is no obligation whatsoever. Learn more and apply here:

- Privacy Policy

Office - 2945 Ramco street West Sacramento CA 95691 | Yard - 3501 First St, West Sacramento, CA 95691

☎ +1 916-380-1218 | [email protected].

California Pre-Trip Inspection 2023

Pre trip is the first & important section of dmv exam.

Think Safety – Touch, Point And Fully Explain. Remember , Do Not Go Inside The Engine Or Crawl Under The Vehicle.

Unsafe Act – Forgetting To Set The Parking Brakes. Safety Of Examiner And Driver Is Highest Priority.

Always Use 3 Points Of Contact When Entering And Exiting The Vehicle. Always Follow Examiner’s Instructions – If You Do Not Understand, Ask Examiner For Clarification.

In-Cab Inspection

Lights and gauges .

- Put On Seatbelt

- Foot Off Brake

- Turn On Auxiliary Power

- Abs Lights Turn On/Off … Trailer Side ABS Light On/Off ..

- Left Turn Signal

- Right Turn Signal

- Four-Way Emergency

- High Beam Headlights Are Functioning

- Def Is More Than ⅛ Full

Emergency Equipment

- Fire Extinguisher – Securely Mounted. Properly Rated And Charged

- 6 Spare Fuses

- 3 Emergency Triangles

Windshield And Mirrors

- Mirrors Are Adjusted To Me, And Clean

- Windshield – Securely Mounted, Not Cracked, No Stickers Except Inspection Sticker, Nothing Blocking My View And They Are Clean.

You Must Demonstrate The Use Of The Following

- Windshield Wipers / Activate The Fluid, The Blades Are Securely Mounted And, Not Damaged

- Horns Electrical / Air (If Equipped)

- Heater / Defroster

Air Brake Check

Key psi numbers to remember.

- 120 – 140 Governor Cut Out

- 4 – 1 Air Leakage (Dual System)

- 3 – 1 Air Leakage Test (Single System)

- 55 Low Air Warning

- 20 – 45 Spring Brake Pop Out

Key Actions To Perform

AAR A ir It Up – A uxiliary On – R elease The Brakes

You Must Explain, Demonstrate And Perform Your Air Brake Check To The Examiner In The Following Manner.

Before Inserting Your Keys Into The Ignition

Apply (Pull Out) Truck And Trailer Brake.

Ensure Truck is in Neutral

Announce “ Clear”

- Chock Your Wheels If On Unlevel

- Turn Key To Auxiliary, Let Your Gauges Fully Sweep

- Turn On The Truck

- Verify Verbally that ABS Light IS Functioning InCab – Side Of Trailer

- Identify the Gauge You Will Be Reading From, (Primary – Secondary).

- Build Your Air Pressure To Governor Cut Out, (Between 120 – 140 PSI).

- You Must Identify The # The Needle Stops Rising On (Governor Cut Out)

- Turn Off The Truck

- Now Turn The Key To Auxiliary

- Release Truck & Trailer Brake, (Wait For Shushing Sound To Go Away).

- Put Your Foot On The Brake

- Identify The PSI The Needle Has Settled Upon

- Announce to the Examiner , “I Am Performing The Applied Air Leakage Test . I Should Not Lose More Than 4 PSI In One Minute On A Dual System, 3 PSI On A Single System, I’m Going To Start My Timer ” When The Timer Is Done, You Must Declare How Much, If Any, PSI You Lost During The Test.

- “Next I will Check the Low Air Warning The Low Air Warning Should Come On No Less Than 55 PSI.” Fan The Brakes Until The Alarm And Light Come On The Dash. You Must Identify The PSI It Comes On At.

- “Now I Will Keep Fanning The Brakes Until The Parking Brakes Pop Out. They

Should Pop Out No Less Than 20, No More Than 45 PSI”. You Must Identify the Number At Which They Pop Out. Make Sure Both Brakes Popped out!

3 Way Brake Test / Tug Test

- Ensure That The Truck Is In Neutral , Brakes Are Applied

- Announce “ Clear ”

- Turn Key To Auxiliary, Allow Gauges To Fully Sweep

- Turn On The Truck, And Build Air Pressure To Governor Cut Out

- With Foot On Brake, Release Truck Parking Brake

- Put In Drive And Tug Against Trailer Brake .

- Now Apply Truck Parking Brake, And Release Trailer Brake

- Put In Drive, And Tug Against Truck Parking Brake .

- Now Release Both Truck And Trailer Parking Brake

- Drive No More Than 5 Mph Forward And Apply Foot Brake . The Truck And Trailer Should Stop Without Pulling You To The

Brake Tests Are Now Complete

Exterior Lights Operation Check

Ask The Examiner To Assist You During Lights Operation Check. You Will Sit Inside The Cab Of Truck, With The Brakes Set, Auxiliary On, And Window Down. Speak Loudly . Tell The Examiner Exactly Which Light You Want Them To Check And Turn On The Corresponding Light.

- Headlights Low And High Beam

- Turn Signals

- 4 Way Flashers

- Clearance Lights

- Tail Lights

- Brake Lights

Inspection Front Of The Vehicle/Engine Area

Identify The Components On The Vehicle And Give Brief Description

- Clearance Lights: Amber In Color, Not Broken Or Missing, Mounted Securely

- T urn Signals Left / Right: Amber In Color, Not Broken Or Missing, Mounted Securely

- Headlights: High & Low, Clear, Not Fogged, Not Broken Or Missing, Mounted Securely

- Check Under vehicle: no loose or hanging parts, no leaks, no puddles

- Check Vehicle Position: Truck & Trailer, No Leans Front To Back, Side To Side

- Coolant Reservoir: Securely Mounted, Filled Above Refill Mark, Cap Is Tight, Not Leaking

- Coolant Hose: Securely Mounted, No Bubbles, No Cuts, No Leaks

- Windshield Washer Fluid: Securely Mounted, Filled Above Refill Mark, Cap Is Tight, Not Leaking

- Windshield Washer Hose: Securely Mounted, No Bubbles, No Cuts, No Leaks

- Engine Oil Reservoir: Securely Mounted , Cap Is Tight, Not Leaking

- Engine Oil Dipstick: “I Will Check My Oil Level With My Dipstick, & Make Sure It Is In Safe Operating Range And Above The Refill Mark.”

- Power Steering Reservoir: Securely Mounted, Filled Above Refill Mark, Cap Is Tight, Not Leaking

- Power Steering Reservoir Hoses: Securely Mounted, No Bubbles, No Cuts, No Leaks

Steering System

- Power Steering Pump: Gear Driven Not Cracked, or Broken & Securely Mounted With Cotter Keys & Castle Nut To The

- Steering Shaft: No more than 10° of play, Not Bent, Not cracked Securely mounted with the Universal joints, no missing bolts or nuts

- Control Arms And Tie Rod:

- Upper Control Arm

- Lower Control Arm

- Passenger Side Control Arm

- Not Bent, No Cracks, Not Broken, Securely Mounted To The Vehicle With Cotter Keys And Bolts. All Are Tight And Present & Sufficiently

Steer Suspension System

- Spring Hangers: Not Cracked, Or Broken, Securely Mounted

- Shackles: Not Cracked, Or Broken, Securely Mounted

- Leaf Springs: Properly Mounted To The Shackles Not Cracked, Or Broken. “If They Were Cracked More Than ¼ Of An Inch I Would Place My Vehicle Out Of Service”.

- U Bolts: Not Cracked Or Broken Securely Mounted To The Spacer, Axle And Springs

- Shock Absorbers: Not Cracked Or Broken, Securely Mounted

Brake System

- Brake Hose & ABS Line: Securely Mounted, Not Worn, Not Cut, No Leaks

- Brake Chamber: Securely Mounted, Not Cracked, & There Are No Leaks

- Brake Chamber Clamp: Securely Mounted, Not Cracked, & There Are No Leaks

- Slack Adjuster & Push Rod: Not Bent Broken Securely Mounted “ When My

Brakes Are Applied It Should Be At A 90° Angle, When My Brakes Are Released I Should Have No More Than 1 Inch Of Free Play ”

- Brake Drum: Securely Mounted, No Holes, Not Bent Or Broken, No Oil Or Contaminates

- Brake Linings: Securely Mounted, They Are No Less Than ¼ Inch Thick, Not Broken Or Missing

Remember : ICD I nflation, C ondition And D epth

- Inflation: I Will Check Inflation With A Tire Gauge And Make Sure It’s Inflated To The Manufacturer’s Specification.

- Condition: Inner And Outer Side Walls Are Evenly Worn, No Cuts Or Bubbles They Are The Same Type. No Recaps On Front Tires

- Depth: No Less Than 4/32 On Both Front Tires No Less Than 2/32 On All Rear Tires

- Tire Rims: Not Cracked, Bent Or Broken, There Are No Welds, & No Rust Trails Indicating Its Loose On The Wheel

- Studs & Bolt Holes: Are Not Broken, Missing, Or Elongated

- Lug Nuts: Tight And Present, No Shiny Threads, & No Rust Trails

- Valve Cap And Stem: Not Broken Or Missing Cap Is Present, Not Leaking

- Hub oil Seal: It Is Full, It’s Not Leaking & The Seal Is In Good Condition

Inspection Side Of Vehicle

Moving Along The Driver’s Side Of The Vehicle You Will Inspect The Following

- Side Lights/Blinkers: Amber In Color, Not Broken Or Missing, Mounted Securely

- All Side Mirrors: They Are Clean, No Missing Parts, Not Broken, Or Damaged, Mounted Securely

- Fuel Tank: Is Not Cracked Or Damaged In Any Way, The Cap Is On Tight, No Leaks From The Tank, Cap, Or Fuel Lines.

- Fuel Tank Straps: Are Secured To The Frame, They Have No Visible Damage & The Rubber Behind Them Is Intact.

- Def Tank: It Has More Than 1/8 In The Tank, Cap Is On Tight, No Leaks From The Tank, Lines Or Cap And It’s Securely Mounted To The

- Sidesteps & Catwalk: Are Clear Of Debris, Not Broken And Securely Mounted To The Vehicle.

- Battery Box: Is Secured To The Frame. All Connections Are Tight & Have No Excessive Connection Cables And Lines Are Not Cracked Or Worn. The Battery Box Cover Is Secure And In Place

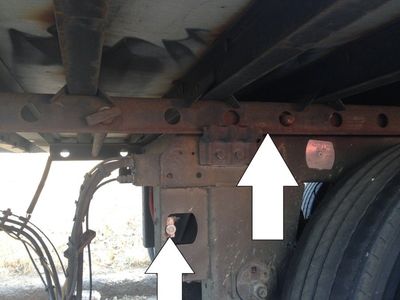

- Frame: The Frame Is Straight, It Has No Cracks, No Broken Welds, No extra holes, Not Damaged In Any Way

- Crossmembers: No Cracks, No Broken Welds, no extra holes, Not Damaged In Any Way

- Torque Bar: Not Bent, Cracked Or Broken And Secured To The Vehicle

You Must Tell The Examiner That Your Drive Axle Suspension Has The Same Components As The Steering Suspension With The Exception Of One Additional Component, The AIR BAGS .

- Air Bags: ( Located Behind The Shocks ) Are Secured To The Vehicle, They Are Not Ripped, Torn Or Cut, & Not Leaking.

Coupling System