Les Vieilles Soupapes Agricoles (VSA) : Toute la passion réunie autour du machinisme agricole d'antan. Venez partager avec nous cette passion. Acquisition, échange, restauration et utilisation de vieilles machines agricoles.

Résultats par : Messages Sujets

recherche pist…

19/4/2024, 08:08

Renault E71

16/4/2024, 16:29

13/4/2024, 12:26

11/4/2024, 17:08

jean-jacques

AGRIA DL660 DIE…

3/4/2024, 12:42

Cherche platine…

28/3/2024, 08:55

Domdom21700

Mf 835 avec fou…

19/3/2024, 20:33

presse ramasseu…

18/3/2024, 13:26

8/3/2024, 10:17

cherche boite d…

29/2/2024, 22:48

motobek1960

Comment monter un compte-tour sur un moteur Perkins 4.108

Les Vieilles Soupapes Agricoles --> :: Toute la mécanique. Vos pannes et vos restaurations :: la mécanique : pannes et remèdes

Re: Comment monter un compte-tour sur un moteur Perkins 4.108

Les Vieilles Soupapes Agricoles :: Toute la mécanique. Vos pannes et vos restaurations :: la mécanique : pannes et remèdes

- Créer un forum | © phpBB | Forum gratuit d'entraide | Signaler un abus | Forum gratuit

Perkins 4.108 manual

manual Perkins 4.108

View the manual for the Perkins 4.108 here, for free. This manual comes under the category marine engines and has been rated by 17 people with an average of a 9. This manual is available in the following languages: -. Do you have a question about the Perkins 4.108 or do you need help? Ask your question here

Do you have a question about the Perkins and is the answer not in the manual?

- Receive updates on solutions

- Get answers to your question

Question and answer

I am trying to find out the name of a piece inside the Perkins 4.108 deisel engine that houses the mechanical rpm cable in the motor. It cylindrical in shape with a square hole in the middle. I have lost that piece and I need to buy one. Can you also help me in finding out the cable I need. Mine is wourn out

How to remove starter motor for Perkins 4.108M

The Perkins 4.108 is a marine engine that is known for its reliability and durability. It is specifically designed for use in marine applications and is often used in sailboats, motorboats, and other types of water vessels. The Perkins 4.108 is a four-cylinder, naturally aspirated engine that has a displacement of 1.8 liters. It is known for its smooth and efficient operation, providing reliable power for extended periods of time. With its compact size and lightweight design, it is relatively easy to install and maintain. One of the key features of the Perkins 4.108 is its fuel efficiency. It is designed to provide superior fuel economy, allowing marine vessels to travel longer distances without the need for frequent refueling. This can be a major advantage for those who use their boats for long journeys or extended periods of time. The Perkins 4.108 also offers a high power-to-weight ratio, meaning that it is capable of delivering a significant amount of power despite its relatively small size. This makes it suitable for a wide range of marine applications, from leisure boating to commercial fishing. In addition to its performance and efficiency, the Perkins 4.108 is also known for its durability. It is constructed with high-quality materials and undergoes rigorous testing to ensure its reliability in harsh marine environments. This engine is built to withstand the demands of the sea, providing peace of mind for boat owners. Overall, the Perkins 4.108 is a trusted marine engine that offers reliable performance, fuel efficiency, and durability. It is a popular choice among boat owners and is widely regarded as a dependable option for marine applications.

Can't find the answer to your question in the manual? You may find the answer to your question in the FAQs about the Perkins 4.108 below.

What is the difference between E10 and E5 petrol?

E10 petrol consists of up to ten per cent ethanol while E5 petrol will contain less than five per cent ethanol. As a result, the percentage of E10 petrol is lower than that of E5 petrol, making it less bad for the environment.

Why do I need a manual to understand the fuel system of my Perkins 4.108 marine engine?

The manual provides detailed information on the fuel system, including the fuel pump, injectors, and filters, allowing you to troubleshoot and maintain your engine's fuel system for optimal performance.

How can a manual help me diagnose and fix cooling system issues on my Perkins 4.108 marine engine?

The manual offers step-by-step instructions on troubleshooting and repairing the engine's cooling system, covering components such as the water pump, heat exchanger, and thermostat, enabling you to address cooling-related problems effectively.

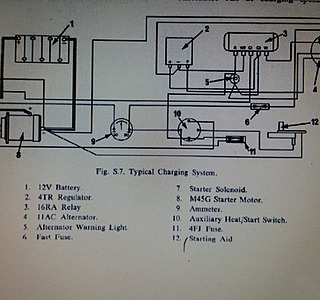

What information can I find in the manual regarding the electrical system of my Perkins 4.108 marine engine?

The manual contains comprehensive details about the electrical system, including the battery, alternator, starter motor, and wiring diagrams, ensuring you have the necessary guidance to diagnose and fix electrical issues.

How can a manual assist me in maintaining and servicing the Perkins 4.108 marine engine's lubrication system?

The manual provides essential instructions on maintaining the lubrication system, outlining oil change intervals, filter replacements, and proper lubricant specifications, allowing you to ensure the engine stays properly lubricated and protected.

What guidance does the manual offer for troubleshooting and repairing common starting issues with the Perkins 4.108 marine engine?

The manual offers troubleshooting charts, step-by-step procedures, and necessary adjustments for efficiently diagnosing and fixing starting problems, ensuring you can address any issues related to the engine's starting system.

Is the manual of the Perkins 4.108 available in English?

Unfortunately, we do not have the manual for the Perkins 4.108 available in English. This manual is available in -.

Is your question not listed? Ask your question here

Nanni V6.270

Perkins 4.236

Nanni N4.38

Nanni N2.14

Doosan L136TI

Doosan AD136TI

Doosan AD136

Nanni V6.320

Perkins T6.354

Perkins HT6.354

- Customer Service & Sales Hours

- Monday - Friday: 8am - 5pm EST Saturday & Sunday: Closed

- Customer Service

- Contact Form

- 888-919-7767

- Order Status

- Sales Tax Forms

- Returns Policy

- Privacy Policy

Perkins 4-108 Marine Diesel Engine

Perkins 4-108 Diesel engine

The Perkins 4.99 was first launched by Perkins in 1958. This sturdy 1.6 litre 4 cylinder diesel engine was fitted in cars, boats and commercial vehicles including the Ford Thames 400E. In the mid 1960’s it was upgraded to become the 4.107 and later the classic 4.108 which continued in production until the 1980’s.

The Perkins 4-108 51 horsepower 4-cylinder marine diesel gives you reliable, durable and safe performance with compact size and low weight. A rotary distributor-type fuel-injection system provides even fuel feed for smooth performance. An automatic advance and retard mechanism ensures fast starts and quick acceleration throughout the speed range. And the Perkins “H” pre-combustion system means clean burning, top fuel economy. Perkins 4-108 diesels were designed for smooth, vibration free running and are also designed for dependability with features like a closed freshwater cooling system to minimize corrosion. The 4.108 is an auxiliary engine that provides plenty of clean, economical power when you need it.

The Perkins 4107/4108 engine, also known as the Westerbeke 40, made its North American debut at the 1960 New York Boat Show. Because of its rugged and quiet cast iron design, relatively low revving operation and low cost replacement parts, the Perkins 4108 marine diesel engine was widely adopted and many thousands are still in use some 60 years after their launch. But they are undoubtedy a noisy and heavy beast by modern standards.

PERKINS 4.108 MARINE DIESEL ENGINE – GENERAL DATA

ENGINE Type: In-line 4-cylinder diesel, 4 cycle. Maximum Horsepower: 51 @ 4000 RPM Displacement: 107.4 cu in. Bore and Stroke: 3.125 x 3.5 in. Compression Ratio: 22:1 Governing: Hydraulic Cooling: Heat Exchanger

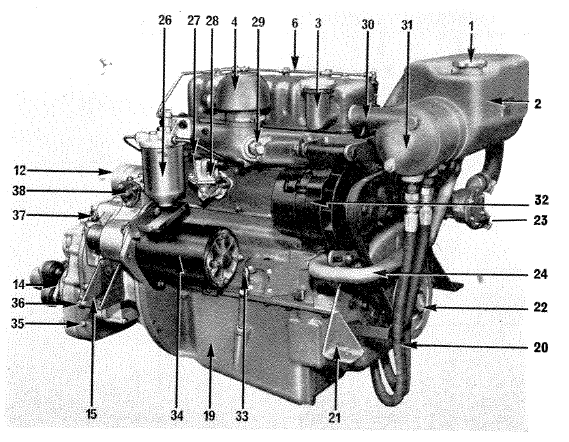

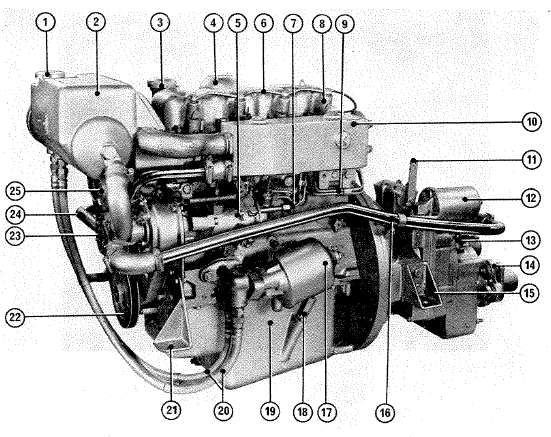

Components of the Perkins 4-108 Marine Diesel Engine

- Fresh Water Filler Cap

Bateaux moteurs

- News des PROs

- Annonces de voiliers

- Annonces de bateaux moteur

- Puces nautiques

- Bourse d'équipier

- Location de bateaux

- Emploi du nautisme

- Devenez PREMIUM

- Concours photos

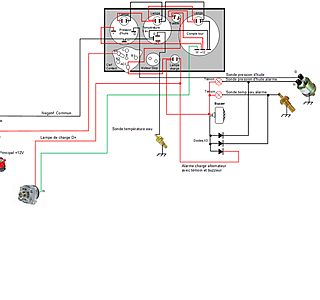

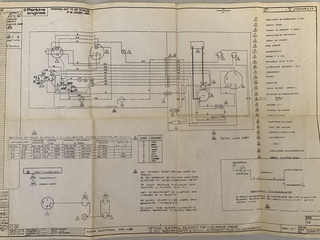

schema electrique Perkins 4108 M

des imbéciles ont sorti mon moteur sous pretexte de réparer l'inverseur et n'ont pas pris de photos des branchements! Résultat:moteur muet. il s'agit du moteur à boite à eau rectangulaire longitudinale. Le bateau est un formidable et rare "Atlantic Clipper" de Maurice Griffiths. C'est à dire qu'il est très difficile de se mouvoir autour du moteur. Merci de m'aider par au moins le plan des raccords de l'alternateur ( c'est un Bosch) et celui du demarreur (marque non lisible mais avec solenoïde séparé.

j'ai refais complètement l'électricité d'un 4108, il n'y a pas grand chose a faire ... tu es d'ou ?, cordialement

je te félicite! Mon bateau est à st. cyprien (66) . Mais je ne suis pas du tout électricien. Si tu pouvais m'envoyer 1photo du branchement alternateur et une du démarreur ce serait bien. codialement aussi.

Bonjour, je viens sur le forum juste maintenant... Je possède un fifty27 des années 70 et souhaiterai refaire le faisceau électrique. As tu un schéma de câblage ? Si oui je pourrai t'adresser mon adresse Mail. Merci

Bonjour je possède un fifty 27 avec un perkins 4.108. Le bateau date des années 70 d'ou des connections en bout de vie. J'ai l'intention de refaire tout le circuit électrique. Si tu peux m'aider avec ton expérience et un plan éventuel je serai preneur.

Voici le schéma, si problème, me contacter par courriel, tu trouveras mon adresse dans mon profil. :doc: :doc:

j'ai regardé le schéma ,malheureusement ce n'est pas le bon ,celui que tu as c'est avec alternateur lucas à régul séparé celui dont il a besoin est beaucoup plus simple dans tous les cas c'est du 2 fils masse isolée alain

aie un peu loin pour te dépanner , je suis de la Marne et mon bateau est à Cherbourg et hélas (pour toi) j'ai vendu celui qui avait un 4.108 j'ai maintenant un jeanneau lamparo avec un 4.236. pour le branchement alternateur tu as le + a mettre sur batterie (coupe batterie) et soit un D+ ou tu mets l’excitation fil qui vient du voyant batterie, soit 2 cosses une petite pour le voyant et une grosse pour l’excitation si mes souvenirs sont exact , ça dépend du type d'alternateur. pour le démarreur + batterie (coupe circuit) et fil sur le solénoïde qui vient du contact.... si besoin d'autre renseignements ou pas bien compris ou moi pas bien exprimé demande moi...... on envoie des photos j'essayerai de te guider ... cordialement didier

les schémas électriques et ladoc technique sont sur le web en tapant: doc technique perkins 4108

Bonsoir. Pouvez-vous me parler, s'il vous plaît, de ce modèle "Atlantic Clipper 36" à propos duquel je cherche des informations sans trouver grand chose ? Je vous remercie de votre attention, en espérant vivement que vous pourrez m'en parler avec votre expérience. Cordialement. Bruno.

Bonjour, je relance ce fil ayant un 4108 M actuellement. Quelqu un aurait il l experience ou le shema pour Ultra Simplifier le circuit electrique du 4108 ? Je recherche : elimination de tous les fils inutiles + recablage simplifie des fonctions principales de controle (alarmes pression huile, temperature, etc..) Peut on envisager d enlever totalement le faisceau et de rcabler un par un les fils? (La distance entre mon moteur et le tableau de controle etant environ 1m20) Merci do vos idees, je suis situe region du canet roussillon.

voila l ami tu peus tout enlever cela te permettera de bien comprendre le fonctionement de ton moteur il y a deux circuits le premier s appel la commande et le deuxieme s appel la puissance c es tout de la logique comprendre comment fonctionne un élèment . tu commence chose part chose ex: une sonde il y a un fil de + qui arrive( 12v) ou un - a ta sonde . quand ta sonde ce rétracte elle laisse passer l info soit un moins soit un plus .si ton fil arrive avec un moins il repart avec un moins .si il arrive avec un plus il repart avec un + et il arrive vers une lampe temoins . si ta sonde ce rétracte ca veus dire quel chauffe donc la lampe s allume c es vrais que ce n es pas simple de t expliqué mais va doucement demande sur hisse heo tu aura toujours quelq'un pour te répondre sur le sujet que tu bloque prend quand meme des photos cela ve bien t aider voila

Chez parts4engines on vend des faisceaux 11brins au metre

c'est la meilleure solution on enlève tout et on recommence c'est dommage que tu ne sois pas par chez moi ,c'était réglé en moins de 2 H commence par réunir tous le - ensemble et les amener sur celui du démarreur tu repars de là avec un 30mm2 vers un cb et au - de la batterie de démarrage . et après c'est du fil a fil pour les instruments et le branchement classique pour l'alternateur et le solénoide alain

bonjour et meilleurs vœux a tous @chrisja je te répond sur le forum tout le monde en profitera je précise : si négatif a la masse relis mon message au dessus après tu as la sonde d'huile et température d'eau et je pense que c'est tout ...... si je me trompe on va me rectifier.... après tu fais un joli tableau interrupteur voyant et fusible pour les accessoires vhf, gps , sondeur , lumiere etc etc et si tu n'as pas de tableau j'en fait ...!!! www.leboncoin.fr[...]993.htm www.leboncoin.fr[...]920.htm

cordialement didier

Moi j'ai pas d'alarme de température sur mon Perkins... Seulement la sonde. Par contre j'ai alarme et sonde de pression. Mais j'ai le capteur de régime, qui utilise deux fils ! Ils sont tous différents. Ca veut dire quoi "Muet" ? Y'a du jus sur le tableau (voyants qui s'allument) ? Le buzzer sonne ? Le voyant batterie s'allume ? Le voyant pression s'allume ? Tu peux allumer le préchauffage (tu le sais, puisque ça fume dans le bateau) ? Le démarreur n'a qu'1 ou 2 fils : + qui sort du relais, et sans doute le - qui rejoint la carcasse du moteur (ou un autre relais). L'alternateur en a 3 ou 4 : le -, le + (c'est les deux gros câbles), le D+ (auquel doit être connecté le voyant batterie), et éventuellement le W (pour brancher un compte tours).

tiens l ami cela va t aider a mieux comprendre ton branchement d un 4108 et a tous ceux qui veulent de la part de madoli j en ai d autres mais celui la est simple pour celui qui ne maitrise pas les élèctrons :-)).

Très bien ce petit plan pour les débutants.... Juste une question il y a un bouton "moteur stop" mais je ne vois pas les branchements et bien sur c'est justement ce que je recherche. Cordialement

Bonjour à tous, Merci Madoli58 pour toutes ces infos ! ca va grandement m'aider pour refaire mon élec moteur. j'ai quelques questions : - quelle section de câble entre le fusible réarmable et le contacteur (clé de contact) - quel ampérage pour le fusible en sortie de batterie ? - ou est le démarreur dans ce beau schémas ? merci pour votre aide !

suivant :-) si ca rend service .

voila mon 4108 que je refait c es du régale c es facile pour celui qui connait mais sur un bateau on maitrise pas vraiment tout .la mecanique reste de la mécanique .l élèc c es pareil surtout si tu a des supports ( documents). bon courage a tous

Roland 6142 bonjour,

Sur le perkins 4108 l’arrêt moteur est un câble que tu actionnes en tirant dessus, il est relié directement à la pompe à injection sur la petite manette juste à coté de la commande de l'accélérateur.

Le plan Electrique que j'avais mis sur le forum, c'etait le plan de mon bateau : un gin fizz.

Bonjour quelqu un pourrait m'aider pour démonter la dynamo du compte tour pour la nettoyer sur un perkins 4108.MERCI

Schéma électrique 4108 new

Phare du monde

Phare d'Artrutx Minorca 2022

S'identifier

Pas encore de compte ? Monter à bord !

Forums plaisance et nautisme

Dans quel univers souhaitez vous ajouter votre Question ou votre Discussion ?

Échanges sur la voile et les voiliers : technique, nouveautés, vie à bord, navigation, tour du monde...

Échanges sur les bateaux à moteur : gros cubes, mécanique, technique, nouveautés, sortie en mer...

Espace convivial d'échanges, débat d'idées, polémiques, enguelades, autour de l'univers du nautisme

Forum des actualités du site, nouveautés, bugs, suggestions d'améliorations et évolutions...

Perkins 4.108 (ED) engine for Agri & TP

complete engine, used

Complete, reconditioned engine, reconditioning your engine, be called back by an expert, your alberto advantages.

Payment in instalments

Premium warranty

Control adaptability

Delivery & Returns

Latest perkins 4.108 (ed) engines delivered.

Perkins 4.108 (ED) engine

Perkins A4.108 engine

Long Block Perkins 4.108 (ED)

Our offer for the perkins 4.108 (ed) engine.

At a glance, find the options available on the replacement engine market for the Perkins 4.108 (ED).

Features of the Perkins 4.108 (ED) engine

The Perkins 4.108 (ED) is part of the 4.108 series, a 4-cylinder diesel engine designed for materials handling , industrial and marine applications, then called the 4.108M. It can be found on loaders, mini-excavators and boats.

Our 4.108 (ED) offer consists of complete used or reconditioned engines, as new is no longer available. Depending on the condition of your engine, our advisors can offer you the option of reconditioning . Get the information you need to make your choice .

Engine specs

Cylinders : 4

Indirect injection

Power: 41 kW - 56 hp

Displacement: 1.76 l

Inquiry for Perkins 4.108 (ED) engine

To facilitate the processing of your request and the compatibility analysis , we recommend that you provide the information listed below with your request.

- Machine type, make, reference and year

- motor serial no.

- Photos of all four sides of the engine

Length: 499 mm

Width: 577 mm

Height: 639 cm

Weight: 146 kg

Perkins 4.108 (ED) engine applications

We have already delivered replacement Perkins 4.108 (ED) engines for the following applications:

Our engine brands

- LAWN TRACTORS

- BACKHOE LOADERS

ATTACHMENTS

- Kohler Engines

- Onan Engines

- Kawasaki Engines

- Tecumseh Engines

- Briggs Statton Engines

- Honda Engines

- Yamaha Engines

- Kubota Engines

- Perkins Engines

- Yanmar Engines

TRACTORS SPECIFICATIONS

- John Deere Specs

- Massey Ferguson Specs

- Case IH Specs

- New Holland Specs

- Cub Cadet Specs

- Kubota Specs

- Kioti Specs

FRONT END LOADERS

- John Deere Loaders

- Kubota Loaders

- Massey Ferguson Loaders

- Case IH Loaders

- New Holland Loaders

- Ford Loaders

- Bush Hog Loaders

- Alo Quicke Loaders

- Koyker Loaders

- JD Tractors

SERVICE AND REPAIR

- MF 3000-3100

- MF 5400-5600

- MF 6100-6200

- MF 6400-6600

- MF 7400-7700

- MF 8100-8200

- MF 8400-8700

- CASE IH 385-885

- CASE IH 1190-1690

- JD 4044, 4052, 4066

- JD 5055E, 5065E, 5075E

- JD 5300, 5400, 5500

- JD 5325, 5425, 5525

- JD 5620, 5720, 5820

- JD Troubleshooting

- Kubota Service-Repair

- MF Service-Repair

- NH Troubleshooting

- Ford Troubleshooting

________________________________________________________________________________

Perkins 4.108 Engine

General Technical Data Perkins 4.108 Engine Specifications Engine Model ............... Perkins 4.108 Engine Type ............... 4-Stroke four-cylinder liquid-cooled diesel Number of Cylinders ............... 4 Cylinder Arrangement ............... In-line Engine Bore, in (mm) ............... 3.13 (79.4) Engine Stroke, in (mm) ............... 3.50 (88.9) Displacement, cu.in (L) ............... 107.4 (1.76) Aspiration ............... Naturally aspirated Rated Engine Power, hp (kW) ............... 37-45 (30-36) Rated Engine Speed, rpm ............... 3000-3600 Combustion System ............... Indirect injection Compression Ratio ............... 22.0:1 Firing Order ............... 1-3-4-2 Electrical System Rating, Volts ............... 12 Lubrication System Oil Pressure ............... 30-60 psi (207-414 kPa) Oil Capacity ............... 5.1 qts (4.8 L) Oil Pump ............... Rotor Type Relief Valve Type ............... Spring Loaded Plunger Relief Valve Pressure Setting ............... 50-65 psi (345-448 kPa) Oil Filter Type ............... Full flow, paper canister element Cooling System Cooling System Type ............... Water Cooled Coolant Capacity ............... 7.8 qts (7.4 L) Thermostat Type ............... Wax Capsule Water Pump Type ............... Centrifugal, belt driven from Crankshaft Pulley Fuel System Injection Pump Type ............... DPA Injection Pump Model ............... CAV Lift Pump Type ............... Diaphragm Lift Pump Drive Method ............... Eccentric on camshaft Final Fuel Filter Type ............... Paper element Dimensions and Weight Overall Width, in (mm) ............... 21.2 (538) Overall Height, in (mm) ............... 25.2 (639) Overall Depth, in (mm) ............... 20.1 (508) Net Weight, lbs (kg) ............... 319 (145) Perkins 4.108 Maintenance Data Cylinder Block and Valves Cylinder Bore Inside Diameter (Maximum), in (mm) ............... 3.1307 (79.520) Cylinder Head (Max. Out of Flatness), in (mm) ............... 0.003 (0.08) Intake Valve Clearance, in (mm) ............... 0.012 (0.30) Exhaust Valve Clearance, in (mm) ............... 0.012 (0.30) Engine Oil and Filters Engine Oil Type ............... SAE 30 or 15W-40 Oil Classification ............... API Service CC, CD or CF Oil Capacity, qts (L) ............... 5.1 qts (4.8 L) Oil Filter Part Number ............... 2654403 Fuel Filter Part Number ............... 26561117 Service Intervals Change Engine Oil ............... Every 100 hours Change Oil Filter Element ............... Every 100 hours Check Belt Tension ............... Every 100 hours Replace Final Fuel Filter ............... Every 400 hours Check and Adjust Valve Clearance ............... Every 400 hours Service Atomiser ............... Every 400 hours Perkins 4.108 Service Specifications Cylinder Block and Liners Total Height of Cylinder Block between Top and Bottom Faces ..... 9.936-9.939 in (252.374-252.451 mm) Parent Bore Diameter for Cylinder Liner ............... 3.249-3.250 in (82.525-82.550 mm) Main Bearing Parent Bore ............... 2.3950-2.3955 in (60.833-60.846 mm) Camshaft Bore Diameter No.1 ............... 1.794-1.7955 in (45.568-45.606 mm) Camshaft Bore Diameter No.2 ............... 1.784-1.787 in (45.314-45.390 mm) Camshaft Bore Diameter No.3 ............... 1.776-1.778 in (45.110-45.161 mm) Tappet Bore Diameter ............... 0.562-0.56325 in (14.275-14.307 mm) Fuel Pump Drive Hub Bearing Bore Diameter ............... 1.8125-1.8141 in (46.037-46.078 mm) Interference Fit of Cylinder Liners ............... 0.003-0.005 in (0.076-0.127 mm) Inside Diameter of Cylinder Liner after Finish Boring and Honing ......... 3.125-3.126 in (79.375-79.40 mm) Height of Cylinder Liner in relation to Cylinder Block Top Face ............... 0.023-0.027 in (0.584-0.686 mm) Overall Length of Cylinder Liner ............... 6.495-6.505 in (164.973-165.227 mm) Cylinder Head and Valves Cylinder Head Overall Length ............... 20.000 in (508.000 mm) Cylinder Head Overall Depth ............... 2.617-2.633 in (66.472-66.878 mm) Pressure for Water Leakage Test ............... 20 psi (138 kPa) Cylinder Head Bore for Guide ............... 0.4995-0.5005 in (12.687-12.713 mm) Cylinder Head Bore for Combustion Chamber Inserts ............... 1.250-1.252 in (31.750-31.801 mm) Cylinder Head Bore Depth for Combustion Chamber Inserts ........ 0.373-0.376 in (9.474-9.550 mm) Intake Valve Guide Inside Diameter ............... 0.3141-0.3155 in (7.978-8.014 mm) Intake Valve Guide Outside Diameter ............... 0.5021-0.5026 in (12.753-12.766mm) Intake Valve Guide Overall Length ............... 2.130 in (54.102 mm) Exhaust Valve Guide Inside Diameter ............... 0.3141-0.3155 in (7.978-8.014 mm) Exhaust Valve Guide Outside Diameter ............... 0.5021-0.5026 in (12.753-12.766 mm) Exhaust Valve Guide Overall Length ............... 2.440 in (61.98 mm) Intake Valve Stem Diameter ............... 0.312-0.313 in (7.925-7.950 mm) Intake Valve Guide To Stem Clearance ............... 0.0011 -0.0035 in (0.028-0.089 mm) Intake Valve Head Diameter ............... 1.410-1.414 in (35.814-35.916 mm) Valve Seat Angle ............... 45 deg Intake Valve Face Angle ............... 45 deg Intake Valve Overall Length ............... 4.592-4.608 in (116.637-117.043 mm) Exhaust Valve Stem Diameter ............... 0.3115-0.3125 in (7.912-7.937 mm) Exhaust Valve Guide To Stem Clearance ............... 0.0016-0.004 in (0.041-0.102 mm) Exhaust Valve Head Diameter ............... 1.191-1.195 in (30.251-30.353 mm) Exhaust Valve Face Angle ............... 45 deg Exhaust Valve Overall Length ............... 4.600-4.616 in (116.840-117.246 mm) Valve Spring Free Length ............... 1.780 in (45.212 mm) Crankshaft Crankshaft Overall Length ............... 21.125 in (536.575 mm) Crankshaft Main Journal Diameter No.1 and 2 ............... 2.248-2.2485 in (57.099-57.112 mm) Crankshaft Main Journal Diameter No.3 ............... 2.2475-2.248 in (57.086-57.099 mm) Crankshaft Main Journal Length No.1 ............... 1.40625 in (35.719 mm) Crankshaft Main Journal Length No.2 ............... 1.496-1.504 in (37.998-38.202 mm) Crankshaft Main Journal Length No.3 ............... 1.499-1.502 in (38.075-38.151 mm) Crankpin Diameter ............... 1.9993-2.0001 in (50.78-50.80 mm) Crankpin Length ............... 1.1875-1.1895 in (30.162-30.213 mm) Crankshaft End Float ............... 0.002-0.015 in (0.0508-0.381 mm) Main Bearing Shell Width ............... 1.245-1.255 in (31.623-31.877 mm) Main Bearing Outside Diameter ............... 2.3955 in (60.846 mm) Main Bearing Inside Diameter ............... 2.2505-2.2515 in (57.163-57.188 mm) Main Bearing Running Clearance (No.1 and 2) ............... 0.002-0.0035 in (0.051-0.089 mm) Main Bearing Running Clearance (No.3) ............... 0.0025-0.004 in (0.063-0.102 mm) Pistons and Piston Rings Overall Height (Skirt to Crown) ............... 3.147-3.150 in (79.934-80.010 mm) Piston Height in relation to Cylinder Block Top Face ............... 0.002-0.006 in (0.051-0.152 mm) Bore Diameter for Piston Pin ............... 1.06255-1.06275 in (26.989-26.994 mm) Piston Pin Outside Diameter ............... 1.0625-1.0627 in (26.987-26.993 mm) Piston Pin Length ............... 2.673-2.687 in (67.894-68.250 mm) Top Compression Ring Groove Width ............... 0.0805-0.0815 in (2.045-2.070 mm) 2nd Compression Ring Groove Width ............... 0.0645-0.0655 in (1.638-1.664 mm) 3rd Compression Ring Groove Width ............... 0.0645-0.0655 in (1.638-1.664 mm) 4th Oil Control Ring Groove Width ............... 0.126-0.127 in (3.200-3.225 mm) 5th Oil Control Ring Groove Width ............... 0.190-1.191 in (4.826-4.851 mm) Top Compression Ring Width ............... 0.0771-0.0781 in (1.958-1.984 mm) Top Compression Ring Groove Side Clearance ............... 0.0024-0.0044 in (0.061-0.112 mm) 2nd and 3rd Compression Ring Width ............... 0.0615-0.0625 in (1.562-1.587 mm) 2nd and 3rd Compression Ring Groove Side Clearance ............... 0.002-0.004 in (0.051-0.102 mm) 5th Scraper Ring Width ............... 0.1865-0.1875 in (4.737-4.762 mm) 5th Ring Groove Side Clearance ............... 0.0025-0.0045 in (0.063-0.114 mm) Top Compression Ring End Gap ............... 0.009-0.014 in (0.229-0.356 mm) 2nd and 3rd Compression Ring End Gap ............... 0.009-0.014 in (0.229-0.356 mm) 5th Scraper Ring End Gap ............... 0.009-0.014 in (0.229-0.356 mm) Connecting Rod Small End Bush Length ............... 0.935-0.955 in (23.749-24.257 mm) Small End Bush Outside Diameter ............... 1.221-1.222 in (31.013-31.039 mm) Small End Bush Inside Diameter before Reaming ............... 1.0495-1.0545 in (26.657-26.784 mm) Small End Bush Inside Diameter after Reaming ............... 1.06315-1.0632 in (27.004-27.005 mm) Small End Bush to Piston Pin Clearance ............... 0.00045-0.0007 in (0.0114-0.0178 mm) Connecting Rod Big End Bore Diameter ............... 2.146-2.1465 in (54.508-54.521 mm) Connecting Rod Small End Bore Diameter ............... 1.21875-1.21975 in (30.956-30.981 mm) Length from Centre Line of Big End to Centre Line of Small End ....... 6.217-6.219 in (157.912-157.963 mm) Connecting Rod End Float ............... 0.0065-0.0105 in (0.165-0.267 mm) Connecting Rod Bearing Shell Width ............... 0.870-0.880 in (22.098-22.325 mm) Connecting Rod Bearing Outside Diameter ............... 2.1465 in (54.521 mm) Connecting Rod Bearing Inside Diameter ............... 2.0015-2.0025 in (50.838-50.863 mm) Connecting Rod Bearing Running Clearance ............... 0.0015-0.003 in (0.038-0.076 mm) Camshaft No.1 Journal Length ............... 1.347-1.351 in (34.214-34.315 mm) No.1 Journal Diameter ............... 1.791-1.792 in (45.491-45.517 mm) No.1 Cylinder Block Camshaft Bore Diameter ............... 1.794-1.7955 in (45.568-45.606 mm) No.1 Journal Running Clearance ............... 0.002-0.0045 in (0.051-0.114 mm) No.2 Journal Length ............... 1.250 in (31.750 mm) No.2 Journal Diameter ............... 1.781-1.782 in (45.237-45.263 mm) No.2 Cylinder Block Camshaft Bore Diameter ............... 1.784-1.787 in (45.314-45.390 mm) No.2 Journal Running Clearance ............... 0.002-0.006 in (0.051-0.152 mm) No.3 Journal Length ............... 1.000 in (25.400 mm) No.3 Journal Diameter ............... 1.773-1.774 in (45.034-45.060 mm) No.3 Cylinder Block Camshaft Bore Diameter ............... 1.776-1.778 in (45.110-45.161 mm) No.3 Journal Running Clearance ............... 0.002-0.005 in (0.051-0.127 mm) Cam Height ............... 0.266 in (6.766 mm) Perkins 4.108 Tightening Torque Specs Cylinder Head Nuts, lb-ft (Nm) ............... 60 (81) Connecting Rod Bolts, lb-ft (Nm) ............... 42 (57) Main Bearing Bolts, lb-ft (Nm) ............... 85 (115) Flywheel Bolts, lb-ft (Nm) ............... 60 (81) Idler Gear Hub Bolts, lb-ft (Nm) ............... 36 (49) Crankshaft Pulley Bolt, lb-ft (Nm) ............... 150 (203) Atomiser Securing Nuts, lb-ft (Nm) ............... 12 (16) Fuel High Pressure Pipe Nuts, lb-ft (Nm) ............... 15 (20) Dynamo Pulley Nut, lb-ft (Nm) ............... 20 (27) Alternator Pulley Nut, lb-ft (Nm) ............... 30 (41) Thermostart Unit, lb-ft (Nm) ............... 10 (13) Thermostart Insulating Adaptor, lb-ft (Nm) ............... 10 (13)

________________________________________________________________________________________

Kubota D902 Fuel System

Kubota B1550, B6100, B6200 Engine Service

Kubota B5200, B7100, B7100HST Engine Service

Kubota B1700, BX2200, B8200 Engine Check and Maintenance

Kubota L245DT, L2350, L2550 Engine Service and Maintenance

Kubota L2800, L3010, L3130 Engine Checking and Service

Kubota L2501, L3200, L3400, L3800 Engine Service and Maintenance

Kubota L5040, L5740, MX5100, L4200 Engine Service

JD 3120, 3320, 3520, 3720 Engine

JD 3032E, 3038E Service Engine

JD 5620, 5720 Engine

JD 5225, 5325, 5525 Engine

JD 4044R, 4052R Service Engine

Tractor equipment and spare parts

Not Your Father’s 4108!

- Share this via Facebook

- Share this via Twitter

- Share this via Email

We are now supplying factory remanufactured Perkins 4108 marine engines with significant upgrades over a stock Perkins 4108. These upgrades include an optimized fuel injection system producing more horsepower, a serpentine belt system which includes hardened, Rockwell-tested pulleys including a spring loaded, active‚ pulley for the alternator that dampens crankshaft pulses. This active pulley ensures longer life for the alternator as well as the serpentine belt. The upgrades also include a new height output 105 amp alternator, our innovative rear main seal to cure the chronic leaking problem endemic to Perkins 4108, and a spin-on secondary fuel filter with drain petcock. This spin on filter replaces the awkward cartridge style fuel filter which doesn’t have provision to drain it without removing it from Perkins engine.

Recent Tech Tips

Announcing new ownership at foley engines, foley named in boston business journal “book of lists”, foley scrubbers featured in construction equipment guide, award from wpt: foley engines received top sales award, tech tip #240: twin disc shaft lengths, southern loggin’ times september 2021, timber harvesting magazine sept/oct 2021, tech tip #239: twin disc / wpt ibf314 pilot bearing installation made easy.

Customer Focused Toggle content - Customer Focused

- Learn More : About Foley Engines

Same Day Shipping Toggle content - Same Day Shipping

- Learn More : Same Day Shipping

Huge Inventory Toggle content - Huge Inventory

- Learn More : Huge Industrial Engine Products Inventory

Great Pricing Toggle content - Great Pricing

- Learn More : Great Pricing

- Perkins Manuals

Perkins 4.108(M) Manuals

Perkins 4.108(M) Workshop Manual (135 pages)

Table of contents.

- Unified Threads and Engine No. Location 6

- Engine Identification - New Series 7

- Engine Family and Type Codes 7

- Country of Origin Code 7

- Year of Manufacture Code 7

- Index to Engine Photographs 12

- View of Fuel Pump Side of Low-Line Engine 13

- View of Camshaft Side of Low-Line Engine 14

- View of Fuel Pump Side of Engine 15

- View of Camshaft Side of Engine 16

- Technical Data 17

- Engine Weights 18

- Recommended Torque Tensions 19

- Service Wear Limits 19

- Manufacturing Data and Dimensions 20

- Connecting Rod Alignment 22

- Operating and Maintenance 31

- Priming the Fuel System 32

- Preparing & Starting the Engine 32

- To Operate the Cold Start Aid 32

- Earlier Heat Start Switch 32

- Stopping the Engine 33

- Running in 33

- Preventive Maintenance 34

- Keep Engine Clean 34

- Post-Delivery Checkover 34

- Preservation of Laid-Up Engine 34

- Preparing the Engine for Return to Service 35

- Heat Exchanger Cooled Engines 36

- Frost Precautions 37

- Fault Finding 39

- Fault Finding Chart 40

- Cylinder Head 41

- To Remove the Cylinder Head 42

- To Remove the Valves 43

- Combustion Chamber Inserts 43

- Cleaning 44

- Valve Springs 44

- Valve Guides 44

- Valves and Seats 45

- Hand Grinding 45

- Valve Seat Inserts 46

- To Dismantle the Rocker Shaft Assembly 47

- To Re-Assembly the Rocker Shaft Assembly 48

- Push Rods 48

- To Refit the Valves 48

- Valve Seals 48

- Cylinder Head Gasket 49

- To Refit the Cylinder Head 49

- Adjusting Valve Clearances 51

- Valve Adjusting Sequence 51

- Pistons and Connecting Rods 53

- To Remove Pistons and Connecting Rods 54

- To Remove Pistons and Rings from the Connecting Rods 54

- Pistons and Connecting Rods Inspection 55

- To Refit Pistons to Connecting Rods 55

- Fitting the Piston Rings 56

- To Fit Piston and Connecting Rod Assemblies 57

- Fitting New Pistons 58

- Cylinder Block and Liners 59

- Cylinder Liners (4.108 Engines) 60

- To Renew Cylinder Liners 60

- Cylinder Liners (4.99 and 4.107) 61

- To Remove Liners 61

- To Fit New Liners 62

- Crankshaft and Main Bearings 63

- Crankshaft and Main Bearings Description 64

- To Renew Main Bearings and Thrust Washers 65

- To Remove the Crankshaft 67

- To Refit the Crankshaft 67

- Crankshaft Regrinding 67

- Crankshaft Rear End Oil Seal 67

- Crankshaft Regrind Data 69

- Timing Case and Drive 71

- To Remove the Timing Case Cover 72

- To Remove the Crankshaft Front Oil Seal 72

- To Refit the Timing Case Cover 72

- To Remove the Idler Gear and Hub 72

- To Refit the Idler Gear and Hub 73

- To Remove the Camshaft Gear 73

- To Refit the Camshaft Gear 74

- To Remove the Fuel Pump Gear 74

- To Refit the Fuel Pump Gear 74

- To Remove the Fuel Pump Drive Hub 74

- To Refit the Fuel Pump Drive Hub 75

- To Remove the Timing Case Back Plate 75

- To Refit the Timing Case Back Plate 75

- To Remove the Camshaft and Tappets 75

- To Refit the Tappets and Camshaft 77

- Timing Marks 80

- Fuel Pump Timing Marks 80

- To Reset Engine to Its Original Timing 81

- Check Valve Timing 81

- Checking Fuel Pump Timing Using Tool MS67B 82

- Lubricating System 85

- Draining the Sump 87

- The Lubricating Oil Pump 87

- To Remove/Refit the Sump 87

- To Remove the Oil Pump 87

- To Dismantle the Oil Pump 88

- Oil Pump Inspection 88

- To Re-Assemble the Oil Pump 88

- To Refit the Oil Pump 89

- To Dismantle Oil Pressure Relief Valve 89

- To Re-Assemble Oil Pressure Relief Valve 90

- Oil Pressure 90

- Lubricating Oil Filters 90

- To Remove the Filter Element 90

- To Remove Oil Filter Head Casting 91

- By-Pass Valve 91

- To Renew the Filter Element 91

- To Renew Screw Type Oil Filter Canister 91

- Cooling System 93

- Open Circuit Cooling 94

- Closed Circuit Cooling 94

- Sea Water Pump 95

- To Remove Pump 95

- Dismantling 95

- Alignment of Sea Water Pump Adaptor Plate 96

- Fresh Water Pump 97

- Fresh Water Pump Seals 97

- To Remove Water Pump 97

- To Dismantle Water Pump 97

- Cooling System Inspection 98

- To Re-Assemble the Water Pump 98

- To Refit the Water Pump 99

- Heat Exchanger and Oil Cooler 99

- Exploded View of Heat Exchanger 100

- Heat Exchanger Dismantling 101

- Heat Exchanger Cleaning 101

- To Remove Thermostat 102

- To Test/Refit Thermostat 102

- Checking for Correct Adjustment 102

- Water Pump Belt Adjustment 102

- Air Filter and Fuel System 103

- Fuel Oil Filters 104

- To Renew the Oil Filter Element 104

- Pressure Testing of Fuel Lift Pump in Position 105

- To Remove the Lift Pump 105

- To Dismantle Lift Pump 105

- To Re-Assemble the Lift Pump 106

- To Refit the Lift Pump 106

- To Remove Fuel Injection Pump 107

- To Refit Fuel Injection Pump 107

- Maximum Speed Setting 107

- Idling Speed Adjustment 107

- Anti-Stall Device 108

- Atomisers 108

- Testing for Faulty Atomiser 109

- Atomiser Pressures 109

- Atomiser Identification 109

- Fuel Pipes 109

- Bleeding the Fuel System 110

- Priming Procedure after Changing Filter Element 111

- Fuel Oil 111

- Flywheel and Flywheel Housing 113

- Alignment of the Adaptor Plate, Flywheel Housing and Flywheel 114

- Alignment of the Adaptor Plate Face 114

- Fitting Flywheel and Checking Alignment 114

- Alignment of Flywheel Housing Bore 115

- Alignment of the Flywheel Housing Face 115

- Electrical System 117

- Alternator Models AC5 and 11AC 118

- Alternator Maintenance 118

- Alternator Fault Finding on AC5 118

- Warning Lamp Does Not Light up When Switched "On" 119

- Checking the Field Isolating Relay 119

- Checking or Adjusting the Voltage Setting 119

- Checking the Alternator and Control Box 119

- Adjustment of Voltage Setting 120

- Check of Alternator Output 120

- Fault Diagnosis Procedure for 11AC Alternator Fails to Charge 120

- Noise Alternator 120

- DYNAMO Description 121

- DYNAMO Routine Maintenance 121

- DYNAMO Performance Data 121

- DYNAMO Servicing 121

- Brush Gear 122

- Starter Motors 122

- Checking Freedom of Brush Movement 123

- Electrical System Servicing 124

- 'S' Type Starter Drive Assembly 124

- Lubricating Oils 127

- Approved Service Tools 129

- Valve Seat Cutters 131

Advertisement

Perkins 4.108(M) Handbook (50 pages)

- Introduction 4

- Engine Identification 4

- Key to 4.108(M) Engine Photographs 6

- Key to P3.152(M) Engine Photographs 7

- Key to 4.236(M) Engine Photographs 8

- Key to 6.354(M) Engine Photographs 9

- Key to HT6.354(M) Engine Photographs 10

- Key to T6.354(M) Engine Photographs 11

- Key to 6.354(M) Lowline Engine Photographs 11

- Key to V8.510(M) Engine Photographs 12

- Key to TV8.510(M) Engine Photographs 13

- Key to 4.108(M) Lowline Engine Photographs 14

- Preparation for Starting 16

- Starting the Engine 16

- Earlier Heat Start Switch 16

- Typical Engine Control Panel 16

- Starting the Engine (Alternative Method) 17

- Starting the Engine (P3.152(M) Engines) 17

- Starting the Engine (TV8.510) 17

- Starting the Engine (V8.510) 17

- To Stop Engine 18

- Cold Starting 18

- Instruments 19

- Engine Oil Pressure Gauge 19

- Gearbox Oil Pressure Gauge 19

- Turbocharger Oil Pressure Gauge 19

- Periodical Attentions 20

- Tachometer 20

- Water Temperature Gauge 20

- Post Delivery Checkover 22

- Preservation of Laid up Engine 23

- Oil Recommended for Preservation of Fuel System 24

- Preparing the Engine for Return to Service 25

- Frost Precautions 26

- Fuel System 27

- Fuel Oil Specification 27

- Bleeding the Fuel System 27

- Engines Fitted with In-Line Fuel Injection Pumps 28

- Fuel Filters 29

- Engines Fitted with S.I.G.M.A Rotary Type Fuel Injection Pumps 29

- To Renew Filter Elements 29

- Idling Speed Setting 30

- C.A.V. Rotary Type Pumps 30

- S.I.G.M.A. Rotary Type Pumps 30

- In-Line Pumps 30

- Anti-Stall Device 31

- Cooling System 32

- Atomiser Testing and Replacement 32

- Coolant Capacities 32

- Lubricating System 33

- Colling System Maintenance 33

- Rubber Impeller Type Water Pump 33

- Heat Exchangers, Oil Coolers and Air Charge Coolers 33

- Screw Type Oil Filter 34

- Renewing Oil Filter Elements 34

- To Renew Screw Type Oil Filter 34

- Oil Pressure 34

- Lubricating Oils 35

- Borg-Warner 35

- Self Changing Gears 36

- Nicor TMP Type 12000 Mk II 36

- Parsons 'DA' 36

- Propeller Shaft Trailing 36

- Checking Tappet Clearances 37

- Electrics 38

- Alternator 38

- Starter Motors 38

- Electronic Corrosion 38

- General Precautions 39

- Hints on Running 41

- On Board Tools 41

Perkins 4.108(M) Handbook (49 pages)

- Table of Contents 6

- On Board Tools 7

- Engine Photographs 8

- Engine Identification 13

- Opening Instructions 15

- Instruments 18

- Preventive Maintenance 20

- Post Delivery Checkover 21

- Preservation of Laid up Engine 22

- Frost Precautions 25

- Cooling System 31

- Lubricating System 37

- Checking Valve Clearances 38

- Gearboxes 39

- Electrics 42

- Approved Lubricating Oils 45

- Fault Finding 47

- Emergency Measures 49

Related Products

- Perkins 4.10SM

- Perkins 4.107

- Perkins 4.108

- Perkins 415GM

- Perkins 4.154

- Perkins 4.135

- Perkins 4.182

- Perkins 4.154 M

- Perkins 4.107(M)

- Perkins 4008-30 SD8

Perkins Categories

Upload manual.

THE 10 BEST Moscow City Tours

City tours in moscow.

- Private Tours

- Walking Tours

- 5.0 of 5 bubbles

- 4.0 of 5 bubbles & up

- 3.0 of 5 bubbles & up

- 2.0 of 5 bubbles & up

- 3rd Transport Ring (TTK)

- District Central (TsAO)

- Garden Ring

- Good for Big Groups

- Good for Couples

- Budget-friendly

- Good for Kids

- Good for a Rainy Day

- Good for Adrenaline Seekers

- Hidden Gems

- Honeymoon spot

- Adventurous

- Things to do ranked using Tripadvisor data including reviews, ratings, photos, and popularity.

1. Moscow Private Tours

2. Moscow through the Eyes of an Engineer

3. Moscow Free Tour

4. Bridge to Moscow

5. Spanish Guide Moscow - Day Tours

6. Go Russia Travel Company

7. Privilege Tour

8. Moscow Navigator

9. Put-in Tours

10. Walks With Folks

11. Moskovskiye Gulyaki

12. Moscow Bike Tours

13. Happy Moscow Tours

14. Tour of Moscow - Day Tours

15. Kremlin Tour

16. IdeaGuide - Your Personal Guide in Moscow

17. Tsar Visit

18. Excursions in Russia

19. VikiTours

20. Moscow Greeter

21. MoscowMe

22. Gulyayem po Moskve

23. Tour Gratis Moscu

24. Tour-Moscow

25. Gorodskoi Voyazh

26. Rusiatourmoscu

27. Moscow 360

28. Express to Russia

29. Russia With Love

30. Angel Taxi - Day Tour

What travelers are saying

- Put-in Tours

- Spanish Guide Moscow - Day Tours

- Walks With Folks

- Happy Moscow Tours

- Moscow Bike Tours

- IdeaGuide - Your Personal Guide in Moscow

- Moscow Private Tours

- Tour Gratis Moscu

- Moscow Free Tour

- YourLocalGuide Moscow

- Moscow Navigator

- Moscow through the Eyes of an Engineer

- Angel Taxi - Day Tour

- Your Moscow Guide & Driver

- Excursions in Russia

- Vadim Pavlov Guide and Driver in Moscow

- Buenos Aires

- Paris Christmas Light

- Thessaloniki

- Kuala Lumpur

- Mexico City

- Kristiansand

- Panama City

St. Petersburg

- Johannesburg

- Benalmadena

- Gran Canaria

- Palma de Mallorca

- San Sebastian

- Bournemouth

- Derry-Londonderry

- London Christmas Light

- Stratford-upon-Avon

- Los Angeles

- New Orleans

- Philadelphia

- San Antonio

- San Francisco

- St. Augustine

- Trolley Tour

- Washington D.C.

- Ho Chi Minh

- GBP (£) USD ($) AUD ($) HKD ($) ZAR (R) CNY (¥) NOK (kr) CZK (Kč) GBP (£) CAD ($) AED (د.إ) CHF (₣) ISK (kr) SEK (kr) DKK (kr) EUR (€) SGD ($) INR (₹) NZD ($) MXN ($) THB (฿) MYR (RM)

- 🛒 0

- Login / Sign Up

Password reset successful. We've sent the new password to your registered email. Please check your email for the confirmation.

Sorry, it looks like this email isn't registered.

No Cancellation Charges up to 24 hours before the chosen travel date. 100% cancellation fee applied within 24 hours of travel date.

For groups of 12 or more, you may send us an inquiry at [email protected]. Although we do not guarantee bulk deals for all our tours, there are some tours for which we can offer discounted pricing. Ordinary hop-on-hop-off bus tickets are entitled to group savings. Attractions, pass items and combo tickets aren't.

Due the nature of this type of tour and varying demand, group travellers should be aware that there is no guarantee that the group will be able to travel altogether as the available seats vary from stop to stop and depends on demand each day. The group may need to split up and/or wait for the next bus(s).

As, we cannot guarantee that the group shall be able to travel together as one group, therefore we will reduce the group size down to 4-5 smaller groups per ticket (depending upon group size).

City Sightseeing: Moscow Hop-On, Hop-Off Bus Tour

This Tour Is Not Available Right Now

Click here to explore more activities in moscow.

Lowest Price Guarantee *

Select Date, Travellers and Ticket

- The Bus Tour offers unlimited 360° panoramic views of main sights of Moscow.

- Access to audio-guide in 10 different languages which enables to know about Moscow’s history and traditions.

- The three-bus tour routes and 40+ stops around Moscow completes the trip. Draw an itinerary to explore the city on your own.

- There can be a boat tour and bus tour to enjoy panoramic views of Moskva River.

- Smartphone Voucher Accepted. (No need to print)

The City Sightseeing at Moscow begins at Bolotnaya Square with Hop-on-Hop-off bus service. The bus operates on the Red, Green and Orange lines. If you have limited time in Moscow, start your trip on the Redline and get yourself acquainted with the city’s 16 best attractions. The green line, however, covers 26 amazing spots so if you are staying for an extended period catch the green line.

- Pushkin Museum of Fine Arts

- Alexander Garden

- GUM State Department Store

- Sofiyskaya Embankment

- Cathedral of Christ the Saviour

- University Square, Vorobyovy Gory Observation Deck

- Hotel Ukraina Pier

- Zaryadye Park

- Memorial Museum of Cosmonautics

- VDNKh Metro Station

- Cosmonauts Alley

- Ostankino Television Tower

- Red Route: Schedule: 10:00 - 18:00 , Loop: 60 Minutes , Frequency: 15 Minutes

- Green Route : Schedule: 10:00 - 18:00 , Loop: 120 Minutes , Frequency: 30 Minutes

- Orange Route : Schedule: 10:00 - 18:30 , Loop: 140 Minutes , Frequency: 30 Minutes

- 24 / 48-Hours Hop-on Hop-off Bus Ticket

- Red Line Audio Guide: Russian, English, German, Spanish, Italian, French, Chinese, Arabic, Portuguese, Farsi

- Green Line Audio Guide: Russian, English, German, Spanish, Italian, French, Chinese, Arabic

- Orange Line Audio Guide : Russian English, German, Spanish, Italian, French

- Guided walking tour

- Boat Tour (If option selected)

- Hotel Transfers

- Entrance Fees (Unless Specified)

Redemption Info

You can board the bus at any stop and voucher can be exchanged directly with the driver. Printed vouchers required for this tour and are accepted at all stops. You will receive a ticket in exchange for your voucher, which you must keep until the expiry date/ tour. Please check your ticket to know when it expires. After exchanging your voucher for a ticket, your voucher will no longer be valid. In loss of voucher/ticket, company is not liable for any refund. Book Now! You can use your ticket any day within 12 months.

Know Before You Go

Wheelchair Access, Heating Please note that face masks must be worn on board the bus. Orange Route is temporarily suspended

Operational Details: Walking Tour

- Daily at 10:45 a.m.

- Duration: 2 hours 30 minutes

- Meeting point: next to the monument to Saints Cyril and Methodius (Kitay-Gorod metro station)

Capital River Boat Tour

- May - October: from 11:30am to 6:30pm (Subject to change)

- Duration: 60 minutes

- Departure Point: Zaryadye Park Pier

Useful Downloads

Cancellation policy, other cities in russia.

IMAGES

VIDEO

COMMENTS

Le compte tours de mon Perkins 4108 ne fonctione plus. Un professionnel m'a répondu que la réparation allait entrainer beaucoup de frais. Capteur Perkins qui n'existe plus, accessibilité aux boitiers électriques très difficile sur mon voilier. Bref j'ai renoncé à la réparation. 2e point, l'indicateur de température ne semble pas ...

Re: Comment monter un compte-tour sur un moteur Perkins 4.108. C'est le principe : une roue phonique ( poulie avec des dents "carrées" ) ou poulie alu avec des inserts acier , un capteur et un compte tours programmable. La mise en place risque de ne pas être simple.

The Perkins 4107/4108 engine, also known as the Westerbeke 40, made its North American debut roughly 65 years ago at the 1960 New York Boat Show. Because of its rugged and quiet cast iron design, relatively low revving operation, and low-cost replacement parts, the Perkins 4108 engine has been widely adopted with thousands still in use.

Jay Foley of Foley Engines is taking an out-of-date Perkins 4.108 engine and bringing it into the 21st century. With an array of engine upgrades, this Not Your Father's 4.108 is a sailor's dream. Greg Jones is Content Director and Editor of Engine Builder Magazine. Located in Worcester, MA, not far from the water, Foley Engines specializes in ...

The Perkins 4.108 is a marine engine that is known for its reliability and durability. It is specifically designed for use in marine applications and is often used in sailboats, motorboats, and other types of water vessels. The Perkins 4.108 is a four-cylinder, naturally aspirated engine that has a displacement of 1.8 liters.

The Perkins 4.108 engine is known for its compact design, making it suitable for installations with limited space. This efficiency in size does not compromise its power output, as it continues to deliver remarkable performance in a compact package. Fuel Efficiency. Fuel efficiency is a standout feature of the Perkins 4.108 engine.

Alternateur avec régulateur. Tableau de bord à compte-tour électrique. Contact. E-mail : [email protected]. Téléphone : +230 460 13 13. Actualités. La Série 4.108 est une famille de moteurs diesel Perkins pour les applications : TP/INDUSTRIE/AGRICOLE, GENSET, MANUTENTION, MARINE.

View and Download Perkins 4.108 service data online. 4.108 engine pdf manual download. Also for: 3.152 series, 4.203 series, 6.3544 series, V8.540 series, 4.236 series.

Related Manuals for Perkins 4.108. Engine Perkins 4.108 Service Data (66 pages) Engine Perkins 4.10SM Handbook. Marine diesel engine (49 pages) Engine Perkins 415GM Installation Manual. Sabre marine auxiliary engines (96 pages) Engine Perkins 415GM User Handbook Manual (124 pages)

Manuals and User Guides for Perkins 4.108. We have 2 Perkins 4.108 manuals available for free PDF download: Workshop Manual, Service Data.

The Perkins 4107/4108 engine, also known as the Westerbeke 40, made its North American debut at the 1960 New York Boat Show. Because of its rugged and quiet cast iron design, relatively low revving operation and low cost replacement parts, the Perkins 4108 marine diesel engine was widely adopted and many thousands are still in use some 60 years after their launch.

Sur le perkins 4108 l'arrêt moteur est un câble que tu actionnes en tirant dessus, il est relié directement à la pompe à injection sur la petite manette juste à coté de la commande de l'accélérateur. ... 17 jan. 2021. 0. Bonjour quelqu un pourrait m'aider pour démonter la dynamo du compte tour pour la nettoyer sur un perkins 4108 ...

Any necessary adjustments in this respect to the fuel pump should be carried 01.11 by the C.A.V. dealer or Perkins Distributor for the territory concerned. For any further information apply to Technical Services Department, Perkins Engines Limited, Peterborough or to one of the Perkins Companies listed on Page 2.

The Perkins 4.108 (ED) is part of the 4.108 series, a 4-cylinder diesel engine designed for materials handling, industrial and marine applications, then called the 4.108M. It can be found on loaders, mini-excavators and boats. Our 4.108 (ED) offer consists of complete used or reconditioned engines, as new is no longer available.

Perkins 4.108 Service Specifications Cylinder Block and Liners Total Height of Cylinder Block between Top and Bottom Faces ..... 9.936-9.939 in (252.374-252.451 mm)

We are now supplying factory remanufactured Perkins 4108 marine engines with significant upgrades over a stock Perkins 4108. These upgrades include an optimized fuel injection system producing more horsepower, a serpentine belt system which includes hardened, Rockwell-tested pulleys including a spring loaded, active‚ pulley for the alternator that dampens crankshaft pulses.

We have 3 Perkins 4.108(M) manuals available for free PDF download: Workshop Manual, Handbook . Perkins 4.108(M) Workshop Manual (135 pages) Brand: Perkins | Category: Engine | Size: 9.28 MB Table of Contents. Contents. 5. Unified Threads and Engine No. Location. 6. Engine Identification - New Series ...

4. Bridge to Moscow. 455. City Tours • Cultural Tours. Basmanny. By Charito1967. Our tour guide was the best, very knowledgeable and lots of patience and caring to explain and to help us in all we r... 5. Spanish Guide Moscow - Day Tours.

The Bus Tour offers unlimited 360° panoramic views of main sights of Moscow. Access to audio-guide in 10 different languages which enables to know about Moscow's history and traditions. The three-bus tour routes and 40+ stops around Moscow completes the trip. Draw an itinerary to explore the city on your own.

If you are looking for customised Moscow Sightseeing Tour at the best prices, get in touch with us for an exhilarating holiday to Russia. Grand Russia offers Moscow City Tour & Travel packages at affordable prices with best city travel guide. Enquire now for the best City Sightseeing & Nightlife Tour in Moscow. Call +7 905 772 00 73.

Access to three hop-on hop-off routes and 30+ stops around Moscow. Enjoy an unlimited Hop-On Hop-Off Bus Tour with 360-degree panoramic views of Moscow's main sights. Listen to an audio guide in 8 available languages so you can learn all about Moscow's history and traditions. Choose to add the Boat Tour and enjoy panoramic views from the Moskva ...

Le 57e Tour de Bretagne s'élance ce jeudi 25 avril de Locmaria-Plouzané pour une étape de 146 km jusqu'à Plougonvelin (Finistère). Notre envoyé spécial sur...