What to Do When a Well Pump Keeps Tripping Breaker?

Well pump is a lifesaver for some families. Most rural families use an alternative source of water supply to fulfill their water demands. Although a well pump is a great alternative, an issue with the machine can make your life miserable.

Among the problems, tripping is one of the most common and, at the same time, irritating problems. Don’t be surprised when you see the well pump keeps tripping breaker all of a sudden. It’s a normal situation when something like overload, pressure switch problem, breaker problem, etc. happens.

This article will cover everything regarding the issue. Don’t worry. Stay till the end.

- 1.1 1. Overloading The Circuit

- 1.2 2. Fault In The Wiring

- 1.3 3. Weak Breaker

- 1.4 4. Well Pump Motor Defect

- 1.5 5. Clogged Impeller

- 1.6 6. Bad Seals

- 1.7 7. Pressure Switch

- 2 Video of Well Pump Tripping Breaker

- 3.1 Inspect The Pressure Switch

- 3.2 Disconnect The Motor

- 3.3 Inspect The Pump Motor

- 3.4 Fix The Blockages

- 3.5 Check The Pipes, Pump Boxes, Bearings, And Shafts

- 4 Tips To Follow While Working With The Well Pump Tripping Breaker Issue

- 5.1 How can you tell if your well pump is bad?

- 5.2 Can a well pressure switch cause breaker to trip?

- 5.3 What causes the pump to trip?

- 6 Conclusion

Why Does A Well Pump Keeps Tripping Breaker?

The situation can be frustrating when a well pump or submersible water pump keeps tripping the breaker. Before replacing the well pump, it’s always better to find out the reasons behind the issue.

These are the 7 most common reasons for a well pump to keep tripping its breaker –

1. Overloading The Circuit

One of the main reasons for the breaker tripping issue is overloading. Overload normally means more power input than the device can handle.

When the circuit is overloaded, the circuit breaker may start to act weirdly. In such circumstances, tripping is a common outcome.

Solution: When the overloading issue happens, you have to do something to make it go away. Removing the clogs in the circuit is the way to get the job done here.

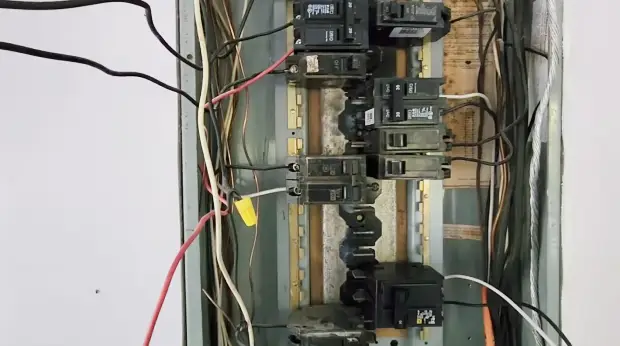

2. Fault In The Wiring

Another reason for the tripping problem is faulty wiring. The wires may be short or damaged. In such cases, you may find the tripping issue as an outcome of the wiring fault.

There may be a loose connection in the electrical box too. You may find a similar outcome in this situation also.

Solution: Check the entire wiring of the well pump. If you don’t think you will be able to inspect, hire a professional. After that, fix the damage to the wiring.

3. Weak Breaker

The breaker may also trip when the breaker itself is faulty. It’s a common instance that appliances get older and lose their temperament. If that’s the case, the breaker won’t be able to perform its function as it’s supposed to.

Solution: When the breaker itself is weak or faulty, you won’t have any option but to replace the breaker. Try buying a premium breaker. Otherwise, you may face issues again with it.

4. Well Pump Motor Defect

Don’t be surprised. A well pump may keep tripping when there’s a defect in the well pump motor. Sometimes the well pump performs poorly due to a problem with the pump’s motor.

So, the pump tripping problem isn’t impossible to fix when there’s a problem with the motor. That’s why checking the pump motor is another crucial step to finding the root of the tripping problem.

Solution: Replacing or changing the pump motor is the only option here. Similar to the breaker, try to get a good-quality pump motor as a replacement.

5. Clogged Impeller

Sometimes the impeller may get clogged. As the impeller is a major component of a well pump, the clogging of it’s a big concern. You may face problems like continuous breaker tripping until the clog is fixed.

Solution: Try to remove all the clogs within the impeller. To do that, you have to take the cover or seal of the casing first. Then, you will see the impeller. Remove it from the machine and then clean the impeller properly.

6. Bad Seals

The seals of the well pump may also be why your well pump keeps tripping its breaker.

When the breaker is in a position where the mechanical seal has failed, you may face the tripping issue. Things like this become common since a failed seal allows water to enter the pump parts.

Solution: When the seal problem is the main issue, you will have to work with the seal. Try changing the seal or fixing the leak in the seal.

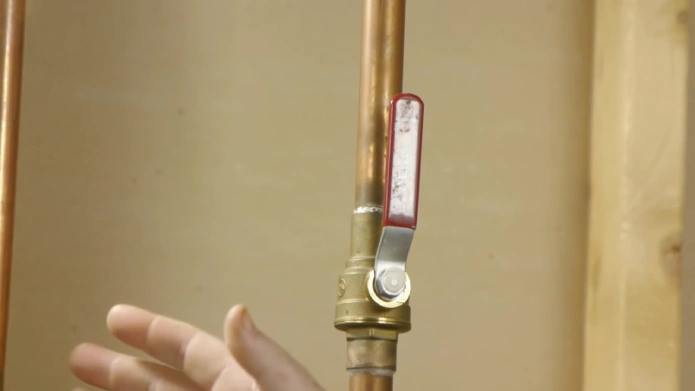

7. Pressure Switch

Sometimes you may think, will a bad pressure switch trip the breaker ? Yes, a bad pressure switch may also be the reason for a well pump to trip its breaker.

A pressure switch can become weak or bad due to the burnt or bad contacts on the pressure switch. If that happens, it can lead to a situation like tripping the breaker.

Solution: When there is an issue with the pressure switch, try replacing the bad contacts. They are the main culprit in this situation.

- How to reset the well pump pressure switch without a lever?

- Can you burn out a well pump?

- Well pump is running but not building pressure.

Video of Well Pump Tripping Breaker

To get a more simplified visualization of the reasons for the issue, check out this video.

How To Diagnose The Well Pump When It Keeps Tripping Breaker

Sometimes you may find a new well pump tripping breaker . Old or new, it is important to get to the root of the issue. Besides inspecting the individual symptoms or studying the reasons, a thorough diagnosis of the well pump is also a useful way to get rid of the issue. Follow the next steps to get the job done smoothly.

Inspect The Pressure Switch

The first step in diagnosing the well pump will be to inspect the pump’s pressure switch. Since a bad pressure switch is one of the main reasons that cause the breaker to trip, it’s important to see whether it is okay or not. If you find the pressure switch is faulty, replace it as soon as possible.

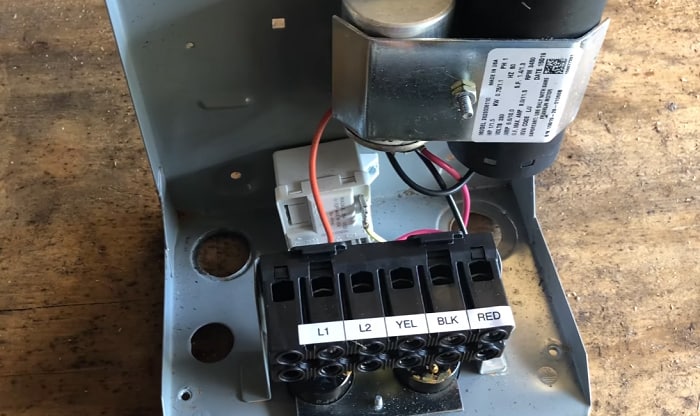

Disconnect The Motor

After you are done with the pressure switch, it’s time to work with the pump motor. Sometimes, issues with the pump motor can lead to face problems with the well pump. That’s why you have to disconnect the motor from the pump so that you can surely know what the culprit is.

To disconnect the motor from the pump, turn off the power source first. Then, remove the bolts or turn the clamp to disconnect the motor.

Inspect The Pump Motor

When splitting off the pump motor from the pump is over, you have to inspect the motor to know if it’s okay. You have to measure the motor’s resistance to know the answer.

To do this, taking the help of a digital multimeter is a must. When the reading of the multimeter is below 1 Ohm, the pump motor is not good. You have to replace it.

Fix The Blockages

Fixing the blockages is the next step when you are done with the motor. You have to free the pump from any sort of blockage so that there is no overload issue. Checking the box baskets and pipes of the pump is an important step to clear off the blockages.

Check The Pipes, Pump Boxes, Bearings, And Shafts

When the mentioned four steps are done, you can also check the pipes, the pump box, bearings, and the shafts to see if they’re okay.

Checking these parts is also important as any fault within them may lead to the tripping of the breaker.

Tips To Follow While Working With The Well Pump Tripping Breaker Issue

In most cases, working with the well pump may seem difficult as most of the people doing DIY are not experts. the following tips may help you more-

- Diagnose the well pump thoroughly. You may try to skip one or two parts of the diagnosis if you see them as not important. Do not do that. Even faults within the minor parts of a well pump may lead to a major problem.

- Use a premium pump motor as a replacement. Going for some cheap alternatives is tempting. But if you go for it, you may face a lot of issues with your pump in the future.

- Don’t go for cheap alternatives while replacing bearings or shafts. Just like the motor, cheap bearings or shafts may also cause problems in the future.

- Wear protective gear to ensure the best safety. For instance, use rubber gloves while inspecting the motor of the pump with a multimeter.

- Don’t hesitate to hire a professional when you are out of moves. It’s very much possible to become clueless while working with a well pump. Don’t try to experiment with something. Hire an expert right away.

- Well pump overheats and shuts off?

- Pros and cons of constant pressure well pumps

- Can you use a pool pump for a well pump?

How can you tell if your well pump is bad?

There are a lot of symptoms to give the verdict that your well pump is bad. If you find the symptoms like –

- Muddy or murky water coming out from the tap,

- The tap sputtering water,

- The taste of the water is way off than usual, or

- Loud noises coming out from the pump,

They all indicate the pump has gone bad.

Can a well pressure switch cause breaker to trip?

A well-pressure switch can also cause the breaker to trip. It happens especially when the pressure switch becomes weak or bad to perform properly.

What causes the pump to trip?

The reasons for a pump to trip are a lot. Among them, the main causes are overloading, motor defects, bad circuit breakers, clogged impellers, bad seals, and bad pressure switches.

The issue we’ve tried to cover here is an irritating and frustrating one. It’s never a pleasing scene to see your well pump keeps tripping breaker.

However, don’t go for the prompt replacement of the pump without diagnosing. Finding the root of the problem will help a lot to solve the problem efficiently and with much less money.

As an Amazon Associate, I earn from qualifying purchases.

Professional Plumber and Blogger

James is passionate about plumbing and is also a Professional Plumbing Course Tutor. He has experience of over 15+ years of as a plumber in San Diego, California. He completed many plumbing projects in commercial and residential areas. James cooperated and shared his on-field plumbing experience with the writing team to make the guides helpful.

Similar Posts

Harbor Freight Shallow Well Pump Problems: How to Fix?

Sooner or later, your shallow well pump is bound to present you with some defects, even if it’s from a renowned brand like Harbor Freight. The most common Harbor Freight Shallow well pump problems include pulsing water, murky or smelly water, or sometimes, no water at all! Inflated utility bills are also a matter of…

Well Pump Running But Not Building Pressure: How To Fix It?

A well pump creates pressure to force water from the source deep into the ground where it can be used. Your pump can break if it gets too much pressure, but what to do when your well pump is running but not building pressure? It’s a widespread problem for every pump user. Several factors can…

Cast Iron vs Stainless Steel Water Pump: Which one is Best?

You have decided to buy a water pump. Without this, your home is not fit for living or you can’t set up your factory. But the thing is what type of water pump you will buy? Will your water pump be made with cast iron or with stainless steel? To answer this question or to…

![circuit breaker trips well pump Can You Burn Out A Well Pump? [Reasons & Quick Solutions]](https://pumpingpies.com/wp-content/uploads/2022/08/Can-You-Burn-Out-A-Well-Pump-Reasons-Quick-Solutions-768x432.png)

Can You Burn Out A Well Pump? [Reasons & Quick Solutions]

A good quality well pump generally lasts longer; you can say, more than 10 years. But the fact is true that you need to constantly take care of the well pump in case it shows any problems. But the question is: can you burn out a well pump? The answer is YES. Your well pump…

How To Keep Outside Well Pump From Freezing?

A frozen well pump can disturb the water supply, damage the system, and cost an expensive repair. In contrast, learning how to keep outside well pump from freezing will help you get a continuous water supply, avoiding all tiresome efforts. You can protect your outside well pump in plenty of ways, including by building a…

How Long Can A Well Pump Run Before Burning Out?

If you have a well pump system in your house, you’ve stressed at one point about how long a well pump can run before burning out. A top-quality well pump can run for almost 24 hours without any interruptions. Average-quality well pumps last for about 12-18 hours. If the pump is run continuously without any…

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

(352) 316-4088

- Our Warranties

- Employment Opportunities

- City & Municipal Water Testing

- Water Pressure & Water Storage Tank Systems

- Hard Water Treatment

- Reverse Osmosis System

- Water Purification & Water Filters

- Water Softener Installation & Repairs

- Well Camera Surveys

- Solar Powered Well Pumps

- Water & Well System Inspections

- Well Drilling Services

- Well Pump Maintenance

- Well Pump Installation

- Well Pump Repair

- Well Water Testing

- Service Areas

Why Does My Well Pump Keep Tripping the Breaker?

You go to turn on your water only for nothing to come out. Confused, you decide to go check your breaker box, and, sure enough, the circuit breaker on your water pump has tripped. With so many possibilities of what could have happened, it can be hard to determine which one is the culprit. We at Perry’s Pump Repair will go over the five most common reasons your water pump is tripping your breaker and how to fix it.

5 Reasons Your Water Pump Is Tripping Your Circuit Breaker

Overloaded circuit.

This is one of the leading causes your submersible water pump will trip your breaker. Overloading is a phenomenon that happens when more energy than the circuit can handle passes through the device. The breaker prevents an overload of amperage from harming your pump or anything connected to it. If your water pump is pulling more energy than it should, this can cause the breaker to trip.

Solution : This is something you’ll want to leave to professionals. Electricity can be extremely dangerous to mess with if you aren’t professionally trained. We suggest you call your local electrician or reach out to us to see if it’s time for a new water pump .

Rain and Lightning

Here in Gainesville, you know we get almost daily summer thunderstorms and plenty of rain. While these weather conditions are just considered a part of everyday life in Florida, they can occasionally cause problems for your water pump.

A direct lightning strike can cause your water pump breaker to trip. Much like an overloaded circuit, this is due to the sudden surge of voltage all at once. Rain, on the other hand, can also cause a trip in your circuit breaker. This can be a sign of deeper problems such as deteriorating seals or even FLooding in your pump.

Solution : If your circuit breaker trips immediately after a lightning strike, you should be able to switch back on fine with no issue. If it pops again, the lightning may have caused damage to your wires, and you’ll want to call in a professional to prevent hazards like an electrical fire. If you believe rain may be the culprit, reach out to us so we can inspect and repair any damaged seals or FLooding.

Leaks in Pump

Sometimes, your water pump or its outer shell (called the water pump housing) can develop a leak. This can be caused by several different factors such as faulty sealant or using the incorrect coolant. If a leak has developed, it may get water on its wires or inside the pump itself, causing them to short-circuit and trip the breaker.

Solution : Since it may be hard to determine where the leak is or if it’s safe for an untrained hand to repair, leaks are best left to a professional water pump repair service like Perry’s Pump Repair. One of the best ways to solve this is to keep it from happening in the first place by having a preventative maintenance plan.

Wiring Issues

If you’re finding your breaker is tripping as soon as you turn it back on, it may not be an issue with the pump itself but its wiring. The wires could be fried, short-circuited, or simply not connected securely to an electrical source. Occasionally, wire damage can be caused by rodents or other pests that may have chewed through them.

Solution : Since this is dealing with electricity, you’ll want to have an electrician check your wiring and fix any issues they may see.

Clogged Impeller

One of the key components of your submersible water pump is its impeller. The impeller uses the energy from the motor to actually pump your water. Through normal use and wear, the impeller may become clogged, causing your circuit breaker to trip. If you’re noticing a frequently tripping breaker and a grinding noise from your water pump, a clogged impeller is likely the issue.

Solution : Often, this is an easy fix to do at home. Identify where your water pump’s impeller is and simply remove any debris from the area.

Call in the Professionals at Perry’s Pump Repair for All Your Water Pump Maintenance Needs

A tripped water pump circuit breaker can be quite frustrating. Not only does it indicate a problem, but it keeps water from flowing into your home. While we may not be electricians, we are well pump experts, and we can tell you what needs to happen next. We’ll help you identify what the issue is, how to fix it, and treat it to last with our warranty guarantee if we can help. Call us today to see how we can help keep your water pump properly functioning and maintained.

“Looking for a upright man to work on all your well problems? Perry’s Pump Repair is the place to call. They can help you over the phone or be on-site. We see that they are first looking out for YOU! I had some bad times with other companies selling all to me, but all I needed was one or two things. (up and running)”

Timothy Moore

“We hired Perry’s Pump Repair to install a new 4″ submersible well a few weeks back. Mr. Chris and his sweet wife answered all of our many questions … we had plenty! The communication before, during, and after the process exceeded our expectations. We appreciated that he used 100% USA parts.”

Kristina Walker

“These are guys who stayed until 10 pm in the rain and mugginess to get my well pump replaced. They might not be the cheapest outfit around but they warranty their work and their pumps. The one I had replaced was only 3 years old and not under warranty so Perry’s 5-year coverage on my new pump is comforting.”

Brad MacDonald

Anytime I have a problem with my well, I call these guys. Even in Jacksonville, they get me on the schedule as soon as they can. Always within 2 days. Each time they are courteous and quick.

Our company motto is “ Expect to be Impressed! ” Schedule your water consultation appointment today. We service all types of water needs from residential to commercial. We look forward to earning your business. Proudly serving the North Central Florida area.

ADVERTISEMENT

- POST a QUESTION or COMMENT about diagnosing problems with the well water pressure tank or water storage tank that show up as pump operating problems

We also provide a more comprehensive INDEX to RELATED ARTICLES for this topic, but we recommend that you use the page top or bottom SEARCH BOX as a quick way to find information you need.

Well Pump keeps Tripping Circuit Breaker or Blowing Fuse

On 2023-06-13 by InspectApedia-911 (mod)

@Mark, Thank you so much for taking the time for that detailed follow-up note. It will certainly help other readers. It sounds like we are of a similar age and have similar work experience and interests. We appreciate the note.

On 2023-06-13 by Mark

Ok, here is what it was. The old system was a 100 amp service via #10 wire connected to a "fuse box" with a manual shutoff handle. From there #10 wire to an outlet mounted on the wall in the pump room. A pig tail from the outlet to the JRS5 pump pressure switch. The low level shut off was wired to the pressure switch. Oh yeah, none of this was grounded.

What it is now. 200 amp service via #6 wire to new Square D service panel and a new 20 amp breaker. From there it's new #10 wire to new plastic gang box mounted on the wall in the pump room. Brand new pigtail from the outlet to the pressure switch and a new pressure switch.

A new low level shutoff cut into the new pigtail to act as an interrupt for the pressure switch. The new system is grounded front to back, direct from the ground rod outside back to the pump.

What happened... As near as I can figure out the low level connection had grounded out and since there was no breaker to trip there was effectively 100 amps going directly into the cistern via the low level wiring which did exactly what you would expect.

Now with the new service the pump is working correctly and cycling at the proper time.

Quick side note here: The power was off from 8am Sunday morning to 5:30pm Sunday and then on again off again the rest of the night with 100 volts max. all day yesterday which is not good for the pump or any other machinery but oh well.

Thanks for the responses and the help it's greatly appreciated. Background... retired master carpenter with. degree in architecture, more than 50 years in the field working with the other trades. Plus I know that if I don't know, go find some one that does. Thanks again.

On 2023-06-08 by InspectApedia Publisher

@Mark, I get it, but Watch out : if you are not trained and familiar with proper electrical wiring & safety, you could be shocked or killed.

On 2023-06-07 by Mark

Thank you for the quick response, I won't be working on the pump again until this weekend and I will take pics of the pump and pressure switch. I have replaced all the wiring from the meter to a new service panel dedicated to the pump and the pump runs and cycles like it's supposed to right up to when I connect the low level switch.

I really don't understand because I had a low level switch that was working and one day it just quit. I'm thinking this weekend I will also replace the pressure switch and if I have to I can replace the pump with one i had rebuilt. If that doesn't do it, I don't know.

One other thing, I don't live in the U.S. and reliable power is not common here. Supposedly to save rolling black outs the power company will drop the voltage on an irregular basis. To the point you can see and hear when they do it.

Plus if I try to call an electrician the guy that shows up will know less than I do and want to use my tools, if you get my meaning. Once again, thank you and I will get back to you after the weekend.

On 2023-06-07 by InspectApedia Publisher - jet pump from ground cistern will burn the cord from the low level switch, literally catching fire underwater

@Mark, This sounds scary as all get-out to me. I want to help but from just your brief text I can't bet your life on a mere guess at what's wrong. Look for a wiring error in your low water level switch setup, but first I'd look at the pump and its wiring and control for improper wiring or a short circuit., You may already realize this but you're describing an error that can kill you or anyone else touching the pump, its wiring, controls, or anything else having to do with the water system. Can you attach a photo of your pump and in a second comment a sketch of your wiring plan? Do you have the IO manual for your Gould JRS5 pump? IF not check these documents https://inspectapedia.com/water/Goulds-Pump-Motor-Application-Installation.pdf ITT GOULDS PUMPS INSTALLATION, OPERATION & TROUBLESHOOTING MANUAL [PDF] (2005) found at https://inspectapedia.com/water/Goulds-Jet-Pump-Manual.pdf or for newer models of the same pumps https://inspectapedia.com/water/Goulds-Jet-Pump-Manual.-2022.pdf For other readers, the Goulds JRS pump is illustrated below. Other pump instructions from Goulds - submersibles, motors, controllers, other controls GOULDS JET PUMPS INSTALLATION & TROUBLESHOOTING MANUAL GOULDS PUMP MOTOR APPLICATION & INSTALLATION DATA [PDF] - includes wiring details for control box for several pumps

I have a JRS5 jet pump pushing water from an in ground cistern into the house. When I try to connect a low level switch it's like a ground fault and the power to the whole house goes out.

If I leave it connected long enough it will burn the cord from the low level switch, literally catching fire underwater. The pump runs fine, cycles like it's supposed to until I connect the low level switch. Any ideas?

On 2022-10-07 by InspectApedia-911 (mod) - My pump hums and throws the breaker

@Ronnie, The most common causes of what you describe are a seized motor that needs to be replaced or possibly a bad starting capacitor.

On 2022-10-07 by Ronnie

My pump hummes and throws the breaker

On 2022-06-07 by InspectApedia (mod) - a leak at the connection from the pump to the assembly/ tank and pressure switch

@Rick, Trust me, it happens to all of us. Do let us know what you find out as that will help other readers as well.

On 2022-06-07 by Rick

I had a leak at the connection from the pump to the assembly/ tank and pressure switch. After repair, I started the pump and it still leaked. I fixed it again and while I was at it I replaced the pressure gauge and pressure switch.

I went to restart and the fuse popped/tripped (old-style fuses)? Could it be a failed pump? It wasn't pumping much water when I first tested it. (bad pump?)

I checked the wiring and I think its wired wrong. Instead of putting same colors to one side I separated one on each side.. Lets see what happens. Duh, moment.

On 2022-05-14 by Inspectapedia Com Moderator - short circuit in your pressure control switch or a motor that is seized

@AUGUSTINE IMEVBORE, That sounds to me like you've got a short circuit in your pressure control switch or a motor that is seized

On 2022-05-14 by AUGUSTINE IMEVBORE

I have two tank that the pumping machine supply water they're not link together they're separated i closed one tank with the control supply so that one tank can be filled up and close the one that is filled up and open the one that is close for water to enter and it will eject the fuse the minutes I open the control supply to the second tank.

What could be the cause

I have been pumping water like that for some times closing one for one to full before opening the other for water enter.

On 2021-12-20 by Inspectapedia Com Moderator - well water stinks terribly and after a lot of rain the water will sometimes turn greyish black

@Cindy, I don't know from just your description whether the problem is damaged or incorrect wiring or a seized pump motor. The pump could be seizing or jamming from debris in the water supply.

On 2021-12-19 by Cindy

Have a well pump only 1yr old. Well itself is old and I believe it’s a shallow well. The water stinks terribly and not safe to drink, after a lot of rain the water will sometimes turn greyish black.

My question however is now the well pump breaker box keeps blowing one of the fuses. I have the round fuses and there’s 2 the screw into the second small fuse to well pump.

It just started doing it and iv tried several new fuses and every time I kick the breaker on it sparks and pops the fuse any ideas on what could be causing this?

On 2021-10-28 y inspectapedia.com.moderator (mod) - Why does my sumo pump pressure breaker keep getting hot and tripping off

@Uche, When a water or well pump keeps tripping the circuit breaker, most-likely there is a failing pump motor drawing high current, perhaps from a bad bearing, or perhaps from having run the pump dry. Also see the electric motor diagnostics at ELECTRIC MOTOR DIAGNOSTIC GUIDE

On 2021-10-28 by Uche

Why My sumo pump pressure breaker keep getting hot and tripping off

On 2021-09-29 by inspectapedia.com.moderator (mod) - electrical tests on well pump vs dead short

@Dennis, I don't think that's a complete analysis or test. Even disconnecting the hot and neutral or two hot (if it's a 240V circuit) at the panel would not disconnect them at their other end - in the pump.

On 2021-09-29 by Dennis

@inspectapedia.com.moderator, can I remove the wires from the breaker in the house and put an ohm meter on them and if it shows an open would that eliminate the wires from the house to the breaker at the well?

On 2021-09-28 by inspectapedia.com.moderator (mod) - location of the electrical problem in the pump circuit

@Dennis, Thank you for an interesting question. I don't think that we can assume that we know where the fault is by which breaker is tripping. While your speculation is reasonable it's also the case that two different circuit breakers May simply not respond on exactly the same time line to the same overcurrent. I'm saying that the difference could be between the breakers not where the fault is occurring.

On 2021-09-28 by Dennis

My well is powered from the house. There is a 30 Amp breaker there and another one at the well. The breaker in the house trips immediately upon being reset but not at the well. I wired it to a different 30 Amp breaker and it tripped. Would the problem be between the well breaker and the breaker in the house?

On 2021-09-14 y inspectapedia.com.moderator (mod) - causes of pressure switch burn-up

@Janet, it might be best to have an electrician inspect and test your pump circuit to look for the cause of pressure switch burn out - of which some common causes include - pump motor seizing - excessive short cycling of the pump (search this site for that phrase) - low voltage - improper wiring or loose, corroded connections - pump needs a separate control box that in turn is switched by the pressure controller

On 2021-09-14 by Janet

I have replaced my pump to my sprinkler system but the pressure switch keeps burning out. I have replaced the pressure switch 3 times. Can you give me some suggestions?

On 2021-09-04 by inspectapedia.com.moderator (mod) - Well breaker trips.

@Jonathan, If tapping the pressure control switch does anything at all I suspect either burned points in the switch or, more-common, debris clogging of the pressure switch's sensor port; try replacing the switch. Other causes are listed in the diagnostic suggestions at WATER PRESSURE PROBLEM DIAGNOSIS TABLE https://inspectapedia.com/water/Water_Pressure_Table.php

On 2021-09-04 by Jonathan

Well breaker trips. I reset and tap on the pressure control box to bring it back on. Contacts in pressure switch look pretty bright. What else could cause this ? Thank you.

On 2021-08-20 by inspectapedia.com.moderator (mod) - well breaker trips in wet weather

@Bill, Try the diagnostics at https://inspectapedia.com/water/Water_Pressure_Table.php

It's possible that water caused a short circuit or water damage to your pump controls or, if wiring was not properly routed and weather-protected, even to an electrical connection outside the building or at the well.

On 2021-08-190 by Bill

After a lot of rain one day, my water pump breaker tripped. I then attempted to reset breaker and it kept tripping. The next day, tried resetting the breaker again and it stayed on but still have no water.

On 2021-04-30 by (mod) - causes of well breaker trip

@chris, A tripping circuit breaker usually means that the current being drawn on the circuit is too high. In the case of a water pump that may mean that the pump motor itself is failing. For example a bad bearing can cause the pump to draw more current as it tries to turn. An experienced plumber or electrician who installs pumps can do some simple tests for you to examine the circuit and the pump to determine if you need to replace it. That approach is particularly useful if your pump is a submersible one that's in the well because it's nice to have an idea of the problem before you go to the trouble of pulling the pump up out of the well.

On 2021-04-30 by chris

Water pump keeps tripping breaker. I replaced the pressure switch and I am still getting same results.

On 2021-01-29 by (mod)

Kyle That is a smart guess. Failing bearings can mean that the rotor has difficulty turning due to resistance which in turn can draw High current which in turn can trip a circuit breaker.

On 2021-01-29 by Kyle - 99 problems and my hot tub is ONE!

I own a hot tub that is a dual pump system. One pump sounds as advertised, the other sounds like the bearings are going bad. Could this be a culprit as to why the junction box circuit breaker keeps tripping?

On 2020-10-05 by (mod) - what's wrong with my pump - trips the control box

Andrea I can't say with just the information in your text but common reasons for a water pump or any electric motor to trip a breaker is that the motor is drawing excessive electrical current; In turn that's often caused by a failing electrical motor.

On 2020-10-05 y Andrea

What's wrong with my pump?

My water pump works for ten minutes and shuts off by itself by tripping the control box

On 2020-08-25 by SK

My domestic well works great under normal conditions, washing car, auto floats on water trough, etc. The problem is that if you run the water hose with no restrictions (flooding garden area), it pops breaker in about 10-12 minutes?

On 2020-07-30 by Ben

A fuse to our well pump blew and actually started on fire and burned and melted the entire fuse box. It didn’t even trip the breaker. Just trying to find out why and how so we can prevent it from happening again.

On 2020-07-14 - by (mod) -

Mike Well, thank you, that's interesting and strange problem isn't it. I suspect it's a bad pressure switch

On 2020-07-13 by Mike

A well which only services a sprinkler system is not functioning. The pressure switch is mounted inside the well casing and connects directly to the pitless adapter. Whenever you turn on the pump, it trips the breaker in about 3 seconds. However, if the pressure switch is pulled from/disconnected from the pitless adapter, the pump runs just fine. It does not make any unusual noises and pumps plenty of volume with its usual pressure.

On 2020-05-11 - by (mod) -

On 2020-05-11 by ablservices150

Bore hole pump keeps tripping electric fuse , pump not old about 5 year , tried new fuse , cleaned steady press inverter out no blockages, , inverter runs for a bit then status light comes on trips fuse

On 2019-01-23 by Tom Reed @Tom Reed, Both times the washer has been filling.

On 2018-01-07 by (mod) - The well keeps tripping but when I reset it nothing kicks on Cody I suspect that the pump or its impeller is damaged, OR your pump is protected by a control that switches off the pump when it is not moving water (such as if the well has run dry or if pipes have frozen)

On 2017-10-15 by (mod) - Do you think it's possible that the voltage being delivered to the pump is too low, or the pump is drawing more current than the generator can supply?

Larry, You raise a common concern: I often hear from people having water equipment or well problems particularly for systems that are used in irrigation or lawn watering systems. You'd need one of the following to avoid over-taxing the pump and perhaps burning it up:

However the AMT pump is not self-priming and is not designed for application where a water lift-height is involved. You probably need a model that can lift your water. - a restricted water flow rate + pressure tank that lets the pump stay off for 10-20 minutes at a shot - a quite large water pressure tank and a pump that could get ahead of the water usage rate, fill the tank and then stay off for 10 or 20 minutes at a time,

I can't from this alone know whether the well is running out of water or the pump is overheating but as a 5 minute recovery period is enough to get the water on again I suspect an over-heating pump motor. Measuring current draw on the pump circuit might diagnose this trouble.

Perhaps, Matthew, But I'd bet on a failing pump or shorted wiring. Or perhaps a bad start / run capacitor

one circuit breaker of the two continues to trip at odd this connects to the well we had a well man replace the bladder tank today and the pressure switch and the pressure gauge was replaced 2 months ago. we replaced the bladder tank after removing a filter and finding it full of mud from the pump do you have any suggestions Reply:

Water has got into sump pump and blows fuse when started.can it be fixed or do I need new pump.tried hair dryer but still blows fus Reply:

2016-07-11 by Anonymous - water pump amps check

Ok Checked the amp requirements. Label says it needs 12.6 amps with a high of 16 amp usage. It is a 10 amp Square D breaker.

Also should say that if we turn the sprinklers on manually it works fine. It still runs fine after we reset the flipped breaker. Would switching out to a 15 amp breaker work?

I'm really scared about this, Anon

. I don't understand your system, don't understand why someone put a 10 amp breaker onto a 12-16Amp circuit, and I note that

Watch out : just touching a live contact when fooling around inside the electrical panel can kill you.

Let's get an electrician in there to find out what the heck is going on with your pump circuit.

The pump between my tank and house keeps popping breaker. Pump motor revs high low high low then breaker pops after about 15 seconds.

2016-06-06 by Anonymous - pump keeps shutting off and we have no water

But, our new pump keeps tripping the overloads on the Pentair control box. We have a 3HP pump. supposed to put out 20GPM and our pressure switch is set at 40 to 60lbs.

We installed a cycle stop valve to reduce the requirement for additional pressure tanks...did everything the well repair team suggested.

The pump still runs at 17.4 A after startup. the FLA is listed at 14.3 I believe and the max was 16.5.

The repair team did not have/give me the model number and the manual, but i did look at it once. they have installed a monitor , but with winter, our demand is reduced dramatically and it the pump has not tripped.

Continue reading at WATER PRESSURE PROBLEM DIAGNOSIS TABLE for table listing causes & cures for well pump or water pressure problems, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX .

- MUNICIPAL WATER PRESSURE DIAGNOSIS - If your water supply is from a city or municipal water system

- WATER PRESSURE PROBLEM DIAGNOSIS TABLE - succinct guide to pump & well problem causes & cures

- WATER PRESSURE TABLE 1: PUMP WON'T RUN, WON'T STOP, or CYCLES

- WATER PRESSURE TABLE 2: PUMP RUNS, WEAK or NO WATER PRESSURE

- WATER PRESSURE TABLE 3: PUMP RUNS, NO WATER or INSUFFICIENT WATER

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator . Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like. You will not receive a notification when a response to your question has been posted. Please bookmark this page to make it easy for you to check back for our response. Our Comment Box is provided by Countable Web Productions countable.ca

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested CONTINUE READING or RECOMMENDED ARTICLES .

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: [email protected] . Alan Carson is a past president of ASHI, the American Society of Home Inspectors. Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME . Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.

- Search forums

- Pumps and Tanks Well Forum & Blog. Water is life.

Well Pump Tripping Circuit Breaker

- Thread starter OnlyWhnChasd

- Start date Aug 5, 2014

Users who are viewing this thread

OnlyWhnChasd

- Aug 5, 2014

Well-Known Member

Tell us about the breaker.

Paid Advertisement

- 1 minute ago

- Add bookmark

Cary Austin

When running water for an extended period of time, does the pump cycle on and off every few minutes or does it run continuously at low pressure?

Reach4, it is on a 2-pole (I think that's what you call them) 50 amp breaker--two 25s that are "connected" together so it is one switch. Valveman, that is a great question. I am embarrassed to say I don't know. How do I tell when the pump is running? That seems like such a stupid question. I'm ashamed for myself. LOL

Interesting about the breaker. I always figured more was better so I never thought you could have one that was too large. I will look at having that swapped out. That would be awesome if that was the fix. I'm currently having visions of needing a new well pump--something that I would imagine is not going to be cheap on a 400+ foot well! Now that you've explained how (and I thank you for that!) I will investigate how the pump is running. Possible the pressure tank is bad? I do notice that when I fill the washing machine in the basement that the water pressure to drop throughout the house. Could that be a sign of a bad pressure tank or just part of living on a well? This stuff is all new to me...

A breaker won't blow because it is too large. However 50 amp breaker blowing without something smoking (exaggerating a bit) is suspect. I also hope the only problem is the breaker. The pressure drop when you fill the washing machine is unusual. Most washing machines don't draw water so fast. A clogged or under-sized whole-house filter could cause such a symptom of the whole house pressure dropping when filling the washer. Look at the pressure gauge at the pressure tank while filling the washer. I expect it to not instantly drop during such a load. You can troubleshoot that problem after you get the first problem resolved.

OnlyWhnChasd said: Could that be a sign of a bad pressure tank or just part of living on a well? This stuff is all new to me... Click to expand...

Back the the breaker--I misread your previous post and I think I'm misunderstanding the breakers. It is not a 2-pole 50 amp. It is a 2-pole with each switch labeled 25 amp--like the picture you posted above only 25 on the labels instead of 50. So perhaps the breaker is about right then as a 2-pole 25 amp? As for the pressure drop, I wouldn't be surprised if the whole-house filter is undersized. To me it looks tiny--smaller than a soda can. The only whole-house filters I've seen before have been those big canister ones that have the special wrench thingie to pry them apart. Thanks for the tip about checking the pressure gauge when filling the washer. I will do that. Breaker issue is definitely the priority though!

If the pump is running continuously when the breaker trips, it is most likely a motor or wire problem. If the pump is cycling on and off every few seconds or minutes while you are using water for extended periods of time, the cycling has probably already damaged the motor. The sooner you stop the pump from cycling the better. You might get lucky and have a bad starting capacitor or even the breakers could be bad. You could stick in a new pair of 30’s and see what happens.

1. I would check the wire size at the pressure switch. If it is #14 or #12, that is what I would expect with a 3/4 HP 240 V pump. If the wire is bigger, then I suspect your pump may be bigger than 3/4 HP. How old is your pump and controller? You may see a number printed on the wire, even if you don't know wire sizes by looking. Don't touch. Just look, after you pull the cover. Put the cover back on then. 2. Valveman suspects that it is possible that the pump is not restarting all of the time. Watching the pressure gauge during one of your big fills that pops a breaker could show that. Replacing the capacitor in the controller is not so expensive either. More expensive than a breaker, but still fairly cheap. Since you are not wanting to repeat your test too often, maybe you could record the pressure gauge by shooting a movie with a camera, evn the one on your smart phone, so that you could review the event. If during the movie, the pump goes on and off a few times, that could point to a problem and solution. There are more troubleshooting things that could be checked.

Checked the wire, it is #12. I don't know how old the pump is. The house itself was built in 1989 and we just bought it about six months ago. I'm looking at the controller and it lists a model of Goulds pump that was available in its 2009 product catalog (came up when I Googled) so maybe not that old? However, maybe they same model pump is available today that was available 20 years ago. I don't know how that works. I suppose it's also possible the controller is new but the pump isn't? I may pop the cover on the controller and just see if there is any evidence of the capacitor being bad. I've read that sometime they leak a tar type substance when they go bad? I am guessing around $2-3,000 to replace the pump, so I'm all in for replacing the breaker/capacitor/controller! Of course they way things usually work for me is all that stuff is replaced and I still end up spending $3k.

In the Trades

$3000.00 sounds like a lot, but when you factor in the amount of water that $3000.00 investment will give you, the water is damn near free.

craigpump said: $3000.00 sounds like a lot, but when you factor in the amount of water that $3000.00 investment will give you, the water is damn near free. Click to expand...

Jack of all trades Master of one

- Aug 6, 2014

A 3/4 HP motor should not require 25 Amps or even close to that at 230V. Why would you want to up the breaker to 30 amps ? 5750 Watts should make something smoke on the well motor controller, if it is drawing 25 amps. Chance is that there is something else on that circuit, Maybe a pool filter pump, or air conditioner, Water Heater ?

My book shows a 25 amp breaker is the right one to use for a 3/4HP. I would use a 30 anyway, because there is usually a light or something else tied in.

valveman said: My book shows a 25 amp breaker is the right one to use for a 3/4HP. I would use a 30 anyway, because there is usually a light or something else tied in. Click to expand...

I agree with you, but that is what the book says. Deadheading would actually drop the amps by about 50%.

Similar threads

- Oct 3, 2023

- Jan 15, 2024

- Mar 25, 2024

- Chaplain Pat

- Mar 16, 2024

- Oct 31, 2023

This is awkward, but...

It looks like you're using an ad blocker. We get it, but (1) terrylove.com can't live without ads, and (2) ad blockers can cause issues with videos and comments. If you'd like to support the site, please allow ads.

Well Pump Overload Keeps Tripping: Effective Solutions and Maintenance Tips

Well Pump Overload Keeps Tripping

If you have a well pump that keeps tripping its overload , it can be quite frustrating. The overload is a safety feature that protects the pump from overheating and burning out. When the pump draws too much current , the overload trips and shuts off the power to the pump. This can happen due to various reasons , such as a clogged or damaged impeller , low voltage , or a faulty pressure switch . It is important to address this issue promptly to avoid further damage to the pump and ensure a continuous water supply .

Key Takeaways :

Remember to consult a professional if you are unsure about troubleshooting or repairing the well pump overload issue .

Understanding Well Pump Overload

Definition of well pump overload.

Well pump overload refers to a situation where the electrical system of a well pump becomes overwhelmed with excessive current, leading to the tripping of the overload switch or circuit breaker . This can occur due to various reasons , such as mechanical issues , electrical faults , or an excessive load on the pump motor.

To better understand well pump overload , let’s take a closer look at its definition and the importance of overload protection in well pumps.

Importance of Overload Protection in Well Pumps

Overload protection plays a crucial role in ensuring the smooth and efficient operation of well pumps. It helps prevent damage to the pump motor and other components by detecting and responding to excessive current flow .

Here are some key reasons why overload protection is important in well pumps:

Preventing Motor Damage : Excessive current can cause the motor in a well pump to overheat, leading to potential damage or even failure . Overload protection helps to monitor the current and prevent the motor from operating beyond its safe limits .

Avoiding Electrical Issues : Overloaded well pumps can cause electrical issues, such as tripping circuit breaker s or blowing fuses . These issues not only disrupt the water supply but can also pose a safety hazard . Overload protection helps to prevent such electrical problems by cutting off power when necessary.

Extending Pump Lifespan : By preventing the motor from operating under excessive load , overload protection helps to extend the lifespan of the well pump. This can save homeowners from costly repairs or premature replacement of the pump.

Ensuring Continuous Water Supply : Well pumps are responsible for delivering water to households. Frequent pump overload tripping can disrupt the water supply, causing inconvenience and discomfort. Overload protection helps to maintain a consistent water flow by preventing pump failures due to overload.

To better understand the causes of pump overload tripping and how to fix well pump overload issues, it is important to consider various factors such as impeller tip wear, electrical faults , or even crack in the pump housing. Regular well pump maintenance can help identify and address these issues before they lead to overload situations.

In conclusion, understanding well pump overload and the importance of overload protection is crucial for maintaining the efficiency and longevity of well pumps. By implementing proper maintenance practices and ensuring the correct operation of overload protection mechanisms , homeowners can avoid costly repairs and ensure a continuous supply of water from their wells .

Common Reasons Why Well Pump Overload Keeps Tripping

If you have been experiencing frequent tripping of the overload switch on your well pump, it can be quite frustrating. This issue can disrupt the water supply to your home and cause inconvenience. In order to address this problem effectively, it is important to understand the common reasons why a well pump overload keeps tripping. By identifying the underlying causes , you can take appropriate measures to resolve the issue and ensure a consistent water supply .

Electrical Issues

One of the common reasons for a well pump overload switch to trip is electrical issues. Electrical problems can occur due to various factors such as faulty wiring, inadequate voltage supply , or issues with the circuit breaker . When the electrical system is not functioning properly, it can cause the pump motor to draw excessive current, leading to overload and subsequent tripping of the switch.

To troubleshoot electrical issues, it is recommended to check the circuit breaker associated with the well pump. If the breaker keeps tripping, it could indicate a problem with the electrical supply. In such cases, it is advisable to consult a professional electrician to inspect the wiring, voltage supply , and circuit breaker to identify and rectify any electrical issues .

Pump Motor Problems

Another common cause of well pump overload tripping is pump motor problems . The motor is a crucial component of the well pump system, responsible for drawing water from the well and delivering it to your home. If the motor is not functioning properly, it can lead to excessive current draw and overload.

Well pump motor issues can arise due to various factors such as overheating, worn-out parts , or a malfunctioning impeller . Overheating can occur if the motor is running for extended periods without sufficient cooling or if there is a lack of proper ventilation . Worn-out parts , such as bearings or seals, can also contribute to motor problems and increased current draw .

To address pump motor problems , it is recommended to perform regular maintenance on the well pump system. This includes checking the motor for any signs of overheating, inspecting and replacing worn-out parts , and ensuring proper lubrication . Regular maintenance can help prevent motor issues and reduce the likelihood of overload tripping.

Faulty Wiring

Faulty wiring is another potential cause of well pump overload tripping. Over time, wiring can deteriorate due to factors such as age, exposure to moisture, or rodent damage . Faulty wiring can result in increased resistance , which in turn leads to higher current draw and overload.

To identify faulty wiring, it is important to visually inspect the wiring connections and look for any signs of damage or corrosion. Additionally, using a multimeter to measure the resistance of the wiring can help pinpoint any issues. If faulty wiring is detected, it is crucial to have it repaired or replaced by a qualified electrician to ensure safe and reliable operation of the well pump system.

In conclusion, there are several common reasons why a well pump overload keeps tripping. Electrical issues , pump motor problems , and faulty wiring can all contribute to this problem. By addressing these issues promptly and seeking professional assistance when needed, you can resolve the overload tripping and ensure a consistent water supply to your home. Remember to perform regular maintenance on your well pump system to prevent future issues and prolong its lifespan .

The Connection Between Well Pump and Breaker Tripping

How a Bad Well Pump Can Trip Breaker

When it comes to well pump troubleshooting, one common issue that homeowners may encounter is a breaker tripping . This can be quite frustrating, as it disrupts the flow of water to your home. Understanding the connection between a bad well pump and a tripped breaker is essential in resolving the problem effectively.

There are several reasons why a well pump can trip a breaker . One possible cause is an overload switch tripping . This occurs when the well pump motor draws too much electrical current , exceeding the capacity of the breaker. When this happens, the breaker automatically shuts off to prevent damage to the electrical system.

Another potential cause of a tripped breaker is well pump electrical issues. Over time, the electrical components of the pump may deteriorate or become faulty. This can lead to frequent pump overload tripping , as the pump struggles to function properly. In such cases, it is important to address the underlying electrical problem s to prevent further issues .

Why Well Pump Keeps Tripping the Breaker

There are various factors that can contribute to a well pump repeatedly tripping the breaker. Identifying the root cause is crucial in finding a solution and avoiding future problems .

One possible cause is a well pump motor overheating . If the motor becomes too hot, it can cause the breaker to trip. This can happen due to a lack of proper ventilation or a malfunctioning motor . Regular well pump maintenance , including cleaning and inspecting the motor, can help prevent overheating issues .

Another reason for a well pump tripping the breaker is an electrical overload . This can occur if the pump is drawing more electricity than it should, potentially due to a malfunctioning component or a wiring issue . In such cases, it is important to address the underlying electrical problem to avoid further damage to the pump or electrical system .

In some instances , a well pump breaker keeps tripping due to issues with the impeller. The impeller is responsible for drawing water into the pump and pressurizing it for distribution. If the impeller is damaged or clogged, it can cause the pump to work harder, leading to electrical overload and breaker tripping . Regular maintenance and cleaning of the impeller can help prevent this issue.

To summarize, the connection between a well pump and breaker tripping is often related to electrical issues, motor overheating, or problems with the impeller. By understanding these potential causes , homeowners can take appropriate measures to troubleshoot and resolve the problem effectively. Remember, if you are unsure about any electrical work , it is always best to consult a professional to ensure safety and proper repairs .

Troubleshooting Well Pump Overload Issues

If you’re experiencing frequent pump overload tripping or other electrical issues with your well pump, it’s important to identify and address the problem promptly. In this guide , we’ll walk you through the process of troubleshooting and fixing overload issues on your well pump. By following these steps , you can ensure the proper functioning of your well pump and avoid potential damage or failure.

Identifying the Problem

When your well pump’s overload switch keeps tripping, it indicates that there is an electrical overload or fault in the system . To pinpoint the cause of the overload, you can follow these steps :

Check the circuit breaker : Start by inspecting the circuit breaker that controls the well pump. If the breaker keeps tripping, it could indicate an issue with the electrical supply or the pump itself. Make sure the breaker is properly sized for the pump’s electrical requirements .

Inspect the impeller : The impeller is a crucial part of the well pump that helps draw water from the well. If the impeller is damaged or clogged, it can cause the pump to work harder and overload the electrical system. Check for any debris or obstructions that may be affecting the impeller’s performance.

Examine the water flow : Insufficient water flow can also lead to pump overload problems . If the well is not supplying enough water , the pump may run continuously, causing the motor to overheat and trip the overload switch. Check for any issues with the well’s water supply, such as low water levels or a malfunctioning pressure tank .

Inspect the electrical connections : Loose or faulty electrical connections can contribute to well pump overload issues. Ensure that all electrical connections , including wiring and terminals, are secure and free from corrosion. Faulty connections can cause excessive resistance and lead to electrical overload.

Steps to Fix Overload Tripping on Well Pump

Once you have identified the cause of the overload tripping on your well pump, you can take the necessary steps to fix the issue. Here’s what you can do:

Reset the overload switch : If the overload switch has tripped, you can try resetting it to see if the problem resolves. Locate the overload switch, usually located on the pump motor, and follow the manufacturer’s instructions to reset it. However, keep in mind that simply resetting the switch may not address the underlying issue causing the overload.

Address impeller or water flow issues : If the impeller is damaged or clogged, clean or replace it as necessary. Ensure that there are no obstructions affecting the impeller’s performance. If the water flow from the well is insufficient, consider consulting a professional to assess and improve the well’s water supply.

Check for motor issues : Overheating of the well pump motor can lead to overload tripping. Inspect the motor for any signs of overheating, such as excessive heat or unusual noises . If you suspect motor issues, it’s best to consult a qualified technician to diagnose and repair the problem.

Ensure proper maintenance : Regular maintenance of your well pump is essential to prevent overload issues. Follow the manufacturer’s recommended maintenance schedule , which may include tasks such as lubricating bearings, checking electrical connections , and inspecting the pump for any signs of wear or damage.

By following these troubleshooting steps and addressing the underlying causes of well pump overload , you can ensure the efficient and reliable operation of your well pump system. If you encounter persistent overload issues or are unsure about performing any repairs yourself, it’s always recommended to seek professional assistance to avoid further damage or safety hazards .

Special Focus: Submersible Well Pumps

Submersible well pumps are an essential component of residential water systems . These pumps are designed to be submerged in the well, allowing them to efficiently draw water from deep underground. In this special focus , we will explore the common overload issues that can occur with submersible well pumps and provide troubleshooting tips to help you resolve these problems .

Overload Issues in Submersible Well Pumps

Overload issues in submersible well pumps can be frustrating and disruptive to your water supply . When an overload occurs, it typically means that the pump is drawing too much electrical current , causing the circuit breaker to trip. This can be caused by a variety of factors, including mechanical problems , electrical issues, or even issues with the well itself.

One common cause of overload is a problem with the impeller, which is responsible for drawing water into the pump. If the impeller becomes damaged or clogged, it can put extra strain on the motor, leading to an overload situation . Regular maintenance and cleaning of the impeller can help prevent this issue.

Another potential cause of overload is a crack or leak in the pump housing. If water is able to enter the housing, it can cause the motor to overheat and draw excessive current. Inspecting the pump housing for any signs of cracks or leaks and promptly addressing them can help avoid overload issues.

Troubleshooting Overload in Submersible Well Pumps

When faced with an overload issue in your submersible well pump, there are several troubleshooting steps you can take to identify and resolve the problem. Here are some tips to help you get started:

Check the circuit breaker : Start by checking the circuit breaker to ensure it hasn’t tripped. If it has, reset it and monitor the pump to see if the overload issue persists.

Inspect the impeller : Remove the pump and inspect the impeller for any signs of damage or blockage. Clean or replace the impeller as necessary.

Check for leaks : Examine the pump housing for any cracks or leaks. If you find any, repair or replace the housing to prevent water from entering and causing an overload.

Verify the power supply : Ensure that the power supply to the pump is adequate and stable. Fluctuations in voltage can contribute to overload issues.

Consider professional assistance : If you’ve tried troubleshooting on your own and the overload problem persists, it may be time to seek the help of a professional well pump technician . They have the expertise to diagnose and fix more complex issues .

Remember, regular maintenance and inspection of your submersible well pump can help prevent overload issues from occurring in the first place . By addressing any problems promptly and taking the necessary steps to keep your pump in good working condition , you can ensure a reliable and uninterrupted water supply for your home.

So, if you’re experiencing frequent overload tripping , motor overheating, or other electrical issues with your submersible well pump, don’t panic. Follow the troubleshooting tips mentioned above and reach out to a professional if needed. By addressing the root cause of the overload problem, you can restore the functionality of your well pump and enjoy a steady supply of water once again.

Preventive Measures to Avoid Well Pump Overload Tripping

Well pump overload tripping can be a frustrating issue that disrupts the flow of water in your well system . However, there are preventive measures you can take to avoid this problem and ensure the smooth operation of your well pump. By following regular maintenance practices and seeking professional inspection, you can minimize the risk of well pump overload tripping.

Regular Maintenance

Regular maintenance plays a crucial role in preventing well pump overload tripping. By keeping your well pump in good condition , you can avoid potential electrical issues and ensure its longevity . Here are some maintenance tips to consider:

Inspect the electrical connections : Regularly check the electrical connections of your well pump to ensure they are secure and free from any signs of damage. Loose or corroded connections can lead to overload problems, so it’s important to address them promptly.

Monitor the motor temperature : Well pump motor overheating can be a common cause of overload tripping. Keep an eye on the motor temperature and make sure it doesn’t exceed the manufacturer’s recommended limits . If you notice excessive heat, it’s advisable to consult a professional to diagnose and fix the issue.

Clean the impeller : The impeller is a vital part of the well pump that helps in the movement of water. Over time, debris and sediment can accumulate on the impeller, affecting its efficiency and causing overload problems. Regularly clean the impeller to ensure smooth water flow and prevent pump overload tripping.

Check for leaks : Inspect the well pump housing for any signs of leaks. A leak can disrupt the flow of water and cause the pump to work harder, leading to overload situations. If you notice any leaks , it’s important to address them promptly to avoid further complications .

Professional Inspection

While regular maintenance is essential, seeking professional inspection is equally important to prevent well pump overload tripping. A professional can identify potential issues that may not be visible to the untrained eye and provide appropriate solutions . Here’s why professional inspection is beneficial:

Identify underlying causes : A professional inspection can help identify the root causes of pump overload tripping. They have the expertise to diagnose electrical issues, motor problems, or any other underlying factors that may contribute to the overload situation . By addressing these causes , you can prevent future occurrences of pump overload tripping.

Ensure proper pump sizing : Sometimes, pump overload problems can arise due to an incorrectly sized pump . A professional can assess your well system ‘s requirements and recommend the appropriate pump size . This ensures that the pump is not overworked, reducing the risk of overload tripping.

Verify the functionality of the overload switch : The overload switch is a safety feature that protects the well pump from excessive electrical currents . During a professional inspection , the functionality of the overload switch can be tested to ensure it is working correctly. If any issues are detected, the professional can repair or replace the switch as needed.

By following regular maintenance practices and seeking professional inspection, you can significantly reduce the chances of well pump overload tripping. These preventive measures not only help in avoiding inconvenience but also contribute to the longevity and efficiency of your well pump system. Remember, a well-maintained pump is less likely to encounter electrical overload issues , ensuring a continuous supply of water to your home.

In conclusion, a well pump overload that keeps tripping can be a frustrating and inconvenient problem . It is important to understand that this issue can be caused by various factors, such as a faulty pressure switch , a clogged or damaged pump , or an electrical problem . To troubleshoot this issue, it is recommended to check the pressure switch , inspect the pump for any clogs or damage, and ensure that the electrical connections are secure. If the problem persists, it is advisable to seek professional help from a qualified technician who can diagnose and fix the issue effectively. Regular maintenance and inspection of the well pump can also help prevent future overload tripping .

What Are Some Effective Solutions for Well Pump Overload Tripping?

When facing troubleshooting well pump cycling issues like overload tripping, there are several effective solutions to consider. Firstly, ensure the power supply is adequate and not causing voltage fluctuations. Additionally, inspect the pressure switch for any faults or adjustments needed. Moreover, check for any water leaks or blockages that may be leading to excessive cycling. Lastly, have a professional assess the pump’s horsepower and consider upgrading if necessary.

Frequently Asked Questions

1. what is a submersible well pump.

A submersible well pump is a water pump designed to operate underwater, specifically in the water well. Its main job is to push water from the well into the plumbing system of your home.

2. What Causes a Submersible Pump Overload to Trip?

Overloads in submersible pumps can trip due to several reasons , including power surges , motor overheating, worn-out wiring , or a malfunctioning pump . It’s crucial to identify and address the cause to prevent further damage.

3. Why Does My Well Pump Keep Tripping the Breaker?

Your well pump may keep tripping the breaker because of electrical issues. It could be due to a faulty breaker , an overloaded circuit , a short circuit , or even a ground fault .

4. How Can I Troubleshoot a Submersible Well Pump?

Troubleshooting a submersible well pump involves checking for power supply issues , inspecting the pump for damage, testing the pressure switch , and examining the water delivery system. If you are not experienced with electrical systems , it’s advisable to hire a professional.

5. What are the Common Submersible Pump Problems?

Common problems with submersible pumps include motor failure , water not being pumped, the pump running continuously, overload switch tripping , and the breaker for the well pump repeatedly tripping.

6. Will a Bad Well Pump Trip Breaker?

Yes, a bad or malfunctioning well pump can trip the breaker. This usually happens when the pump is drawing more power than the circuit can handle, or if there’s a short circuit within the pump.

7. How Do I Reset the Overload Switch on My Well Pump?

To reset the overload switch, you first need to switch off the main power supply . After waiting for a few minutes to let the motor cool down, you can then press the reset button on the overload switch. If the issue persists, consult a professional.

8. What are the Signs of Well Pump Failure?

Signs of well pump failure can include low water pressure , the pump constantly running, dirty water , air spitting from the faucet, high electricity bills , and frequent circuit breaker trips.

9. How Can I Fix Overload Tripping in My Well Pump?

Fixing overload tripping involves identifying the root cause. It could be a wiring issue , a faulty motor , or a problem with the pump itself. Once the problem has been identified, you can then repair or replace the faulty component .

10. How Can I Prevent Overload Tripping on My Well Pump?

Regular maintenance and inspection of your well pump can help prevent overload tripping. Ensure the pump is not overworked, the wiring is in good condition , and the motor is not overheating. If you notice any issues, get them fixed promptly to prevent further damage.

- Well pump replacement parts

- Well pump current draw

- How well do heat pumps cool

- External well pump

- Well pump bladder

- Insulated water well pump covers

- Installing a water hydrant from well pump

- Well pump not running

- Well pump surge protector

- Well pump runs constantly

The TechieScience Core SME Team is a group of experienced subject matter experts from diverse scientific and technical fields including Physics, Chemistry, Technology,Electronics & Electrical Engineering, Automotive, Mechanical Engineering. Our team collaborates to create high-quality, well-researched articles on a wide range of science and technology topics for the TechieScience.com website.

All Our Senior SME are having more than 7 Years of experience in the respective fields . They are either Working Industry Professionals or assocaited With different Universities. Refer Our Authors Page to get to know About our Core SMEs.

Serving South Carolina Since 1960

Why Does The Breaker On My Well Pump Keep Tripping?

One of the most common reasons why the breaker on your well pump might keep tripping is due to an overloaded circuit. This typically happens when too many devices or appliances are simultaneously drawing power from the same circuit. For instance, if your well pump shares a circuit with other high-powered appliances, the combined energy requirement may exceed the circuit’s capacity, causing the breaker to trip as a safety measure.

As the owner of Austin Drilling & Well Repair Inc, a licensed well pump repair company in Columbia, SC, I understand the importance of a reliable well pump for a consistent water supply. However, a tripping circuit breaker can disrupt your well’s performance, leaving you without water and in need of prompt solutions. In this comprehensive guide, we’ll explore common reasons why the breaker to your well pump may trip and offer practical tips to address the issue effectively.

Reason 1: Overloading of the Circuit An overloaded circuit is one of the most common reasons why the breaker to your well pump may trip. When the well pump draws more current than the circuit can handle, the breaker automatically shuts off the power to prevent electrical hazards.

Solution: Reduce the electrical load on the circuit by disconnecting or turning off any other electrical appliances or devices connected to the same circuit. Consider redistributing electrical loads across different circuits to ensure balanced power distribution.

Reason 2: Motor Issues Issues with the well pump motor can also lead to breaker tripping. Motor problems, such as a short circuit or damaged windings, can cause excessive current draw, triggering the breaker’s protection mechanism.

Solution: If you suspect motor issues, it’s best to seek professional assistance from Austin Drilling & Well Repair Inc. Our experienced well pump technicians can inspect and diagnose the motor for any damage or malfunction. Depending on the severity of the problem, we can recommend motor repairs or replacements.

Reason 3: Waterlogged Well Pump A waterlogged well pump is a common issue in wells with a submersible pump. When the pump’s motor becomes flooded with water, it can cause the breaker to trip due to electrical short circuits.

Solution: A waterlogged well pump requires immediate attention from a professional well contractor. Contact Austin Drilling & Well Repair Inc to inspect the well and determine the cause of the waterlogging. Proper sealing and wellhead maintenance can prevent this issue from recurring.

Reason 4: Faulty Wiring or Connections Loose or damaged wiring and connections within the well pump system can lead to increased resistance and heat buildup. This can trip the breaker as a protective measure.

Solution: Regularly inspect the wiring and connections of your well pump system. If you notice any loose or damaged components, contact Austin Drilling & Well Repair Inc to perform necessary repairs or replacements. Ensure all connections are securely tightened to prevent future issues.

Reason 5: Ground Faults Ground faults occur when an electrical current flows through an unintended path, bypassing the intended circuit. This can cause the breaker to trip.

Solution: Addressing ground faults requires expertise and specialized equipment. Contact Austin Drilling & Well Repair Inc to perform a thorough well inspection and identify any ground faults in your well pump system. Proper grounding of electrical components is crucial for preventing future tripping.

Well Pump Breaker Keeps Tripping: Call Today

A tripping breaker can be frustrating and disruptive to your well’s performance. By understanding the common reasons why breakers trip and implementing the recommended solutions from Austin Drilling & Well Repair Inc , you can address the issue effectively and ensure a reliable water supply from your well. Regular maintenance and professional inspections are essential for preventing future breaker trips and maintaining the optimal performance of your well pump system . If you encounter repeated breaker tripping or require expert assistance, our dedicated team of well professionals is here to provide reliable solutions and exceptional service to keep your well operating smoothly.

Free Water Analysis

Installations.

803-926-5402

Monday – Friday 8am – 5pm

Information

Accreditation.

© AUSTIN DRILLING INC | All Rights Reserved

NOTICE. This Website Uses Cookies And Third Party Services to provide necessary website functionality, improve your experience and analyze our traffic. By using our website, you acknowledge and agree to our Terms of Use , Privacy Policy , Cookie Policy , and Accessibility Statement .

- Why Does My Well Pump Trip The Breaker?