Taiwan Bike Tour: Giant Bicycles’ Taichung Factory Visit

- Click to share on Facebook (Opens in new window)

- Click to email a link to a friend (Opens in new window)

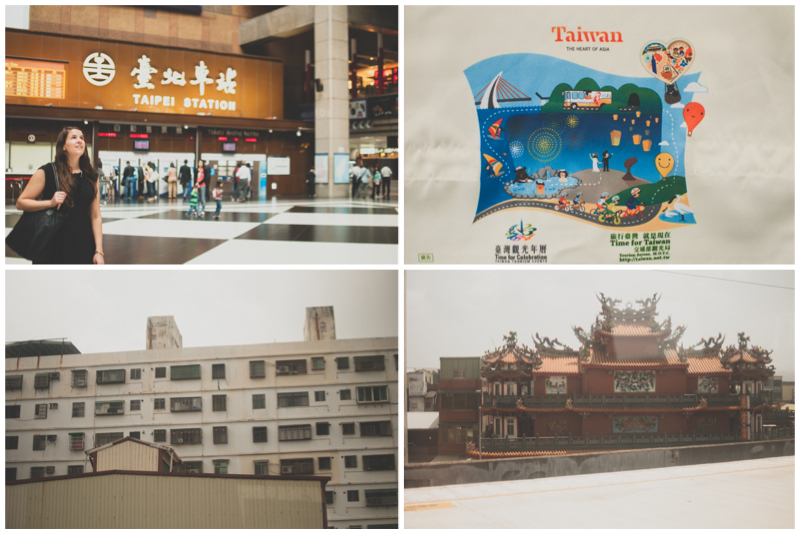

We were invited to visit Taiwan by the island’s trade organization’s for their first ever “Bike Bloggers Tour”, an outreach program to share both their passion for cycling and their capabilities for world class design, manufacturing and assembly.

The largest company we visited was Giant. Their world headquarters is in Taichung, arguably the bicycle manufacturing capital of the world. Chances are pretty good one or more of the bikes you own is designed, made and/or assembled here.

Our time was a bit limited, which precluded me from seeing very much of the actual manufacturing. I did see some of the alloy bikes being made, along with racks upon racks of frames fresh off the line from major brands other than Giant. As in, some of the top three or four global brands other than Specialized. Much of our tour at the assembly line, where finished frames become complete bikes, along with a healthy overview of Giant’s history and their growing influence in Taiwan’s overall cycling culture…

COMPANY HISTORY & CULTURE

A quick history: Founded in 1972, the Giant brand wasn’t established until 10 years later. They started researching carbon fiber in 1985 and were the first company to mass produce carbon bikes. In 1986, they started setting up subsidiary companies in Europe to expand globally.

In 1992, they established their first Chinese factory, and now produce frames in both Taiwan and mainland China. The gear and components are outsourced. They only make frames, forks and rims, but they design the components and gear in house before being sent out for production.

In 2011, they produced 5.7 million bikes total, including Giant and other brands. They started as an OE-only manufacturer, but as the Giant brand grows, the percentage of OE business versus their own products has shifted dramatically. As of 2011, OE manufacturing contributes 30% of their business, but the rest Giant. Their three biggest markets are China and Europe with 30% each and the US with 20%. They have 11,275 dealers worldwide.

They’re already the world’s largest bicycle manufacturer. The vision now is to expand the cycling culture. They do that through three markets dubbed PSI – Performance, Sport and “Innovative Lifestyle”. That last one is actually exclusive of the growing commuter segment, and they say that’s because they’re not cost competitive in that market. That said, they have a wide range of urban, cruiser and e-bikes that certainly cross over into commuter capabilities…they just look more like “lifestyle” products, and Europe sees a bigger collection of the line than the US. Hopefully it’ll soon include the awesome Anyroad gravel bike !

They also offer the Giant Cycling Tour Service in Taiwan, China and Japan. It’s a fully supported touring set up that they’ll likely expand to Europe and the US in the future.

One thing we don’t see much of yet is the Right Ride fit system. It’s not quite as technical of a system as Retül, Serrota and others aimed at performance riding and custom bike builds. Rather, it’s more about just getting the average cyclist to be comfortable on their bike so they’ll enjoy the sport more and stick with it.

The LIV line is a newer women’s specific grouping, and that’ll likely continue to expand, too.

In Asian markets, they have Giant Stores, which are 100% Giant. At present, there aren’t a whole lot of these in North America or Europe. You’ll have to head to Denver, Montreal or Amsterdam to see one of their concept stores. If we had to guess, you’ll start seeing more of these as they start pushing for a bigger brand presence to compete with Specialized and Trek. Beware the sleeping dragon, me thinks.

So, why and how are they going to create and grow the culture?

Not too long ago, King Liu, Giant’s president, decided to start riding. Yes, it seems obvious that the top brass in any cycling company should be an avid cyclist. But many of the largest companies are simply run as businesses, where the widgets could be interchangeable with any other widget as far as many executives are concerned. That was then. The “now” is that King Liu has made it his mission to change the culture of cycling in Taiwan and China from one of just commuting to one that shows how fun cycling is and how happy and healthy it can make you feel.

To do this, he instituted several major rides, and the company continues to develop rides and events to bring more people into the fold. The largest is the Formosa 900, a 900-mile ride around Taiwan. They brought along most of the executive team and managers from around the globe.

They’re also adding bike rental stations throughout Taiwan and making them free for the first 30 minutes. They’re hoping this encourages more people to get off their scooters and onto bikes. Add to that youth programs, a cycling tour around Taipei, a bike oriented hotel and increased event support and creation targeting different demographic and user (or potential user) groups. Obviously, more people riding more types of bikes is good for business, too.

One of the biggest initiatives is the One Bike One. 72,919 riders were verified to participate in a relay ride around Taiwan, which set a Guiness World Record.

THE FACTORY

Giant’s Taichung factory produces the high end frames. They segment into frame manufacturing, painting and assembly. Sadly, no photography was allowed in the manufacturing section, so I’ll try to paint pictures with words.

It’s something else to walk past rows of hundreds if not thousands of raw alloy frames for three or four of the world’s largest brands all stacked up side by side. It’s even more astounding when you see that every frame is hand made. All of the small builders we’ve visited and covered? Imagine that times a billion. There are no robotic welders here. Rows of work stations have bins full of hydroformed tubes all being hand finished, drilled, stamped with serial numbers, etc. Watching the cable stops get blasted with fire while a worker hand solders them in place is cool. Seeing an entire row of people doing it in unison is even more cool.

Manufacturing stations are mostly set up in a tri-position format where three people can work from the same parts bins performing the same activity – say, welding headtubes to downtubes. If that station is caught up, they can move to where they’re needed, varying the workday a bit and keeping production running smoothly and evenly.

I was hoping to see the carbon bikes being laid up, but our schedule was a bit too tight.

THE ASSEMBLY LINE

Bikes are assembled on a massive conveyer belt running along the edge of huge room set up just to funnel the right parts into the right place at the right time. A row of about 30 people transform it into a complete bike ready to be boxed in an average of one complete bike every 31.5 seconds. That includes a basic derailleur tune so it’s shifting reasonably well in the stand. The logistics give me nightmares, but it’s fantastic to watch.

Above is the primary assembly line. Here’s how things get to that point:

Ceiling mounted hook conveyers bring painted frames in at one end of the room.

They drop down in one corner where forks and headsets are installed.

This video shows the wheels being tensioned, followed by the fastest handlebar taping I’ve seen. Under two minutes per side…could you do that?

Behind, there’s a whole bank of people and machines that are building wheels in sync with what bike’s being built on the assembly line. Meanwhile, a bank of people are assembling and wrapping handlebars.

Wheels are placed on their own hook conveyer belt (left) and carried overhead to the assembly line. Workers grab them and drop them into the frames. The appropriate wheels are built, trued and wrapped with tires and tubes to coincide with the type of bike that’s being built, reaching the assembly line at just the right time. Same with the handlebars, and component and parts packaged are placed on the carts and trays in the proper order. Imagine scheduling all that!

Each worker only does one or two small steps in the assembly process. Here, the front derailleur is mounted. Another worker ran cable housing for the brakes and slipped the cable through…which means someone was cutting and capping the pieces of cables in predetermined sizes. Sooooo many baby steps.

These fellas were fine tuning the shifting, running up and down the gears and tweaking as necessary. Any good shop is going to give it a once over, but when they pull it out of the box, this gives the shop a good first impression of the brand.

A sign at the end of the line keeps workers apprised of their progress. On the left is the amount of time that line has been stopped during the day (4:03). On the right is the target number of frames for that line that day (620), their estimated actual output (593) based on build times and the percentage of target output. The signs on the bottom show the goals – less than 20 minutes of downtime on the line per day and at least 96% of the desired output.

At the end of the line, bikes are put into boxes, then boxes are loaded into containers. Lots and lots of containers.

TOUR OVERVIEW

Part of TAITRA’s goal with the Bike Bloggers Tour was to showcase the island’s industry and lifestyle in a positive light, perhaps separating them from the “cheap Chinese carbon” and “evil child labor” thoughts that so many people (or at least the most vocal) love to spout anytime an Asian-made product is highlighted. First off, about half of Taiwan’s population is pretty content to call themselves an independent country, only minimally associating themselves with the PRC. So there’s that. There’s also what I saw, which I’ll be sharing in a variety of posts covering small brands and large, from unique components and gear to another of the largest manufacturers in the world.

As for Giant, there’s only one shift, 8:00am to 5:30pm, that can make up to 5,000 bikes per day. There were no child laborers and no insane ’round the clock slave shifts. Oh, and no suicide nets on the windows. Workers can move between stations as needed to alleviate bottlenecks or avoid wasting time if a particular station is slow, so there’s opportunity to move out of a completely monotonous repetition on occasion.

Basically, Giant’s factory looked like any US factory I’ve been to. Lots of people doing rote procedures. Did they look excited to be there? Not particularly, but neither do the sock sewers at DeFeet or tube benders at Thule. It’s a job, and working conditions were clean and orderly and, other than the dudes welding the cable stops on the top tubes, reasonably safe looking. And I suspect the cable stop welders were doing it right, it’s just a process that looked quite foreign to me.

Tyler Benedict is the Founder of Bikerumor.com . He has been writing about the latest bikes, components, and cycling technology for almost two decades. Prior to that, Tyler launched and built multiple sports nutrition brands and consumer goods companies, mostly as an excuse to travel to killer riding locations throughout North America.

Based in North Carolina, Tyler loves family adventure travel and is always on the lookout for the next shiny new part to make his bikes faster and lighter.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Aha. So that’s why you always have to re-wrap the bars on low end Treks after the customer has ridden them for a few months.

The guys at Canyon in Germany do it much faster.

Nifty. It definitely is a tape job just to protect the bars in transit. Not a “wrap” job. Anywhoo, I wonder if I can get a job there. I’m sure they have a welfare system with free medical for immigrants, right? I’m packing my bag.

@rustydogg It’s a communist country so no one has to pay for that stuff. duh

But yeah, you should leave.

Oh wait, Taichung, not the mainland factory. Duh on me. Medical is still covered and they have a lovely intake for immigrants. Welfare I’m not sure about. Their unemployment rate is half what ours is though so you shouldn’t have to worry about welfare.

Scott – FYI, Taiwan is a democratic country……you’re thinking of China, which is a communist country.

When did Taiwan become a communist country?

LOL, we’re doomed.

Giant, Trek, Cannondale….Rocky Mountain?

Wow… there’s a lot of soul in those bikes…. that’s depressing

@jack @topmounter Please read my second comment.

Giant, Trek, not Cannondale, Scott, and someone elses bikes…..

Who the f*ck cares who makes who’s bikes and who is riding what. The people who move the bicycle industry and keep it afloat are not reading this blog. Might as well make a dollar where you can. Very depressing video though if taken on its own terms.

Didn’t get to see any fancy high end hydroforming or seeing Yeti frames being made 🙁

Nice article. I’m glad to see Giant open their doors and let everyone see how the operate.

If it comes to “soul” – I cannot see a huge difference on how any other consumer product is made (expect that it is a bike of course). In the end it is the feeling you have when riding one of these bike. If you want it different then pay more and have a bike mechanic build things from scratch….on another note: Taiwan is a high developed country as well, even too expensive for Apple making there high priced products there….

I would be interested to know what sort of wages these workers get and whether they are considered fair trade factories

@Justin and Rasek

The factory in TW produces Giant, Trek, Canyon, Scott, Colnago, Yeti and a few other smaller brands.

Excellent story!

I spent many months in Tachia (not Taichung) at the Giant factory as a design engineer and customer (BikeE) and it is an impressive operation. I never had any concern about working conditions or wages.

I did get a tour of the carbon factory and it is pretty darn amazing.

You might have included a little more detail about the early days (as Schwinn’s sole supplier), King Liu and Tony Lo literally bootstrapped the business.

Thanks for a good read.

…Literally bootstrapped the business? That’s some McGuyver bike construction!

@RUSTY – Actually, that is very much the wrap job that comes on finished bikes. You don’t think that shops do that in-house, do you? Not since Cannondale moved to Asia has a production bike come with unwrapped handlebars.

BMC’s come unwrapped. . .

What a bunch of racists.

S-works bikes come unwrapped. But yes most lower end bikes come pre-wrapped.

+ 1 for a Giant concept store we have here in Bristol, UK

@Scott – 10/18/12 – 4:21pm

If you review your basic grade 9 world geography, you can avoid sounding as ‘knowledgeable’ as Palin on world geography.

Explains the poorly trued rims…

Great stuff though. Impressive facility. Too bad we have so many people in the US on welfare… Might be able to make stuff like that here as well if we could get people to work. I guess going to school and getting a degree in the US means you no longer have to work unless it pays you what you think you deserve.

Please could someone tell which brands of bikes that Giant produce???

Giant makes : scott,trek ,yeti ,merida makes :merida,specialized cannondale is made by the same guys of xfusion forks i think ,what a shame … few days ago i saw a video of scott carbon experts ,oops those workers had the logo scott but the same colors of giant workers ,lollllllllllll

How to I get to visit the Giant factory in Taichung? can anyone help me out here?

I’m planning to visit Taichung by December of this year. Can I purchase a personal bike directly in the factory?

No, you can’t make a personal visit to Giant factory unless you are with some type of organization. You can’t purchase a bike from their factory. They will tell you to buy one from one of many Giant bikes shops in Taichung. There are a lot of them. Why would you want to buy one from the factory? They won’t give you a special price and there aren’t any benefits from going there to get one. Also, if you want to bring it back overseas, it’s going to cost you more than if you bought one from your home country.

Giant and Merida make bikes for other brands. Besides Giant and Merida, there are only a handful of factories in Taichung that make bikes for other high end bike manufacturers such as BMC. Everyone in the bike industry knows what the other one is doing because most of the bikes come out from the same factories that their bikes are made from. When bike companies sell their bikes as one of a kind, exotic, and original, you would be surprised. They’re all made by the same factory guy working on other bike brands under the same roof.

Factory workers in bicycle factories in Taiwan don’t earn a lot of income, but most of them have college degrees. Most people in Taiwan have college degrees. However, in Taiwan, factory workers get a bonus for Chinese New Year and other such holidays, which can add up to a substantial amount. Also, factory workers know that their working conditions may not be the best, but the don’t complain out loud like westerners would and there are not many unions here. Some factory workers work much more than 8 hours a day; sometimes 10-12 hours a day, and that’s without over time. All you can do is appreciate where your bike came from.

This message is for Paul who worked for Giant. I’m glad you had a great experience working for Giant in Taichung as a design engineer, but you most understand that YOUR working conditions were fine because Westerners get treated differently than local workers do. If you didn’t know that, you were quite blind. Try being a factory worker and you would know that your job as an “engineer” being a foreigner is quite different from a local worker working under harsher conditions on the factory floor under Taiwanese management. This might sound racist, but Taiwanese workers do not treat their workers better than Westerners. I have experience and I still work here. Don’t ask me what I do, but I’m not blowing smoke up your butt.

There is no such thing as fair trade practices in the bike industry in Taiwan. Don’t say that to people here. They will laugh at you or not know what you are talking about. Working in bicycle factories is certainly not a sweat shop, but it can be tough if you were to compare it to Western standards. You can’t compare Western standards and expect people here to work like you where you live. It’s a different place with different culture and thinking. It’s like comparing apples and oranges. You wouldn’t try to ask an apple tree to grow oranges, would you?

Follow Us On

Subscribe Now

Sign up to receive BikeRumor content direct to your inbox.

2-FOR-1 GA TICKETS WITH OUTSIDE+

Don’t miss Thundercat, Fleet Foxes, and more at the Outside Festival.

GET TICKETS

BEST WEEK EVER

Try out unlimited access with 7 days of Outside+ for free.

Start Your Free Trial

Powered by Outside

A tour of Giant’s Taichung factory

Heading out the door? Read this article on the new Outside+ app available now on iOS devices for members! >","name":"in-content-cta","type":"link"}}'>Download the app .

When it comes to big bike brands, they don’t come much bigger than Giant. For more than 40 years the Taiwanese-based company has been making bikes of all varieties for cyclists around the world including, for the past 27 years, high-end carbon fibre road bikes. CyclingTips’ roving reporter Dave Everett visited the Giant factory in Taichung, Taiwan to find out what goes into the company’s carbon frames and to learn a bit more about the Giant story.

I’m pretty sure I know where the name “Giant” came from. This is the first thought that pops into my head as I drive up to the gates of Giant’s factory in Taichung. The complex is immense — it’s that big that it has its own water tower , which has been freshly painted with bright blue racing strips and the Giant logo.

Giant is one of the main players when it comes to producing bikes, not just under its own brand name but for many of the other major bike brands as well. Giant can currently call itself the number-one producer in the bike assembly world and standing outside the gates of their Taichung factory it’s hard to see how any other manufacture could compete against this. The factory is the size of a village.

The visionary behind the brand is Mr King Liu who, back in 1972, started producing steel frames for the Taiwanese market. Unfortunately King Liu wasn’t in on the day I visited — he’d just finished a 12-day cycling tour of Taiwan despite being over 80 years old. His face was still one of the first things I spotted as I walked into Giant’s head office though, situated in a seven-story building on site.

A brief history

Giant is one of the major players in carbon production today and the company’s plant in Taichung, known as the C-Tech factory, is state of the art. History shows that Giant was beaten to the market by American firm Kestrel when it came to the first fully carbon frame , but in 1987 Giant were the first company to market with a mass production carbon frameset: the Cadex 980 C .

Come the following year and Giant spread its wings. The first order of frames for Europe came from the Netherlands. With a rapid expansion new facilities were soon needed and in 1992 Giant opened up its first Chinese base. Today Giant owns and operates a total of six factories in China and nine worldwide.

It wasn’t until 1997 that Giant eventually moved into sponsoring a big-name cycling team in the form of Manolo Saiz’s Spanish super-squad ONCE. The sight of the team’s bright yellow (or pink when competing in the Tour de France) kit is a sight from the late ’90s that many cycling fans will remember.

The team rode a controversial (if you worked at the UCI at least) and ground-breaking bike: the TCR . At that stage the pro-issue bikes were still made of alloy and it wouldn’t be until 2003 that the TCR was produced in carbon. Later incarnations of the frame, the TCR Advanced, would carry T-Mobile riders to victory after Giant managed to lure Walter Godefroot’s German team away from Pinarello.

Since then Giant has sponsored several major teams including HTC-Highroad, Rabobank through to Blanco and now the Giant-Alpecin squad.

Brandon Chou, my guide for the afternoon, told me that the compact road design was developed by Mike Burrows , the designer behind the bike ridden by Chris Boardman on his way to winning the 4000m pursuit at the 1992 Barcelona Olympics. Giant then employed Burrows to develop an all-new road bike design, influenced by MTB frame design.

“We were surprised to find out that a compact road design provided several advantages,” Brandon told me. “It was lighter, stiffer and even faster [when compared with] traditional frames.”

Further expansions

In 2008 Giant created its women’s-only brand Liv and the company also has its Momentum line , a separate brand catering to the town bike market which, I’ve been told, is a hit in China.

A sub-division of the Momentum line is YouBike . These bikes are for the bike share schemes in Taipei, Taichung and Changhua. Giant designed and built 10,000 of these bright orange bikes which are easy to spot in a city filled with scooters that the locals dash about on. I’m told Giant were also consulting partners with London’s “Boris Bikes” bike share scheme.

Giant’s design and marketing is taken care of out of an office in California which makes sense when you realise 25% of Giant’s market is in the US. Unsurprisingly China is the company’s largest market with 28% of its products sold there, while Australia accounts for 7%. The remaining 40% is spread throughout Europe and the rest of the world. Worldwide, Giant has no fewer than 11,125 dealers and the company’s annual turnover for 2013 was a staggering US$1.8 billion .

Into the factory

I’m guided out of the office and across the parking lot where Brandon waves to two security guards. They let us pass into the entrance and the factory’s main loading area. While walking past racks upon racks of carbon and alloy frames Brandon points out that he’ll let me know where I can take pictures. A lot of the areas here are off-limits — the processes they have in place are to be kept confidential.

The sheer scale of the place is something that, even wandering around, you can’t quite grasp. The whole plant covers 67,000 square meters — about the same amount of space as nine football pitches. Obviously one of my first questions is: how many bikes are produced here in a year? So far I’ve passed more racks of bikes than I’ll likely see in the rest of my lifetime.

The answer is a staggering one million a year, or 6.3 million across all of Giant’s nine factories worldwide. It makes me think that the popular Katie Melua song with the line “There are 9 million bicycles in Beijing” mightn’t be too far off the mark. Apparently one million Giant ATX bikes were sold last year alone.

Here in the Taiwan factory they produce frames not just under the Giant name but under many other brand names as well. While wandering around I eagerly spot several top-tier brands — brands from Italy, America and Switzerland are sat alongside Giant Propels and TCR framesets, all having rolled off the same production line.

The factory in Taichung is where Giant produces its high-end carbon frames. In China they have a second factory that makes the more affordable frames. With the number of Propels lined up on the steel racks here it slightly blunts the feeling of exclusivity you get when looking at one solitary Propel in your local bike shop.

Giant is able to churn out 500 carbon bikes a day, 70% of which are Giant’s own designs: Propels, TCRs and the company’s top-end mountain bike, the Anthem Advanced. The remaining 30% of frames they make are for their customers; the international players. This is only 10% of the whole factory’s output — a total of 3,500 bikes are made here daily.

Carbon sheeting

Like with my SRAM factory visit there are areas of the Giant factory that are off-limits to the visiting press. The main area is where they produce the rolls of carbon sheeting. Behind closed doors threads that are not produced by Giant are weaved together (see image below). These are then pre-impregnated with Giant’s own resin formula.

Giant wouldn’t reveal whether the company’s procedure for making carbon sheeting is any different from any other brand, but the fact that so many large and prestigious brands choose to go with Giant as their production partner must mean they are doing something right.

The only secret Brandon let me in on is the fact it’s not the carbon sheeting they like to keep quiet but rather it’s the make-up of their resin. Giant developed the resin with a chemicals partner that they have to keep secret for fear of other brands partnering with said company. It’s all very hush hush.

I’m told that each roll of carbon that Giant produces has a shelf-life of one month. If it isn’t used in this time it’s scrapped. Like any carbon it needs to be kept cold for best performance and the freezer here chills the carbon to -20 degrees Celsius. Before production the carbon needs eight hours to thaw before being sent for hand cutting.

My tour of the carbon facility is pretty limited; instead I’m shown how they turn this carbon sheeting into the frames and components we all recognise.

Building a frame

Through a large window I peer at multiple rows of women all decked out in clothing more suited to an operating theatre than a bike factory. They each sit concentrating on small sections of what will eventually turn out to be a frameset. It’s pointed out to me that this work is intricate and that they find women best suited to this work.

I’m told that they’ve found that women tend to be more patient and can focus on a singular job better than the guys. It’s a recurring theme that I’ve seen at many factories. Blokes apparently aren’t patient enough — we let our brains wander and our big, cumbersome hands tend to fumble. (The paint shop is another domain where you’ll only see women.)

In front of each of the workers sits a tray with small sheets of carbon cut out into different shapes. Each of these shapes must be placed in a correct order and in the exact spot they are needed. It’s a process that takes the staff up to three months to learn. Lay a sheet a few millimetres in the wrong direction or in the incorrect order and the characteristics and integrity of the frame may be compromised.

Each tray holds numerous pieces of carbon. Once these pieces have been placed and smoothed out with the aid of a hot air gun, they are racked up for the next person to apply their eight sheets of carbon. Between six and eight trays are needed for each frame.

Industrial sized hair dryers are used to soften up the carbon layers to lay them smoothly on to the previous layer and to allow the resin to become tacky enough to attach the next piece. The shaping of the tubes is formed over plastic rods with a plastic bag between the tube and the first carbon layer. This bag is left in place for the next step in the moulding process.

As many as 300,000 pieces of carbon can be used in any one day with each frame taking anywhere between 300 and 400 individual pieces. One frame takes a total of 18 hours to produce and goes through 32 different pairs of hands before it’s ready to leave for painting. In this time it’ll undergo 14 quality checks.

One item that is checked particularly rigorously is forks. I’m told that every fork must be made to 100% perfection. On a frame small wrinkles in carbon layup can be doctored but with a fork every piece must reach an extremely high standard. If even the slightest defect is observed in an X-ray machine then the fork is discarded.

Of the 2,000 staff here it’s the old pros of the factory that get to make the real cool stuff. Only the staff who have been at Giant long enough to acquire the skills are allowed to build the top-end Propels.

The climate-controlled room where the lay-up process happens is situated within one of the main factory units, yet it’s like its own self-contained environment. Everything is monitored: humidity, air pressure, temperature, air flow and the particles floating in the air. A computer monitors all of this 24 hours a day, seven days a week. Alarms sound if problems arise.

All around the oasis that is the calm carbon lay-up rooms people are busying themselves on machines that have clearly been churning out bike parts in staggering numbers for years and years. The paint on the machines has been worn away and replaced with a layer of factory dust.

It’s here that the moulding takes place. The carbon pieces are precisely placed into steel moulds and then clamped with the secondary top mould . Each mould is a CNC-machined steel plate for a different piece of the bike, from the seatstays through to the bottom bracket. Each of these moulds is for a single size of bike. These are then placed into an oven where they are baked while 16kg per square cm of pressure is forced into the plastic bags to inflate the carbon and force it in to the mould’s shape.

Piecing it all together

The assembly line for Giant’s alloy frames looks just like a car production plant but on a smaller scale. A long conveyor belt slowly slides the frames along to different members of staff who mount a single part, be it a rear mech hanger or a stem. This is all timed to perfection — a calculated 37 seconds is allowed for each job.

At one section of the main assembly conveyor belt wheels slowly descend from above off yet another conveyor belt that looks like it runs from a separate part of the factory. It strikes me that there are whole areas of the factory I’ve not seen yet, where people are rapidly putting tyres and tubes on to these wheels, probably within 37 seconds as well.

The whole unit I’m in has bikes hanging in the air in various states of completion, all of them swinging this way and that. At the end of the conveyor belt a bike is placed in a cardboard box, again in 37 seconds, and sent off up a steep ramp to a warehouse.

The warehousing is monstrous but it too is off limits with the camera. I stand there trying to count the pallets of bikes. I work out that each pallet holds six bikes and that the single section I manage to take in before I’m whisked away is 15 pallets long by 10 pallets high. How deep it goes I’ll never find out.

Trucks wait with their containers slowly being crammed full of new bikes.

I drove away from Giant’s Taichung factory with many thoughts about my visit, not least just how impressive and streamlined frame production can be. Giant has more than 42 years of experience and history behind it, and the company is a market leader at least in part because of the efficiency it has in place here and at its other facilities.

Sure, it might not be driven by the same sort of passion you’d find from a small bespoke brand but the passion is definitely present. It’s just hidden away behind the sound of heavy machinery and multiple lorries taking shiny new bikes to millions of happy new owners.

CyclingTips would like to say thanks to Giant Australia for helping to organise the factory tour. An early version of this article suggested that Mike Burrows still works at Giant and that the Taichung factory’s daily output is 5,000 bikes, not 3,500.

Photo gallery

Popular on Velo

\n >\", \"path\": \"https:\/\/velo.outsideonline.com\/news\/rapha-north-america-abruptly-closes-bentonville-office-lays-off-staff\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"rapha north america abruptly closes bentonville office, lays off staff\"}}\u0027>\n rapha north america abruptly closes bentonville office, lays off staff\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"time to plan your next trip: 5 companies with new bike bags at sea otter","url":"https:\/\/velo.outsideonline.com\/gravel\/gravel-gear\/new-bike-bags-at-this-years-sea-otter\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/gravel\/gravel-gear\/new-bike-bags-at-this-years-sea-otter\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"time to plan your next trip: 5 companies with new bike bags at sea otter\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/gravel\/gravel-gear\/new-bike-bags-at-this-years-sea-otter\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"time to plan your next trip: 5 companies with new bike bags at sea otter\"}}\u0027>\n time to plan your next trip: 5 companies with new bike bags at sea otter\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"over 114,000 acres of maine wilderness are now open to gravel biking","url":"https:\/\/velo.outsideonline.com\/gravel\/maine-promotes-gravel-cycling\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/gravel\/maine-promotes-gravel-cycling\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"over 114,000 acres of maine wilderness are now open to gravel biking\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/gravel\/maine-promotes-gravel-cycling\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"over 114,000 acres of maine wilderness are now open to gravel biking\"}}\u0027>\n over 114,000 acres of maine wilderness are now open to gravel biking\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"sea otter randoms: the one about carrying cargo of all kinds","url":"https:\/\/velo.outsideonline.com\/urban\/urban-gear\/sea-otter-randoms-the-one-about-carrying-cargo-of-all-kinds\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/urban\/urban-gear\/sea-otter-randoms-the-one-about-carrying-cargo-of-all-kinds\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"sea otter randoms: the one about carrying cargo of all kinds\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/urban\/urban-gear\/sea-otter-randoms-the-one-about-carrying-cargo-of-all-kinds\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"sea otter randoms: the one about carrying cargo of all kinds\"}}\u0027>\n sea otter randoms: the one about carrying cargo of all kinds\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"7 new bikes we found at sea otter","url":"https:\/\/velo.outsideonline.com\/road\/road-gear\/7-new-bikes-we-found-at-sea-otter\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-gear\/7-new-bikes-we-found-at-sea-otter\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"7 new bikes we found at sea otter\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-gear\/7-new-bikes-we-found-at-sea-otter\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"7 new bikes we found at sea otter\"}}\u0027>\n 7 new bikes we found at sea otter\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"tadej poga\u010dar seizes li\u00e8ge-bastogne-li\u00e8ge with dominant solo display","url":"https:\/\/velo.outsideonline.com\/road\/road-racing\/tadej-pogacar-seizes-liege-bastogne-liege-with-dominant-solo-display\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-racing\/tadej-pogacar-seizes-liege-bastogne-liege-with-dominant-solo-display\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"tadej poga\u010dar seizes li\u00e8ge-bastogne-li\u00e8ge with dominant solo display\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-racing\/tadej-pogacar-seizes-liege-bastogne-liege-with-dominant-solo-display\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"tadej poga\u010dar seizes li\u00e8ge-bastogne-li\u00e8ge with dominant solo display\"}}\u0027>\n tadej poga\u010dar seizes li\u00e8ge-bastogne-li\u00e8ge with dominant solo display\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"tom pidcock leaves li\u00e8ge in frustration: \u2018i was setting all-time power numbers\u2019","url":"https:\/\/velo.outsideonline.com\/road\/road-racing\/tom-pidcock-leaves-liege-in-frustration-i-was-setting-all-time-power-numbers\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-racing\/tom-pidcock-leaves-liege-in-frustration-i-was-setting-all-time-power-numbers\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"tom pidcock leaves li\u00e8ge in frustration: \u2018i was setting all-time power numbers\u2019\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-racing\/tom-pidcock-leaves-liege-in-frustration-i-was-setting-all-time-power-numbers\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"tom pidcock leaves li\u00e8ge in frustration: \u2018i was setting all-time power numbers\u2019\"}}\u0027>\n tom pidcock leaves li\u00e8ge in frustration: \u2018i was setting all-time power numbers\u2019\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"\u2018cycling sucks sometimes\u2019: what poga\u010dar, van der poel and pidcock said before li\u00e8ge-bastogne-li\u00e8ge","url":"https:\/\/velo.outsideonline.com\/road\/road-racing\/cycling-sucks-sometimes-what-pogacar-van-der-poel-and-pidcock-said-before-liege-bastogne-liege\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-racing\/cycling-sucks-sometimes-what-pogacar-van-der-poel-and-pidcock-said-before-liege-bastogne-liege\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"\u2018cycling sucks sometimes\u2019: what poga\u010dar, van der poel and pidcock said before li\u00e8ge-bastogne-li\u00e8ge\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-racing\/cycling-sucks-sometimes-what-pogacar-van-der-poel-and-pidcock-said-before-liege-bastogne-liege\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"\u2018cycling sucks sometimes\u2019: what poga\u010dar, van der poel and pidcock said before li\u00e8ge-bastogne-li\u00e8ge\"}}\u0027>\n \u2018cycling sucks sometimes\u2019: what poga\u010dar, van der poel and pidcock said before li\u00e8ge-bastogne-li\u00e8ge\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"gallery: 16 attention grabbing bikes from the sea otter classic","url":"https:\/\/velo.outsideonline.com\/road\/road-gear\/16-attention-grabbing-bikes-sea-otter-classic\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-gear\/16-attention-grabbing-bikes-sea-otter-classic\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"gallery: 16 attention grabbing bikes from the sea otter classic\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-gear\/16-attention-grabbing-bikes-sea-otter-classic\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"gallery: 16 attention grabbing bikes from the sea otter classic\"}}\u0027>\n gallery: 16 attention grabbing bikes from the sea otter classic\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"can ineos grenadiers take it to tadej poga\u010dar at the giro d\u2019italia \u2018our plan is to be aggressive\u2019","url":"https:\/\/velo.outsideonline.com\/road\/road-racing\/can-geraint-thomas-stop-tadej-pogacar-at-the-giro-ditalia-our-plan-is-to-be-aggressive\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-racing\/can-geraint-thomas-stop-tadej-pogacar-at-the-giro-ditalia-our-plan-is-to-be-aggressive\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"can ineos grenadiers take it to tadej poga\u010dar at the giro d\u2019italia \u2018our plan is to be aggressive\u2019\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-racing\/can-geraint-thomas-stop-tadej-pogacar-at-the-giro-ditalia-our-plan-is-to-be-aggressive\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"can ineos grenadiers take it to tadej poga\u010dar at the giro d\u2019italia \u2018our plan is to be aggressive\u2019\"}}\u0027>\n can ineos grenadiers take it to tadej poga\u010dar at the giro d\u2019italia \u2018our plan is to be aggressive\u2019\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"carapaz roars to stage win in tour de romandie as race leader ayuso blows","url":"https:\/\/velo.outsideonline.com\/road\/road-racing\/richard-carapaz-roars-to-stage-win-in-tour-de-romandie-as-race-leader-juan-ayuso-blows\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-racing\/richard-carapaz-roars-to-stage-win-in-tour-de-romandie-as-race-leader-juan-ayuso-blows\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"carapaz roars to stage win in tour de romandie as race leader ayuso blows\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-racing\/richard-carapaz-roars-to-stage-win-in-tour-de-romandie-as-race-leader-juan-ayuso-blows\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"carapaz roars to stage win in tour de romandie as race leader ayuso blows\"}}\u0027>\n carapaz roars to stage win in tour de romandie as race leader ayuso blows\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"sea otter randoms: riser handlebars, nifty racks, and tubes aren\u2019t dead","url":"https:\/\/velo.outsideonline.com\/news\/sea-otter-randoms-riser-handlebars-nifty-racks-and-tubes-arent-dead\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/news\/sea-otter-randoms-riser-handlebars-nifty-racks-and-tubes-arent-dead\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"sea otter randoms: riser handlebars, nifty racks, and tubes aren\u2019t dead\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/news\/sea-otter-randoms-riser-handlebars-nifty-racks-and-tubes-arent-dead\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"sea otter randoms: riser handlebars, nifty racks, and tubes aren\u2019t dead\"}}\u0027>\n sea otter randoms: riser handlebars, nifty racks, and tubes aren\u2019t dead\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"mathieu van der poel realistic about quest for monument sweep: \u2018even with roubaix legs i cannot follow poga\u010dar\u2019","url":"https:\/\/velo.outsideonline.com\/road\/road-racing\/mathieu-van-der-poel-realistic-about-quest-for-fourth-monument-even-with-roubaix-legs-i-cannot-follow-pogacar-here\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-racing\/mathieu-van-der-poel-realistic-about-quest-for-fourth-monument-even-with-roubaix-legs-i-cannot-follow-pogacar-here\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"mathieu van der poel realistic about quest for monument sweep: \u2018even with roubaix legs i cannot follow poga\u010dar\u2019\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-racing\/mathieu-van-der-poel-realistic-about-quest-for-fourth-monument-even-with-roubaix-legs-i-cannot-follow-pogacar-here\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"mathieu van der poel realistic about quest for monument sweep: \u2018even with roubaix legs i cannot follow poga\u010dar\u2019\"}}\u0027>\n mathieu van der poel realistic about quest for monument sweep: \u2018even with roubaix legs i cannot follow poga\u010dar\u2019\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"xpedo\u2019s new power meter pedals are ready for the spotlight","url":"https:\/\/velo.outsideonline.com\/road\/road-gear\/xpedo-new-power-sonik-omni-and-thrust-omni-meter-pedals-sea-otter-classic\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-gear\/xpedo-new-power-sonik-omni-and-thrust-omni-meter-pedals-sea-otter-classic\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"xpedo\u2019s new power meter pedals are ready for the spotlight\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-gear\/xpedo-new-power-sonik-omni-and-thrust-omni-meter-pedals-sea-otter-classic\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"xpedo\u2019s new power meter pedals are ready for the spotlight\"}}\u0027>\n xpedo\u2019s new power meter pedals are ready for the spotlight\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"8 new shoes from giro, q36.5, shimano, fizik, lake, and crankbrothers","url":"https:\/\/velo.outsideonline.com\/road\/road-gear\/8-new-shoes-from-giro-q36-5-shimano-fizik-lake-and-crankbrothers\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-gear\/8-new-shoes-from-giro-q36-5-shimano-fizik-lake-and-crankbrothers\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"8 new shoes from giro, q36.5, shimano, fizik, lake, and crankbrothers\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-gear\/8-new-shoes-from-giro-q36-5-shimano-fizik-lake-and-crankbrothers\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"8 new shoes from giro, q36.5, shimano, fizik, lake, and crankbrothers\"}}\u0027>\n 8 new shoes from giro, q36.5, shimano, fizik, lake, and crankbrothers\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"highbar wants to revolutionize your helmet straps","url":"https:\/\/velo.outsideonline.com\/news\/highbar-wants-to-revolutionize-your-helmet-straps\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/news\/highbar-wants-to-revolutionize-your-helmet-straps\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"highbar wants to revolutionize your helmet straps\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/news\/highbar-wants-to-revolutionize-your-helmet-straps\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"highbar wants to revolutionize your helmet straps\"}}\u0027>\n highbar wants to revolutionize your helmet straps\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"the ritchey montebello brings steel goodness to all-road","url":"https:\/\/velo.outsideonline.com\/road\/road-gear\/ritchey-montebello-brings-steel-goodness-to-all-road\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-gear\/ritchey-montebello-brings-steel-goodness-to-all-road\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"the ritchey montebello brings steel goodness to all-road\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-gear\/ritchey-montebello-brings-steel-goodness-to-all-road\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"the ritchey montebello brings steel goodness to all-road\"}}\u0027>\n the ritchey montebello brings steel goodness to all-road\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"the cadex race integrated bar is as light as it is good looking","url":"https:\/\/velo.outsideonline.com\/road\/road-gear\/cadex-race-integrated-bar-first-look\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-gear\/cadex-race-integrated-bar-first-look\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"the cadex race integrated bar is as light as it is good looking\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/road\/road-gear\/cadex-race-integrated-bar-first-look\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"the cadex race integrated bar is as light as it is good looking\"}}\u0027>\n the cadex race integrated bar is as light as it is good looking\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"there are three marquee off-road races in the us this weekend. who\u2019s going where and why","url":"https:\/\/velo.outsideonline.com\/gravel\/gravel-racing\/best-off-road-races-north-america\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/gravel\/gravel-racing\/best-off-road-races-north-america\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"there are three marquee off-road races in the us this weekend. who\u2019s going where and why\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/gravel\/gravel-racing\/best-off-road-races-north-america\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"there are three marquee off-road races in the us this weekend. who\u2019s going where and why\"}}\u0027>\n there are three marquee off-road races in the us this weekend. who\u2019s going where and why\n \n \n \n \n \n\n \n \n \n \n \n\n \n "},{"title":"the thesis n1 wants to be your sole drop bar bike for everything","url":"https:\/\/velo.outsideonline.com\/gravel\/gravel-gear\/thesis-n1-do-everything-drop-bar-bike\/","markup":" \n \n\n\n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/gravel\/gravel-gear\/thesis-n1-do-everything-drop-bar-bike\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"the thesis n1 wants to be your sole drop bar bike for everything\"}}\u0027>\n \n \n \n \n \n \n\n \n \n\n \n\n \n \n\n \n \n >\", \"path\": \"https:\/\/velo.outsideonline.com\/gravel\/gravel-gear\/thesis-n1-do-everything-drop-bar-bike\/\", \"listing_type\": \"recirc\", \"location\": \"list\", \"title\": \"the thesis n1 wants to be your sole drop bar bike for everything\"}}\u0027>\n the thesis n1 wants to be your sole drop bar bike for everything\n \n \n \n \n \n\n \n \n \n \n \n\n \n "}]' > >", "name": "footer-menu", "type": "link"}}'>advertise >", "name": "footer-menu", "type": "link"}}'>privacy policy >", "name": "footer-menu", "type": "link"}}'>contact >", "name": "footer-menu", "type": "link"}}'>careers >", "name": "footer-menu", "type": "link"}}'>terms of use >", "name": "footer-menu", "type": "link"}}'>site map >", "name": "footer-menu", "type": "link"}}'>my newsletters manage cookie preferences privacy request healthy living.

- Clean Eating

- Vegetarian Times

- Yoga Journal

- Fly Fishing Film Tour

- National Park Trips

- Warren Miller

- Fastest Known Time

- Trail Runner

- Women's Running

- Bicycle Retailer & Industry News

- FinisherPix

- Outside Events Cycling Series

- Outside Shop

© 2024 Outside Interactive, Inc

- MAGAZINE OFFERS

- BIKE INSURANCE

- Best Products

- Maintenance

- Accessories

- Long-Term Reviews

- BikeRadar Podcast

- First Look Friday

- Bike of the Week

- Tech Features

- Routes and Rides

- Bike Galleries

- BikeRadar Bargains

- Buyer's Guides

- Fitness & Training

- Sizing & Fit

- Mountain Biking UK

- Cycling Plus

Inside Giant's Taiwan frame factory – part one

All-access tour inside the world's largest bicycle manufacturer

James Huang/Future Publishing

James Huang

Giant Bicycles truly lives up to its name – it's the undeniable 800lb gorilla of the bicycle industry. In 2012, the company generated US$1.8 billion in annual revenue globally, both under its own label and as a builder for other brands.

All of its carbon fibre and premium aluminium frames are manufactured in a sprawling facility in Taichung, Taiwan, and BikeRadar brings you an in-depth, all-access look inside.

- Inside Giant's Taiwan frame factory - part two

- Inside Giant's Taiwan frame factory - part three

- Inside Giant's Taiwan frame factory - part four

Inside giant bicyles' taiwan factory

Video: Inside Giant Bicyles' Taiwan factory

Founded in 1972 by current company chairman King Liu, Giant started as a contract manufacturer. Things weren't looking rosy from the outset. That year, Giant produced just 3,800 bicycles. That's all changed now, however, thanks to a hard-earned reputation for consistently delivering high build quality at reasonable prices – first in steel for Schwinn back in its heyday, then aluminium and now carbon fibre.

Today, Giant builds more than 6.3 millionbikes worldwide annually – a number equivalent to roughly half of all adult bikes sold in the United States each year. Of that, about 70 percent bear the Giant brand name while the remaining 30 percent is contract work for others.

One of the biggest keys to Giant's financial success has been its long-standing decision to integrate as many parts of the manufacturing process under its own roof. According to Giant CEO Tony Lo, this not only helps to ensure quality but it also decreases long-term costs – after all, fewer outside steps means fewer markups along the way, and fewer questions about whether something was done correctly.

Giant's Taiwan factory

For example, Giant doesn't just weld its own aluminium frames; it also smelts its own alloys and forms its own aluminium tubing. And for carbon frames, Giant isn't merely content to take delivery of pre-preg carbon fibre sheets that were manufactured by a third party. Save for creating the fibres themselves, Giant is unique among large manufacturers in that it controls the entire process every step of the way afterward.

For part one of this four-part series, we'll take a look at how the manufacturing juggernaut turns that raw fibre into usable materials.

From fibre to fabric

Carbon fibre arrives at the Giant factory in surprisingly small spools. Multiple types of fibres are used, too, varying in characteristics such as modulus (or stiffness) and tow (how many fibres are bundled together per strip).

Raw carbon fibre is fed off of the spool through a variety of guides and rollers - sort of like a huge sewing machine

From here, the fibres are fed into what's best described as a huge, industrial loom that lays them out in even layers. Giant makes all of its unidirectional fabrics in-house but woven cloth – the mostly cosmetic layer that many people imagine when they think of carbon fibre – is purchased pre-made.

Either way, all of that carbon fibre starts out dry and has to be impregnated with resin. Exactly how that happens has up until now been an extremely closely guarded secret but we were given exclusive access to view the process ourselves – and more importantly, document it.

Where the magic happens: this is where custom resins - produced in-house - are carefully applied to sheets of raw carbon fibre

Giant stores its custom two-part epoxy resins in separate containers that are combined only when needed in a special mixing applicator. The carbon fibre sheets are sandwiched in between enormous stainless steel rollers (picture a newspaper printing press) and that mixing applicator then applies the blended resins to one side of the sheet in a back-and-forth pattern.

As the sheet is squeezed through, the rollers not only force the resin in between the fibres but they also guarantee a uniform distribution throughout the sheet.

The two-part epoxy resin is thoroughly blended as it passes through the mixer tube, which is then rasters back and forth to provide the steel roller with an even amount of material to apply to the carbon fibre sheet on the other side

Just after the sheet passes through the rollers, backing paper is applied to both sides to keep the sheet from sticking to anything and then it's all rolled up on giant tubes.

Mind those fingers!

This process only works for woven and unidirectional sheets, however. Bicycle frames require layered orientations too, and these have to be made in an additional step.

Those unidirectional sheets are fed on to a computer-controlled cutting table that lops off sections at predetermined angles depending on what's needed.

Sections of 45-degree bias ply unidirectional carbon fibre are butted together before new backing paper is applied

Workers then remove the backing paper from one side of the sheet and overlap the layers by hand. When all is said and done, what's left is a two-layered pre-preg sheet with fibres that are now angled relative to each other – and it all still fits on the same roll as before to facilitate storage.

The finished pre-preg sheets are rolled on to huge cardboard tubes for storage

From there, it's off to the freezer where the pre-preg materials are stored until they're needed.

Freezer storage for the carbon fibre sheets

In part two of this exclusive series, we'll show you how this carbon fibre is transformed into complete frames. Trust us – you won't want to miss it.

Share this article

- Terms & Conditions

- Subscribe to our magazines

- Manage preferences

Inside the Belly of a Giant: Factory Tour

Like seeing a cow on a farm and being reminded of where our food comes from, and all the hard work that goes to put it on our table, visiting a bike factory feels the same for me. I wanted to see the scale, the engineering, the humans behind it all, and the hard work it takes to put a bike in my garage. I too wanted to feel a little less arrogant and grateful.

Lucky for me my dream came true on a grand scale as I recently got the chance to visit the Giant HQ Factory in Taichung, Taiwan.

Giant is arguably the largest bicycle manufacturer in the world and the HQ in Taichung is one of half a dozen locations that churn out over 6 million bikes a year. That’s a massive scale that can only be seen to be appreciated and as we walked amongst the people and machines I was struck most notably by the scale of human effort it takes to build our bikes. Yes, there are some fantastic machines and amazing modern engineering involved but building a bicycle still isn’t at the level of robotic craftsmanship like the auto industry – every piece of our bikes is touched by a very hard working and dedicated Giant employee.

What I took away from my visit wasn’t the amazing skill and workmanship, or scale of the operation, it was the very family nature that even such a large scale operator as Giant has. Despite what you may think of manufacturers at this scale, I personally found that they still do love bikes too. Even the CEO loves riding bikes and dedicates a far portion of his time and money to help others in Taiwan enjoy the same. Here are some photos of our tour. It’s pretty much near impossible to capture the whole process so here is a very abbreviated version. If only I was allowed to take photos of the research and development work spaces. So many cool toys.

- Submit for Review

- Terms & Conditions

Enjoy reading this?

Get similar articles delivered directly to your inbox

Tech: Inside Giant's Taiwan bike factory, part one

All-access tour inside the world's largest bicycle manufacturer

This article first appeared on BikeRadar .

Tech: Inside Giant's Taiwan bike factory, part two

Giant Bicycles truly lives up to its namesake as the undeniable 800lb gorilla of the bicycle industry. In 2012, the company generated US$1.8 billion (billion!) in annual revenue globally, both under its own label and as a builder for other brands. All of its carbon fiber and premium aluminum frames are manufactured in a sprawling facility in Taichung, Taiwan and BikeRadar brings you an in-depth, all-access pass inside.

Founded in 1972 by current company chairman King Liu, Giant first started as a contract manufacturer and things weren't looking too rosy from the outset. That year, Giant produced just 3,800 bicycles. That's all changed now, however, thanks to a hard-earned reputation for consistently delivering high build quality at reasonable prices – first in steel for Schwinn back in its heyday, then aluminum and now carbon fiber.

Today, Giant now builds more than 6.3 million bikes worldwide annually – a number equivalent to roughly half of all adult bikes sold in the United States each year.

One of the biggest keys to Giant's financial success has been its long-standing decision to integrate as many parts of the manufacturing process under its own roof. According to Giant CEO Tony Lo, this not only helps to ensure quality but it also decreases long-term costs – after all, fewer outside steps means fewer markups along the way and fewer questions about whether something was done correctly.

For example, Giant doesn't just weld its own aluminum frames; it also smelts its own alloys and forms its own aluminum tubing. And for carbon frames, Giant likewise isn't merely content to take delivery of pre-preg carbon fiber sheets that were manufactured by a third party. Save for creating the fibers themselves, Giant is unique among large manufacturers in that it controls the entire process every step of the way afterward.

For part one of this four-part series, we'll take a look at how the manufacturing juggernaut turns that raw fiber into usable materials.

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

From Fiber To Fabric

Carbon fiber arrives at the Giant factory in surprisingly small spools. Multiple types of fibers are used, too, varying in characteristics like modulus (or stiffness) and tow (how many fibers are bundled together per strip).

From here, the fibers are fed into what's best described as a huge, industrial loom that lays them out in even layers. Giant makes all of its unidirectional fabrics in-house but woven cloth – the mostly cosmetic layer that many people imagine when they think of carbon fiber – is purchased pre-made. Either way, all of that carbon fiber starts out dry and has to be impregnated with resin. Exactly how that happens has up until now been an extremely closely guarded secret but we were given exclusive access to view the process ourselves – and more importantly, document it.

Giant stores its custom two-part epoxy resins in separate containers that are combined only when needed in a special mixing applicator. The carbon fiber sheets are sandwiched in between enormous stainless steel rollers (picture a newspaper printing press) and that mixing applicator then applies the blended resins to one side of the sheet in a back-and-forth pattern. As the sheet is squeezed through, the rollers not only force the resin in between the fibers but they also guarantee a uniform distribution throughout the sheet.

Just after the sheet passes through the rollers, backing paper is applied to both sides to keep the sheet from sticking to anything and then it's all rolled up on giant tubes.

This process only works for woven and unidirectional sheets, however. Bicycle frames also require layered orientations, too, and these have to be made in an additional step.

Workers then remove the backing paper from one side of the sheet and overlap the layers by hand. When all is said and done, what's left is a two-layered pre-preg sheet with fibres that are now angled relative to each other – and it all still fits on the same roll as before to facilitate storage.

From there, it's off to the freezer where the pre-preg materials are stored until they're needed.

In part two of this series, we'll show you how this carbon fiber is transformed into complete frames. Trust us – you won't want to miss it.

Thank you for reading 5 articles in the past 30 days*

Join now for unlimited access

Enjoy your first month for just £1 / $1 / €1

*Read any 5 articles for free in each 30-day period, this automatically resets

After your trial you will be billed £4.99 $7.99 €5.99 per month, cancel anytime. Or sign up for one year for just £49 $79 €59

Try your first month for just £1 / $1 / €1

New disc brake-equipped Giant Trinity TT bike spotted at Tour de Romandie

POC Aspire cycling glasses review: A sturdy and stylish modern classic

UCI Gravel World Series – Frederik Rassmann, Debora Piana break away to win Giro Sardegna

Most Popular

Giant bikes in Taiwan: A look inside the factory

- by Klaus Bardenhagen

- Dezember 2, 2012

- 6 Kommentare

How Giant bikes are produced in Taiwan

Giant has become one of Taiwan’s most recognized brands. Like Asus or Acer in the IT industry, the bicycle producer started out as an original equipment manufacturer (OEM) for Western companies. Beginning in the 1980s, Giant (Chinese: 捷安特 or 巨大) established its own brand.

Many customers in Europe or the U.S. are probably still not aware that it’s a Taiwanese company, and that their Giant bikes may have been produced in Taichung.

Who is the biggest of them all?

With a sales revenue of US$1.56 billion in 2011, Giant defines itself as currently being the world’s largest bicycle manufacturer . The company has 10,000 employees globally. About 2,500 of them work in Taiwan, where Giant was founded 40 years ago.

In 1972, its first year, the company produced less than 4,000 bikes. Giant puts the number at 5.7 million for 2012.

Giant bikes: Made in Taiwan. At least some of them.

When visiting the company headquarters in Taichung with a group of foreign journalists, we had a chance to look inside the manufacturing plant next door. My video gives you an impression of how Giant produces bikes there.

Like so many Taiwanese companies, Giant is taking advantage of low labor costs in China. In 1992, its first factory opened in Kunshan. Today, Giant is operating five plants in China. But unlike other companies, it has not given up on Taiwan as a place for manufacturing.

„Taichung is our head factory,“ Giant Global Group CEO Antony Lo (羅祥安) told us during our visit. „Here, we are making high-end products: carbon fibre and light-weight aluminum.“ In the plant right next to Lo’s office, 2,000 workers are producing parts as well as assembling about 1 million bikes per year.

Giant: not trying to produce as cheap as possible

„We don’t provide anything cheap,“ Lo said. „People are looking for good quality; they are not looking for cheap products.“ His company has positioned itself as a leading provider for rather high-priced sport, fitness and lifestyle bikes. In Germany, for example, typical Giant bikes range from EUR300 to EUR1,000, with the high-end price range between EUR1,500 and EUR3,000. This also includes e-bikes that have recently been gaining popularity. „We like to provide premium quality products at a popular price,“ said Lo.

The global trend is Giant’s friend: „In the past, most people used their bikes for mobility, transportation, or lifestyle. But now the global trend is that more and more people start cycling for fitness and health reasons .“

That’s why, according to Lo, Giant is seeing strong growth in European markets like Germany and the Netherlands, and in Asian countries like South Korea and Taiwan, where the number of cyclists has increased in recent years.

Migrant workers making Giant bikes in Taiwan

Because I am very interested in the situation of migrant workers in Taiwan , and had read that Giant Taiwan employs many South-East Asians, I asked Lo how his company is dealing with this situation.

According to him, about 20% of the workers in the Taichung plant are migrant workers — about 350 to 400 people. „We choose them very carefully,“ Lo said. „We have people in Thailand and Indonesia to interview applicants over there. In Taiwan, we have dormitories and people who can speak their language to take care of them.“

Asked if his company pays all migrant workers Taiwan’s minumum wage (currently NT$18,780 / US$645 per month), or if they earn more, Lo said: „We pay according to the skill level. Some of them, we will give more than the minimum wage.“

Lo said that Giant has long-term relationships with many migrant workes. Usually, they can work in Taiwan for three years before they have to return to their home countries. „Most of them go home for one month and then come back to us. Many of them have been working with us for more than 10 years.“

Foreign labor is not just relevant in Taiwan, said Lo. For the European market, Giant is operating a manufacturing plant in the Netherlands . Many of the 400-500 workers there are Polish. „I think if you do the balance right, local workers plus guest workers, that’s a good system.“

I published a report about Giant on the Deutsche Welle website. It has been translated into Chinese: 來自台灣的自行車巨頭

Cycling in Taipei

Although Giant is operating Taipei’s public Youbike system , the city is not yet really suited for bike commuting. I attached a camera to my bike and filmed this POV video to give you an impression of what cycling in Taipei feels like:

What is your opinion about Giant bikes? Have you noticed them becoming more popular in your country?

I am a German reporter living and working in Taiwan. Read more English posts on this mostly German blog. Follow me on Twitter , Facebook , Plurk , or Google Plus .

English posts you might want to have a look at:

- Some wild photos and videos from the Gay Pride Parade in Taipei

- Taiwanese girls dating Western foreigners. What is a Xicanmei 西餐妹 ?

- Taipei Dome construction. How Taipei citizens do not get a second forest park, but just another shopping mall

- Jingmei Prison shows how Taiwan does not deal with its past

Das könnte auch interessant sein:

- Eine Premium-Marke aus Taiwan: Wie Giant erfolgreich Fahrräder baut

- Cheap labor, no rights? Taiwan’s 2nd class foreigners

- Ich erzähl‘ dem WDR was von Taiwan

- Support a documentary on South-East Asian migrant workers in Taiwan

Powered by YARPP .

- Tags: Fahrradfahren , Gastarbeiter , Industrie , Interview , Meine Medien-Berichte , Taichung

Klaus Bardenhagen

6 antworten.

Hello, I am owner of 2013 Giant Glory frame and I want to tell you unpleasant story which concerns me. In 2013 I bought a new frame in internet shop. Seller told me by phone that frame came from polish distribution and has full warranty rights. I read at internet site of polish distributor that this frame has 3 years time of warranty. 2 years I have used bike built on this frame according to specifications. Unfortunately, after this time I found a little crack between top tube and seat tube (I checked on internet forums and this is common issue for this model). I reported this immediately to shop, but they told me that polish distributor rejected warranty right.

I was so unpleasantly surprised and confused. I decided to figure out why my frame was rejected. I made a phone call to polish distributor and he informed me that shop bought this frame as a full bike (glory 2), took bike to pieces and sold me only a frame. The point is that I lost my warranty rights through these activities and nobody told me about it. In polish and EU law warranty duties are on seller site for 2 years, but I found this crack 3 weeks after so I was completely ignored by the shop… I think the crack was there much earlier, but I can’t prove it. In this way I stay with broken frame, with no money to replace it. I worry to ride it because I don’t want to hurt myself when frame will break up. I’m writing to you guys because you are my last chance. I really love my Giant and still want to ride on it. Greetings from Poland, Łukasz Madej

hello dear I am Ibrahim From Egypt and I am looking to be an agent for Giant bicycles in Egypt I import bikes from china from a long time and now I am interesting to import giant bikes from taiwan so how can i contact with your company please tell me i am waiting for your rebly thanks Ibrahim samir

Please if you could produce. Beer bikes, I.e cart. Ride for.8 to 10 people, on paddle . Thank you

- Pingback: Bicycles, Factories, Software, and Steel | Farnsworth Engineering

- Pingback: How “Giant” become a real Giant! | Fixed Gear Taiwan

- Pingback: Fahrradfahren in Taipei: Immer schön vorsichtig | Brennpunkt Taipeh: Deutsche Taiwan-News aus Taipei

Schreibe einen Kommentar Antworten abbrechen

Deine E-Mail-Adresse wird nicht veröffentlicht. Erforderliche Felder sind mit * markiert

Kommentar *

Meinen Namen, meine E-Mail-Adresse und meine Website in diesem Browser für die nächste Kommentierung speichern.

Diese Website verwendet Akismet, um Spam zu reduzieren. Erfahre mehr darüber, wie deine Kommentardaten verarbeitet werden .

Zufallstreffer

Ins Gefängnis fürs Fremdgehen

90 tage taiwan ohne visum – ab 11. januar.

Sag mir, wo die Kinder sind (Taiwans Geburtenmangel)

Deutsche presseschau (und radio) am taiwan-wahltag.

Urheberrechte © InTaiwan.net, InTaiwan.de | Website-Entwicklung von www.sean.su

Immer informiert über Taiwan auf Deutsch: Für meinen Newsletter anmelden

Immer informiert über Taiwan auf Deutsch:

Für meinen Newsletter anmelden

Cycling Foundation, Tours and Museums

we make your life better with our services and bicycles.

Giant Group has played an active role in popularizing cycling in Taiwan. Having established the Cycling Lifestyle Foundation, Giant Adventure, YouBike and the Cycling Culture Museum, Giant Group hopes to make everyone familiar with bicycles. By reaching out to one another, we can create a better tomorrow where cycling is enjoyed all over the globe.

Cycling Lifestyle Foundation

With their sights set on creating a healthier community by encouraging cycling in Taiwan, the Cycling Lifestyle Foundation hosts cycling events every year. It donates bicycles to Taipei City and New Taipei City which can be rented at riversides. The Foundation urges our government to ensure a safe and friendly cycling environment for all.

Giant Adventure

Giant Adventure is a provider of all-inclusive cycling tours around the world. With a commitment to helping our customers fulfill their dreams and explore the possibilities of life. Giant Adventure provides detailed domestic and overseas bicycle touring itineraries. All itineraries and services are adjusted according to an individual’s level of cycling experience. Join us to see how bicycle touring can spice up your life!

YouBike is a 24-hour automated public bicycle rental system. It provides a point to point bicycle rental service. By combining excellent service management with a pleasant cycling experience and a simple registration system, YouBike encourages us all to use bicycles for daily travel. In addition, YouBike has partnered with the public transportation system to ease congestion in urban areas, and make travel more energy-efficient.

Cycling Culture Museum

The Cycling Culture Museum is the first museum to explore the world of bicycles through interactive technology and the aesthetics of workmanship. The museum houses a collection of antique bicycles, installation art, movies and more. The various items show visitors the different kinds of bicycles and their history. We hope that this interaction with our collection will help people to see bicycles in a different light.

EXTENDED: Spring Sale - Save up to $1,500 on Select Bike + up to 50% OFF Gear SHOP SALE

INTRODUCING: THE 2023 GIANT FACTORY OFF-ROAD TEAM

Wednesday, January 4, 2023

Teams/Riders

18-year-old Remy Meier-Smith is the current U19 men’s downhill national champion in Australia. Remy had five podium finishes in the DH World Cup series as a junior last year.