ELECTRICAL CLASSROOM

A complete Electrical Engineering portal

Buchholz relay – Working Principle, Construction and Operation

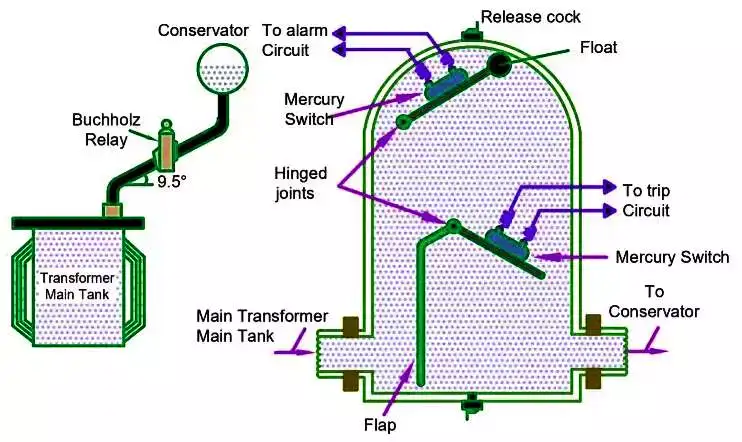

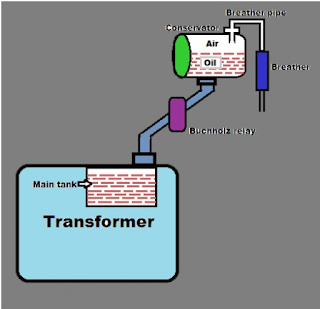

A Buchholz relay in a transformer is an oil-activated relay, used to sense abnormalities such as short circuits, overheating, and oil leakages inside a transformer. It is a cylindrical object found in the pipe connecting the conservator to the main tank, in large oil-immersed transformers . It is very common in all oil-immersed transformers rated higher than 500kva.

The working principle of Buchholz relay

Construction and design features, fault diagnosis, protection features, buchholz relay – alarm and trip circuits, advantages and disadvantages of buchholz relays.

Faults that occur inside an oil-filled transformer generate heat, much enough to decompose the insulating oil into gases such as hydrogen, carbon monoxide, methane, etc. These gases gradually move toward the conservator through the connecting pipe, but a part of them get trapped inside the Buchholz relay. The trapped gases displace oil inside the relay. Hence the level of oil in it falls, activating the float switches inside.

In the case of large faults, a huge amount of gases are produced by the decomposition of oil. This results in an oil surge that moves toward the oil conservator. This oil surge pushes down the flap attached to the transformer side of its outlet. This part can be understood only after reading the following sections.

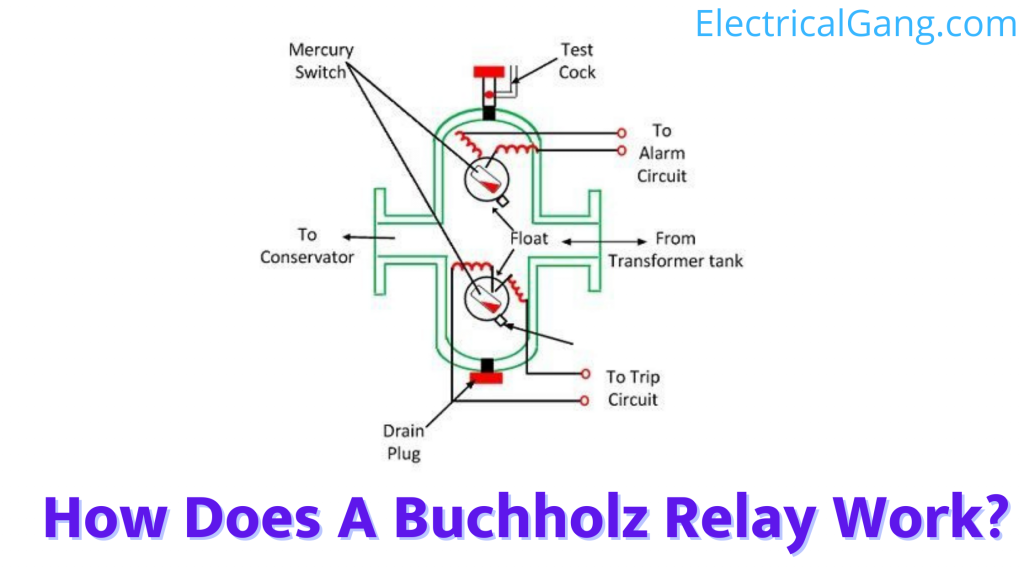

The external casing and terminal box of a Buchholz relay are made up of aluminum alloy. It is a weatherproof and oil-tight design that holds inside two float switches, one at the top and the other at the bottom, for sensing oil level and flap to sense oil surge. Two reed switches/mercury switches, one for alarm and the other for circuit breaker trip are attached to the float switch. These switches are connected to the terminals within the terminal box at the top of the relay. An inspection window is provided to monitor the oil level inside it. The viewing window is fitted with scaled sight glasses which enables the monitoring of the oil level inside the relay.

A gas-release cork is provided at its top to expel the accumulated gases. An electrical circuit contact test button and the terminals are enclosed in a weather-resistant cast aluminum alloy terminal box fitted at the top of the relay. A drain cork is provided at the bottom of the casing. The electrical circuitry is Modern relays that come with provision for analog and digital signal options for continuous gas accumulation and flow speed monitoring.

Why is the Buchholz relay used in the transformer?

It is used to detect the faults that occur inside the main tank of the transformer such as inter-turn faults, insulation breakdowns, short circuits, earth faults, overheating of the core, oil leakage, etc. It senses these faults and interrupts the transformer’s input supply, so that greater damages may be prevented. It also serves the purpose of fault diagnosis.

It triggers the alarm and/or trips the input supply to the transformer based on the level of oil inside it. It also responds quickly to the unusual oil flow from the transformer main tank to the oil conservator. It is a protection and monitoring equipment not only for transformers but also for oil-immersed chokes with an oil conservator.

It is important to diagnose the reasons for the trip before reenergizing the transformer. The samples of gases trapped in the relay are collected on the occurrence of a fault. The trapped gases must be analyzed immediately. The color of the gases collected indicates the type of fault as follows:

- Whitish gas: it is caused by electric arcing in contact with paper, cotton, and silk

- Yellowish gas: it is caused by wood and cardboard

- Greyish gas: it is caused by a breakdown of the magnetic circuit

- Black gas: it is caused by free arcing in the oil

A Buchholz relay protects the transformer from the following conditions:

- short-circuited core laminations

- short-circuit between phases/ earth

- overheating of transformer winding

- oil leakage from the main tank.

- puncture of bushing insulators inside the tank

- Earth faults

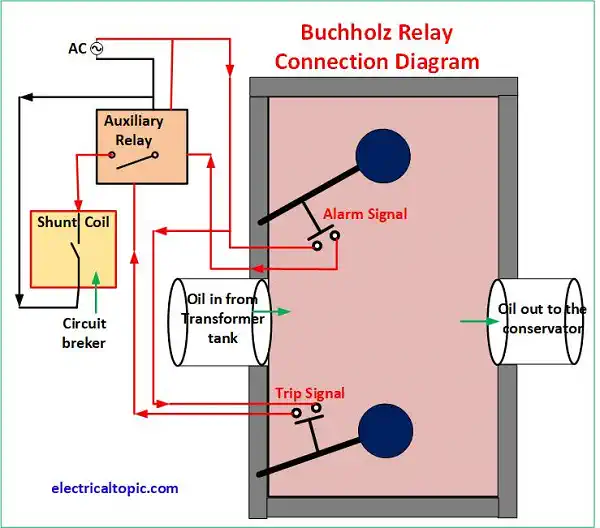

In case of slight faults gas passing from the main tank to the conservator gets trapped in the relay. The oil level lowers slightly, so as the upper float. This operates the alarm contact. The same thing shall happen if free gases are present in the main tank.

In case of severe faults such as oil leakages, overheating of core/windings oil level in the relay and conservator falls continuously. Eventually, the relay, connecting pipe, and conservator are emptied and the lower float switch is operated. This activates the trip contacts and the transformer is disconnected from the supply.

In the case of short circuits, the gas generation is violent and causes oil to rush from the main tank to the conservator. This lowers the flap fitted to the lower float and activates the trip contacts, thereby isolating the input supply to the transformer, and avoiding severe faults.

Mounting arrangement

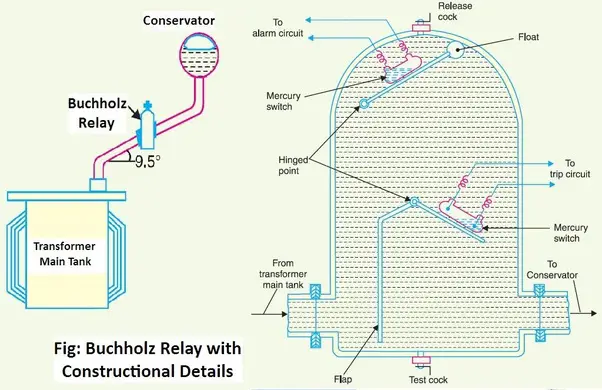

A Buchholz relay is located on the pipe connecting the main tank and the conservator of the transformer. The pipe is normally tilted at an angle of 5 degrees to the horizontal in order to allow easy oil flow.

The upper reed switch (attached to the upper float switch) is connected to an alarm circuit and the lower reed switch (attached to the lower float switch) is connected to the trip circuit of the circuit breaker at the incoming side of the transformer. During large faults, the lower reed switch activates the trip circuit of the circuit breaker and interrupts the power supply to the transformer, thereby avoiding large accidents.

Smart Buchholz relay

Smart Buchholz relays are equipped with sensors for sensing the oil temperature and moisture content of the transformer oil and the properties of gas accumulated in the relay during faults. These sensors send the sensed data to Programmable logic controllers or Substation automation systems. This enables the continuous monitoring of the relay from a remote location. It is also equipped with the standard features of conventional relays.

They can detect faults at the early stage and is the simplest form of transformer protection. However, the drawback is that it can be used only in the oil-filled transformer.

Buchholz relay: A device that detects faults inside oil-filled transformers by sensing the level and flow of oil and gas. It is a cylindrical object located in the pipe connecting the main tank and the conservator of the transformer.

Working principle: The relay has two float switches and a flap that activates alarm or trip contacts when the oil level falls or surges due to fault conditions. The contacts are connected to external circuits that alert the operator or disconnect the power supply to the transformer.

Fault diagnosis: The relay collects gas samples from the transformer oil during faults. The color and composition of the gas indicate the type and severity of the fault. The relay also has sensors for monitoring the oil temperature and moisture content.

Advantages and limitations: The relay is a simple and effective protection and monitoring device for transformers. It can detect faults at an early stage and prevent major damage. However, it can only be used in oil-filled transformers.

3 thoughts on “Buchholz relay – Working Principle, Construction and Operation”

Explained beautifully

BUCHHOLZ RELAY GATE VALVE ,

DN:80 , L:180MM , H1:300MM , D:200MM , K:160MM , Number OF Holes:8 , BODY: BRONZE , SUITABLE FOR TRANSFORMER OIL , WORKING TEMPERATURES: -25 TO 115 C PACKING MADE OF GRAPHITE AND ASBESTOS FREE MATERIAL SEALING RING MADE OF NBR , PAINT: OIL RESISTANT , FOR ARC FURNACE TRANSFORMER Qty: 1 stock

RELAY BUCHHOLZ FOR THE MSEF TRANSFORMER CONTACT OPERATED BY UPPER FLOAT SWITCHES FOR GAS ACCUMULATIO N AND LOW OIL, SWITCHES VALUES: 200cm3 INDICATED VALUES OIL FLOW: < C/L PIPE 1.0m/s. TAMINI TRASFORM ATORI MELEGNANO (MI) – ITALY, IEC: 60076, ARC FURNACE THREE PHASE TRANSFORMER, N DEGREES 65898 – FOR INDOOR INSTALLATION TYPE/MODEL: RR DN 80 _ SCH 4 / 306 MAKE: ET

Leave a Comment Cancel reply

What is Buchholz Relay and How does it work?

Table of Contents

What is Buchholz Relay?

Buchholz Relay is a safety device mounted on oil-filled power transformers and reactors, equipped with an external oil reservoir (called Conservator). It is a mechanically operated device used as protective equipment mostly for transformers. It is the most important part of transformer that protects the transformer from internal faults.

Buchholz Relay is a gas-actuated relay installed on the pipe connecting the Conservator to the main tank of the transformer. Such Relays are used in power transformers having a rating of more than 500kVA, but not used in small transformers because of economic considerations.

Working Principle of Buchholz Relay

Buchholz Relay works on the theory of gas detection. Whenever a fault occurs inside the tank of the transformer such as insulation failure between windings, breakdown, and heating of the core, then heat is produced by fault current. That heat causes the decomposition of transformer oil into gas bubbles of different hydrocarbon gases, CO 2 , and CO.

Also Read: What is Relay? Types, Applications, and Working of Relay

The generation of gas depends on the intensity and magnitude of the fault. These gas bubbles move upward through the pipe and accumulate in the upper part of the Relay container causing a fall in oil level. The collected gas displaced the oil level in Relay and the displacement is equivalent to the volume of gas collected. That causes the upper float to close the upper mercury switch and activates the alarm circuit.

Construction of Buchholz Relay

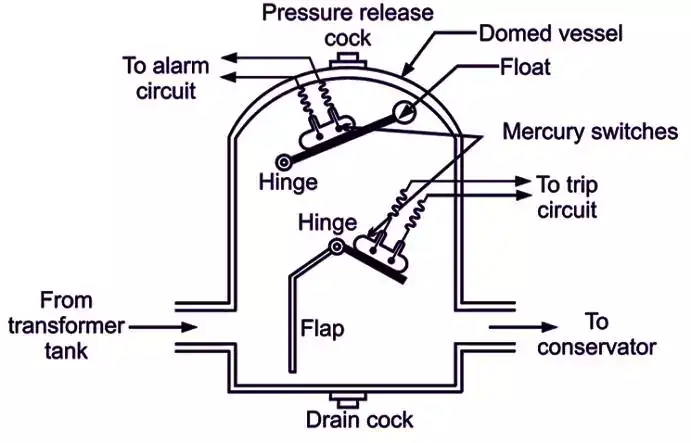

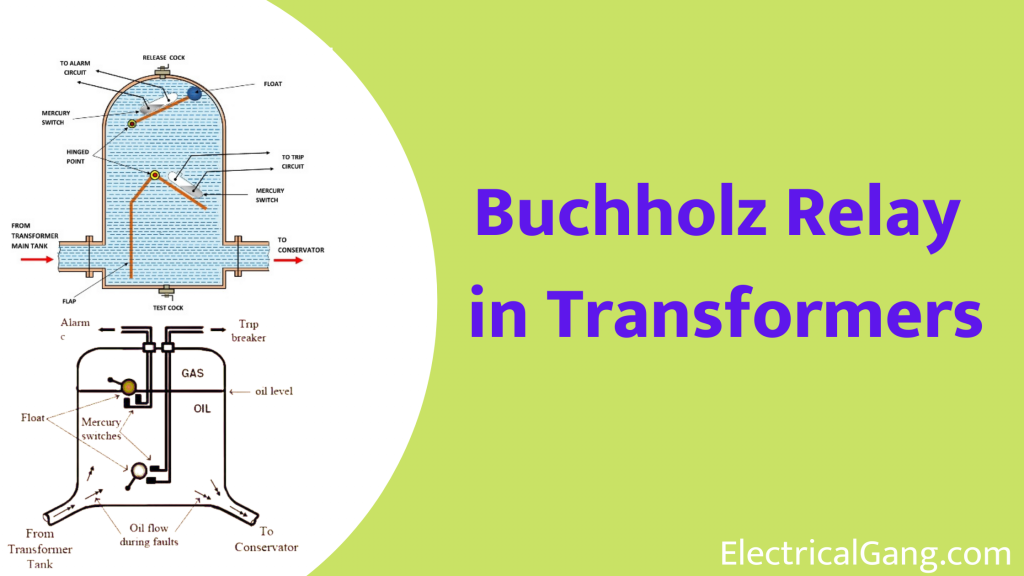

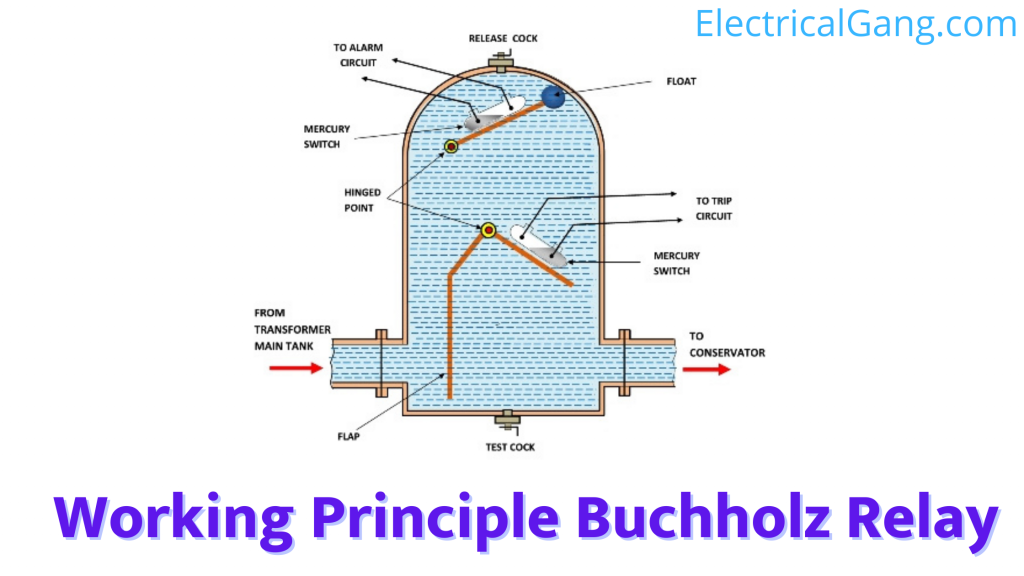

Buchholz Relay consists mainly of two hinges placed in an oil-filled metallic chamber and this chamber is connected through a pipe between the Conservator and the main tank of the transformer. There are two hinges, one is connected to the float at the top and the other is connected to a flap at the bottom of the metallic chamber. Both hinges are accompanied by a mercury switch.

One hinge is placed at the upper portion of the metallic chamber connected to float along with the mercury switch. This mercury switch is connected to an alarm circuit and used for activating the alarm in case of a minor fault.

Another hinge is placed at the lower portion of the chamber and is connected to a flap along with a mercury switch. This mercury switch is used for actuating the trip circuit in case of a severe fault in the transformer. Hence the Construction of Buchholz Relay is shown in the above figure.

How does Buchholz Relay work?

Operation of Buchholz Relay:

The operation of Buchholz Relay is very simple, and it works on mainly two different cases as explained below.

Case 1: A minor fault occurred inside the transformer tank

When a minor fault occurs inside the transformer tank, heat is produced by the fault current. The produced heat causes the decomposition of transformer oil into gas bubbles. These gas bubbles flow upward through the pipe and get collected in the chamber. These gases displaced the oil in the Buchholz Relay chamber and the displacement of oil is equivalent to the volume of gas collected.

Read More: Why Transformer is rated in kVA, not in kW?

The displacement of oil causes the upper float to close the upper mercury switch that is connected to the alarm circuit. Hence during a minor fault in the transformer, the alarm gets activated. The collected amount of gas indicates the severity of the fault. Since there is a minor fault, the production and flow of gas are not enough to move the lower flap of the Buchholz Relay. Hence in case of a minor fault, the lower flap remains unaffected, and only an alarm is generated by the upper float.

Case 2: When a severe fault occurred in the transformer

When a major fault occurs like a phase-to-earth fault (short circuit), the heat generated is high, and a large amount of gas is produced. These gas bubbles similarly flow upward through the pipe, but their motion is high enough to tilt the lower flap in the Buchholz Relay . Hence the lower flap closes the lower mercury switch that is connected to the trip circuit and hence they trip the transformer from supply. Hence in this way, the transformer gets isolated from the supply during major faults or severe fault conditions. Hence Buchholz Relay also provides protection against major faults in transformers.

Advantages of Buchholz Relay

- The severity of the fault can easily be identified with the help of Buchholz Relay without even dismantling the transformer.

- It indicates the internal faults due to heating and it also helps in preventing the major fault.

- In case of a major fault, the transformer can easily be isolated with the help of Buchholz Relay to prevent accidents.

Limitations of Buchholz Relay

The following are some disadvantages or limitations of Buchholz Relay:

- As it is a mechanically operated relay, its response time is high as compared to other electrical and electronic relays. Its minimum operating time is 0.1 sec whereas, the average operating time is 0.2 sec.

- It doesn’t protect connecting cables. So, a separate protection scheme is required for the protection of cables.

- It can be only used in oil-immersed power transformers.

- It is not suitable for small rating distribution transformers.

- It can only detect the fault below the oil level in the transformer.

When does Buchholz Relay operate?

Buchholz Relay operates mainly under three conditions:

- Whenever gas bubbles are formed inside the transformer tank due to heating of Windings.

- When the level of transformer oil falls below a certain pre-set value.

- Whenever transformer oil flows rapidly from the Conservator to the main tank and vice-versa.

- What are colorful Aerial marker balls on Power lines and why are they used?

- Difference between AA and AAA Batteries| AA vs AAA Batteries

- Fleming’s Left-Hand Rule and Right-Hand Rule

- Different Types of Electrical Loads | Resistive, Inductive and Capacitive Load

- Star-Delta Starter – Working with Power and Control Circuit

- Surge Impedance and Surge Impedance Loading (SIL)

- What are different types of Electricity Tariffs and its characteristics

- Difference between Voltage and Ampere (Volts vs Amp)

- What is Two’s Complement? A brief Guide

- Core Balance Current Transformer (CBCT) or Zero Sequence CT (ZCT)

- RVDT- Construction, Working, Application, Advantages and Disadvantages

- LVDT- Construction, Working, Application, Advantages, and Disadvantages

- Power Factor Correction techniques

- Causes and Disadvantages of Low Power Factor

- What are NO NC?| Difference between NO and NC

Hey, I'm Satish Gupta an Engineer by profession and blogger by passion. I am writer and founder of this blog, Here I publish contents related to Electrical and Electronics Engineering..

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Buchholz Relay: Working Principle, Construction and Operation

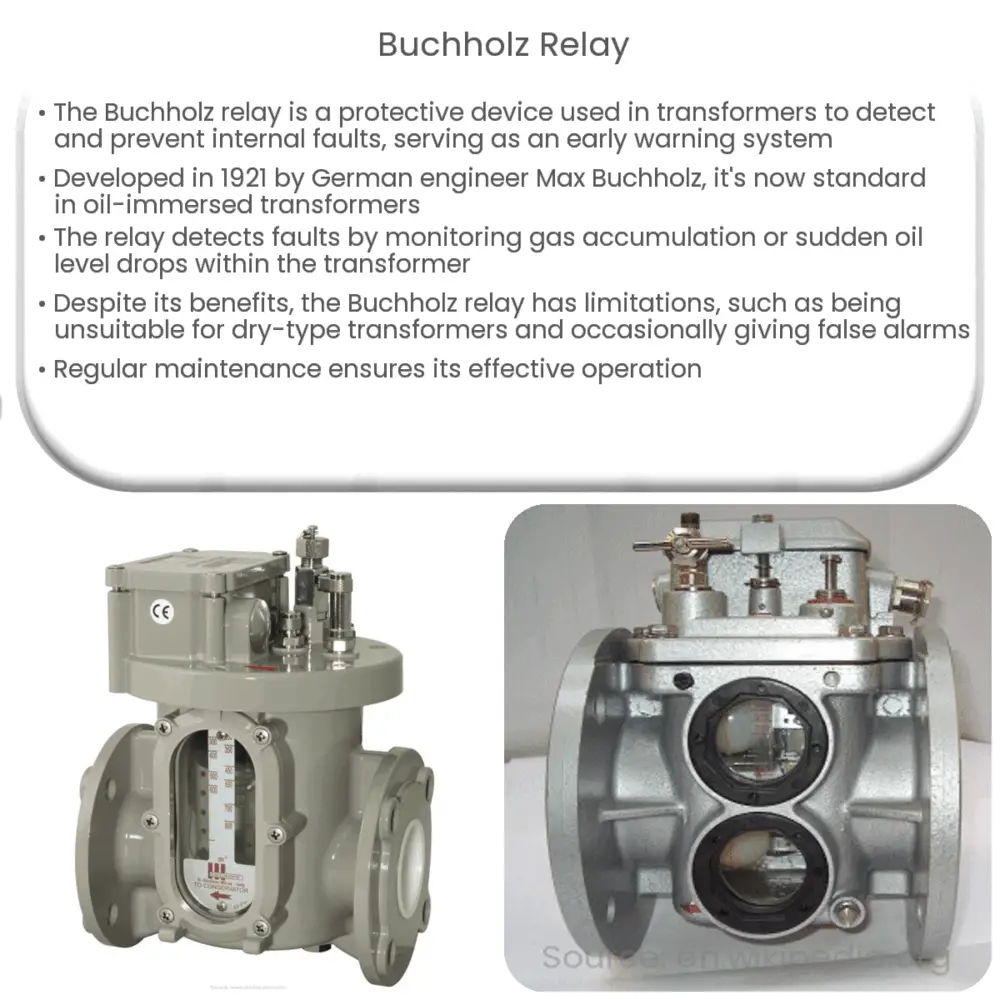

Buchholz relay, like any other relay, is a sensing device used to sense abnormal working of a transformer in a critical operation like a power transformer. It was devised in the year 1921 by Max Buchholz, hence the name. Sensing abnormality is important so that based on that feedback, some corrective or preventive action can be taken and the effect of the fault is not spread across the entire power system.

A Buchholz relay is employed in an oil-immersed transformer as it is an oil-activated relay. High-power transformers like those in power stations are subjected to high load current causing an equivalent rise in temperature. Thus it is important to cool it down for its normal operation and that’s why the core of these transformers is immersed in oil.

The oil absorbs the heat from the core and releases it into the atmosphere as the air passes. However, during an abnormal situation like short-circuit and overheating of the transformer or if the oil is leaking out, the Buchholz relay activates to protect the transformer and the entire power system from any spill-over effect.

Working principle of Buchholz relay

Unlike other relays that are electrically or electronically operated, the Buchholz relay is mechanically operated and an efficient relay system. It mainly consists of two parts – The Float hinged at the top and the flap hinged at the bottom near the transformer’s main tank as shown in the picture below.

Buchholz relay provides protection against short-circuiting, overheating, and oil leakage in a transformer.

When the transformer is highly loaded, it causes overheating of the transformer. Continuous operation of the transformer at such a rising temperature may damage it. That’s where the Buchholz relay comes to the rescue.

Due to overheating of the windings, more insulating oil is required by the transformer to cool down. This oil eventually evaporates in the form of Carbon-Mono-Oxide, Carbon-Di-Oxide, and other hydrocarbon gases. This causes a drop in the level of the transformer oil in which the core of the transformer has been immersed. With the drop in the level of the oil, the floating plate hinged at the top also lowers down.

A mercury switch is attached to the float plate at the top. This switch is nothing but a simple two-terminal device containing mercury. These two terminals are connected to an alarm circuit. When the float plate goes down due to the lowering of the oil level in the transformer, the liquid mercury inside the switch causes both terminals to short. As the terminals are connected to an alarm circuit, shortening causes the alarm to activate.

In this way, the operator of the transformer is alerted about the overheating problem of the transformer. The operator thus opens the release cock at the top of the relay to collect the accumulated gases due to oil evaporation. Based on that, he/she can decide on the corrective action.

In case of leakage of oil too, the oil level falls down. This may cause the transformer temperature to shoot up even though it is operating under normal conditions with normal parameters.

The leakage of oil causes the oil level in the transformer to fall abruptly. This causes the floating plate to lower down and the mercury switch activates the alarm circuit to alert the operator.

It must be noted that in case of overheating or in case of oil leakage, the relay raises an alarm instead of shutting down the transformer. While in the case of short-circuit, the Buchholz relay sends a trip signal to the circuit breaker causing the transformer operation to stop.

This is because in the case of overheating or oil leakage, there is a potential chance of a problem or it might be that the transformer is undergoing some maintenance or test.

But in case of short-circuit, immediate prompt action is of utmost importance and priority. That’s why the relay directly sends a trip voltage to the circuit breaker. Let’s understand how the relay works against a short-circuit fault.

Short-circuit fault can happen when the load connected to the transformer draws a short-circuit current or if there is an inter-turn short-circuit within the transformer due to insulation breakdown. In both cases, the windings of the transformer are subjected to huge electrical stress and hence the temperature of the transformer begins to rise enormously. This rise in temperature is higher than the cooling effect of the oil.

Therefore, more oil is evaporated instantly in the process of cooling down the transformer and hence more oil enters from the main tank towards the transformer.

As the oil inside the transformer evaporates at a rapid rate, the one entering through the main tank enters rapidly as well. Hence the force of this oil from the main tank causes the flap to move forward. The flap is hinged with another plate carrying a mercury switch (as shown in the picture above). As the flap moves forward, the plate attached to the mercury switch moves upward. This causes the mercury inside the switch to displace and it connects the two terminals of the switch.

The terminals are connected to a trip circuit externally and as the circuit gets completed by the mercury within the switch, it causes the trip circuit to activate. This trip circuit activates a circuit breaker which disconnects the transformer from the entire power system. In this way, the Buchholz relay protects the transformer in case of a short-circuit fault or an inter-turn fault.

In this case, no alarm is raised but the relay acts as a protection device itself.

Advantages of Buchholz relay

- Simple construction and working without the need for any external electrical power as it operates mechanically.

- The relay separates the overloading fault from short-circuit and inter-turn fault. In case of overloading, the relay activates an alarm while in case of short-circuit it takes swift action by activating a trip circuit.

- Low maintenance is required.

Disadvantages of Buchholz relay

- This relay works only in the case of an oil-immersed transformer.

- It relies on the oil level strictly to function instead of the actual circuit itself. Thus it doesn’t stop the fault before it reaches the transformer. It only activates when the fault reaches the transformer.

- The response time of the relay is very high compared to other relays. It takes about 0.1s to activate.

- The relay doesn’t guard the connecting cables, so separate protection is required.

Testing of Buchholz Relay

There are different types of testing techniques for a Buchholz Relay.

- Electrical Test

The earthing insulation is subjected to about 2000V for 1 minute to test the insulation strength.

- Leakage Test

The Buchholz relay is filled with oil and is subjected to a temperature of 90 degree Celsius. The leakage rate is tested after 30 minutes.

- Functional Test

The testing of the Buchholz relay can be done on a specially designed PLC-controlled testing unit. Under this test, the response from various contact points within the relay is recorded and tested.

Precautions required with Buchholz relay

The Buchholz relay may activate a false alarm or trip signal even if there is no actual fault. For example, when the oil is added to the transformer through the main tank during normal operation, air may get into it along with the oil. This air gets accumulated under the relay cover and may cause the relay to trigger an alarm.

That’s why a mechanical locking system is provided in the relay so that the mercury switches could be locked when the oil is being added to the transformer.

The lower float plate can also move forward even during normal oil intake by the transformer thus causing the trip circuit to activate. This can happen due to loose or inaccurate hinges. Hence, proper maintenance is required at times.

- Electrical Slip Ring: What is it? Types of Slip Rings

- What is a Process Alarm? Its Types

- Different Faults in Three Phase Induction Motor & their Remedies

- What is Type 1 and Type 2 Coordination?

- Design Basis for Fire Detection & Alarm System

- PRD of Transformer|Pressure Relief Device for Transformer

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Transformer Buchholz Relay

Introduction

A Buchholz relay is an electrical transformer protection device . For conservator type electrical transformers , a gas actuated relay or Buchholz relay is installed between the conservator tank and the main tank. Gas actuated relays have two functions, whereas a Buchholz Relay has three. The Buchholz relay is named after its inventor, Max Buchholz .

Location of Buchholz Relay on Transformer

Buchholz Components

Buchholz relays are usually installed with two floats and one baffle plate . The floats are installed in high and low positions within the relay housing . The baffle plate is attached to a spindle running vertically through the relay housing.

.png)

Buchholz Relay Components (3D model based upon design at Mibos.com)

How Buchholz Relays Work

The below video is an extract from our Introduction to Electrical Transformers Online Video Course.

Fault 1: Small Electrical Faults

Operator: Upper Float

Effect: Alarm

Small electrical faults within the transformer tank heat the insulating liquid and create small gas bubbles . These bubbles rise to the top of the tank and exit to the Buchholz relay. It is not possible for the gas to pass through the relay so it will slowly accumulate within the relay housing and displace the insulating liquid. If the fault continues, the volume of the gas will become so large that the upper float will fall (it is floating on the liquid) triggering an alarm .

Fault 2: Low Insulating Liquid Level

Operator: Lower Float

Effect: Alarm and Shutdown A large reduction in insulating liquid within the transformer could lead to a catastrophic failure of the transformer. In order to avoid this, the Buchholz relay will shut down the transformer should a low liquid level be detected. A decreasing liquid level will first be detected by the upper float which will activate an alarm as the liquid level within the relay drops. If the liquid level continues to drop, the lower float will fall and the transformer will trip/shutdown .

Fault 3: Large Electrical Faults

Operator: Baffle Plate

Effect: Shutdown

A large electrical fault will create a large volume of gas and this will displace a large volume of liquid within the transformer tank. As there is no room for this displaced liquid within the transformer tank, the insulating liquid moves in the direction of the conservator tank at high velocity ( pressure/shock wave ). The sudden movement of liquid through the relay causes the baffle plate to rotate, which activates a switch and/or pushes the lower float down , and trips the transformer.

Fault and Operator Summary

Small Electrical Faults = Upper float drops. Lower float no movement. Baffle plate no movement.

Low Insulating Liquid Level = Upper float drops. Lower float drops. Baffle plate no movement.

Large Electrical Faults = Upper float drops maybe. Lower float drops. Baffle plate pushes lower float down.

Are you enjoying this article? Then be sure to check out our Electrical Transformers Video Course . The course has over two hours of video , a quiz , and you will receive a certificate of completion when you finish the course. Enjoy!

What is the difference between a gas actuated relay and a Buchholz relay?

Gas actuated relays operate based upon the amount of gas generated by small and/or large electrical faults, they do not measure the transformer liquid level. Buchholz relays operate based upon the amount of gas generated by small electrical faults, large electrical faults and the transformer insulating liquid level.

General Faults

General faults within the transformer may also lead to one or more of the operators within the relay causing alarms or trips. Whatever the reason for the fault, all alarms and trips should be fully investigated. If the transformer has tripped, the reason for this trip must be ascertained prior to the transformer being returned to service.

Reasons for Faults

Small electrical faults could be caused by eddy currents , local overheating , partial discharges , or, poor insulating liquid conditions .

Large electrical faults are more likely due to winding-winding faults , phase-phase faults , or ground faults .

A reduction in insulating liquid level is most likely due to leakage from the transformer tank or associated piping and appendages. Gaskets , seals , joints and welds are the usual leakage locations.

Testing and Maintenance

It is normally possible to test the float operators by pumping air into the float chamber to displace the liquid, which causes the floats to drop. The baffle plate can be tested by rotating a rod, or handheld lever, which is mounted on the casing of the relay. The condition of the electrical switches themselves can be checked by measuring the resistance when using a standard multimeter.

Note: Some people disapprove of pumping air into the float chamber to test the relay, although its the author's experience that there are as many people for the procedure as against. There are pros and cons, but these are discussed in the saVRee Transformer Maintenance course and are beyond the scope of this article.

Buchholz Relay Cross Sectional View

Additional Resources

https://owlcation.com/stem/How-does-a-Buchholz-relay-work

https://www.electricaleasy.com/2014/06/buchholz-relay-construction-working.html

https://en.wikipedia.org/wiki/Buchholz_relay

Please select your billing country

Country is required field

Are you sure that you wish to revert back to the viewer’s default settings?

What is a Buchholz Relay? Working Principle

A transformer is a very important component in electrical applications. It is used to step up or step down a voltage. It can come in both lower and higher voltages. For higher voltages (more than 500 kVA), mostly oil-filled transformers are used.

As they work in higher voltages, there are bound to occur many internal faults like insulation failure, oil failure, windings failure, partial discharge, short circuits, arcing, etc.

If these failures are not detected, then they will result in damage to the transformer. For this, a special type of relay called the Buchholz relay is used.

In this post, we will learn the concept of a Buchholz relay.

Table of Contents

What is a Buchholz Relay?

The Buchholz relay is used to detect internal faults in an oil-filled transformer. Remember that oil is used as insulation for the transformer body. Buchholz Relay works on the theory of gas detection .

The Buchholz relay is also termed as safety device used in the oil-filled transformers.

Refer to the below image for understanding.

When internal faults occur inside, the current shoots up to a very high abnormal range. This high current automatically increases the operating temperature inside. As oil is filled inside, due to the excess heat generated, it starts to evaporate. As it starts to turn into gaseous form, moves upwards towards the oil conservator.

The relay is placed between the conservator and transformer tank (body). It detects this gas and immediately trips the circuit. This means the transformer is shut off for operation, which prevents any untoward incident.

Working Principle of Buchholz Relay

As discussed earlier, the Buchholz relay works on gas detection. Refer to the below image for understanding. It majorly consists of two float switches (one upper and one lower). It is arranged exactly between the transformer tank output and the conservator input.

Now, the formula is simple – the less the trip current, the less the heat generated, and the less will be gas generated; the more the trip current, the more will be heat generated and more will be gas generated.

So, in a normal working conditions without any trip, there will no gas from the tank into the transformer. But, in an abnormal condition with any failure, the oil will start to evaporate and gas will be generated. This gas will then start flowing through the relay to the conservator reservoir.

Now, you can see that the gas first enters from the lower entry and goes out from the relay through the upper entry. The lower entry has a lower float (blue color circle) and the upper entry to has an upper float (blue color circle).

The float’s mechanical design is such that the upper float can be displaced by a small amount of gas, while the lower float requires a rapid and substantial gas displacement. In case of minimal gas presence, the upper part will be affected while the lower part will remain unaffected.

After some time, the gas will slowly start moving the upper float, and once moved, it will switch the contact of an alarm circuit to generate an alarm. This will indicate that a failure has started to generate in the transformer tank.

If the gas suddenly moves swiftly and in a large quantity from the bottom entry, then its force will move the lower float. This will immediately switch the contact of the trip circuit and trip the transformer connection. Thus, this relay will prevent the transformer from being damaged.

The mechanical lock is provided in that relay so that one can lock the movement of mercury switches (float) when oil is topping up in the transformer. This mechanical locking also helps to prevent unnecessary movement of breakable glass bulbs of mercury switches during transportation of the Buchholz relays.

Schematic Diagram of a Power Transformer

The part numbers are mentioned below.

- Conservator tank

- The oil level indicator (end of conservator tank)

- Buchholz relay for detecting gas bubbles after an internal fault

- Piping to conservator tank and Buchholz relay

- Tap changer to change output voltage

- The motor drive of the tap changer (can be controlled by an automatic voltage regulator)

- Drive shaft for tap changer

- High voltage (HV) bushing connects the internal HV coil with the external HV grid

- High voltage bushing current transformers for measurement and protection

- Low voltage (LV) bushing connects LV coil to LV grid

- Low voltage current transformers .

- Bushing voltage-transformer for metering the current through the passing bushing

- Yoke of the core

- Limbs connect the yokes and hold them up

- Internal wiring between coils and tapchanger

- Oil release valve

- Vacuum valve

In this way, we saw the working of the Buchholz relay.

If you liked this article, then please subscribe to our YouTube Channel for Electrical, Electronics, Instrumentation, PLC, and SCADA video tutorials.

You can also follow us on Facebook and Twitter to receive daily updates.

- Industrial Circuit Breakers

- Electrical Motor Concepts

- Relays in Air Circuit Breaker

- Induction Motor Over Voltage

- Purpose of Electrical Substation

Recommended Articles

Electrical Power Grid Automation

What is an Electrical Drive? Types, Advantages, Disadvantages

Applications of Variable Frequency Drive (VFD)

Why Three-phase Voltage is 440 Volts?

Motor Control Circuit Wiring

Pros and Cons of Soft Starter

What is Megger Test?

Residual Current Circuit Breaker (RCCB)

Advantages of Star and Delta Systems

What is an Instrument Transformer? – Types, Principle, Advantages

Leave a Comment Cancel reply

More articles.

Circuit Breaker Making Capacity

Difference between Stepper Motor and DC Motor

Difference Between Electric Field and Magnetic Field

Types of Electrical Wiring

What is a Magnetic Contactor? – Principle, Types, Advantages

Single Phase versus Three Phase Power

Difference between RCCB and RCBO

What is insulation? How to Choose the Insulation Material?

Difference Between MCB and RCBO

Transformer Buchholz Relay Working principle and Connection diagram.

- Transformer

- Oil transformer

- Buchholz relay

- Buchholz relay.

- Connection diagram.

- Working principle.

- Why buchholz relay is used?

1- Buchholz Relay:

Buchholz relay is known as oil and gas actuated protection relay. It is safety device which is used above 500 KVa capacity of transformers. It is installed between the conservator and main tank. It is not required for small rating transformers below 500 KVA.

When the fault is occurred inside the transformer then the gas will generate in oil tank and it will travel to the conservator side where Buchholz relay is installed before conservator. After detecting fault the buchholz relay provides tripping signal to the HT panel breaker.

1. Major fault occurred in transformer tank and generating gas in tank than it will provide alarm and trip protection.

2. Oil level going to down than it will provide protection alarm and trip condition.

2- Connection diagram:

3- Working principle:

1- during fault condition:.

When any internal fault occurs in main tank due to failure of winding insulation or core heating than oil temperature will increase fastly and oil will start evaporating form as gas. Gas will move upside and will enter inside the relay resultant gas float valve will move to upside. For alarm closing condition. After closing alarm contact supply breaker will be tripped.

2- During Loss of Oil Condition:

any leakage or loss of oil in main tank is protected by the lower float of gas protection relay. If the oil level is low or any leakage of oil than low side float will move down side and will connect the trip contact and finally breaker supply will be tripped

4 - Why buchholz relay is used?

Oil Transformer is a costly equipment. Due to over heating, overload or short circuit in the oil tank, resultant winding insulation may be failure or explosion in oil tank then a gas is generated and it flows to the conservator side. So prevention for winding and explosion in tank, The buchholz relay is is installed in the middle of tank and conservator. When a fault is occurred in a tank then due to high pressure gas the buchholz relay is activated and a signal of alarm and tripping is sent to the transformer incomer breaker. So in this way the oil transformer can be prevented by buchholz relay. Buchholz relay has two important features which is mentioned in below.

- Due to any fault in transformer oil tank then it provides alarm and tripping signal for protection.

- Loss of oil level in tank then it provides alarm and tripping signal for protection.

Go back to index ↑

Related topic.

- What is the Oil temp indicator relay, working principle, and connection diagram?

- What is the winding temp indicator relay, working principle, and connection diagram?

- What is the Safeties of oil transformer, Technical features and applications?

- What is the oil type transformer, working principle and connection diagram?

- What is the parts of oil transformer, working principle and connection diagram?

Electrical and Mechanical Job Interview Training. Get boost in your job or get new opportunity

Electrical E-book

(Get important knowledge about industrial electrical, building maintenance in E-book )

HT system, LT system, Transformer, Electrical panel, Motor and Starter, Circuit breakers, Protection relays, Measuring meters. Read More ➠ Electrical E-Book

Technical Interview

( Electrical system, Diesel generator, BMS, AC, Chiller plant, UPS, WTP, STP, ETP, Fire and safety.)

electrician, maintenance supervisor, AC operator, chiller plant operator, DG operator, BMS operator, Shift engineer, Maintenanceengineer, technical executive, sr. engineer, assistant facility manager, Read More ➠ Technical Interview

Learn Fast and Improve Your Skill in Electrical Field Basic and practical theory, repair and maintenance, protection and testing.

For any query :- write to us as below mentioned email .., for official :- [email protected], for technical information :- [email protected], for interview preparation :- [email protected].

Buchholz Relay, 8 Answers You Should Know

A Buchholz relay is a protective device commonly used in oil-filled transformers.

Its primary function is to detect and provide protection against incipient faults, such as the development of gas or excessive heat within the transformer oil.

The relay is named after its inventor, Max Buchholz, who introduced it in 1921.

It is commonly used for the protection of oil-immersed transformers that are filled with oil and are likely to get electrical surges over time.

These surges may end the transformer into a potential security threat to life and infrastructure near the transformers.

Buchholz relay, itself is inside a container filled with oil and this container and its oil are practically separate from the internal part of the transformer and its oil respectively.

Table of Contents

What type of relay is the Buchholz relay?

The Buchholz relay is a specialized type of protective relay used in conjunction with oil-filled transformers.

It is specifically designed to protect against various types of faults that may occur within the transformer.

The Buchholz relay is considered a gas and oil-operated relay due to its operating principle, which involves the detection of gas and oil flow changes within the transformer.

The relay contains a float that is sensitive to the presence of gas or significant oil flow variations. When certain faults, such as internal arcing or overheating, occur in the transformer, they can generate gas or cause turbulence in the oil.

The Buchholz relay detects these changes and triggers alarms or initiates a protective trip to shut down the transformer.

So, to summarize, the Buchholz relay is a specific type of gas and oil-operated relay designed for transformer protection.

Buchholz relay working principle

The Buchholz relay operates based on the principle of detecting changes in the oil and gas conditions within an oil-filled transformer.

It is designed to provide protection against various faults, particularly those that result in the generation of gas or abnormal oil flow. Here’s an overview of the working principle of the Buchholz relay:

- Float Mechanism : The Buchholz relay contains a float with a hinged mechanism. This float is typically located in the piping connecting the main oil tank and the conservator tank of the transformer.

- Oil Flow and Gas Accumulation Detection : Under normal operating conditions, the transformer oil circulates between the main tank and the conservator tank in a relatively stable manner. However, when certain faults occur within the transformer, they can lead to changes in the oil conditions.

- Gas Accumulation: The relay is designed to detect the accumulation of gas within the transformer oil. This can happen due to internal arcing, partial discharges, or other types of faults.

- Abnormal Oil Flow: The relay can also detect abnormal oil flow caused by factors like overheating, which may lead to increased oil turbulence.

- Tilting of the Float : When gas bubbles or abnormal oil flow occurs, the float inside the Buchholz relay tilts. The tilting of the float is proportional to the severity of the fault.

- Alarm Contacts: These contacts are activated when the fault is at an early stage. They are used to signal an alarm, alerting operators to a potential issue in the transformer.

- Trip Contacts: If the fault worsens or becomes severe, the trip contacts are activated. These contacts initiate a protective trip, shutting down the transformer to prevent further damage.

The Buchholz relay’s ability to detect incipient faults and provide both alarm and tripping functions makes it a crucial component in the protection scheme of oil-filled transformers.

It helps prevent catastrophic failures and ensures the safety and reliability of the transformer and the overall power system.

Read also my article Transformer Most Common Faults

Uses of Buchholz relay

The Buchholz relay is a critical protective device used in oil-filled transformers to detect and respond to various faults and abnormal conditions.

Its primary purpose is to enhance the safety and reliability of the transformer and the power system. Here are some key uses of the Buchholz relay:

- Detection of Incipient Faults: The Buchholz relay is specifically designed to detect incipient faults within the transformer. Incipient faults are early-stage faults that may lead to more serious issues if not addressed promptly. The relay can detect phenomena such as gas accumulation or abnormal oil flow, which may indicate internal problems like partial discharges, arcing, or overheating.

- Early Warning System: The relay provides an early warning by activating alarm contacts in response to the detection of incipient faults. The alarm signals alert operators or monitoring systems to the presence of a potential issue in the transformer. This allows for proactive maintenance or investigation to prevent further damage.

- Prevention of Catastrophic Failures: In the event that the fault progresses and reaches a critical level, the Buchholz relay activates trip contacts. These contacts initiate a protective trip, disconnecting the transformer from the power system. This action prevents catastrophic failures and extensive damage to the transformer and associated equipment.

- Enhanced Transformer Safety: By monitoring and responding to internal faults, the Buchholz relay contributes to the overall safety of the transformer. This is particularly important in preventing events such as transformer explosions or fires that can pose risks to personnel and equipment.

- Reduced Downtime and Maintenance Costs: Early detection of faults allows for timely maintenance and repairs, reducing the risk of unplanned outages and minimizing downtime. Proactive maintenance based on Buchholz relay alarms helps extend the operational life of the transformer and reduces overall maintenance costs.

- Compliance with Industry Standards: Buchholz relays are commonly used in oil-filled transformers and are often required by industry standards and regulations. Compliance with these standards ensures that transformers meet safety and reliability requirements.

In summary, the Buchholz relay plays a crucial role in transformer protection by detecting incipient faults, providing early warnings, and initiating protective measures to prevent catastrophic failures. Its use enhances the overall reliability and safety of power distribution systems.

Is the Buchholz Relay an overcurrent relay?

No, the Buchholz relay is not an overcurrent relay. The Buchholz relay is a protective relay designed specifically for the detection of faults and abnormal conditions within oil-filled transformers.

It operates based on the changes in oil and gas conditions within the transformer rather than monitoring electrical currents.

The primary function of the Buchholz relay is to detect incipient faults, such as internal arcing, partial discharges, or overheating, that may lead to more severe issues if not addressed promptly. It achieves this by sensing the presence of gas or changes in oil flow within the transformer oil.

In contrast, overcurrent relays are a type of protective relay that monitors the electrical current flowing through a circuit.

They are designed to detect overcurrent conditions, which could result from short circuits, ground faults, or other electrical abnormalities.

Overcurrent relays are commonly used in power systems to trip circuit breakers or disconnect equipment in the event of excessive current flow.

While both Buchholz relays and overcurrent relays are protective devices used in power systems, they serve different purposes and operate based on different principles to safeguard transformers and electrical circuits, respectively.

At which angle is a Buchholz relay fixed?

The Buchholz relay itself is not fixed at a specific angle; rather, it contains a float mechanism inside that tilts when certain conditions are detected.

The float is hinged and positioned within the oil flow path between the main tank and the conservator tank of the transformer.

When a fault occurs within the transformer, such as the generation of gas due to internal arcing or abnormal oil flow, the float tilts in response to the changes in oil and gas conditions.

The angle of tilt is not standardized and can vary depending on the design and specifications of the specific Buchholz relay and transformer.

Manufacturers may provide information on the relay’s sensitivity and the corresponding tilt angle in the product documentation.

Why are mercury switches used in the Buchholz Relays?

It’s important to clarify that, in standard Buchholz relays, mercury switches are not used.

Buchholz relays typically employ mechanical contacts, rather than mercury switches, for the alarm and trip functions.

The float inside the Buchholz relay is connected to mechanical contacts. When the float tilts due to the presence of gas or other anomalies in the transformer oil, it activates these contacts. The contacts are typically designed to be robust and reliable, allowing for the proper signaling of alarms or initiating a trip signal.

Mercury switches were more commonly used in some types of relays and switches in the past, but due to environmental and health concerns associated with mercury, there has been a move away from its use in many applications, including relays.

If you have specific information about a Buchholz relay using mercury switches, it might be a unique or specialized design, and you should refer to the product documentation or contact the manufacturer for accurate details on the relay’s construction and components.

However, in standard Buchholz relays, mercury switches are not a common or standard component.

Why Buchholz relay is called a gas-actuated relay?

The Buchholz relay is often referred to as a “gas-actuated relay” because it operates based on the presence of gas within the transformer oil.

It is designed to detect faults and abnormal conditions within oil-filled transformers, and one of its primary functions is to respond to the generation of gas as a result of various internal faults.

Here’s how the gas-actuated principle works in the Buchholz relay:

- Gas Accumulation Detection: When certain faults occur inside the transformer, such as internal arcing or partial discharges, they can generate gases. Additionally, overheating can also lead to the release of gases from the insulating oil. The Buchholz relay is sensitive to these changes.

- Float Mechanism: The relay contains a hinged float positioned within the oil flow path between the main tank and the conservator tank of the transformer. When gas accumulates due to a fault, the gas rises to the top of the relay.

- Float Tilt: As gas accumulates, the float tilts in response to the rising gas. The tilt of the float is proportional to the severity of the fault or the amount of gas generated.

- Contact Activation: The tilting of the float activates mechanical contacts within the relay. These contacts are connected to the alarm and trip circuits. The alarm contacts are triggered when the fault is at an early stage, indicating a potential issue. The trip contacts are activated in more severe conditions, initiating a protective trip to disconnect the transformer from the power system.

So, the term “gas-actuated relay” highlights the Buchholz relay’s ability to respond to the presence of gas as an indicator of internal faults within the transformer.

This distinctive feature makes the Buchholz relay a crucial component in the protection scheme for oil-filled transformers, providing early detection and prevention of potentially catastrophic failures.

What type of fault does Buchholz relay employ for?

The Buchholz relay is designed to respond to specific types of faults and abnormal conditions that may occur within oil-filled transformers.

It is particularly sensitive to incipient faults, which are early-stage faults that have the potential to develop into more severe issues if not addressed promptly. The primary faults and conditions that the Buchholz relay is designed to detect include:

- Internal Arcing: When an arc occurs inside the transformer, it can generate gases. The Buchholz relay is sensitive to the accumulation of gas, which is an indication of internal arcing.

- Partial Discharges: Partial discharges within the transformer can also lead to the generation of gas. The Buchholz relay can detect the presence of gas caused by partial discharges.

- Overheating: Excessive heat within the transformer can lead to the degradation of insulating materials and the release of gas. The Buchholz relay is responsive to abnormal oil flow or gas accumulation caused by overheating.

- Faulty Windings: If there is a fault in the windings, such as a short circuit or insulation failure, it can lead to the generation of gas. The Buchholz relay can detect gas related to faults in the windings.

- Oil Flow Anomalies: Changes in the oil flow pattern, such as rapid or turbulent oil flow, can indicate a fault or abnormal condition. The Buchholz relay is sensitive to such oil flow anomalies.

The Buchholz relay’s ability to detect gas and respond to these specific fault conditions makes it a valuable component in the protection scheme for oil-filled transformers.

By providing early warning through alarm signals and initiating protective trips in more severe conditions, the Buchholz relay helps prevent catastrophic failures and ensures the safety and reliability of the transformer and the power system.

How many Buchholz relays are used in a transformer?

The number of Buchholz relays used in a transformer depends on the transformer’s design, size, and specific requirements.

In many cases, a transformer may have one Buchholz relay installed, typically in the piping between the main tank and the conservator tank.

For smaller transformers or transformers with lower ratings, a single Buchholz relay might be sufficient to monitor the entire unit.

However, for larger transformers or transformers with multiple compartments, there could be multiple Buchholz relays installed.

In some complex transformer configurations, where there are separate compartments or sections with independent oil circulation systems, each compartment might have its own Buchholz relay. This allows for more precise monitoring of different parts of the transformer.

The key purpose of the Buchholz relay is to detect faults and abnormal conditions within the transformer oil.

Its placement and the number of relays depend on the transformer’s construction, and the relay locations are typically determined during the transformer design phase.

It’s important to consult the transformer’s technical documentation or specifications to determine the specific number and configuration of Buchholz relays used in a particular transformer.

The transformer manufacturer or the entity responsible for the transformer’s maintenance can provide accurate information regarding the number and location of Buchholz relays for a specific transformer model.

Buchholz relay alarm and trip functions

The Buchholz relay provides two main functions: alarm and trip. These functions are crucial in the protection scheme of oil-filled transformers, helping to detect and respond to various faults and abnormal conditions. Here’s how the alarm and trip functions work in a Buchholz relay:

- Gas Accumulation or Oil Flow Anomalies: When the Buchholz relay detects incipient faults such as internal arcing, partial discharges, or abnormal oil flow, it responds by tilting its float mechanism. This tilt is proportional to the severity of the fault.

- Contact Activation: As the float tilts, it activates the alarm contacts within the relay. These contacts are part of the alarm circuit.

- Alarm Signal: The activation of the alarm contacts triggers an alarm signal. This signal can be used to alert operators or monitoring systems that there is a potential issue within the transformer.

- Early Warning: The alarm function provides an early warning, allowing for proactive investigation and maintenance to address the detected fault before it develops into a more serious problem.

- Severe Fault Conditions: If the fault within the transformer worsens or reaches a critical level, the float tilts further.

- Trip Contacts Activation: The additional tilt of the float activates the trip contacts within the relay. These contacts are part of the trip circuit.

- Protective Trip: The activation of the trip contacts initiates a protective trip. The trip signal is sent to the transformer’s protective relay or circuit breaker, leading to the disconnection of the transformer from the power system.

- Catastrophic Fault Prevention: The trip function is designed to prevent catastrophic failures by isolating the transformer from the power system when severe faults are detected.

In summary, the Buchholz relay’s alarm function provides an early warning for potential issues within the transformer, while the trip function initiates a protective trip in more severe conditions to prevent extensive damage.

These dual functions contribute to the overall protection of oil-filled transformers and the reliability of power distribution systems.

Install my Free Android App on Google Play :

Electrical Cables Most Common Tables “Electrical Cables Tables”

And, my Electrical Calculations App “ Fast Electrical Calculator ”

Discover more great content by subscribing to My channel

Looking to stay ahead of the game in the world of electrical engineering? Subscribe to my YouTube channel and gain access to exclusive content you won’t find anywhere else!

The staff I recommend

(Amazon Affiliate Links to products I believe are high quality):

- Economy 120 Volt/60Hz AC Power Source – Step-Down Voltage & Frequency Converters 1800W

- UNI-T Digital Multimeter Tester UT139C

- 50-Amp Extension Cord for RV “100ft”

- Voltage Stabilizer 110/220v

- Hair Dryer “best selling “

- TOSHIBA EM131A5C-BS Countertop Microwave Ovens

Disclaimer : This contains affiliate links to Amazon products. I may earn a commission for purchases made through these links.

You Might Also Like

Keeping transformers safe in high ambient temperatures, the top culprits: what causes transformers to overheat, unveiling the hidden dangers: transformer oil loss hazards, detecting transformer oil leaks: signs, impact, and solutions.

Electrical Transformer: 5 Basic Questions You Should Know

Buchholz Relay in Transformers | The Definitive Guide

The Buchholz relay was first used by Max Buchholz in 1921. Relays are used for security purposes. Which we use for power transmission and distribution.

This relay is mounted on the top of the transformer. Which is used as a protective cover for the dielectric failure of the transformer. As current leakage, fractional discharge, hot spots, and arcing are events that act as oil corrosion insulation by producing a dangerous flow. The transformer produces a dangerous flow of gas in the tank.

When the transformer was closed, it has a big economic impact on the power supply network operation. Thus, it aims to ensure accurate measurement of the position of the transformer. In today’s article, we will see what is Buchholz relay, what is its construction, what is the working principle of Buchholz’s relay is, and what are its uses.

In This Post

What is Buchholz Relay?

Buchholz Relay is used for the protection of the transformer. Used for transformers larger than 500KVA and filled with oil. The Buchholz Relay is a relay that reacts with oil and gas.

This is used to protect the transformer from all these defects such as short circuit, inter-turn, core, insert, etc. inside the transformer. The relay will understand all these defects and it will be turned off with the help of the alarm circuit.

Suggested Read: What Is a Coupling Capacitor | Construction of Coupling Capacitor | Applications of Coupling Capacitor

Construction of Buchholz Relay:

Inside the Buchholz Relay is an oil tank. It has two hinged floats. A mercury switch is attached to both of these floats in the top part of one tank and in the bottom part of the other tank. The upper float mercury switch is connected to the alarm circuit. While the bottom float switch is connected to an external trip breaker. The figure below is for further understanding.

Working Principle Buchholz Relay:

The principle of working with Buchholz Relay is very easy to understand. This relay is capable of working mechanically. This means being mechanically active at work. When there is a small defect inside the transformer such as its insulation failure, the increase in temperature will stop the transformer from working.

Different hydrocarbons will decompose into gases, such as CO2 and CO. Until the transformer insulating oil dissolves, Buchols will accumulate at the top of the container, causing the oil level in it to drop. Lowering the oil level means lowering the float position and tilting the mercury switch. The contact of this mercury switch is closed and the alarm circuit is activated.

Sometimes bubbles of air can accumulate in the upper part of the Buchholz container due to leakage in the main tank of the transformer. This will also lower the oil level in the tank and activate the alarm circuit. By collecting and analyzing the gas from the gas release point at the apex of the relay, we can know that we can predict the faults of the transformer.

Extremely serious faults such as a short circuit occurring between the phase and the earth are the faults in the tap shifting equipment which brings a surge in the oil and which strikes the baffle plate. And causes the lower-level mercury switch to shut down.

The circuit connected to the transformer from the switch stimulates the trip circuit of the breaker and separates the faulty transformer from the rest of the electrical power system of the inter-tripping connected to both sides of the LV and HV connected to this transformer. This is how the Buchols relay works.

How Does A Buchholz Relay Work?

Whenever there is a major or minor defect in the transformer, heat is emitted by the defect. And this heat is the main cause of the decomposition of oil. So that gas bubbles are created and continue to flow upwards which gathers the Buchholz Relay.

The collected gas transfers the oil and hence the displacement is equal to the proportion of the collected gas. Due to the transfer of oil, the upper mercury switches off due to the above float. Which is connected to the alarm switch. So this alarm is activated even if any small problem has occurred. The amount of gas stored indicates the severity of the defect that occurs.

The small problem is not enough to move the bottom float so the bottom float does not affect it. If there is a major defect like a phase-to-earth short circuit then a large amount of gas is produced in such a problem. This gas will go up just like a small fault but this gas is enough to bend the bottom float. In this case, the lower float can source a low mercury switch that can travel from the supply to the transformer.

Buchholz Relay Testing Procedures:

The methods for testing Buchholz Relay are as follows:

- Leakage Test.

- Electrical Test.

- Functional Test.

#1. Leakage Test:

- The Buchholz Relay can be packed with oil at a temperature of 90° C and the force of the bar and can be checked for outflow after 30 minutes.

#2. Electrical Test:

- The connections of the earthing insulation are ensured by running a 2000 V voltage for 1 minute.

#3. Functional Test:

- Buchholz Relay is tested by a PLC panel specially designed for this purpose. Also, the response status of all the contact systems will be checked.

Advantages of Buchholz Relay:

The Benefits of Buchholz Relay Are as Follows:

- The severity of the defect can be determined without opening the transformer .

- The Buchholz Relay heat shows the internal cause which helps to avoid its major defects.

- The transformer can be easily disassembled with the help of this relay to prevent accidents if any major defects occur.

Disadvantages of Buchholz Relay:

The disadvantages of Buchholz Relay are as follows:

- This only works for oil-absorbing transformers.

- This relay can detect faults only when the oil level is low

- Separate protection is required for the cable as it does not protect the cable attached to the transformer.

- High reaction time.

- The shortest operating time of this relay is 0.1 seconds.

Applications of Buchholz Relay:

The application of Buchholz Relay is as follows:

- Insulation failure of core bolts.

- Bushing Pierce.

- Short circuit between stages.

- Winding short circuit.

- This relay can be used in loose and bad electrical contacts.

Operating Conditions of Buchholz Relay:

The Buchholz Relay operates in three main scenarios as follows:

- When any small or big mistake due to bubbles forming in it.

- Whenever oil leaks from the transformer and its level decrease.

- Whenever oil in the transformer flows from the protection tank to the main or from the main tank to the protection tank.

Like this post? Could you share it with your friends?

Suggested Read –

- Netflix Not Working on Vizio Smart TV

- How to Fix Hulu Streaming Problems in Minutes

- What is a Stepper Motor? | Types of Stepper Motors

- The Ultimate Guide to Fixing Hisense TV Problems

- Alexa Device Is Unresponsive | Here’s How to Fix It

Vishnu Patil

Hey, I am Vishnu Patil and I'm an Electrical Engineer and Electrical maestro. I have more than 10 years of experience with electricals. Through ElectricalGang I want to spread my knowledge with everyone else.

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

What is Buchholz Relay? Working & Limitations

Buchholz relay is a special type of relay which is designed to detect the internal faults by monitoring the gas and oil movement in oil-immersed transformers. This relay is named after Max Buchholz in 1921. This relay is used in the transformer having the rating higher than 500KVA. Due to economic consideration, this relay is not used in the transformer having less rating.

Buchholz relay is located in the pipeline connecting the transformer main tank and the conservator. As we proceed further, we will learn the construction and working principle of the Buchholz relay .

This relay is mainly used in oil-immersed transformer for providing protection against all types of internal faults. These internal faults could cause gas accumulation or strong oil flow in the oil circuit. These internal faults can be

- short-circuited core laminations

- bad contacts

- overheating of windings

- earth faults

- broken-down core insulation

- short-circuit between phases

- falling of oil level due to leaks

- puncture of bushing insulators inside the tank

- ingress of air as a result of a defective oil circulation system

Construction of Buchholz Relay

Buchholz relay is mainly connected in the pipeline between the main tank and the conservator tank in an inclined position as seen in fig. 1 (left side diagram). It is designed in the form of a vessel filled with oil which is dome in shape as seen in fig. 1 (right side diagram).

This relay is subdivided into two portions inside the vessel depending on its purpose and also its structure, i.e. the upper part and the lower part.

The purpose of this upper part is to alarm us about the faults. The upper portion of this relay consists of a flap that is hinged at one end and a float at another end. A mercury switch is placed on this flap. When there is movement is the flap due to the movement of oil then the terminals of the mercury switch makes contact with the alarm circuit’s terminal. This will close the alarm circuit and alarms us alert at the time of internal faults.

The purpose of this lower part is to detect serious faults. The lower portion of this relay consists of a flap that is hinged at one end and a float at another end. The flap plate is placed in just between the flow path of the oil and gas between the main tank pipe mouth and the conservator pipe mouth. A mercury switch is placed on this flap. When there is movement is the flap due to the movement of oil then the terminals of the mercury switch makes contact with the trip circuit’s terminal and thus completes the trip circuit. This will opens the circuit breaker to disconnect the supply.

The Buchholz relay’s vessel contains a release tap at the top, to exhale the extra gas from creating any types of damage due to pressure.

Working of Buchholz relay

The working principle of Buchholz relay depends upon the generation of hydrogen gas (H 2 ) inside the transformer oil tank due to internal fault. When the transformer oil is exposed to a considerable amount of heat, then it gets decomposed and produces hydrogen gas (H 2 ).

If any fault occurs inside the transformer, then a large amount of heat will be produced. The heat generated will decompose some part of the transformer’s oil in the main oil tank. The hydrogen gas (H 2 ) will be generated due to the decomposition of oil inside the tank.

As hydrogen gas (H 2 ) is lighter than the oil, it moves upwards towards the conservator tank through the pipeline. The Buchholz relay is connected in the pipeline between the main tank and the conservator tank. When gas entered the relay from the transformer main tank, some amount of gas is entrapped by the upper portion of the Buchholz relay.

The amount of hydrogen gas generated depends upon the amount of heat generated. If more amount of heat is generated then more amount of H 2 is generated. Therefore more gas will be accumulated inside the relay chamber. When the amount of H 2 gas tends to approach a predetermined safe value, then it creates a pressure to the float which leads to tilt the flap. After the movement of the flap, the upper mercury switch will get closed circuited. This will complete the alarm circuit. This is how the alarm circuit is working under any faulty condition.

If a severe fault occurs inside the transformer, then a large amount of heat will be produced inside the transformer main tank. This large amount of heat will decompose the oil. Hence a large amount of H 2 gas will be generated.

This large amount of H 2 gas rushes upwards towards the conservator tank via Buchholz relay. This will tilt the lower part flap. Due to movement of the flap, the mercury switch terminals will complete the trip circuit and open the circuit breaker operating the transformer. This is how the trip circuit is working under any severe faulty condition.

Occurrence of fault ⇒ Decomposition of transformer oil ⇒ Generation of H 2 gas ⇒ Entrapping in relay chamber ⇒ Movement of flap ⇒ Trip circuit.

Advantages of Buchholz relay

1. This relay senses the internal developing faults in a transformer at an early stage. Hence it protects the costly oil-immersed transformers from damage.

2. The operation and handling of this relay are quite easy.

Limitations of Buchholz relay

1. This relay is used only in the oil-immersed transformers.

2. Using this relay in transformers for rating less than 500 KVA is uneconomical.

3. It can only detect the fault below the oil level.

4. The response time of this relay is high.

Image reference: Quora

- Oil Circuit Breakers | Advantages & Disadvantages

- Core Balance Current Transformer – Working, Advantages & Applications

- Air Blast Circuit Breakers – Working, Advantages & Disadvantages

- What is Electrical Fault? Types, Causes & Effects

- Gas Insulated Substations Advantages and Disadvantages

- Digital Frequency Meter – Block Diagram & Working

- Beat Frequency Oscillator Working & Limitations

- Liquid Insulating Materials

- Circuit Breakers

- Ground Fault Current Interrupter Protection Circuit

Leave a Comment Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Bridging the gap

- Buchholz relay in Transformer? | Operation and Principle

The Buchholz relay is a protective device used in electrical power transformers to detect and prevent internal faults, such as overheating or insulation breakdown. It is named after its inventor, Max Buchholz, a German engineer who patented it in 1921. The Buchholz relay is typically installed in the oil-filled conservator tank of a power transformer.

What is a function of Buchholz relay?

The primary function of the Buchholz relay is to provide early warning and protection against faults that can occur within the transformer. It operates based on the principle that certain types of faults in a transformer, such as an internal short circuit or partial discharges, can generate gas and oil flow disturbances within the transformer tank. The Buchholz relay is designed to detect these gas and oil flow disturbances and activate an alarm or trip signal to disconnect the transformer from the power source, thereby preventing further damage.

Buchholz relay is a type of oil and gas actuated protection relay universally used on all oil immersed transformers having rating more than 500 kVA. Buchholz relay is not provided in relays having rating below 500 kVA from the point of view of economic considerations.

Working principle

It relies on the fact that an electrical fault inside the transformer tank caused by the generation of gas. And if the fault is high enough, it will be accompanied by a surge of oil from the tank to the conservator

Read also: Power Transformer MCQs

Whenever a fault occurs inside the transformer, the oil in the transformer tank gets overheated and generates gases. The generation of the gases depends mainly on the intensity of fault produced inside the transformer.

The heat generated during the fault will be high enough to decompose the transformer oil. As a result of this, the gases produced detect the winding faults. This is the basic principle behind the working of the Buchholz relay that we need to understand for the understanding of protections of transformers.

An experienced electrical professional having more than 8 years of experience of the industry in diverse fields of engineering including Electrical Design & Consultancy, Audit & Inspection, Execution of Construction Projects having expertise in designing of HighRise buildings, Residential & Commercial buildings, Offices, Schools, Restaurants and some Industrial projects

Related Posts:

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Buchholz Relay

The Buchholz relay is a protective device for oil-immersed transformers, detecting faults early to prevent damage and ensure power system reliability.

Buchholz Relay: A Comprehensive Overview

A Buchholz relay is a vital protective device used in transformers to detect and prevent faults. Transformers are essential components in power distribution systems, responsible for stepping up or stepping down voltage levels. However, they can develop internal faults, such as short circuits, insulation failure, or partial discharges. These faults can lead to excessive heating and gas formation within the transformer, which can damage the unit or cause it to fail altogether. The Buchholz relay serves as an early warning system to help prevent such incidents.

History and Development

The Buchholz relay, named after its inventor Max Buchholz, was first developed in 1921. Max Buchholz was a German engineer who sought to improve transformer safety by designing a device that could detect faults before they became severe. His invention has since been widely adopted and is now a standard component in oil-immersed transformers.

How a Buchholz Relay Works

A Buchholz relay is typically installed in the oil-filled pipe connecting the transformer tank to the conservator, a reservoir that holds the oil. The relay operates on the principle that gas is generated during a fault within the transformer. This gas accumulates in the relay chamber, causing a float to drop, which then activates a switch that sends a signal to a control panel or trips the circuit breaker. In some cases, the relay can also be triggered by a sudden drop in oil level due to a leak or rupture.

Types of Faults Detected

Buchholz relays can detect various types of faults within a transformer, including:

- Inter-turn short circuit: This fault occurs when the insulation between the transformer’s windings breaks down, causing a short circuit. The resulting current flow can generate excessive heat and gas.

- Core insulation failure: A fault in the insulation between the transformer’s core and windings can lead to a short circuit, generating heat and gas.

- Partial discharges: These occur when high voltage stresses cause electrical discharges in the oil, which can produce gas and lead to further insulation breakdown.

- Oil leakage or rupture: A sudden drop in oil level, due to a leak or rupture, can also trigger the Buchholz relay.

By detecting these faults early, the Buchholz relay helps prevent catastrophic failure and damage to the transformer, ensuring the reliability of the power distribution system.

Advantages of a Buchholz Relay

There are several advantages to using a Buchholz relay in oil-immersed transformers:

- Early fault detection: The relay’s ability to detect faults early can help prevent more severe damage, extending the life of the transformer and reducing maintenance costs.

- Simple and reliable operation: The Buchholz relay’s mechanical design is straightforward, with few moving parts, making it a reliable and low-maintenance device.

- Cost-effective: Installing a Buchholz relay is a relatively inexpensive way to improve the safety and reliability of a transformer.

Limitations of a Buchholz Relay

Despite its advantages, there are some limitations to using a Buchholz relay: