Join 100,000+ Drivers

- Sponsorship

- Thinking of Becoming a Truck Driver?

- Getting a CDL License

- Trucking Driving Jobs Guide

- Trucking Company Guide

- Trucker Life

- Paid CDL Training

- CDL Schools

- Professional Driving Skills + Knowledge

- Owner Operator

- Latest Articles

- Truck Driver Skills

The Pre-Trip Inspection: A Practical Guide For the Truck Driver

Updated February 24th, 2022

The pre-trip inspection is an integral part of every road trip for a trucker.

It’s probably the most disliked and most often overlooked part of the job of the professional truck driver in the trucking industry.

This inspection is meant to be a thorough check of the truck, trailer and load.

The check is to ensure that everything is in correct working order, prior to the truck and driver, departing on a trip.

Any damage or issues found during the pre-trip inspection which needs attention, must be addressed before departure.

CDL Test Pre-Trip Inspection

If you just came through the process of getting your CDL, you can breathe a sigh of relief.

You don’t have to check all 500 or so items that you had to memorize for the test every single day.

Out on the road, a thorough pre trip shouldn’t take more than 10 to 15 minutes.

DVIRs – Daily Vehicle Inspection Report

According to federal law ( FMCSR Section 396.11 ), every day, a driver must submit a Daily Vehicle Inspection Report (DVIR) for each power unit he operates. Multiple trailers can go in one report.

DVIRs are either paper or electronic.

Not every trucking company (ahem) enforces this policy, so some truck drivers can go months or years without submitting a DVIR.

Minimum DOT Pre-Trip Inspection Requirements

- Service brakes including trailer brake connections

- Parking brake

- Steering mechanism

- Lighting devices and reflectors

- Windshield wipers

- Rear vision mirrors

- Coupling devices

- Wheels and rims

- Emergency equipment

Your trucking company’s DVIR might be more thorough.

This is a thorough Q&A on DVIRs which you can refer to.

Inspecting a New Truck

When you are assigned a new truck (either daily or just once), there are a few additional things you need to check for on the pre-trip inspection.

Truck Compliance

- Cab card and book – This is a book containing the registration, inspection, permits, cab cards, IFTA paperwork, and any other important papers for the truck. Make sure it is in the truck and all the paperwork is up to date.

- Inspection sticker – This is outside the truck. Find it and make sure the truck is not overdue.

- IFTA stickers – These are the fuel tax compliance stickers. They are on both sides of the truck. Make sure the current year is displayed.

- Elog device – Most trucks are required to have a working elog device.

- Required permits – These are in the cab card book. The most common permits are Heavy Motor Vehicle Trip Permit (Oregon) and the Weight Distance Tax Permit (New Mexico).

- New York HUT sticker – This is usually on the front of your truck. It’s a type of permit.

- License plate – Make sure the license plates on the front and back of the truck match.

- FMCSA Safety Regulations and Hazardous Materials book – These will be given to you by your company. They must stay in your truck within arms reach from the driver’s seat.

- Paper logbook – If your e-log stops working, you must log your hours in a paper logbook, which must be kept in your truck.

- Medical card – You must keep your current medical card in your truck. Always have your CDL on you as well.

- Orange triangles – You must have 3 triangles for when you break down.

- Fire extinguisher – Must be charged and secured to the truck. No rolling around on the floor.

- Extra fuses – If your truck doesn’t use circuit breakers, you must have spare fuses.

- Load bars and/or straps

- Extra oil, coolant, and windshield washer fluid

- Line antifreeze and diesel anti-gel

- Chains and bungees

- Gladhand seals

- Hammer, wrench, wire cutters, cable cutters, knife with glass-breaker

The Class A Pre-Trip Inspection Process

Unless I have to bobtail to pick up my trailer, I inspect my truck and trailer together.

The best way to memorize a thorough pre trip is to do it the same way each time.

Your process will look different from mine, but as long as you are consistent, you will be less likely to miss anything.

I do the inspection first thing each morning as well as every time I swap trailers.

Paperwork and Trailer

- Check the paperwork. It should be the first thing checked when you get to your truck.

- Match the trailer number to your paperwork. If your trailer has a seal, make sure it matches too.

- Unsealed trailer. If your trailer does not have a seal, open it and confirm the product matches the bills. If you are picking up an empty trailer, open it and make sure it’s actually empty.

- Confirm your destination. Ensure the destination is the same as on your trip sheet or load assignment. If there is a discrepancy, call your dispatcher.

I personally like to start with checking under the hood of the rig. Not everyone does, but I do.

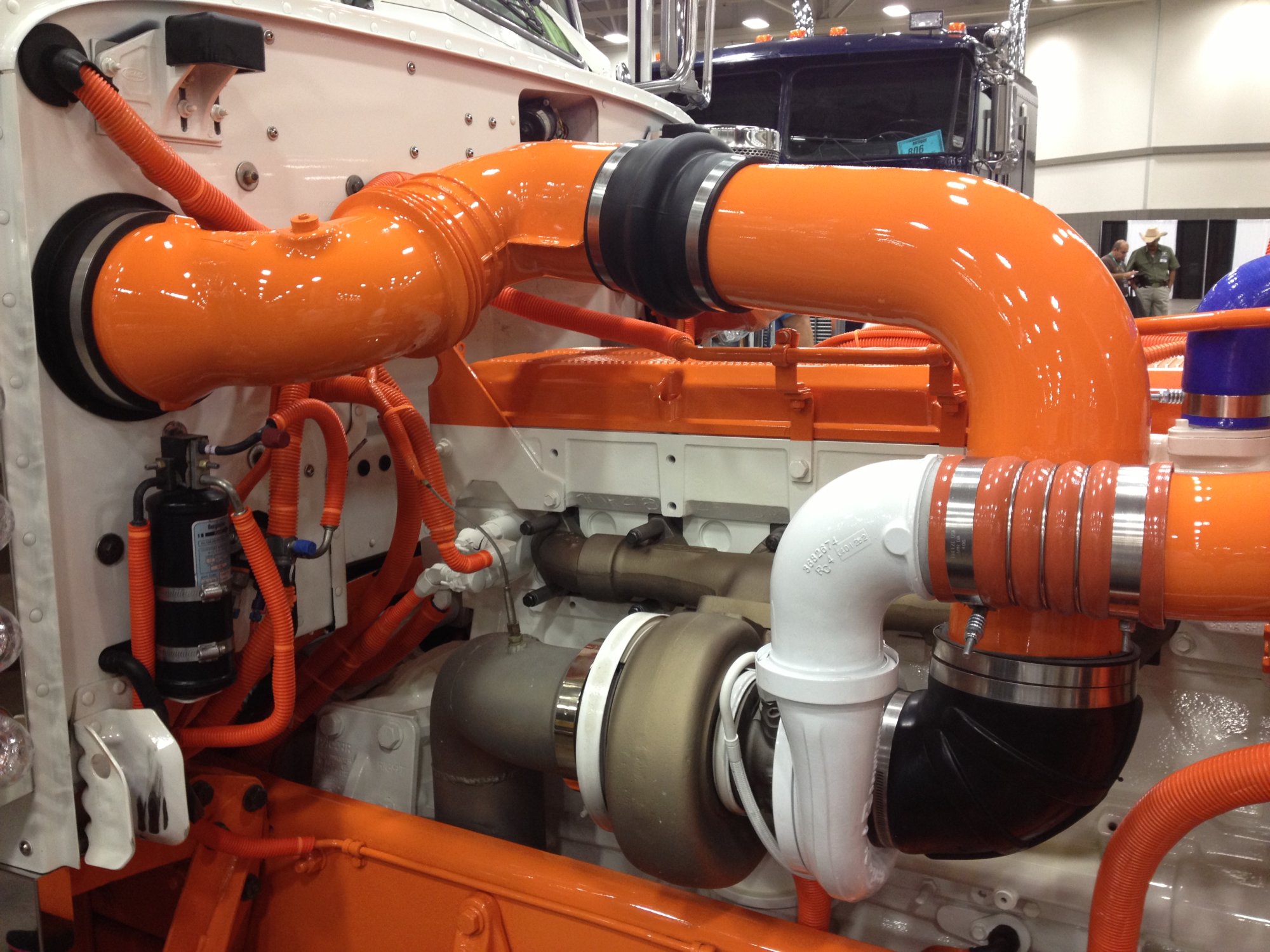

Under the Hood of the Truck

I walk around the front of the truck, making sure all the lights work. Then I open the hood.

- Fluid levels – Check all fluids: coolant, oil, power steering fluid, and windshield washer fluid. Make sure caps are tight for the rad, oil filler, power steering fluid and the dip-stick is seated properly.

- Alternator, water pump, power steering pump –Make sure these are in good working order, and the belts are not worn or have too much slack.

- Observe at the engine block. Check for leaks, fluid running down the side of the engine. Check for wear, cracking or fraying. Inspect fan belts for proper tension and signs of wear.

- Hoses – Check all hoses for leaks, cracks, and tears.

- Wiring – Check wiring for wear.

- Steering linkage – Check linkage for worn or missing parts.

- Tires – Tires should be properly inflated and have decent tread. If there are flat spots on the tire, it needs to be replaced.

- Hub seal – Make sure it’s not leaking and wiped with oil if transparent.

- Brakes – Brake chambers should not be out of round and should be free of grease. Shoes should not be worn down too much.

- Slack adjusters – Pull slack adjuster. If it travels more than an inch, it needs to be adjusted.

- Suspension – Shocks should be in good condition, and not covered in grease or oil.

Back of the Truck

Next, I check the back of my truck because it’s easier to check this before hooking to a trailer.

- Tires – Tires should be properly inflated and have decent tread. If the tires have flat spots, the tire needs to be replaced.

- Suspension – Shocks and airbags should be in good condition, and not covered in grease or oil.

- Drive shaft – Driveshaft should be undamaged and free of grease. Make sure there is no debris in the u-joints.

- Frame – The frame should not have any welds and not cracked or significantly rusted.

- Fifth wheel – The fifth wheel should be properly greased and not broken.

- Fuel tanks – Fuel tanks should not be leaking.

- Stairs and catwalk – Stairs and catwalk should be free of debris and not broken.

Tires should be checked with a tire gauge.

Tip . This is especially if you are slip seating. Tire thumpers aren’t very accurate. If you use a tire thumper, still check with a tire gauge from time to time.

Drives and tandems should be inflated to 100-110 psi and have a minimum tread or 2/32in. Steer tires should be inflated to 110-120 psi and have a minimum tread of 4/32in.

Tires under 50 psi should be replaced, as they can’t retain enough air pressure.

Flat spots can occur from dragging tandems in the winter or when trying to slide the tandems. Tires with flat spots should be replaced.

Check tires for damage, nails, and punctures.

Next, I jump in my cab and start my truck.

- Gauges – Make sure air, oil, and water temperature gauges rise to normal levels.

- Mirrors – Adjust mirrors before moving your truck.

- Windshield wipers – Make sure they work and sit flat against the windshield.

- Horn – Make sure the city and air horns both work.

- Heat and A/C – Check to see if heat and/or air conditioning is working.

- Seat belt – Seat belt should not be frayed and should move freely.

Coupling and Air Lines

This is what could happen if you don’t do the tug test.

The pre-trip inspection is a pretty important thing to do.

Learn your pre-trip procedure and do it when required.

This is why you should always do a tug test when picking up a trailer. The passenger side of the front of the trailer is resting on the frame of the truck and NOT hooked up to the 5th wheel.

The front left corner of the trailer is supported by retracted landing gear only. (Not good!)

The truck driver in this photo (hopefully) learned how critical a pre-trip is. Don’t end up in a pickle like this guy.

Next, I hook up to my trailer.

- Tug test – I back under my trailer until I hear a click, and then immediately do a tug test.

A tug test tests both your coupling and your brakes. If you pull away from your trailer, you aren’t hooked properly.

If you pull your trailer with you, your trailer brakes are out of adjustment. Be absolutely sure to write it up and have it corrected before departure.

- 4 Ways + Headlights. I also turn on my four-way flashers and headlights.

- Airlines and pigtails – Next, hook up airlines and pigtails (electrical connection). Inspect to make sure they aren’t leaking or ripped.

- Visual check of Fifth wheel – Look at the fifth wheel arm under the trailer to make sure it is coupled. The arm should be in.

- Landing gear – Raise the landing gear and check for damage.

Next, I check the bulkhead (front of the trailer).

- Wall – Make sure the wall is not damaged.

- Inspection sticker – Check the DOT inspection sticker to make sure it’s not out of date.

- Registration paperwork – Check the front trailer box to make sure the registration is good.

- Reefer unit – If you are pulling a reefer, select the pre trip function on the unit and run it. It should be completed by the time you are finished your pre trip inspection.

Next step for the pre-trip inspection is to check the side of the trailer and the tandems.

- Lights – Lights should be on and flashing.

- Suspension – springs or airbags should be in good condition, and not covered in oil or grease.

- Tandem pins – Tandem pins should be locked in position, and slider arm should be in its cradle.

- Cables – Make sure the tandem cables aren’t dragging on the ground.

- Underbelly – Make sure there are no damaged beams under the trailer. Check the entire length.

- Mudflaps – Mud flaps should not be torn and hanging.

Back of Trailer

Next, I check the back of the trailer.

- Doors – Doors and hinges should not be damaged.

- Door latches – Doors should be closed and secured.

- Seal – Seal should be intact and match paperwork.

- DOT bumper – DOT bumper should not be damaged

- License plate – Check for the license plate. They tend to wear out and fall off.

Passenger Side

Next, I check the passenger side.

- Brakes – Brake chambers should not be out of round and should be free of grease.

- Suspension – Springs or airbags should be in good condition, and not covered in grease or oil.

- Mudflaps – Mud flaps should not be torn.

Ready to Roll

Finally, I jump in my truck and double check my paperwork and destination.

I release my air brakes, roll forward, and push the service brake.

If everything is good, I’m ready to roll.

Post-Trip Inspection

When I’m done for the day, and every time I swap trailers, I do a post-trip inspection. If I am swapping trailers, I do a pre-trip on the new trailer as well.

A post-trip includes:

- lowering the landing gear

- removing the airlines

- uncoupling, and walking around the trailer checking tires, lights, seal, and mudflaps

Then I finish my paperwork and go home.

Slip Seating

If you slip seat (meaning you are in a different truck each shift), your pre- trip check should be more thorough than if you are permanently assigned a truck.

This also applies to the first inspection after being assigned a truck.

Please be courteous and write up any problems or issues found, so the next driver of the vehicle doesn’t have to deal with it.

Side Note: Clean out your truck and throw away any trash. Common courtesy goes a long way in trucking, between drivers.

Pre-Trip Inspection F.A.Q.

Most breakdowns can be avoided with proper preventative measures, such as daily inspections.

Thorough inspections should be done at the start of each shift. Inspections of trailers should be done every time you swap trailers.

Each driver should do a thorough pre-trip every time they swap drivers.

It should take about 10-15 minutes to perform a pre trip inspection.

The DOT. Make sure you stay in compliance so you don’t end up with hefty fines and an out of service.

The best way to memorize your pre trip inspection routine, is to do it the same way every time. That way you’re less likely to miss something. If you have questions, ask your safety team at your company.

Fluids in the engine, engine hoses and wires, brakes and suspension, mudflaps, trailer registration and inspection paperwork, and license plates.

A Few Trip Planning Tips

- Buy and learn to read a trucker’s atlas. It’s useful to plan routes and avoid restricted roads. I find this road atlas a necessity as a professional truck driver.

- Buy a decent trucking GPS , but don’t rely on it 100%. Use common sense.

- Don’t use the GPS in your elog device. It will put you in a lake.

Please note that minimum requirements for the inspection are established by the FMCSA.

But these may vary by state, trucking company, truck type, and trailer type.

It is your duty as a professional truck driver to perform a thorough pre-trip inspection before each trip and before you drive.

You’ll save yourself from headaches, fines and unnecessary accidents.

More Articles You May Like

- Trucking Terms – A Guide to Our Industry’s Lingo

- The 18 Wheeler – A Comprehensive Guide to Big Rigs

CDL Truck Driver Skills – Tips, Tricks + Knowledge to Kick Your CDL Skills Up a Notch!

- The D.O.T. Physical- A Guide For the Truck Driver

Everything You’ll Want To Know About Paid CDL Training

Custom Big Truck Sleepers Photo Gallery Collection

The Best Trucking Companies to Work For 2024 USA

5 Best GPS For Truckers – A Professional Driver’s Guide

Twice a month we email you the best tips and new articles to help you better navigate the trucking industry..

10 Truck Driving Safety Tips Every Professional Driver Should Follow

A veteran 40+ years truck driver shares 10 of the all time, tried and true truck driving safety tips ALL professional truckers should know AND follow! If every driver of EVERY vehicle on the road followed these safety tips, our roads would be SO much safer.

Trucker Tips Master Guide: Expert Advice From Experienced Truck Drivers

A collection of trucker tips from million milers and experienced drivers. These are gold nuggets for the new truck drivers!

Instruction, clear advice, videos and photos for truck driver skills, maneuvers and information for all professional truck drivers.

A practical guide to paid CDL training programs. Recommended Company Sponsored Schools, Requirements, pros + cons, what to expect from company-sponsored cdl training programs.

Is a Career As a Department of Defense Truck Driver For You?

As a Department of Defense (D.O.D.) truck driver, your role is integral to the logistics and supply chain operations of […]

Navigating Fair Truck Driver Pay: Are You Earning Enough?

Ready to take control of your truck driver pay? Discover key factors impacting your earnings and ensure you’re compensated appropriately […]

The Best Tanker Trucking Companies to Work, U.S., 2024

Top Tanker Trucking Companies in the US To Work For Tanker work typically falls to the ‘better carriers’. Tanker carriers […]

Best Flatbed Trucking Companies, US, 2024: Our Top Picks

There are over 1 million truck drivers working for flatbed trucking companies in the U.S. trucking industry. However, not all […]

Best Trucking Companies For New Drivers in the U.S., 2024

For new drivers entering the trucking industry, diving into the right pool can make all the difference. The foundation of […]

Follow Smart Trucking

Complete pre-trip inspection checklist for truck drivers

By The Schneider Guy

Estimated reading time: 4 minutes

As a truck driver, performing a CDL pre-trip inspection is one of the most common and repeated tasks you will complete. Pre-trip inspections help truck drivers ensure their tractor and trailer are safe to operat e before hitting the road.

Keep reading to learn what a p re -trip inspection is and what should be on a p re -trip inspection checklist .

What is a pre-trip inspection?

A pre-trip inspection includes checking over the tractor and trailer a truck driver will be operating . A pre-trip should be completed before the operation of a vehicle :

- At the beginning of a driver’s shift.

- Any time a new trailer is picked up.

- After a 10-hour break.

A thorough inspection usually takes anywhere from 30 minutes to one hour and should be logged as on-duty, not driving (line 4) .

How to complete a CDL pre-trip inspection

CDL pre-trip inspection checklist

1. passenger-side engine: .

- Air filter housing: Secure mounting, cover in place.

- Windshield washer fluid reservoir: No leaks, proper fluid level.

- Turbocharger: No oil or exhaust leaks.

- Engine air ductwork: No cuts, clamps secured.

- Alternator: Mounting secured, no broken or loose wire.

- Accessory drive belt: Not cracked or frayed.

- Air conditioner compressor: Secure m ounting .

2. Front brakes (covers all five brake components):

- Brake drum: No cracks.

- Brake lining: No cracks or damage.

- Slack adjuster: Proper angle to the brake chamber, clevis and cotter pin intact.

- Brake air line: No bulges or cuts, fitting tight .

- Brake chamber: Mounting bolts secured, band clamp secured.

3. Front wheel:

- Tire: ABCs (abrasions, bulges, cuts), pressure = 120 PSI, tread depth = 4/32 min ( DOT ) .

- Wheel: Not cracked or bent.

- Hub oil: Not leaking, at proper level – if it’s a sealed unit, can’t check level.

- Oil seal (outer): Not leaking.

- Valve cap: Not missing.

- Lug nuts: None missing, no streaks or shiny areas, none loose.

4. Driver side of engine:

- Radiator brace: No cracks or missing bolts.

- Radiator: Not leaking, secure mounting.

- Water pump: No cracks, not loose or leaking.

- Fuel water separator/filter: Not leaking, secure mounting.

- Pitman arm/drag link: Not cracked, castle nut secured with cotter pin.

- Steering gear box: Secure to frame, not leaking.

- Power steering reservoir: Secure mounting , no leaks, proper level.

- Dipstick: Right level, secured after check.

- Steering shaft: Secure, not loose or damaged.

- Fuel pump: No cracks, not loose or damaged.

- Oil filler cap: Secure, no cracks.

- Engine coolant reservoir: No leaks, proper fluid level.

5. Steer axle suspension:

- U-bolts: No cracks, no loose or missing nuts.

- Leak spring: No cracks, not loose or shifting.

- Tie rod: Secured with castle nuts and cotter pins.

- Shock absorber: Secure mounting, not leaking oil.

- Axle: Not cracked.

6. Rear suspension:

- Spring mount: No cracks, secure mounting.

- Tire: ABCs (abrasions, bulges, cuts), pressure = 110 PSI, tread depth = 2/32 min ( DOT ) .

- Airbag (bellows): Fully inflated, secure mounting, not ruptured.

7. Side of cab:

- Mirrors: Secure m ounting , no broken glass.

- Doors: No damage, glass not broken, hinges secured, opens and closes well.

- Lights and turn signals: Working, not cracked.

- Steps: Mounted, secured to skirting.

- Battery box: Secure m ounting , cover latched.

- DEF cap: Cap secured.

- Fuel cap/tank: Gasket in place, vent in place, chain secures the cap to the tank.

- Side skirting: No damage, panels secure.

- Side box: Secured, safety triangles present.

- Side of sleeper berth: No body damage.

- Sleeper berth window: No cracks.

8. Rear of cab:

- Electrical cord: No bare wire, no corrosion, check the plug at the end of the cord.

- Air line: Not tangled or worn, rubber grommets not worn, fittings tight.

- Cab shock absorber: Secure mounting, not leaking oil.

- Cab airbag (bellows): Not ruptured, securely mounted.

9. Driveshaft/rear frame:

- Driveshaft: Not cracked.

- Universal joint: Not cracked, not missing bolts, no shiny areas.

- Differential: Not leaking oil.

- Frame: Straight, no non-factory welds.

10. Fifth wheel area:

- Pivot pin: Keeper pin and cotter key intact.

- Slider lock pins: Fully engaged.

- Release arm: Not bent.

- Slider rail: No broken welds or missing bolts.

- Slider stop blocks: Welds not broken, not missing bolts.

- 5th wheel platform: Well-greased, tilted down.

11. Front of trailer:

- Top rail: No cracks or collision damage.

- Clearance lights: Not broken, working properly.

- Registration: Not missing, readable.

- Document box: Not missing or loose.

- Air line /glad hands: No bulges or cuts in air lines, rubber grommets not damaged on glad hands.

- Electric hook up: No broken pins, cover intact.

- PM sticker: Current, legible.

- Height sticker: Legible, legal for route.

- Placard holder: Not broken or missing rivets.

- Tracking device: No cracks or collision damage.

12. Side of trailer:

- Top rail: Not cracked, no collision damage.

- Clearance light: Not broken, operational.

- Bottom light: Not cracked, no collision damage, no missing bolts.

- Landing gear: Legs straight, no broken welds in bracing, sand pads secured and clean handle in cradle.

- Reflector tape: Clean.

- Side panels: No holes or cuts, no missing rivets.

13. Rear of trailer:

- Latches: Secured, not damaged.

- Lights: Not broken or missing, operational.

- Splash guard: Brackets and guard secured.

- License plate: Secure and clean, light is working.

- Bumper: Not damaged, no broken welds.

- Door hooks: Not loose, no missing bolts.

- Hinges: Not cracked, no missing bolts on both sides.

- Door seals: No separation, no rubber tubing sticking out.

14. Trailer suspension:

- Air line: No bulges or cuts, fittings are tight and not rubbing.

- Axle: Not bent or broken.

- Clevis pin/cotter key: Not missing.

- Slack adjuster: Proper angle, clevis pin and cotter pin intact.

- Brake linings: Minimum of ¼ inch thick, not cracked.

- Brake drum: Not cracked.

- Tire: (ABCs), tread depth = 2/32 , air pressure = 110 PSI.

- Spring: Not broken, not shifted.

- Spring mount: No broken welds.

- U bolts: Not loose, not cracked.

- Torque rod: Secure mounting, bushings intact.

- Spring brake chamber: Secure m ounting , band clamp secure.

15. Gauges/inside the truck:

- Fuel: Matches visual when looking in the tank.

- Def level: Maintain a minimum of one light bar.

- Oil pressure: 25-50 PSI.

- Speedometer: 0-60 MPH.

- Air pressure: 90-120 PSI.

Please note that the list above is just an example. It is important to remember the type of driver you are, the company you work for and the type of truck you drive can impact your CDL pre-trip inspection . Be sure to consult your company guidelines or speak with your leader for more information on your post-trip inspection requirements.

Get more great driving tips and guides.

Schneider Guy loves the "Big Orange." He's passionate about the trucking industry and connecting people to rewarding careers within it. He's been the eyes and ears of our company since our founding in 1935, and he's excited to interact with prospective and current Schneider associates through "A Slice of Orange."

Related posts

8 CDL Road Test tips to help you pass

How hard is it to get a CDL?

How to get your CDL – 7 simple steps for new truck drivers

CDL Pre-Trip Inspection Checklist

Studying this Class-A CDL pre-trip inspection checklist is an important part of truck driver training. Before getting your Class-A CDL and finding an entry level truck driving job , most states will require students to pass a DOT (department of transportation) pre-trip inspection test and a general knowledge test .

Each company’s pre-trip inspection varies slightly. Most likely you will have to do the coupling system, light check and in-cab inspections plus one of the remaining three sections.

Pre Trip Inspection Checklist

Download free and print it! Printable Pre Trip Inspection Checklist (PDF)

There are many sections to learn but the test is not as difficult as it may seem. Studying our simplified Class-A pre-trip inspection checklist and taking classes at your local CDL training school will get you prepared.

Engine Compartment

Driver door fuel area, coupling area, light check, in-cab inspection and brake tests, belt driven alternator, belt driven water pump, brake chamber, brake lining, caste nuts and cotter pins, coolant reservoir, gear box and hoses, gear driven air compressor, gear driven power steering pump.

- General Hoses

Leaf Springs

Power steering fluid reservoir, shock absorber, slack adjuster and push rod, spring hanger, steering column, what to check for:.

When checking the engine compartment, you will always want to make sure the following components are properly mounted and secured. You should also make sure they are not cracked, bent or broken. The items you will need to check for include:

- Make sure all of the wires are connected. The belt should not be cracked or frayed and the free play on the belt should be between ½ to ¾ of an inch.

- The free play on the belt should be between ½ to ¾ of an inch. Also check all the hoses running to and from the water pump to make sure nothing is leaking.

- The brake chamber should not be leaking air.

- The brake drum should be properly mounted and secure.

- The brake hose is rubber, so it is important to make sure it is not leaking air.

- Check for oil or debris on the lining. There should be at least ¼ of an inch of friction material.

- Make sure all three caste nuts and cotter pins are present.

- The reservoir should not leaking and must be filled to the manufacturer’s specifications.

- Make sure the drag link is properly mounted and secure, and not cracked, bent or broken.

- The gear box and hoses should have no abrasions, bulges or cuts, and should not be leaking.

- Although the air compressor is hard to see, you must make sure it is properly mounted and does not leak.

- The steering pump is located in the same place as the air compressor and is also gear driven. Ensure the steering pump is not leaking.

General Hoses (Passenger and Driver’s Side)

- The hoses should be secure at both ends. There should be no abrasions, bulges or cuts. Fluids run through these hoses, so it is important to make sure they are not leaking.

- The hub seal (or axle seal) should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure none of the leaf springs have shifted.

- Check for leaks under the truck.

- There should be no lug nuts missing. Look for rust trails, powder residue and cracks around the bolt holes.

- The oil level should be filled to the manufacturer’s specifications.

- Make sure the pitman arm is properly mounted and secure. It should be not cracked, bent or broken.

- Make sure this reservoir is not leaking and filled to the manufacturer’s specifications.

- The rim cannot have any unauthorized welds.

- Make sure the shock absorber is not leaking. If it is leaking, the leak will be at the point where the top and bottom portion of the shock meet.

- With the brakes released and pulled by hand, the push rod should never move more than one inch.

- The spring hanger should be properly mounted and secure.

- Make sure the steering column is properly mounted and secure. It should not be cracked, bent or broken.

- Look for abrasions, bulges or cuts on the tread or sidewalls. Tread depth should have a depth no less than 4/32 of an inch. Tires must be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- Make sure the tie rod is properly mounted and secure, not cracked, bent or broken.

- Make sure all are accounted for.

Back to top of Engine Compartment

Catwalk and Steps

Door and hinges, drive shaft, exhaust system, frame and cross members, spring mount.

Again it is important to make sure these items are properly mounted and secure. Look for cracks, bends, and breaks.

- The actual airbag is rubber, so it is important to check for abrasions, bulges, cuts and leaks, in addition to any missing mounting bolts.

- The axle seal should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure to mention the brake chamber is not leaking air.

- Make sure the brake drum is secured properly. Also look for cracks, bends and breaks.

- Check the brake hose at both ends to make sure it is not leaking air.

- There should be no oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- The cat walk and steps should be clear of any loose objects.

- Physically demonstrate that the doors open, close and latch properly. Door seals should not be worn, torn or rotten.

- The drive shaft should not be twisted and the u-joints should be free of any debris.

- The tread and sidewalls should have no abrasions, bulges or cuts. The tread depth should be no less than 2/32 of an inch. Tires should be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- The exhaust system should show no signs of leaks.

- There should be no unauthorized holes or welds. Bundle up the cross members to ensure none are missing.

- Fuel should not be leaking from the tank and the cap should always be on tight.

- Rust trails could indicate loose bolts, while powder residue and racks around the bolts could mean the bolts have been over-tightened.

- Mirrors should be clean for best visibility.

- Make sure the mud flap is secured properly. Also look for cracks, bends and breaks.

- Make sure to mention there should be never be any unauthorized welds.

- The shock absorber should be secure at both ends and not leaking. If it does leak, it will leak in the middle.

- With the brakes released and pulled by hand, the push rod should not move more than one inch.

- If you are equipped with duals, check to see there is proper spacing between the tires and there is nothing stuck.

- The spring arm should be secure at both ends.

- The spring mount should be secure at both ends.

- Make sure the torque arm is secured properly. Also look for cracks, bends and breaks.

- Make sure to check and mention that no U-bolts are missing.

Back to top of Driver Door Fuel Area

Electric Line

Locking jaws, mounting bolts, release arm, sliding fifth wheel locking pin.

- Air lines should be secure at both ends with no abrasions, bulges or cuts. They should not be leaking, dragging or tangled.

- Make sure the apron is properly mounted and secure. Look for cracks, bends and breaks.

- Make sure there is enough space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

- The electric line should be secure at both ends. There should be no abrasions, bulges, cuts or exposed wires.

- The gap is not an actual item, however there should be no space between the apron and the skid plate.

- The seals should be in good condition with no cracks, signs of rotting, or leaking air.

- Make sure the king pin is properly mounted and secure. Look for cracks, bends and breaks.

- You must physically check that the locking jaws is fully locked around the king pin.

- No mounting bolts should be missing.

- Make sure the platform is properly mounted and secure. Look for cracks, bends and breaks.

- The release arm should be in the fully locked position.

- The skid plate needs to be properly lubed.

- The pin must be in the fully locked position.

Back to top of Coupling Area

Header Board

Landing gear, rear door and hinges.

- Shock Absorbers

Tandem Frame and Release

Trailer tire.

- Again make sure the airbag has no abrasions, bulges, cuts or leakings. The airbag should not be missing any mounting bolts.

- The brake chamber should be properly mounted so that is does not leak air.

- The brake hose should be secure at both ends with no abrasions, bulges, cuts or leaks.

- Check for oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- There cannot be any missing cross members.

- The header board cannot have any holes or missing rivets.

- The landing gear must be fully raised and the cradle handle secure.

- Rust trails indicate loose bolts. Powder residue and cracks around the bolt holes could be an indication of over-tightened bolts.

- The rims cannot have any unauthorized welds.

- The rear door should open, close and latch properly. Door seals should not be worn, torn or dry rotten.

- The shock absorber should be checked at both ends for leaks.

- When the brakes are released and pulled by hand, the push rod should not move more than one inch.

- Release handle and locking pins should be in the fully locked position.

There should be no abrasions, bulges or cuts to the tread or sidewalls. Tread depth should be no less than 2/32 of an inch. The tire should be properly filled to manufacturer’s specifications and checked with an air gauge.

- Front of the truck

- Both sides of the truck

- Rear of the truck

- Both sides of the trailer

- Rear of the trailer

Back to top of Trailer

The five functions are:

- Left turn signal

- Right turn signal

- Four way flashers

- High/low beams

- Brake lights

Back to top of Light Check

- Airbrake Test

Air Pressure Gauges

Emergency equipment, heater and defroster, lighting indicators, oil pressure gauge, parking brake, service brake check, water temperature gauge, windshield and mirrors, windshield wipers and washers.

The last section is In-Cab Inspection and Brake Tests. For the In-Cab Inspection you will once again want to make sure all of the following components are properly mounted and secure. As well as the following:

Air Brake Test

There are three stages to an air brake test:

- Applied Pressure Test – When doing the Applied Pressure Test, you will want to build the air pressure to governor cut out. Put the truck in the lowest gear, turn the engine off and immediately turn it back on. Push in the tractor and trailer valves which will then release the parking brakes. Push and hold the brake pedal, allowing the gauges to stabilize. When the gauges have stabilized, announce the Primary and Secondary PSI. Listen for air leaks while doing this.

- Warning Light and Buzzer – Pump down on the brake pedal until the warning light and buzzer comes on. This is typically at or before 60 PSI.

- Tractor/Trailer Protection Valve Pop Out – Pump down on the brake pedal until the tractor and trailer protection valves pop out, this will be between 20 and 40 PSI.

- The air pressure gauges should build to governor cut out.

- Your truck should have a fire extinguisher, three red reflective triangles and spare electrical fuses.

- Demonstrate both the heater and defroster are working properly.

Horns (Air Horn and City Horn)

- Blow both horns to make sure they are working.

- Check the left turn, right turn, four way flashers and high beams; also point these out on the dashboard.

- Make sure transmission is in neutral and then fully depress the clutch. Turn the key on, check the ABS light, announce when it comes on and off, and start the engine.

- The seat belt should not be ripped or frayed and should adjust and latch properly.

- The engine oil pressure gauge should rise to normal operating range.

- Trailer Parking Brakes – Set the trailer brake, release the tractor brake, then tug lightly on the trailer.

- Tractor Parking Brakes – Set the tractor brake, release the trailer brake and tug lightly on the trailer.

- Release both the tractor and trailer brakes. Drive at idle speed. Apply the service brake to make sure you come to a complete stop and that it doesn’t pull to the left or right when applying the brakes.

- The voltmeter should be charging between 13 and 14 volts.

- The water temperature gauge should also rise to normal operating range.

- The windshield and mirrors must be clean, with no obstructions and in proper adjustment.

- Demonstrate the wipers and washers are working properly by spraying the windshield.

Back to top of In-Cab Inspection and Brake Tests

During a CDL pre-trip inspection, truckers inspect many aspects of their commercial vehicle, including the overall safety of the vehicle; major hoses, fluid levels, and vehicle belts; the clutch or gear shift; and emergency equipment. The driver demonstrates their knowledge by walking around the vehicle, checking various safety components and explaining why each part should be checked for safety.

Reference and practice tests:

- Printable Pre Trip Inspection Checklist (PDF)

- CDL General Knowledge Practice Test

- Pre Trip Inspection Practice Test

- CDL HAZMAT Endorsement Practice Test

Edited for 2024 on 12/5/23

Platform Overview

The Connected Operations Cloud

Apps & Driver Workflows

Messaging, dispatch, documents, ELD

Video-Based Safety

AI cameras, driver coaching, safety reports, in-cab alerts

Equipment Monitoring

Location tracking, utilization, continuous diagnostics

Vehicle Telematics

Real-time GPS, routing, fuel, maintenance, electrification

Site Visibility

Remote visibility, proactive alerting, on-the-go access

Integrations

Developer API

Start building with our API

App Marketplace

Install turnkey integrations

OEM Integrations

Unlock embedded telematics data

Experts Marketplace

Find certified Samsara experts

By Business Need

Reduce costs across your business

Automate regulatory compliance

Ensure safety wherever you operate

Identify and eliminate risks

Sustainability

Prepare for transition to renewables

Customer Experience

Build customer loyalty and retention

By Industry

Transportation & Logistics

Food & Beverage

Field Services

Construction

K-12 Schools

Higher Education

Passenger Transit

Customer Success

Customer Stories

Education & Training

Customer Support

Help Center

Developer Portal

Customer Tips

Case Study Highlight

DHL consolidates 7 separate point solutions with Samsara’s integrated platform

Read more ➔

Nutrien Ag Solutions

Nutrien Ag Solutions cuts distracted driving in half 90 days after installing AI Dash Cams

Video Library

Product Tours

Fleet Safety Guide

Business Resilience

State of Connected Operations

See how leaders are adopting cutting-edge technologies, empowering their workforce, and unlocking new revenue streams.

Optimization

Make More Possible

Find ways to make more possible across your organization to empower your workers, increase efficiency, and reduce operational costs.

Build Your EV Fleet

Get the essentials on fleet electrification and better understand how an EV fleet can benefit your business.

Investor Relations

Samsara Ventures

Brand Assets

Featured News

Apply for the 2024 Connected Operations Awards

Samsara's 2023 Environmental, Social, and Governance (ESG) report

What is a Pre-Trip Inspection Checklist for Class A CDL

October 22, 2021

Get Started With Samsara

Key Takeaways

Drivers who have a class A commercial driver’s license (CDL) usually have to complete a pre-trip inspection on their non-passenger commercial vehicles. Having a pre-trip inspection checklist handy helps driver’s know what to expect when they pass their CDL examination and what parts of their vehicle the will need to inspect before heading out on the road.

What is a CDL pre-trip inspection checklist?

A pre-trip inspection checklist helps truck drivers remember all the major systems and parts to inspect before heading out on a route. Knowing how to complete a pre-trip vehicle inspection is an important part of trucking.

Pre-trip inspections for class A licensees

The class A commercial driver’s license (CDL) typically covers non-passenger commercial vehicles . These might include tractor-trailers, tankers, livestock carriers, flatbeds, and more.

The Department of Transportation (DOT) requires drivers to perform a pre-trip inspection before driving a commercial vehicle. Similar to Class B CDL holders, the actual daily pre-trip inspection takes about 15 minutes or less. Typically, the inspection includes the following, with some employers making their own variations.

Brakes and air system

Steering mechanism

Lights and reflectors

Tires, wheels, and rims

Windshield wipers

Rearview mirrors

Emergency equipment

Drivers complete a driver vehicle inspection report (DVIR) recording the completed inspection.

Class A CDL pre-trip inspection checklist

When getting a CDL, drivers need to pass a pre-trip inspection test. It’s more intensive than the inspection drivers perform daily. This pre-trip inspection checklist for a Class A CDL gives drivers an overview of performing an inspection. Check your state’s CDL manual for a complete list of inspection requirements.

Click here for a Class B pre-trip inspection list.

Engine compartment

Fluids - coolant, oil, and power steering : Reservoirs and tanks should not leak. Check hoses for splits or cuts and that they are securely mounted on both ends. Verify proper fluid levels with a dipstick.

Belts - alternator, pumps, compressor : All belts should be securely mounted without cracks or frays. Belt should have no more than 1/2" to 3/4" of play.

Hoses (passenger and driver’s sides) : All hoses, including power steering and coolant hose, should be secured on both ends. They should not have splits, cuts, or leaks.

Air compressor: May be difficult to see. Ensure it’s securely mounted, not broken, cracked or leaking.

Alternator : All wires are properly connected.

Water pump : All hoses are properly connected and not leaking.

Front of tractor/truck

Steering gearbox and hoses : No damage or leaks. Hose should be secured on both ends. They should not have splits, cuts, or leaks.

Steering shaft/steering column : Not bent or broken.

Pitman arm : All caste nuts and cotter pins are present and tight.

Drag link : Rubber is not split and properly greased.

Upper and lower control arms and tie rod : Tie rod should be secure, not cracked or bent.

Front suspension

Spring mounts/spring hanger : Not cracked or broken.

Leaf springs : None are cracked, broken, or shifted.

U-bolts : All accounted for.

Shock absorber : No visible leaks. Leaks will show at the point where the top and bottom of the shock meet. Rubber is not split or shows signs of dry rot.

Airbag : Check rubber for abrasions, cuts or audible leaks plus any missing mounting bolts.

Driver door and fuel area

Mirrors and bracket: Hardware attached properly. Mirror should be clean and not broken.

Door and hinges : Demonstrate door operations, latching properly, hinges intact. Door seals should not be torn or rotten.

Steps : Mounted properly and can hold weight.

Fuel tank: Not leaking; cap is tight with seal intact.

Rear of tractor/truck

Drive shaft : Not twisted, U-joints not broken and free of debris.

Exhaust system: Not loose, no sign of leaks (exterior soot).

Frame : Nothing broken or unauthorized welds.

Catwalk and steps : Properly mounted and clear of loose objects.

Mudflap : Secured, not missing or broken. At the right height.

Coupling area

Air connector: Secure on both ends, no abrasions, cuts, or audible leaks. Connectors should not drag or tangle.

Electric lines : Secure on both ends, no abrasions or cuts. Safety latches in place. Lines should not drag on the catwalk or tangle.

Glad hands : Seals should be in good condition with no cracks, signs of rotting, or leaking air.

Fifth wheel platform : Secure to frame, not cracked, bent or broken. No unauthorized or illegal welds.

Mounting bolts : No missing bolts and mounted tight.

Skid plate: Properly greased.

Release arm : Secure in fully locked position.

King pin : Mounted and secure. No cracks, bends, and breaks.

Locking jaw : Fully locked around the king pin.

Apron : Mounted and secure. No cracks, bends, and breaks.

Sliding 5th wheel locking pins : Pin must be in the fully locked position.

Brake system (both tractor and trailer)

Brake hose : Securely mounted on both ends. No splits, cuts, and not audibly leaking air.

Brake chamber : Not audibly leaking air.

Slack adjuster and push rod : When brakes are released and pulled by hand, the push rod should have no more than 1” of play. It should stay at a 90° angle to the brake chamber.

Brake drum : No bluing from excessive heat.

Brake pads/brake lining : Check for oil and debris on the lining. Minimum brake pad thickness is ¼.”

Wheel system (both tractor and trailer)

Wheel rims : No unauthorized or illegal welds.

Steer tires : Look for cuts, bulges, and abrasions on the tread and sidewalls. Tread depth should be a minimum of 4/32”. Tread should be evenly worn. Check inflation levels on tires with an air gauge, filled to manufacturer’s specifications.

Drive tires : Look for cuts, bulges, and abrasions on the tread and sidewalls. Tread depth should be a minimum of 2/32”. Tread should be evenly worn. Check inflation levels on tires with an air gauge, filled to manufacturer’s specifications.

Valve stem . Properly secured, metal cap in place. Not audibly leaking air.

Lug nuts : All accounted for. Check for rust or cracks.

Hub seal/axle seal : Should not be loose. No visible leaks.

Spacing : If equipped with duals, there must be proper spacing between the tires.

Frame and cross members : Secure, not cracked, bent or broken and none missing.

Header board : Secure and not excessively damaged. No holes or missing rivets.

Landing gear : Must be fully raised and the cradle handle secured. Not cracked, bent or broken.

Doors and hinges: Secured and should open, close and latch properly. Door seals have no separation, no rubber tubing sticking out.

Tandem release : Release handle and locking pins should be fully locked.

Trailers airbag : Check rubber for abrasions, cuts or audible leaks, plus any missing mounting bolts.

Trailer spring mounts/spring hanger : Not cracked or broken

Trailer leaf springs : None are cracked, broken, or shifted.

Trailer u-bolts : All accounted for.

Trailer shock absorber : No visible leaks. Leaks will show at the point where the top and bottom of the shock meet. Rubber is not split or shows signs of dry rot.

Torque arm/radius rod : Secure mounting, bushings intact.

Check all lights on the front, both sides of tractor, truck rear, both sides of trailer, and trailer rear. Turn on to ensure lights and reflectors are working.

Running lights : Walk around the truck and trailer to examine all.

High beams/low beams: Walk around the truck and trailer to examine all.

Turn signals : Signal both right turn and left turn. Walk around the truck and trailer to examine all.

Hazards/4-way flashers : Walk around the truck and trailer to examine all.

Brake lights : Ask the examiner to watch brake lights. Confirm they worked using the side mirror.

License plate lights : Walk around the truck and trailer to examine all.

Reflector tapes : Clean and not worn. Walk around the truck and trailer to examine all.

In-cab inspection and air brake test

Seat belt: No rips or frays and should adjust and latch properly.

Lighting indicators : See lights and reflectors section

Oil pressure indicator : Demonstrate normal operating range.

Water temperature gauge : Demonstrate normal operating range.

Air pressure gauges : Build to governor cut out.

Ammeter/voltmeter : Charging between 13 and 14 volts.

Mirrors : Secure, not cracked or broken. No obstructions and properly adjusted.

Windshield : No more than a 1” crack is permitted. Clean and free of debris.

Windshield wipers and washers: Turn on to show they are working properly.

Horns (city and air) : Show they are working properly.

Heater/defroster : Turn on to show they are working properly.

Safety/emergency equipment : Must have a fire extinguisher, three red reflective triangles and spare electrical fuses. Extinguisher must be fully charged and secured.

Steering wheel : Secured to steering column.

Foot pedals : Free of grease and debris. No obstructions.

Hydraulic brake check : Pump the brake pedal several times. Apply pressure to the pedal and hold for five seconds. The pedal should not move.

Air brake check : Air brake devices vary. Drivers must test three components of the air brake check correctly: applied pressure, warning lights and buzzers, and valve pop-outs.

Parking brake:

Trailer parking brake : Set the trailer brake, release the tractor brake. Put truck in low gear and tug.

Tractor parking brake : Set the tractor brake, release the trailer brake. Put truck in low gear and tug.

Service brake : Release both the tractor and trailer brakes. Drive 3 – 5 mph. Apply the service brake and come to a complete stop. Ensure steering does not pull to the left or right when applying the brakes.

Watch the video below to see how All Aboard America uses the Samsara Driver App to become nearly 100% paperless and save 30 minutes per trip, totaling 500 hours saved weekly.

Watch Video

Stay in touch

Sign up to learn more about Samsara.

Pre-Trip Inspection Checklist for Truckers

July 28, 2023.

Table of Contents

The most important element of a truck driver’s daily routine is the pre-trip inspection. Pairing a comprehensive pre-trip inspection with a regular preventative truck maintenance schedule is key to ensuring your safety and the safety of others on the road . To give you an idea of how essential the pre-trip inspection is, consider that drivers are required by law to record at least one inspection per day.

Finding and fixing mechanical defects early is essential to functioning as a safe operator.

What is a Pre-trip Inspection?

The pre-trip inspection is the process of thoroughly examining the truck before starting a new journey. It ensures the safety of the driver and the others sharing the road with them by identifying and addressing mechanical issues early on, so truckers can prevent unexpected breakdowns, delays, and potential accidents.

Drivers must record at least one pre-trip inspection per day. Learning the process is crucial for obtaining a commercial driver's license (CDL) and continuing a successful career in the industry.

Benefits of a Truck Pre-Trip Inspection

Aside from being a requirement, here are some benefits of conducting a thorough pre-trip inspection:

- Safety is prioritized by the early identification of potential mechanical issues, ensuring a secure journey for truck drivers and others on the road.

- Early detection and resolution of mechanical problems during this essential routine lead to reduced delays and costly repairs.

- Regulatory compliance is showcased as pre-trip inspections are a legal requirement, reflecting professionalism and commitment to safety.

- Smooth schedules are maintained as pre-trip inspections help prevent unexpected breakdowns and disruptions.

- Early issue identification and timely repairs achieve cost savings and prolonged vehicle lifespan.

- Improved fuel efficiency results from ensuring components like tires and engines are in top condition.

- Trust and professionalism are earned by conducting regular inspections, leaving a positive impression on clients, employers, and regulators.

- Reduced on-road accidents are promoted by verifying lights and brakes are in optimal condition.

- Boosted driver confidence is achieved by confirming the truck's peak condition, enabling worry-free journeys.

This powerful routine keeps us safe, compliant, and efficient on our trucking journey.

15-minute Pre-trip Inspection Checklist

A properly conducted pre-trip inspection is a core proficiency evaluated during the CDL exam. The most efficient way to prepare for the pre-trip inspection exam is to use a checklist. Practice using the checklist several times a day until you have the process memorized and have mastered this important truck driver skill . It will serve you well in helping you obtain your CDL and will continue to benefit you throughout your career.

It may seem overwhelming and difficult at first , but with practice, the pre-trip inspection will become a habit. To help you, we’ve prepared this pre-trip inspection guide.

A good starting point is the FMCSA and its regulations concerning the pre-trip inspection. Different companies have produced their pre-trip inspection checklists, so it’s a good idea to consult your company’s guidance and compare it with the FMCSA regulations to ensure you are conducting a compliant inspection.

Some common elements you will encounter on most checklists include:

1. Tire Inspection

Every 10 ° F change in air temperature can make vehicle, truck, and light truck tires lose one psi pressure. A tire with low pressure has a negative effect on the distance needed to stop and miles per gallon of gas.

Ensure no foreign objects are between the wheels and no space between tires and rims. Evaluate the tires for sufficient tread depth and look for cuts, bubbles, or gouges.

Insufficient treads increase the likelihood of losing control from hydroplaning or sliding on standing water, snow, or ice. This is an especially important detail when preparing to drive your truck in winter weather conditions.

2. Lights and Reflectors Check

Verify the proper functioning of exterior lights, turn signals, warning lights, and clean lenses for maximum visibility. Ensure reflectors are free of dirt or debris and intact without cracks or missing pieces.

3. Brake Examination

Assess the brake system both inside the cab and externally. Verify proper brake adjustment with the slack adjuster, inspect brake linings for the appropriate thickness, and ensure air lines are free from damage, leaks, and properly sealed. This includes checking air brakes, parking brakes, and hydraulic braking systems.

4. Engine Inspection

Check the engine compartment for various components, such as the radiator, air compressor, steering gearbox, water pump, belts, hoses, and wiring.

5. Fuel Tank and Battery Check

Visually examine the fuel tank and battery area to ensure no cracks or leaks. Verify the battery levels for sufficient power and proper charging.

6. Fluid Inspection

Inspect fluids under the truck for signs of leaks, including fuel, oil, coolant, power steering fluid, brake fluid, and windshield washer fluid. Check fluid levels and assess the condition of hoses, belts, and wires for safe operation. Pay special attention to the oil pressure gauge for proper functionality.

7. Windshield

Chipped, cracked, or deteriorated glass weakens the final barrier that prevents the driver from being thrown during an accident and can inhibit clear road visibility. Also worn-out wipers will reduce visibility when driving in the rain or snow.

8. Emergency Kit

Road flares, triangles, and a fire extinguisher are the emergency equipment necessary to safeguard the vehicle and the driver should an accident or breakdown occur and must not be missing or broken. The fire extinguisher must be easily accessible, with a current inspection, and maintain the appropriate PSI.

9. Mirrors with Swivel Mounts

Frozen or loose mirrors prevent the driver from properly adjusting them to cover blind spots. It can create a greater risk of hitting the side or colliding when turning.

10. Coupling System Assessment

Examine the coupling system, paying close attention to the kingpin and sliding fifth wheel locking pin. Check the condition of air lines, apron, electrical connections, gap, glad hands, locking jaws, mounting bolt, platform, release arm, and a skid plate that connects the trailer to the cab.

11. Cabin InspectionTemperature

Inside the cabin, check the seat belts for wear or fray and ensure a snug fit. Assess the operation and functionality of inside and outside mirrors, seat position, steering wheel, pedals, windshield, wipers, horns, lights, and gauges. Make sure all alerting systems, including ABS lights, are working correctly.

Verify the temperature, controls that are not working properly can produce physical stress, fatigue, and distraction while driving.

12. Trailer Examination

Conduct a thorough inspection of the trailer for mechanical defects that might hinder secure mounting to the tractor. Look for holes, cracks, breaks, bends, or missing rivets in the headboard, frame, release pins, cross members, release handles, locking pins, doors, and hinges.

13. Back of the Truck Inspection

Before hooking up to a trailer, check the back of the truck for properly inflated tires with decent tread, undamaged brake chambers, intact shocks and airbags, a clean driveshaft without debris in the u-joints, a sturdy and unbroken frame, well-greased fifth wheel, and leak-free fuel tanks. Also, inspect stairs and catwalks for cleanliness and integrity.

A thorough pre-trip inspection should take approximately 15 to 30 minutes to complete.

How to Properly Report a Pre-trip Inspection?

According to current guidelines by the FMCSA , at least one inspection must be logged in your hours of service each day. Previously, drivers were also required to fill out a pre-trip inspection report each day. However, recent changes in the guidelines now only require you to fill out an inspection report for the purpose of recording a defect found during your inspection. If you have uncovered no defects, you are no longer required to fill out the inspection report.

Companies such as JJ Keller produce market inspection reports that you can keep on board your truck in the event you need to fill one out. Additionally, you can, in a pinch, use these reports as a checklist if you are still unfamiliar with the pre-trip inspection process.

Regardless of how long you’ve been working as a truck driver or how many other trucker safety tips you follow, the pre-trip inspection will serve you well to keep you safe as you go about your day. Discovering critical defects early can be the difference between making it to your next stop and ending up broken down on the side of the road , or even worse, involved in a preventable accident.

Download Your Free Pre-Trip Inspection Checklist for Trucks

Frequently Asked Questions

How often should i perform a pre-trip inspection.

It should be conducted before every journey, ensuring the vehicle's safety and readiness for the road.

How long does a pre-trip inspection typically take to complete?

It usually takes 15 to 30 minutes to complete, depending on the complexity of the vehicle and the driver's familiarity with the checklist.

Can I skip a pre-trip inspection if I'm in a rush?

Never skip a pre-trip inspection. Not only is the inspection a legal requirement, but also it is essential for your safety and the safety of others on the road.

Can I keep a pre-filled inspection report for daily use?

While it might seem convenient, it is not recommended. The pre-trip inspection report is meant to reflect the vehicle's actual condition. Using a pre-filled report without physical inspection may lead to inaccuracies and compromise safety.

Can I delegate the pre-trip inspection?

The pre-trip inspection is the driver's responsibility to operate the vehicle. While others can assist, the driver remains accountable for ensuring it is conducted correctly.

Preparing and Planning Loads Has Never Been Easier

Better Paying Loads Without Calling a Broker. Instant Payments After Delivery. Competitive Rates so you keep 82% of your load.

Related Articles

13 Safety Tips for Truck Drivers

12 Essential Tips for Truck Driving in Winter Weather

Essential Truck Driver Skills to Master

Start driving with cloudtrucks.

Have questions? Give us a call at (469) 250-1214

Prime’s Guide to Pre-Trip Inspections

Tractor-trailers can weigh up to 80,000 lb . if you count the semi, trailer and cargo. Operating a heavy tractor-trailer can be dangerous, so drivers undergo extensive training to earn their CDLs and start their careers.

Whether studying for your CDL test or heading to your next customer, pre-trip inspections help you catch problems with your vehicle or trailer. Unchecked issues can lead to accidents or extensive repairs.

Do you know how to perform a pre-trip inspection? Need a quick refresher? Follow our guide to pre-trip inspections to learn the basics. Reach out to our Safety Department for more in-depth information.

Use these quick links to jump to sections of the article:

- The Engine Inspection

- Driver Door Area & Tires

- Trailer Pre-Trip Inspection

Lights & Reflectors

In-cab pre-trip inspection , large truck crash statistics .

Knowing how to operate a semi-truck safely in various conditions is imperative for drivers. In 2019, there were 510,000 large truck crashes, according to FMCSA’s 2021 Pocket Guide to Large Truck and Bus Statistics .

Of these crashes, 4,479 were fatal, and 114,000 were injury crashes involving large trucks. Most fatal large truck crashes involved those weighing more than 33,000 lb.

Accidents happen. Drivers can mitigate their risk of an accident by being responsible behind the wheel , following federal regulations and performing pre- and post-trip inspections.

Your Pre-Trip Inspection Checklist

Drivers must provide a vehicle inspection report at the end of each day. Vehicle inspection reports list any issues that could affect the vehicle’s operation and safety. Inspecting vehicles before and after each trip helps catch problems and keep drivers safe.

At a minimum, each report covers the following parts of a vehicle :

- Coupling devices

- Emergency equipment

- Lights and reflectors

- Parking brakes

- Service brakes

- Steering mechanism

- Tires and rims

- Windshield wipers

Pre-trip inspections take around 15 to 20 minutes. You’ll examine your truck and trailer to ensure it’s ready for the trip.

Before every haul, you should check that you have your license, registration, medical card, updated inspection sticker and FMCSA Safety Regulation manual. If you’re picking up a trailer, always make sure the trailer number matches the number listed on your assignment.

Follow these steps to inspect your tractor-trailer, and watch our video on Prime’s pre-trip inspections . Chock your tires before you begin, so the vehicle doesn’t roll or slip.

Under the Hood: Examining the Engine

Start your pre-trip inspection by looking at the engine. Lower the gear guard so you can open the hood. Remove pins and unlatch the hood to do so. Once the hood is open, step back and look underneath the truck to see if there are any leaks.

Passenger Side

On the passenger side, make sure that your general hoses and alternator are free of cuts, abrasions or cracks. Hoses should be sufficiently secured, exhibiting no signs of leaks.

Driver’s Side

Walk around to the driver’s side and conduct a similar examination. Look at the parts listed below for signs of wear, abrasions and leaks. Your coolant and oil levels should be filled to the manufacturer’s specifications. Keep an eye out for fraying belts, improperly secured parts, and missing castle nuts and bolts.

- Air compressor

- Belt-driven water pump

- Coolant reservoir

- Gearbox and hoses

- General hoses

- Power steering fluid

- Power steering pump

- Shock absorber

- Spring hangers and arm

- Steering linkage

Check Your Brake System

Drivers must check the brake hose, brake chamber and slack adjuster. When pulled by hand, the push rod should not move more than 1” with the brakes released.

Your brake line should be free of debris and oil, and the hose material shouldn’t be worn too thin.

Outside Driver Door Area & Tires

If the engine looks good, inspect the outside of the truck.

- Check your mirror on the driver’s side to ensure it is clean and firmly mounted to the vehicle.

- Open the driver’s door, and examine the door’s seals and hinges for cracks or dry rot.

- The fuel cap should be on tight, and the fuel seal should not leak.

- Ensure that the catwalk and steps at the back are clear of any objects or debris.

In addition to the steps above, drivers should look at the following parts for damage, wear or debris buildup:

- Brake hose, chamber, lining and drum

- Drive shaft

- Frame and cross members

- U-joints and bolts

Check Your Tires (All of Them!)

The tires on your tractor-trailer should have a tread depth of no less than 0.125” and be aired according to the manufacturer’s standards. You can check the air pressure with a gauge and adjust it based on your load and the temperature .

The rims shouldn’t be bent or broken, and there shouldn’t be cracks around the bolt holes. Behind the tire, the mud flap should not be tattered or loosely attached to the vehicle. There should be space between the mud flap and the tire.

Trailer Pre-Trip Inspection

Is the truck good to go? Check! Now it’s time to inspect the trailer. Walk around the trailer and examine it for cracks, abrasions or broken parts.

- Brake hose, lining and chamber

- Frame and cross members

- Shock absorbers

You’ll also want to check that:

- The landing gear is fully-raised with the crank handle secure in its cradle. The landing gear and mud flap should be a proper distance apart.

- The tandem relief’s handle and locking pins are in the fully-locked position.

- The slack adjuster and push rod don’t move more than 1” when pulled by hand.

The back doors of the trailer should latch properly. The trailer’s lock rods and hinges must be intact and not bent. Your trailer should also have door chains for safety when loading and unloading.

Coupling: Back of Tractor, Front of Trailer

A driver’s next step is to examine where the tractor and trailer connect.

- Electric line — Ensure there are no exposed wires. The line should be secure.

- Air line — Your air line should be secured at both ends and not leaking.

- Gladhands — Check for worn or rotted seals on gladhand couplings. Make sure there are no leaks in the gladhands connected to the trailer’s air brakes.

- Trailer apron — No gap should exist between the apron and the skid plate. The skid plate should be lubed.

You should also check the kingpins, mounting bolts, and the sliding fifth wheel and locking pin.

Refrigerated Trailer Inspections

When you inspect one of Prime’s refrigerated trailers , you start by selecting the “pre-trip” option on the trailer’s display. It will take the reefer 10 to 15 minutes to complete a self-inspection and notify you of anything in need of adjustment or repair.

While the reefer’s self-test runs, you should look for any signs of damage on the bottom rail, top rail and sides of the trailer. Reefers are insulated. Drivers need to examine the trailer for cracks and exposed insulation.

You don’t want to drive off without working lights. The lights on your truck and trailer should be securely in place, not cracked and amber in color.

- Clearance lights

- Marker lights

- Headlights

- Tail lights

- Reflective tape on trailer and mud flaps

Once you’ve checked that the lights and reflectors are intact, you should test your lights and turn signals. Climb into your cab and turn the following lights and signals on:

- Left turn signal

- Right turn signal

- Four-way flashers

- Brake lights

Inside your cab, you’ll check that your seat belt latches and is not too worn. Next, check that you have a fire extinguisher that’s charged. Ensure your cab has three reflective triangles under the bunk area and electrical fuses in the glove box.

Once you’ve reviewed your safety gear, adjust your mirrors, start the engine and check the dashboard’s instrument panel:

- Oil pressure — It should be rising as the engine runs.

- Voltmeter — It should show the alternator charging between 13 and 14 volts.

- Air pressure — It should be around 120 to 125 psi.

While you’re here, test the heat and air conditioning, city horn and air horn.

Air Brake Test

With your tires chocked, you can perform an air brakes test. To do so, release both brakes and turn the truck off. When you turn the truck back on, you will apply pressure.

- Apply hard pressure to the brake.

- Watch for the gauges to stabilize.

- Hold a hard brake for one minute. You don’t want to lose more than four psi during this minute.

- Pump down on the brakes until the gauges read at or before 60 psi. Your warning light and buzzer should come on.

- Pump down on the brakes until the tractor and trailer valves pop up between 40 to 20 psi.

Parking Brake Test

After testing your air brakes, you can test your parking brake. Allow the truck to rebuild its air pressure before testing the parking brakes.

- Remove wheel chock.

- Release the tractor brakes and apply the trailer brakes.

- Put the truck in “drive.”

- Give your trailer brakes a light tug, ensuring they hold.

- Switch. Release the trailer brakes and apply the tractor brakes.

- Give your tractor brakes a light tug, ensuring they hold.

- Release both brakes.

- Pull forward to 5 mph, then use the brake pedal. The truck shouldn’t pull left or right. It should come to a smooth stop.

What to Do if There’s an Issue During Pre-Trip Inspection

Contact your fleet manager or road assistance immediately if you find an issue with your tractor or trailer. Prime will take corrective action and advise you on what to do next. Repairs must be made before the tractor-trailer can be dispatched again.

Inspection violations affect both the driver’s and carrier’s records. Violations can decrease a carrier’s CSA score . FMCSA keeps records of driver and vehicle violations. These records are updated monthly.

CDL Pre-Trip Inspection Test

Truck drivers must begin each work day with a pre-trip inspection. The Class A CDL test requires new drivers to know how to do a pre-trip inspection. Student drivers must be able to identify truck and trailer parts and understand how they operate.

You’ll walk an examiner through a pre-trip inspection for that portion of the CDL test. The best way to remember what’s on a pre-trip inspection checklist is to perform inspections the same way each time. The more you practice, the more it will become second nature.

Are you ready to become a driver?

Do you need CDL training? Our Driver Training Program prepares you for your CDL exam and offers experience hauling real loads.

Apply online to start our CDL training program, or contact our Recruiting Department at 866-290-1568 for details.

Recent Posts

What’s The Difference Between Dry Van & Reefer Trucking?

What’s A Good Gift for A Truck Driver?

Truck Driver Exercises to Keep You Fit on the Road

Transportation solutions, carrier solutions, drive for prime, work in house, success leasing.

Created by: Campaignium

Privacy Overview

- Company Culture

- Company Programs

- Leadership Team

- Fleet Maintenance

- Refrigerated Division

- Flatbed Division

- Tanker Division

- Intermodal Division

- Load Tracing

- Documentation

- Qualifications & Expectations

- Pay & Benefits

- Driver Training Program

- CDL Holders

- Driver Awards

- Salt Lake City

- Pittston, PA

- Springfield, MO

- Jobs At Prime

- View Available Loads

- Prime Power Fleet

- Lease & Lease Purchase

- Benefits of Leasing

- How to Get Started

- Pedigree Benefits

- Financing Information

- Equipment Inventory

- Omnitracs Logs

- Company Store

- Submit Pics from the Road

- Driver Verification

- Register / Login

- Trucker's Forum

- Paid CDL Training

- Truck Driving Jobs

- CDL Practice Tests

- High Road Training

- Truck Driver's Career Guide Chapter 5

- Truck Driver Pre-Trip Inspection

The Complete Guide To A Career In Trucking

What does the pre-trip inspection exam include.

You will be expected to be able to perform a complete pre-trip inspection on your vehicle, including both in-cab & external features, as well as the engine compartment.

Fluids, belts, brakes, air brakes, and lights are some of the main components to the test.

The pre-trip inspection will ensure that the vehicle that you are operating is safe and road-worthy to drive.

The In-cab pre-trip inspection:

This section will demonstrate that you know how to check that all in-cab functions are operational, including lights, gauges, etc., and ESPECIALLY the air brakes.

Pre-Trip Inspection - My Way! A must see!: In-Cab Pre-trip Inspection

This Pre-Trip is done on my truck and trailer. I physically took the pictures and edited them to my liking. It is a complete Pre-Trip Inspection and features everything you'll need to know.

Video - PreTrip Inspection - Interior Cab

This video shows how to do an in-cab pre-trip inspection

Video - Srtda in cab pre trip and brake test

This video shows how to do an in-cab pre-trip inspection and brake test.

The External pre-trip inspection:

You will be expected to check lights, tires, rims, fluids, belts, etc. Generally, all the components on the outside of the truck & trailer, including the engine compartment.

Forum - Daniel B.: Pre-Trip Inspection - My Way! A must see!

As stated, these are solely based off of how I like to do the Pre-Trip. I give my personal opinions as well as some helpful tips. Your Instructors advice may vary. In the end, just do it the way your Instructor wants you to do it.

Pre-Trip Inspection Video By Apex CDL Institute

This is a complete Pre-Trip inspection video by Apex CDL Institute

Pre-trip checklist, practice exams, and memory aids:

Pretrip Inspection Study Guide

The purpose of the Pretrip Inspection is to be able to do a thorough safety inspection on a commercial vehicle before heading out onto the highway.

Pre-Trip Inspection Free CDL Practice Tests

Our free Pre-Trip Inspection cdl practice questions are designed to help test your knowledge of the CDL Manual and sharpen your skills for taking the CDL permit and endorsement exams.

Why Join Trucking Truth?

- The High Road Training Program

- The High Road Article Series

- The Friendliest Trucker's Forum Ever!

- Email Updates When New Articles Are Posted

Apply For Paid CDL Training Through TruckingTruth

Did you know you can fill out one quick form here on TruckingTruth and apply to several companies at once for paid CDL training? Seriously! The application only takes one minute. You will speak with recruiters today. There is no obligation whatsoever. Learn more and apply here:

- Privacy Policy

Pre-Trip Inspections: Know Before You Go

You leave your truck for the night and return the next morning. In between, anything could happen. How do you know your vehicle is still in tip-top shape? You won’t unless you conduct a thorough pre-trip inspection.