Rivers of Steel

Top ways to experience nearby attractions

Most Recent: Reviews ordered by most recent publish date in descending order.

Detailed Reviews: Reviews ordered by recency and descriptiveness of user-identified themes such as wait time, length of visit, general tips, and location information.

Rivers of Steel - All You Need to Know BEFORE You Go (2024)

- Mon - Fri 10:00 AM - 4:00 PM

- (3.55 mi) The Inn on Negley

- (4.73 mi) Morning Sun Inn

- (0.73 mi) Holiday Inn Express Pittsburgh E - Waterfront Dr

- (3.40 mi) Shadyside Inn All Suites Hotel

- (5.91 mi) Drury Plaza Hotel Pittsburgh Downtown

- (0.36 mi) Triangle Bar & Grill

- (0.40 mi) Di Salla's Pizza Parlor

- (0.52 mi) Emil's Lounge

- (2.87 mi) Point Brugge Cafe

- (3.50 mi) Prantl's Bakery

Touring the Once-Abandoned Carrie Furnace in Pittsburgh

As I walked away from Carrie Furnace, having spent the previous two hours touring this relic of Pittsburgh’s steel industry, I knew I had just been somewhere special.

Without a doubt, Carrie Furnace is a microcosm of the changes that have occurred in Pittsburgh over the last few decades. What’s old is becoming new again. What was once polluted is becoming green. And what was industrial is becoming artistic. If you want to understand where Pittsburgh has been and where it is going, there is no better place to visit than Carrie Furnace.

Located just outside the Pittsburgh city limits, Carrie Blast Furnace was once part of the Homestead Steel Works. The two furnaces that make up the site were built in 1907 by Carnegie Steel and ran almost continuously until 1978.

Pittsburgh is known as “The Steel City,” and for good reason. At its peak in 1910, the steel industry in Pittsburgh produced more than 60% of the total production in the US. The peak period of production at Carrie Blast Furnace was in the 1950s and 1960s, when the seven blast furnaces here were each producing 1,250 tons of iron ore every day.

During the 71 years of operation, changes were made to the blast furnaces, but they remained virtually unchanged after 1936. This outdated technology was one of the chief reasons that furnaces 6 and 7 were the first ones shut down when the complex began to shut down. It was also the reason that these were the furnaces chosen for preservation by Rivers of Steel National Heritage Area.

After years of work to preserve the site, tours of Carrie Furnace started running in 2010. Having seen photos of the site when planning my trip to Pittsburgh , I knew that this was somewhere that I had to visit.

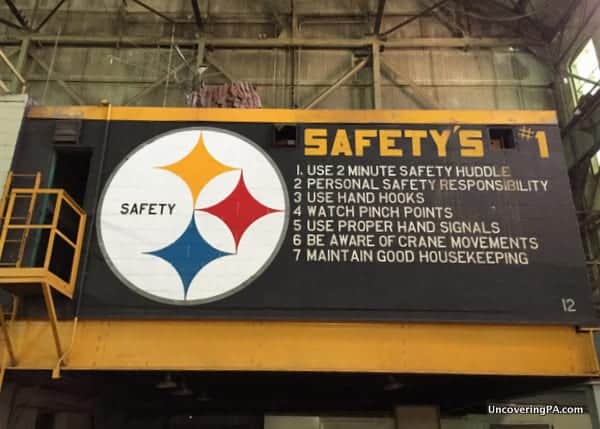

My visit started in the site’s visitor center. Currently, the visitor center consists of little more than a sign-in table and a small waiting area. The vast majority of this very large building, which used to provide a massive amount of air to the furnaces, is used for storage for a variety of pieces of machinery and equipment that the site hopes to restore. If you look across the building, you’ll notice a large US Steel safety sign emblazoned with the three hypocycloids that have been made famous by the Pittsburgh Steelers.

Tours of Carrie Furnace take 1.5-2 hours and are often led by former steel workers. The tour takes visitors throughout much of the site, explaining the Carrie Furnace history, how iron was made here, and how that was turned into steel across the Monongahela River in Homestead.

The highlight of any visit to Carrie Furnace is walking around the furnace itself and learning how iron was made. While certainly on a larger scale, the process of making iron had changed little since the 18th century iron furnaces I’ve visited in eastern Pennsylvania.

While the area has been cleaned up a bit, it is still quite rough around the edges, and really has the feel of exploring an abandoned site. Work continues on the site to improve access and make it safer for visitors. And while this is needed in places, I hope that it doesn’t take away from the very cool urbex feel of the site.

Back outside the furnace, take note of some of the graffiti that is present at the site. It’s not surprising that a place like Carrie Furnace would have issues with graffiti, especially since it was sitting abandoned for many years. To combat this, Carrie Furnace works with the art community and allows sections of the facility to be used by graffiti artists. This cooperation has greatly reduced the amount of unwanted graffiti that occurs on the site and provides a wonderful artistic touch to the harsh metal of the furnace.

Another piece of art on the site is the “Carrie Deer.” Standing 45-feet tall and hidden amongst the structures of the furnace, this deer head is made entirely of pipes and other materials found on site. Constructed by renegade artists between 1997-1998, this piece of art has now been preserved and even has its own documentary.

Those interested in the art and graffiti history of the site can take the Carrie Furnace Urban Art Tour, which covers more than 30 years of art. Carrie Furnace also hosts period art exhibits that are popular with visitors.

Another interesting area is known as the Iron Garden. This area is located where furnaces 1 and 2 once stood. Since the land was used for heavy industry for nearly 100 years, the soil was deeply affected and heavily acidic. Minus some basic maintenance to maintain walking paths, this area has been left to grow back completely naturally.

Ten different signs lead visitors through the Iron Garden and explain how nature is reclaiming the land. I found it very fascinating to see how plants are growing in this area despite the poor soil and large pieces of metal scattered throughout the land. I’ll be very interested to come back in a few years and see how this area has changed.

The Iron Garden is just one example of the environmentally-friendly practices that have been worked into Carrie Furnace. The site also uses solar panels for electricity, goats maintain portions of the land, and waste is composted. While the steel industry was blamed for so much of Pittsburgh’s pollution problems in the mid-20th century, it’s amazing to see the furnace leading the way in Pittsburgh’s green movement today.

I really can’t express how awesome my visit to Carrie Furnace was. Whether you are interested in Pittsburgh’s industrial history , love exploring abandoned places , consider yourself an art aficionado, or just like taking awesome photos, put a tour of Carrie Furnace at the top of your must-do list.

Things Worth Noting Before Touring Carrie Furnace

Carrie Furnace is an industrial site and is still far from pristine. My trip took me up shaking stairs, past rusting metal, and over equipment that hadn’t been moved in decades. All visitors are required to sign a waiver before touring the site. It’s also worth noting that Carrie Furnace is not handicap accessible and only closed-toed shoes are allowed on the tour. Given the nature of the tour, it is not recommended for children under eight.

If you want to learn more about the area’s history, Carrie Blast Furnace is just across the river from the site of the Homestead Strike of 1892. Tucked between the river and a large shopping center, the site features the old Pump House, a large water tower, and several pieces of equipment scattered on the ground.

It was on this site in July 1892 that a battle ensued between striking workers and forces brought in by Carnegie Steel. Several signs on the site tell the story of what happened here.

Also nearby is the Bost Building, which serves as the Rivers of Steel Museum. Further afield is the W.A. Young and Sons Machine Shop and Foundry in Rices Lading.

Note: My tour of Carrie Furnace was hosted by Rivers of Steel National Heritage Area. However, the opinions expressed are my own.

Spending more time in Pittsburgh? Check out the Tour-Ed Mine , the Heinz History Center , the Westinghouse Atom Smasher , and the Nine Run Falls Trail .

You can also check out a few of my favorite seasonal museums in PA .

Carrie Furnace

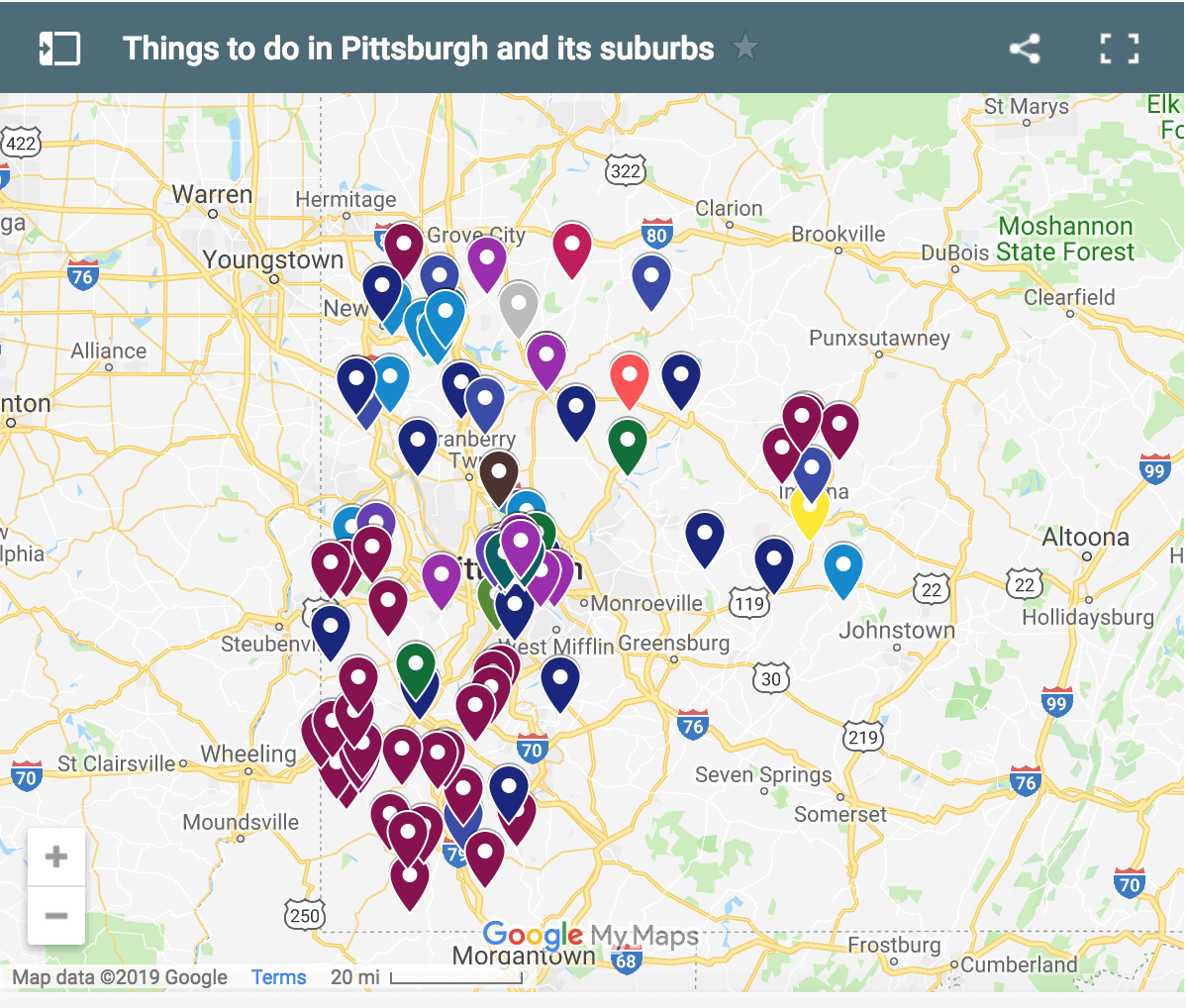

See map below for other area attractions.

Great places to stay in Pittsburgh

- Renaissance Hotel - One of the city's highest-rated hotels on Trip Advisor.

- Residence Inn North Shore - The perfect hotel for sports fans

- Hampton Inn and Suites - The only downtown hotel with free parking

- Hyatt Place - Great value near great attractions

- Find more great places to stay on Vrbo!

Click the map to see more nearby things to do

More nearby places worth exploring

25 Epic Locations for Photos of the Pittsburgh Skyline

Exploring the Beauty of Phipps Conservatory in Pittsburgh

Visiting the Pittsburgh Tattoo Art Museum in Shadyside

Exploring Asian Art and Culture at the Maridon Museum

Find more things to do in the pittsburgh region.

Jim Cheney is the creator of UncoveringPA.com. Based in Carlisle near Harrisburg, Jim frequently travels around Pennsylvania and has visited, written about, and photographed all 67 counties in the state. He has also traveled to more than 30 different countries around the world.

7 thoughts on “Touring the Once-Abandoned Carrie Furnace in Pittsburgh”

Thanks for sharing – I’ll have to check this place out. In addition to the deer, there also was an enormous owl that was created inside one of the buildings… Unfortunately, it had to be dismantled by one of the crews that was brought in to work on the place. Both were the partial works of Tim Kaulen, Pittsburgh sculptor.

Interesting. I hadn’t heard that, but I know that they had to remove some of the art in order to preserve the site itself.

Jim, that looks like a place I could spend days! I’ll certainly plan a visit next time I’m out that way. One quick technical note, from paragraph four: this mill would have consumed 1250 tons of ore, or produced 1250 tons of iron, but it wouldn’t have produced iron ore, that comes from the ground! Thanks again for some great reading.

I was going to point out that the seven blast furnaces “processed” 1250 tons of iron ore per day, not produced…but I see that Jeff beat me to it.

Chris you were right in saying produced 1250 Tons/day. Iron making though is a process that results in the production of 1250 tons of molten iron which is then processed into steel. You may ask “How would this guy know?” Well this guy directed iron making operations for almost 38 years starting with Republic Steel in Youngstown Ohio. Republic Steel recruited me while I was working steady midnights at US Steel in McDonald so I could attend YSU in the evenings. This was around 1970. By the way in Youngstown Ohio within its’ city limits 17 Blast Furnaces operated. Many others operated within 15 miles of Youngstown also. The tragedy is that not one of them is standing. Pity

I’m going to have to take a trip and see these furnaces. Once a Blast Furnace Man always a Blast Furnace Man.

Hard to explain…….probably the only others that would understand were those who worked on Furnaces.

About 38 years ago, I worked for Duqesne Light as a meter reader. Across the Mon from the Clairton Mill Works were semi-abandoned homes right along the river. It was really creepy back then. I can’t imagine that anyone lives there any more. I wish I could give you better directions but I haven’t lived in Pittsburgh since 2001.

You might want to take a drive out and see what’s left.

Right up the street is US Steels Edgar Thomason’s plant that has the last two blast furnaces in PA. They produce over 8000 tons of iron a day.

Leave a Comment Cancel reply

Sharing is caring.

Help spread the word. You're awesome for doing it!

- Visitor Center

- Free Things to Do

- Tours & Sightseeing

- Outdoor Adventure

- Arts & Culture

- Health & Wellness

- Pittsburgh Sports Teams

- Casinos & Gaming

- Film Festivals

- Submit Your Event

- This Week in Pittsburgh

- Annual Events

- Holiday Events

- Halloween Events

- Food Festivals

- Marathons, Runs & Walks

- Pittsburgh Celebrates Juneteenth Freedom Day

- Pittsburgh Black Music Festival

- Hotels & Resorts

- Bars & Nightlife

- Pittsburgh Craft Breweries

- Wineries & Distilleries

- Farms & Farmers Markets

- Visitors Guide

- Multi-lingual Brochures

- Beyond Pittsburgh

- Transportation

- Explore Black Culture & Heritage

- LGBTQIA+ Travel in Pittsburgh

- Pet-friendly Travel

- College Visits

- Senior Travel

- Medical Travel

- Accessibility Guide

- Welcome Centers

- Newsletter Signup

- Downtown Pittsburgh

- Strip District

- Mount Washington

- North Shore & North Side

- Lawrenceville

- East Liberty

- Squirrel Hill

- Monroeville

- Meet in Pittsburgh

- Event Services

- Marketing Toolkit

- Show Your Badge

- About SportsPITTSBURGH

- Sports Event Planner

- Sports Facilities

- Calendar of Events

- Sports Event Attendee

- Power of Sports Economy

- Weddings & Reunions

Rivers of Steel Tours

Rivers of Steel's attractions showcase the artistry and innovation of southwestern Pennsylvania's rich heritage.

Hop on Rivers of Steel's Explorer riverboat for the Uniquely Pittsburgh Sightseeing Tour , a 90-minute sightseeing cruise of Pittsburgh's three rivers that seeks to answer the question “What makes Pittsburgh, Pittsburgh?” This tour shares the big stories of our region’s past—along with many lesser-known tales—as it explores a sense of place. Looking for an experience unique to the Steel City? Visit the Carrie Blast Furnaces National Historic Landmark . A remnant of the once massive, U.S. Steel Homestead Works, the Carrie Furnaces are also a vestige of Pittsburgh's 20th-century dominance of the steel industry. Guided tours lead guests though the belly of this industrial beast, highlighting the drama of the iron-making process, while sharing the stories of the site's technology, its workers, and their culture. The Bost Building National Historic Landmark serves at the Visitor’s Center for the Rivers of Steel National Heritage Area . Exhibits highlight the region’s steel heritage and the 1892 Battle of Homestead, along with temporary art and history exhibitions. Information about more tours, other attractions, and the Rivers of Steel National Heritage Area is available at riversofsteel.com .

Rivers of Steel Tours 623 East Eighth Ave. Homestead, Pennsylvania 15120

Related Stories & Events

NCAA® March Madness® Guide to Pittsburgh

Your companion piece for enjoying the best of Pittsburgh between buzzer beaters

This site uses cookies to enhance your experience.

Quick Search

Location map.

Discover the Burgh

Carrie Furnace Tour – Finding the Steel City’s Roots

Published by Jeremy . Last Updated on June 19, 2019.

Disclaimer : Our site uses demographic data, email opt-ins, display advertising, and affiliate links. Please check out our Terms and Conditions . Pricing, operating hours, or menus may have changed since our initial visit and may not be reflected in subsequent updates. Please confirm these directly with any business or attraction prior to visiting.

Throughout its history, Pittsburgh has been known for a lot of things. The city was host to George Washington on multiple occasions, the departure point of Lewis and Clark on their famous expedition, home to America's early glass industry, and the world's leading supplier of iron and steel- and that is before even getting to the 20th century.

Although these are all incredible in their own right, it is the steel industry in Pittsburgh that made the city famous the world over.

In its prime, Pittsburgh was producing thousands of tons of steel per day- more than half of the entire output of all factories in the United States combined- and boasted a staggering number of mills located along the city's rivers. But by the 1980s this all changed- the steel industry went bust, nearly all of the factories were shut down, and Pittsburgh went through one of the largest depressions from which it only recently emerged.

Since then, most of the factories have been demolished and replaced with new industries. But a small portion of one massive factory, the iron-producing Carrie Furnaces, was rescued by the Rivers of Steel Heritage Foundation and turned into a historical site for future generations to come and learn about how the Steel City got its name.

The Roots of the Steel City at Carrie Furnace

The decline of the steel industry in Pittsburgh is unique in that it was so recent. Often we look back at fallen industries or historical events and can only turn to books, museums, and documentaries to learn from as the generations who lived through it are no longer with us.

This is not the case for Pittsburgh's steel industry.

Not only does a good percentage of the city remember the steel industry vividly, many worked in it for most of their lives (and have strong feelings on its demise on all sides of the spectrum). This gives the Rivers of Steel Heritage Foundation a unique opportunity when preserving the grounds of the Carrie Furnaces as many of the volunteers actually worked at the furnace itself.

In fact, this was one of the highlights of the tour for us as our guide shared stories of what life was like working at the furnace in addition to its history- including his daily tasks, why the industry was such a livelihood to the city, and even why the industry ultimately collapsed (hint: they refused to modernize).

For those who love Pittsburgh history and have already learned a bit about the steel industry at the Heinz History Center , Carnegie's business partner Henry Clay Frick at the Frick house , and are looking for more, this 2-hour tour does a great job at filling in the gaps while exploring the hauntingly beautiful grounds of what remains of the once massive Carrie Furnaces.

But in keeping with our habit of not giving everything away when it comes to museums and guided tours, we're going to leave the rest for you to find out for yourself on a visit.

One of the Best Tours in Pittsburgh

Overall, the tour of the Carrie Furnaces is, without a doubt, one of the best tours you can do in the entire city.

The guides do a stellar job of bringing the history of the furnaces alive, and the tour can only be described as being 100% Pittsburgh. So if you want to find out more about why we are known as the Steel City, do yourself a favor and book a tour as soon as possible.

You won't regret it .

The Carrie Furnaces are located southeast of Pittsburgh just outside of Rankin, PA. Tours are available during the summer months on Saturdays and Sundays and require advanced reservations. For those who want more, be sure to head over to Homestead after your tour to explore more historic sites associated with the steel industry, such as the location of the 1892 Homestead Strike.

To learn more about Pittsburgh's steel heritage , why not tour the Frick House or visit the Heinz History Center ?

Find Another Pittsburgh Attraction

Meadowcroft Rockshelter – 19,000 Years of Human History

Thunderbird Cafe is a Hidden Gem for Music in Lawrenceville

Carnegie Museum of Natural History – Full of World Wonders

Find more to do east of pittsburgh.

Harrison Hills Park – Easy River View Hike Near Pittsburgh

Taqueria el Pastorcito Review – Food Truck Turned Restaurant

Blue Dust Review – A Gastropub Celebrating the Steel City

1 thought on “carrie furnace tour – finding the steel city’s roots”.

Very helpful, thank you.

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

21 Great American Factory Tours You Can Take Right Now

Many historic American factories are open to the public. Here are the ones worth the trip.

There's probably no escaping taking the kids to an amusement park this summer—sweltering in long lines and paying for overpriced junk food. But when that torment is over, take them to a different kind of theme park, one you'll both enjoy: an American factory. You'll see how baseball gloves are made. Or how they print the posters for your favorite concert. Or how a guy at Harley-Davidson takes every bike up to 77 mph on what looks a lot like an automotive treadmill. Sometimes you'll even get candy. And unlike at Six Flags, admission is often free.

1. Hatch Show Print

Nashville, Tennessee: 75 minutes; $15 (adults), $10 (ages 6 to 12)

Nashville's recent "it city" status has our skyline so dotted with cranes that longtime residents have started calling it Little Dubai. I worry that the town where my ten-year-old daughter, Margot, was born is becoming unrecognizable to her. So I decided a tour of the Hatch Show Print letterpress was in order.

"What's a letterpress?" Margot asked.

"They make music posters," I said. She got excited.

"Think they have any of Taylor Swift?" she asked.

"Maybe," I said, explaining that they've been in business since 1879, and have worked with just about every musician you can think of—from Elvis Presley to Elvis Costello.

"Who's Elvis Costello?" Margot asked.

The production process hasn't changed much in over a century. Some of the letter blocks—exactly 0.918 inches high, a standard established in 1886 by the United States Type Founders' Association—are the original end-cut maple versions. This isn't Photoshop. There is no erasing. If even the smallest amount of grit builds up beneath an individual block, it must be sanded by hand so that it prints evenly. The rollers have to be reinked every four prints—each one slightly more faded than the last. These subtle inconsistencies are what make Hatch Show Print posters so special: No two look exactly alike.

The craftsmanship wowed my daughter—just like it had wowed me on my first visit, not long after I moved to Nashville two decades ago. But her favorite part was the end, when we got to browse through an inventory of photo plates and posters dating back to the shop's very first print run. I marveled at the photo plate for Led Zeppelin's first Nashville appearance in 1970. Then I glanced over and spotted Margot. She had the very same grin on her face. She was looking at a poster from Taylor Swift's "Speak Now" tour. —Adam Ross

2. The U.S. Mint

Philadelphia, Pennsylvania (Also Denver, Colorado): 45 minutes; free

From a 40-foot observation deck you'll see coins—tens of millions each day—sliced from metal coils that weigh 6,000 pounds and stretch five football fields. Inspectors use magnifying glasses to check the quality. Just one flaw in one coin and the entire batch is destroyed and recycled.

3. John Deere

Waterloo, Iowa (Also East Moline, Illinois, and Ankeny, Iowa): 90 minutes; free

Tours take place on a tram pulled by—what else?—a John Deere tractor. Huge robotic arms spray each vehicle in signature green and yellow. But the logo is still applied by hand.

4. Airstream

Jackson Center, Ohio: One to two hours; free

Each of the iconic travel trailers has thousands of rivets holding together huge sheets of aircraft-grade aluminum. And every one of those rivets is drilled in by hand. Once finished, the campers go into the rain-test booth, where they're pounded by hurricane-strength rain for 20-minute cycles.

5. Bourbon Barrel Foods

Louisville, Kentucky: 25 minutes; free

The nation's only soy sauce microbrewer—yes, soy sauce microbrewer—uses repurposed bourbon barrels and limestone-filtered Kentucky spring water to create a uniquely smoky-sweet condiment. FDA restrictions keep you from the factory floor, but you can still watch through glass as workers cook soybeans, roast grain, and press mash with six tons of force.

6. Woolrich

Woolrich, Pennsylvania: One hour; free

Woolrich has been churning out fabric since 1830, including blankets for Civil War soldiers. And for the factory's 60-odd employees, working with raw wool—a single blanket takes roughly four pounds—is its own kind of battle. A variety of heirloom machines dye, comb, spin, wind, warp, weave, wash, and roll the material before it can be turned into something you'd cozy up with on the couch.

7. Coors Brewing Company

Golden, Colorado: 30 minutes; free

What kind of dad takes his five-year-old son on a brewery tour? A cool one, I thought, boarding the shuttle bus to the Coors plant in Golden, Colorado—the largest single-site brewery in the world, capable of turning out 13 million barrels of beer annually. To me, it was just another father–son outing—a chance to see something new and learn something interesting. Like the zoo, but with the freshest free beer imaginable. Little did I suspect my boy would end up scarred for life.

In and of itself, the self-guided tour is utterly wholesome, an experience as pure as the vaunted Rocky Mountain spring water that prompted Adolph Coors to set up shop in Golden back in 1873. Exhibits explain ingredients, malting, mashing, etc., while affording a look at impressive mechanized assembly lines that channel endless rivers of freshly filled cans and packed cardboard cases in perfect perpetual motion. It wasn't easy to detach my son's nose from the observation window, but over the clack of the machinery, Daddy discerned the siren song of the samples that await responsible drinkers of legal age at the end of the tour.

As I sipped a cold glass of Coors and my son a soda, we surveyed our surroundings: an ersatz pub, decorated with old advertisements—including one featuring E.T. (left), that lovable extraterrestrial, imploring imbibers to "phone home" for a ride should they overindulge. This seemingly harmless poster, unfortunately, made by far the largest impression of the day on my son. What is that thing? Is it coming to get me? What part of me do you think it would eat first? Years later, the poor lad is still uncommonly concerned with the perceived dangers posed by aliens, even smiling ones in bartenders' aprons.

Then again, if that keeps him out of the taverns for a few extra years, maybe it's not all bad. —Kendall Hamilton

8. Golden Flake

Birmingham, Alabama: 45 minutes; free

When my wife and I moved from New York City to Birmingham, Alabama, five years ago, I'd braced myself for culture shock. I knew as much about college football and black-eyed peas as I do thermonuclear fusion. But while I'm still rusty on the vagaries of the wishbone formation, we definitely came out ahead. We've got a yard now, and a dog, and some savings. And we live ten minutes from a snack-food factory.

Since 1923, Golden Flake, "The South's Original Potato Chip," has been supplying chips and puffs and curls and popcorn and pork skins from Florida up through Virginia, in flavors as unlikely as Tangy Pickle BBQ and just plain Hot. It is tiny next to the Utzes and Pringles of the world, and touring its 700-employee Birmingham facility can feel like visiting a friend's home-brewing shed, if instead of beer he churned out Chili Lime Pork Cracklin Super Strips.

"This is our cheese puff, corn puff, and popcorn department," said both our guide and, I hope, whoever greets me in the afterlife. There are 14-foot drums of vegetable oil and giant rotating seasoning cylinders and kind-looking ladies slicing potatoes in half (by hand, for quality control). The highlight comes at the halfway point: a basket brimming with potato chips plucked fresh off the conveyor belt, intercepted between fryer and bagging station, and offered to you for sampling. It is the perfect bite of a perfect chip. Thin but still crunchy, with just-too-much salt. Whatever's in your pantry seems like wafer-shaped Styrofoam in comparison.

It's just one of several snack breaks on the tour. If your taste buds still want more—and they will—you get a few complimentary bags to take home. Lucky for me, I was already there. —Brian Barrett

Everett, Washington: 90 minutes; $20 (adults), $14 (age 15 and under)

When you're stuck in the middle seat and the baby behind you is wailing, it's easy to forget what a miracle an airplane is. You won't after visiting Boeing—the largest building in the world, big enough to fit Disneyland with 13 acres to spare—and witnessing 30,000 employees assemble millions of parts and miles of wiring into 747s and other jumbo jets.

10. Chevrolet Corvette

Bowling Green, Kentucky: One hour; $10 (adults), $5 (ages 10 to 16)

So you're buying a Corvette Z06. First off, congratulations. A supercar. You're a lucky man. But why stop there? For an extra five grand you can hop on the assembly line at the Bowling Green factory and help build your 650-hp engine, which gets emblazoned with a plaque commemorating the experience. For those on a budget, $10 gets you the standard factory tour—still thrilling, just no keys at the end.

11. Harley-Davidson

York, Pennsylvania: Two hours; free or $35

There's a free tour, but it keeps you on the periphery of the shop. Pay the $35 for the Steel Toe Tour and you get to walk up and down the aisles, right next to the workers as bike parts are delivered to them, on-demand, by a trolley that follows magnetic tracks in the floor. At the end, the guys put each finished Harley on a dyno machine and steadily bring it up to 77 mph, running the bike through all the gears.

12. Fender Guitars

Corona, California: One hour; $10 (adults), $8 (seniors), $6 (ages 13 to 17), free (ages 12 and under)

The first time I saw a Fender Telecaster up close was in 1979 on the stage of the Hollywood Palladium. I was 14, and Joe Strummer was next to me pounding out the chords to The Clash's "White Riot"—the two of us shouting the lyrics along with a few other teenage punks who had also scrambled onstage during the encore.

Strummer was thousands of miles from his London home that night. But his battered axe? That wondrous machine had been born less than an hour south, in Fullerton, California, where in the early 1950s self-described tinkerer Leo Fender revolutionized the electric guitar. Since that encounter with Strummer, I've seen hundreds of other Fenders—as a music journalist as well as in my short time as a drummer, which included a stint with punk legends Bad Religion. But I didn't fully appreciate their magic until I strapped on a pair of Devo-like safety goggles and took my first tour of the Fender Factory.

It all starts with unremarkable blocks of alder and ash. From this wood, about 400 employees—more than a few aging longhairs among them—shape, sand, seal, and paint the classic Telecaster and more angular Stratocaster bodies. They then fit the necks, attach the wound pickups, and connect the knobs. Finally, each instrument is plugged in to a row of new Fender amps to check the sound quality.

In the summer, crowds for the twice-daily tour average 50 people. On the April morning I visited, there were only six of us, including two middle-aged Swedes. Afterward, browsing a showroom filled with memorabilia of Fender-playing guitar gods, I asked the guys what made them travel all this way. One clearly didn't understand En glish. The other only a little. He smiled, pointed to a poster of Jimi Hendrix, and simply said, "Him." Returning the gesture, I pointed across the room, to a display about punk. The centerpiece: a replica of Strummer's banged-up Telecaster. —John Albert

13. Lodge Cast Iron Manufacturing

South Pittsburg, Tennessee: Last weekend in April, 45 minutes; free

You can't get in while the factory is running—it's way too dangerous—but once a year (during April's National Cornbread Festival, naturally) Lodge opens its doors to tourists. Hard to say what's more amazing: the electromagnet that can lift five tons, the furnace that burns at 2,800 degrees Fahrenheit, or the pouring machine that uses ancient sand-molding techniques to create as many as 8,000 skillets an hour.

14. Wood -Mizer

Batesville, Indiana: 30 minutes; free

I live in rural Indiana, in the north part of a farm county. Out here, the sight of a Wood-Mizer, the industrious portable saw mill, passing by behind a pickup or being towed up onto someone's acreage for a few days of transformative deep-woods lumber milling, is a moment of awe, rare and powerful, like catching sight of a panther or something. In the right conditions, three men and a Wood-Mizer can mill enough lumber to build an entire pole barn or a fishing cabin in just a day. It is a tool of thrift, profit, and creativity. I don't own one—I'm just another fanboy—but I do have a hat. And the logo alone gets me silent nods of respect from farmers who otherwise want nothing to do with me.

I bought the hat after going on the Wood-Mizer factory tour in Batesville, Indiana. (It was cheaper than the sawmill.) The six-month-old plant churns calmly forward, the assembly line formed in the shape of a U. There's no shouting. No rushing. No alarm registered along any of the snug, worker-designed assembly. There's notable focus in the workforce—risen from pride, taken from ownership (the 34-year-old company is entirely worker owned)—that permeates the movement and pace from loading dock to shipping dock. For me, the moment I recognized the familiar machine occurred right in the turn of that U, after the powdered orange paint was kiln-dried onto the steel frame. Then the wheels were attached and the custom motor mounted.

And then I couldn't help myself. "There's the big cat," I exclaimed, like some kid seeing a ballplayer parking his car. The guy on the line heard me. "You gonna build something?" he asked, assuming I was a buyer. I smiled and pointed to my factory-supplied earplugs. "I'm just on a tour," I said, but he couldn't hear me. "Build something great," he said. He was standing over a new Wood-Mizer, so it sounded like a promise. —Tom Chiarella

Nocona, Texas: One hour; $5

When Hall of Fame pitcher Nolan Ryan was seven, his father took him to a hardware store in downtown Alvin, Texas, to buy his first baseball mitt. It was a Nokona. Since 1934, the family-owned company has made gloves the same way: hand-lacing and stitching American rawhide, then beating it to hell with a mallet until the pocket is ready to snag a one-hop grounder.

16. Jelly Belly

Fairfield, California: 40 to 60 minutes; free for the self-guided tour, $47 for a guided tour that takes you on the factory floor

The thousands of jelly beans tumbling in hoppers may sound like bingo balls, only here every one drawn out is a guaranteed winner—except maybe the buttered popcorn. You can taste them at every stage of the tour, but save your appetite. The factory store at the end offers unlimited samples. If you paid for the guided tour, called Jelly Belly University, this is where you make up for your tuition.

17. Tabasco Pepper Sauce

Avery Island, Louisiana: One hour; $5.50

When I was growing up in the Cajun Triangle, any time a relative or college friend came to town, my family trotted out one of three old chestnuts: tours of swamps, plantations, or the Tabasco factory. I always hoped for the peppers—because I am afraid of alligators and ghost stories but mainly because, like all good Louisianans, I am obsessed with hot sauce.

Avery Island is only three miles wide, so most of the growing happens in South America. But this is where the rust-colored mash is packed into old bourbon barrels—about 50,000 are stacked in the warehouse—and left to ferment for three years. When ready, it is mixed with vinegar and aged for another month. Finally, the sauce gets bottled and shipped off to 180 countries.

The smells of the tour are as good as the sights—all that spice mixing with nearby forests of azalea trees. But the best part comes afterward, at the free tasting, when someone inevitably volunteers to try the inferno-level habanero sauce. That someone will always be me. —Katie Macdonald

18. Kenyon's Grist Mill

West Kingston, Rhode Island: July 23 to 24 and October 22 to 23; free

Two giant slabs of granite—each more than 150 years old and weighing more than 2,000 pounds apiece—pulverize whole grain and corn into meal and flour. That's it. A simple, centuries-old process that retains all the nutrients of the original grains and corn. Make sure to bring home some Johnny Cake mix.

Kohler, Wisconsin: Three hours; free

Lowell Kappers, the 80-year-old former Kohler employee who led our tour, worked at the Wisconsin factory, north of Milwaukee, for 44 years—31 of them as a cast-iron grinder. Three decades machining crankshafts and rail-track components. Three decades wearing a respirator helmet to keep pulverized iron dust out of his lungs. He retired in 1999 but still shows up two or three mornings a week to give tours. The factory has been offering them since 1926, a couple of decades before Kappers's dad started working there.

The tour is epic: four buildings, three hours, two and a half miles. You sidestep moving forklifts. You cross beneath conveyors shuttling tubs. You watch molten iron flow. In a cavernous brick loft called the pottery, liquid clay pumped from basement tanks filled plaster-of-paris molds before getting glazed and fired in 2,450-degree industrial kilns. In the enameling shop, an employee in a silver heat shield coated a cast-iron shower floor in enamel powder, then slid it into the orange maw of another kiln.

There are so many kilns. But Kappers didn't break a sweat, despite the heat and constant walking. The only time he really lingered was when we got to the aisle where he had worked, the spot where he jockeyed that heavy grinding wheel all those years.

"Noisiest place in the factory," he said. He wasn't complaining. He was proud. And then he was off again. —Phil Hanrahan

20. R.L. Winston Rod Company

Twin Bridges, Montana: 45 minutes; free

I learned to fly-fish on a fiberglass five-weight that my dad bought at Abercrombie & Fitch in the '60s. With his tongue sticking out in a pose of concentration, he showed me the basic ten and two. Wait for the glass to finish its slow backward flex, wait for the line to unfurl, then launch your forearm forward. Be patient, son.

This was the early '90s. By then, Dad's A&F beauty was a relic. Space-age graphite had made fiberglass obsolete. Trouble was, graphite is much stiffer than glass. Graphite rods cast like rocket launchers, and spooky trout require a delicate approach. Based in Twin Bridges, Montana, at the confluence of three legendary trout rivers, 87-year-old R.L. Winston Rod Company has figured out an alchemy that transforms graphite into velvet. The key ingredient is its staff of 40—roughly 10 percent of the population of Twin Bridges. They secure line guides with hand-wrapped thread. They balance rods by feel and sight alone. They hand-fit the ferrules connecting the rod sections to within one thirty-second of an inch. When customers send in broken rods for repair, Winston rebuilds the damaged segments from scratch.

"We've got a machine for attaching guides that's sitting upstairs collecting dust," said my tour guide, production manager Joe Begin. "We find that our employees are more efficient and make fewer mistakes."

This tireless, meticulous labor accounts for the cost of the rods: ranging from $500 to $3,000. That might sound pricey, especially when a perfectly serviceable rod will run you about $200. But near the end of the tour, I was frantically crunching numbers in my head, trying to figure out how many meals I could skip in the coming month. Fortunately, the gift shop sells only hats and sweatshirts. —Elliott Woods

Seattle, Washington: 30 to 40 minutes; free

One look at the sewing floor and it's easy to see how the garment and bag company that C.C. Filson started in 1897 to outfit Gold Rush prospectors has continued to thrive. Veteran employees, some who've been there 30 years, operate antique treadle machines customized to work with the brand's hallmark rugged twill.

*This article origionally appeared in the July/August 2016 issue of Popular Mechanics.

.css-cuqpxl:before{padding-right:0.3125rem;content:'//';display:inline;} Infrastructure & Transportation .css-xtujxj:before{padding-left:0.3125rem;content:'//';display:inline;}

Inside the Final Minutes of a Horrible Train Wreck

What to Learn From the Baltimore Bridge Collapse

Secret Tunnel in NYC Destabilizes Nearby Property

The Secrets of a 26-Year-Old Medieval Castle

How Laser Lightning Rods Could Save Our Buildings

Christopher Payne's Industrial Photography

What It Took to Build the World’s Largest Sphere

Greek Mythology Impacts Longest Suspension Bridge

The Hubris of Building a City From Scratch

A Fully Autonomous Ship's Perilous Journey at Sea

Everyday Explained: What Happens After You Flush

Admission, Hours, and Directions

Thank you for your interest in visiting the National Museum of Industrial History, a Smithsonian Affiliate . We aim to make your experience as enjoyable as possible. If you don’t find the information you are looking for on this page feel free to reach out to us via email at [email protected] or calling us at 610.694.6644.

Hours: The Museum is open Wednesday through Sunday from 10am to 5pm. The museum will be closed Easter Sunday, Thanksgiving, Christmas Eve, Christmas Day, and New Year’s Day.

Tickets: Tickets are available at the admission desk inside the museum or online here . Children (6 and younger): Free Youth (7 to 17): $10 Students: $10 Veterans/Educators/Seniors (65 and older): $12 Adults (18 to 64): $15

Combo tickets for NMIH & Unspun: Stories of Silk exhibit are available here . With this ticket you will be able to follow the stories of the silk through the Kemerer Museum of Decorative Arts (427 N New Street), the Moravian Museum of Bethlehem (66 W Church Street), and the National Museum of Industrial History (602 E 2nd Street).

Special Discount Days: Senior Days: Every first Wednesday of the month, half price tickets for all senior citizens age 65 and older. Student Days: first Thursday of each month will feature half price tickets for students Family Sundays: free admission to all children under 12 years old when accompanied by a paying adult. Adult admission is $15.

Group Discounts: For more information on visiting NMIH with your group, please see our Group Tours page .

Group Guided Tours Group guided tours are available for a $30 docent fee plus individual admission for a group of up to 20 people. If the group is larger than 20 people, additional docents are $30 per additional 20 visitors. Group guided tours are available during or after business hours and must be reserved ahead of time by contacting the Guest Services Manager, Shannon Morris, at 610.694.6644 or [email protected] . Please see our Group Tours page .

Steelworkers’ Archives Tours

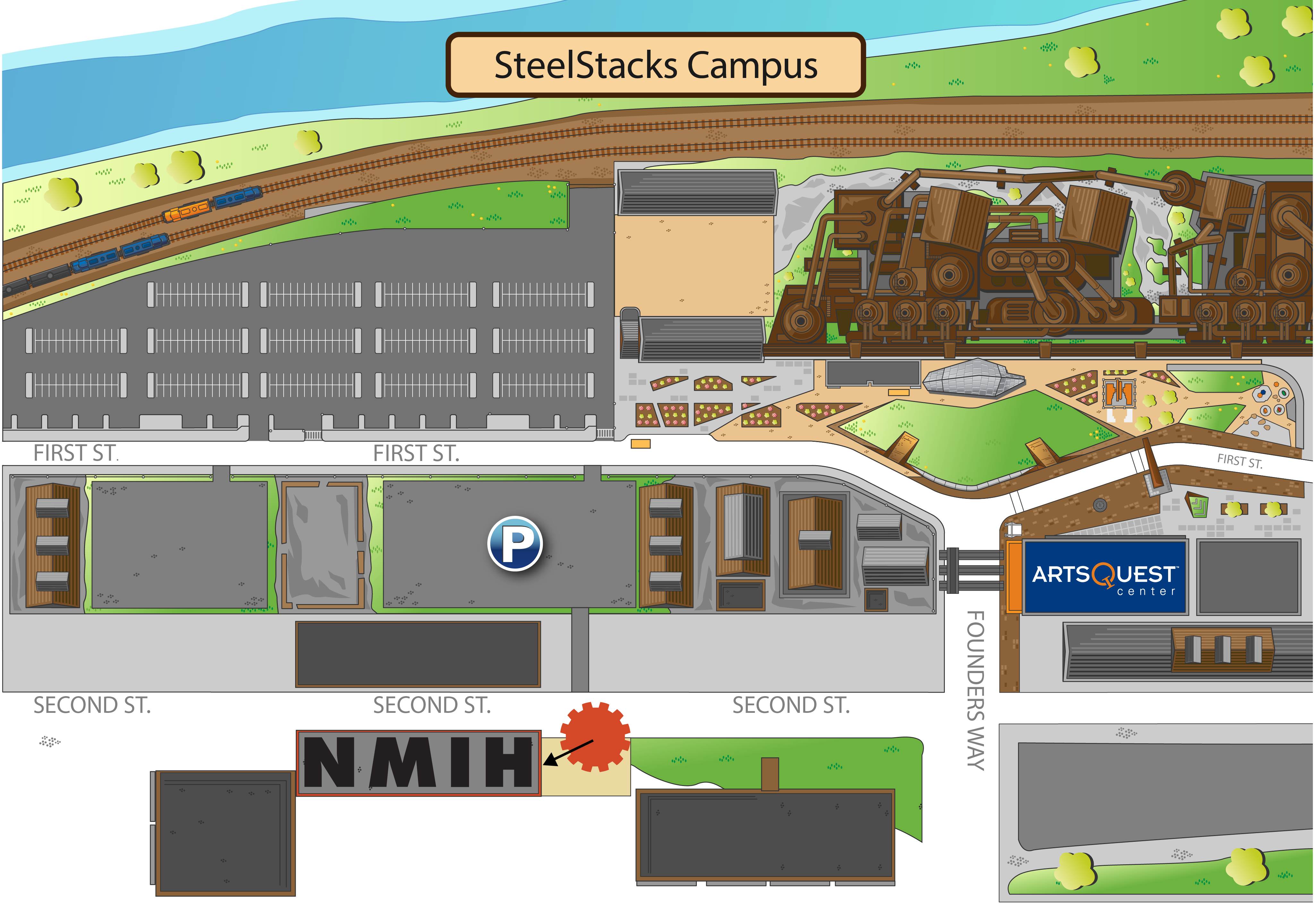

Every Saturday and Sunday from April through December, former steelworkers will lead sidewalk and Hoover-Mason Trestle tours through the Bethlehem Steel plant site. The tours start at 11:30 AM, rain or shine, and leave from the plaza outside the National Museum of History (NMIH), 602 E. Second Street, Bethlehem. Free parking is available in the lot across the street from the museum.

The steelworker guides will take guests on a multi-faceted journey – from the evolution of iron making in the Lehigh Valley to the history of the Bethlehem Plant from its opening to closing, including its importance in World Wars I and II. Along the way, guests will learn about the remaining buildings on the plant site, life in the ethnic neighborhoods surrounding the plant, and what life was like working at the plant. The 1+ hour tour concludes with a question and answer session.

Tickets are $15 per person and free for ages 12 and under. Scheduling is available online only at this time. Tickets may also be purchased in person at the NMIH admission desk. For more information, contact the Steelworkers’ Archives at 610-861-0600.

Also, contact the Steelworkers’ Archives if you are interested in a private group tour. All Sales Are Final – no refunds or exchanges.

Self Guided Mobile Tours Enhance your experience with one of our self-guided tours of the museum or SteelStacks campus using your own phone or device. Inquire at our admission desk for details.

- The Changing Landscape of Bethlehem Steel ($5 per person ) Travel back in time on this self-guided walking tour of the historic Bethlehem Steel Plant! Explore the different phases of the plant as Bethlehem Steel grew from a local iron company to become an international steel titan. This mobile tour provides you with a glimpse into the past with never-before-seen images from the museum’s archival collection.

- Express Museum Tour (included with admission)

- In-Depth Museum Tour (included with admission)

- Young Innovator’s Tour (included with admission)

- Foundry Park Tour (included with admission)

Address: 602 E 2nd St Bethlehem, PA 18015

Parking: Please refer to the map below for museum parking.

Nucor Steel Plant Tour

Description.

- Reviews (0)

1 session December 9th 1pm – 3pm

From the frying pan and into the fire! Get an up close and personal rare view of molten steel being produced. Tour takes up to 21/2 hours. Tour starts at 1pm meet up at the guard shack 10″ before. Late comers may be turned back….don’t be late. First 15 to sign up get the slots.

· Everyone must be over 18 years old for insurance reasons. Unfortunately, there are no exceptions.

· Please wear long pants (no shorts or skirts) and flat-bottomed, closed-toe, sturdy shoes with socks (no sandals, heels, etc.). We provide hardhats, safety glasses, overcoats, and earplugs.

· The tour takes 1.5 – 2 hours. In order to finish on time, please try to arrive 10 minutes or so early to get signed in.

· There are no bags or purses permitted inside the plant. These items should be left in your car or can be checked in at our security office.

· There are no pictures or video recording permitted on the tour.

· The tour requires over a mile of walking and ascending and descending several sets of stairs. We ask that everyone please consider if they are able to do this comfortably ahead of time.

· Visitors will be asked to present picture ID when signing in. Please make sure to bring this with you. Directions to the plant are included below. If you would like directions to the plant from another direction, please let me know.

Directions to Nucor Steel Seattle: 1. Our plant address is 2424 SW Andover St. Seattle, WA 98106. If you are coming via West Seattle Bridge, take the 1st exit on right after crossing bridge(Delridge Way). Exit spits into two options, stay towards the left side and merge onto Delridge Way. Turn right at the 1st stoplight (SW Andover St.). Our driveway is a few hundred feet down on the right after the intersection. Turn into our driveway and continue straight past the plant entrance until the driveway opens up into a parking lot. There are visitor spots on the left, but feel free to park anywhere and walk back to the main plant entrance and check in at the security building next to the scale.

There are no reviews yet.

Your email address will not be published. Required fields are marked *

Your review *

Name *

Email *

Save my name, email, and website in this browser for the next time I comment.

- Raw Materials

- Mould Making

- Flat Making

- Backstamping

- Finished Product

- Distribution

Harley-Davidson Factory Tour

Witness passion forged in steel. Riders call our motorcycles legendary. When you take the H-D factory tour, you’ll see just how legends are made.

Established as an assembly facility in 1973, Harley-Davidson Vehicle Operations in York, PA, assembles the Touring, Softail®, CVO™ and Trike models. They also perform a variety of manufacturing operations – making parts like frames, fuel tanks, and fenders.

At the Vaughn L. Beals Tour Center, you'll explore exhibits that detail the manufacturing and assembly processes of the factory. You'll also have the chance to sit on current production motorcycles and visit the gift shop for tour-related souvenirs. The Kids Corner, a specially designed area for visitors under the age of 12, makes the York facility an ideal family destination.

Your factory tour begins with an introductory video and continues on the factory floor where you'll get a behind-the-scenes look at the people, processes, and products of Vehicle Operations. You'll be guided through the manufacturing of key components and the assembly of Softail, Touring, CVO, and Trike motorcycles. Then it’s on to the end of the line, where every motorcycle is roll-tested prior to shipping.

Over the years, thousands of Harley-Davidson enthusiasts have made the journey to York, Pennsylvania, to witness passion forged in steel.

The free factory tour offers a limited view of the assembly line and designated fabrication areas. Tours last approximately one hour. Free tours begin at regular intervals between the hours of 9am – 2pm Monday through Friday. Tickets are distributed on a first-come, first-served basis for each day’s available tours. It is recommended that you arrive early in the day. Tours are not offered on weekends, major holidays, or during production changes and year-end maintenance. Tour schedule and route are subject to change. Reservations for 10 or more are required.

The Steel Toe Tour gives you a chance to experience Harley-Davidson history and get up close and personal with the Softail,® Touring, Trike, and CVO™ model families. The tour route has been expanded for smaller groups to provide a more personalized tour experience. The Steel Toe Tour takes you through the manufacturing of fuel tanks, frames, and fenders, as well as many employee-only areas in paint and polish.

The Steel Toe Tour goes behind-the-scenes through areas previously unseen by the public. You will be required to wear a safety vest, safety glasses, and steel toe protection, all of which are provided.

Steel Toe Tour Admission Includes:

- One tour ticket

- Commemorative pin

- Group photo

- Safety vest

- One $5 coupon, redeemable in our Gift Shop

Two sessions are offered daily Monday through Friday at 9:30am and noon. Other sessions are added to accommodate peak times. Duration for each tour is approximately two hours. Tour schedule and route are subject to change. Tours sell out quickly. Call 877-883-1450 to reserve your tour. All ticket sales are final and non-refundable.

For more information, visit their website

We use cookies to ensure that we give you the best experience on our website. If you continue to use our website, we will assume that you are happy to receive all cookies (and milk!) from visitPA.com. Learn more about cookie data in our Privacy Policy

Special Deal on Local Flavor: $20 for 2 Adult Multi-Site Museum Passes. Click here for more information !

Walk through history as we guide you to things to learn, places to discover, and events that help connect us to our rich heritage.

- Museums & Sites

- Historic Bethlehem Tours

- Happening This Week

- Coming Soon – Schropp Shoppe

- Group Tours

- Signature Events

- Wedding & Celebration Venues

- Map: Historic Bethlehem

- Directions / Parking

- Professional Photography Permit

- Visit Us FAQs

Unspun: Stories of Silk

Event Series

Discover the stories behind where we came from, how we arrived here, and what we are doing now to serve our community.

- Exhibitions

- Collections

- Culture Connect

Design Your Own Marvelous Miniature Camp

Get to know more about HBMS — dedicated to telling the stories of Bethlehem's past and its lasting impact on our community.

Mission / Vision

- Board of Trustees

- Diversity / Inclusion

- Annual Report

- Press Releases

- Careers / Internships

- About Us FAQs

Find out why our city is The Christmas City while planning your scenic downtown visit and warming to our holiday traditions.

- Christmas Sweets & Treats

- Bethlehem By Night Motorcoach Tour

- Horse-Drawn Carriage Rides

- Christmas City Stroll

- Holiday Wassail Party

- Spirits of Christmas Pub Walking Tour

- Trees of Historic Bethlehem: The Finer Things

- Christmas Events

Live Advent Calendar

- Christmas FAQs

World Heritage

Review updates and progress on Historic Bethlehem’s initiative to grow closer to our World Heritage nomination.

World Heritage Update

- The Journey to World Heritage Site Status

- Video: One Step Closer

- Top 10 Things to Know

- Historic Moravian Bethlehem Story

- Resources & Links

- World Heritage FAQs

Join / Support

Work with us and share in our mission to keep our history alive while building our future together.

- Corporate Giving

- Taking the World Stage Capital Campaign

- Join / Support FAQs

Become a Member Today!

Membership Information

Rise and Fall of Bethlehem Steel Walking Tour

Bethlehem Steel, once the 2nd largest steel producer in the country, helped build some of America's greatest landmarks.

Visitor Center Hours

Closed Today

Rise and Fall of Bethlehem Steel Walking Tour Overview

On the Rise and Fall of Bethlehem Steel Walking Tour learn about Bethlehem Steel which was once the second largest steel producer in the country, helped build some of America’s greatest landmarks — including the Golden Gate Bridge and the Chrysler Building. Discover the humble beginnings, monumental growth, and humbling decline of this 20th-century giant.

The 90-minute walking tour features up-close views of the former steel plant and an in-depth look at the steel-making process and the roles the workers played in our country’s history.

Note: The Hoover Mason Trestle is closed due to snow/ice until further notice.

Rise and Fall of Bethlehem Steel Walking Tour Dates

No dates on the calendar? The Rise and Fall of Bethlehem Steel Walking Tour will return soon. Look for times and dates in the coming days. Can’t wait? Book your Custom Tour today!

Views Navigation

Event views navigation, rise and fall of bethlehem steel tour $30.

- Google Calendar

- Outlook 365

- Outlook Live

- Export .ics file

- Export Outlook .ics file

Our Partners

Visitor Center

505 Main Street Bethlehem, PA 18018

Today's Hours Closed Today

610-691-6055 1-800-360-TOUR

Administrative Office

74 West Broad Street, Suite 310 Bethlehem, PA 18018

610-882-0450

Connect With Us

Translate the Historic Bethlehem Museums & Sites website into your language of choice!

Site Search

Search our website to find what you’re looking for.

Select Your Language

You can select the language displayed on our website. Click the drop-down menu below and make your selection.

Henry Ford's Rouge

Henry Ford’s ultimate goal was to achieve total self-sufficiency by owning, operating and coordinating all the resources needed to produce complete automobiles. His Ford Motor Company once owned 700,000 acres of forest, iron mines and limestone quarries in northern Michigan, Minnesota and Wisconsin. Ford mines covered thousands of acres of coal-rich land in Kentucky, West Virginia and Pennsylvania. Ford even purchased and operated a rubber plantation in Brazil. To bring all these materials to the Rouge, Ford operated a fleet of ore freighters and an entire regional railroad company. Ford’s ambition was never completely realized, but no one has ever come so close on such a grand scale. At no time, for example, did Ford have fewer than 6,000 suppliers serving the Rouge.

The Rouge Fires Up

Ford began buying the property that was to become the Rouge in 1915. In total, he acquired a 2,000-acre stretch of bottomland along the Rouge River. The Rouge River property still was not earmarked for any particular use. Ford had even considered turning the land into a large bird sanctuary. That changed near the end of World War I, when Undersecretary of the Navy Franklin D. Roosevelt engaged Henry Ford to build boats.

In 1917, a three-story structure, Building B, was erected on the Rouge site to build Eagle Boats, warships intended to hunt down German submarines. Building B was the first substantial Rouge building and today serves as part of the Dearborn Assembly Plant. Although the war ended before the Ford Eagle Boats ever went into action, the effort did allow Ford to widen the Rouge River substantially, presenting the possibility of bringing ore boats up the river.

The Rouge soon became the destination of massive Ford lake freighters filled with iron ore, coal, and limestone. The first coke oven battery went into operation in October of 1919, while blast furnaces were added in 1920 and 1922. Iron from the furnaces was transported directly to the foundry where it was poured into molds to make engine blocks, cylinder heads, intake and exhaust manifolds, and other automotive parts. The foundry covered 30 acres and was, at its inception, the largest on Earth. In 1926 steelmaking furnaces and rolling mills were added. Eventually, the Rouge produced virtually every Model T component, but assembly of the Model T remained at Highland Park.

The First Vehicle Assembly

The first land vehicles actually assembled in the Rouge were not cars but farm tractors. No sooner had Henry Ford achieved low-cost transportation with the Model T than he set his sights on doing the same for the world’s farmers. In 1921 production of the world's first mass-produced tractor, the Fordson, was transferred from the original Dearborn plant to the Rouge.

Ford put a mammoth power plant into operation in 1920 that furnished all the Rouge's electricity and one-third of the Highland Park Plant's needs as well. At times, surplus Rouge power was even sold to Detroit Edison Company. An innovative glass plant began operation in 1923. Utilizing a continuous process that Ford had helped develop, it produced higher quality glass at lower cost. In 1928 the Model A became the first low-priced car to use laminated safety glass. By 1930 the Ford was making its own safety glass at the Rouge.

The Rouge achieved the distinction of automotive "ore to assembly" in 1927 with the long-awaited introduction of the Model A. Building B would be the home of assembly operations from that time forth.

Albert Kahn Design

Unionization & United Auto Workers

By 1928, the complex was complete, yet it was never settled. The Rouge continued to operate throughout the Great Depression, yet Ford’s obsession with ever-increasing cost reductions through methodical efficiency studies made life difficult for workers. On May 26, 1937, when a group of union organizers led by Walter Reuther attempted to distribute union literature at the Rouge, Ford security and a gang of hired thugs beat them severely. It would be known as the Battle of the Overpass and became a pivotal event for the United Auto Workers and other unions.

The Rouge settled with UAW representation before World War II broke out. During the war the giant complex produced jeeps, amphibious vehicles, parts for tanks and tank engines, and aircraft engines used in fighter planes and medium bombers.

The Rouge after Henry Ford

In 1947, at the pinnacle of the Rouge’s success, Henry Ford died. The roar of the Rouge began to fade as Ford Motor Company embarked on a new era that stressed decentralization and a more global approach.

Henry Ford II and his new team of "Whiz Kid" managers continued to fully employ the Rouge through the late 1960s, operating in a distinctly different world from Henry Ford. For one, there was a growing awareness of the environment. In the early days of American industrialization, smoke rising from a stack was a positive sign of full employment. As industry matured, government and manufacturers alike became aware that black smoke had other implications.

Air and water quality standards were developed by government agencies. More manufacturing facilities located within a community, accumulatively adding to emissions, meant more stringent controls. This, in part, led to closure of some older facilities. The Rouge, the largest single industrial complex in the world, probably would be the last of its kind.

Decentralization

The company grew to rely more and more on an ever-increasing cadre of suppliers and to methodically extract itself from other fields such as mining, lumbering and glass making. In 1981, steel-making operations at the Rouge became part of a new independent company. When these operations were sold to Rouge Steel in 1989, Ford gave up ownership of all Rouge River frontage and boat docks, as well as about 45 percent of the original 2,000 acres. Over time, the number of operations and jobs at the Rouge dropped. Economic pressures mounted to retire old brownfield manufacturing facilities and to replace them with state-of-the-art greenfield plants.

The Rouge, however, had evolved into a community with a strong sense of its own identity. Families worked from generation to generation in the Rouge, and few were willing to walk away from their hard-earned heritage. That fact became clear in 1992 when the only car still built at the Rouge, the Ford Mustang, was about to be eliminated and assembly operations in Dearborn Assembly terminated.

UAW Local 600, in cooperation with Alex Trotman, then president of Ford’s North American Operations, set out to keep the Mustang in production and to keep production in the Rouge. "Save the Mustang" became synonymous with "Save the Rouge." Working together, the company and the UAW established a modern operating agreement and fostered numerous innovations to increase efficiency and quality. The company, for its part, would redesign and reintroduce the Mustang, and invest in modern equipment.

The Rouge Enters the New Millennium

In 1997, the Rouge was making a comeback. UAW Local 600 membership and the company approved the Rouge Viability Agreement, and the Ford Board of Directors agreed to modernize the company’s oldest and largest manufacturing complex. The first efforts focused on extensive renovations to the Dearborn Engine and Fuel Tank Plant and other plants at the Rouge. Dearborn Assembly Plant would get an environmentally advanced paint operation, and plans called for CMS Energy to develop an entirely new power plant by 2000. Ground was already being cleared for the new high-efficiency power plant when tragedy struck. The Number Six boiler at the Rouge Power Plant exploded and six employees were killed. A dozen more were seriously injured.

Within two hours of the explosion, Ford Chairman and CEO Bill Ford arrived at the scene, offering whatever support he could. "Our employees are like extended members of our family," Ford said, "My heart sank. It’s about the worst feeling you could ever have."

The Rouge entered the new millennium humbled by disaster and downsizing, yet still an industrial giant. About 6,000 Ford employees work at the Rouge. Now called the Ford Rouge Center, the 600-acre site remains Ford Motor Company’s largest single industrial complex. And a massive revitalization effort is under way to restore this icon’s glory.

Learn more:

- Reinventing the Rouge

- The Ford Rouge Factory Timeline

- An Introduction to the History of the Ford Rouge Factory

Attractions

Visit, learn, and experience all five of the Rivers of Steel attractions that showcase the artistry and innovation of southwestern Pennsylvania’s rich heritage.

- Carrie Blast Furnaces

Towering 92 feet over the Monongahela River, constructed of 2.5″ thick steel plate and lined with refractory brick, Carrie Furnaces #6 and #7 are extremely rare examples of pre-World War II iron-making technology.

- Explorer Riverboat

Docked on Pittsburgh’s North Shore, near the headwaters of the Ohio River, an excursion on Explorer offers unparalleled opportunities to experience the beauty and history of Pittsburgh from its majestic rivers.

The Bost Building

A National Historic Landmark, the Bost Building serves as the Visitors’ Center for the Rivers of Steel National Heritage Area and offers exhibits on the region’s industrial and cultural heritage.

The Pump House

Once part of the U.S. Steel Homestead Works, the Pump House’s origins date back to 1892 when it was built by the Carnegie Steel Company. That same year it was the site of the Battle of Homestead, a defining moment in the nation’s labor history.

W.A. Young & Sons Foundry & Machine Shop

Built in 1900, the shop produced parts for steamboats, coal mines, railroads, and for local businesses. When it closed in 1965 the building was locked, leaving all of its tools, equipment, and machinery in place – a perfectly preserved representation of the transition from the 1800s village blacksmith to the large machine shops of the 1900s.

Learn more about the events

Rivers of Steel The Bost Building 623 E. Eighth Avenue Homestead, PA 15120

Tel: 412.464.4020 Fax: 412.464.4417

Get the Latest

Sign up to hear all about upcoming events and recent news from Rivers of Steel.

Example: Yes, I would like to receive emails from Rivers of Steel. (You can unsubscribe anytime)

© 2024 Rivers of Steel.

- Industrial Tour

- Uniquely Pittsburgh Sightseeing Tour

- The Black Experience at the Carrie Furnaces

- Arts & Grounds Tour of the Carrie Blast Furnaces

- Guided Machine Shop Tours

- The Hardest Working River Tour

- Graffiti Arts

- Photo Safaris

- Professional Development

- Team-Building

- Exhibitions at the Bost Building

- Alloy Pittsburgh

- Gledaj! The Gaze of Maxo Vanka

- In the Wide View

- Mini Greens 2

- Festival of Combustion

- Hammer-In Blacksmithing Festival

- Film Premiere: The Ruins Project

- Bost Building

- W.A. Young & Sons Foundry and Machine Shop

- Industrial Grit and Graffiti

- Exhibitions

- Mon Valley Creative Corridor

- Student Programs on the Explorer Riverboat

- Student Programs at the Carrie Blast Furnaces

- Residency and Outreach Programs

- Virtual Education Programs

- Heritage Sites

- Preservation Projects

- Thing to do in the Heritage Area

- Rivers of Steel Heritage Tours

- Outdoor Recreation

- Community Partnerships

- Mini-Grant Funding Opportunity

- About the Heritage Area

- Event Spaces

- +91 8928274974

- [email protected]

- Buttweld Fittings

Pipe Fittings

Forged Fittings

- +91 22 6651 8564

- Factory Tour

- Retail & Consumer

- Sciences & Healthcare

- Industrial & Chemical

- Power Generation

- Food & Beverage

- Socket Weld Fittings

- Threaded Fittings

- Stainless Steel

- Duplex Steel

- Nickel Alloy

- Carbon Steel

WhatsApp us

Sen. Manchin Tours Construction Progress at Form Energy’s Weirton Plant

WEIRTON, W.Va. –

Thursday, Senator Joe Manchin (D-WV), Chairman of the U.S. Senate Energy and Natural Resources Committee, joined Form Energy’s leadership to tour the company’s new iron air battery manufacturing plant, Form Factory 1, which is under construction in Weirton, West Virginia.

Form broke ground on Form Factory 1 — its first factory in West Virginia and the company’s first high-volume battery manufacturing plant — in May 2023.

The speed and scale of construction progress on Form Factory 1 in West Virginia has been accelerated by the passing of the Inflation Reduction Act (IRA), an energy security law designed to incentivize domestic manufacturing and drive energy innovation. The IRA will help ensure that Weirton and West Virginia remain on the cutting-edge of the energy technologies of the future for years to come.

Form Factory 1 is being constructed on a site that previously housed the Weirton Steel Mill. In less than a year, Form Energy has nearly completed building construction, started landing manufacturing equipment inside and begun hiring and training its manufacturing workforce. When operating at full capacity, the factory will employ at least 750 workers in Weirton with good-paying jobs. The manufacturing facility represents a total direct investment of $760 million in Weirton, inclusive of an incentive package of $290 million from the State of West Virginia.

A historic steel community, Weirton is located on the Ohio River with direct access to rail, river and highway infrastructure that will enable Form Energy to transport West Virginia-made batteries across the nation. Form Energy selected Weirton as the home of its first factory after a robust, year-long, nationwide site selection process that included reviewing over 500 candidate locations across 16 states. The company ultimately chose a 55-acre site in Weirton because of the existing transportation infrastructure and the historic steel community’s strong talent base.

“It feels like just yesterday we were gathered here to break ground on this major investment in the Mountain State and seeing the progress today has filled me with tremendous pride and hope for our great state. For generations, West Virginians have done the heavy lifting. We’ve mined the coal that forged the steel that built the tanks and ships that allowed our country to become the greatest industrial might the world has ever known — and soon we can add batteries to that list. The West Virginians who will work in this facility will once again be stepping up to the plate and building on our legacy as America’s energy powerhouse, something all of West Virginia can be proud of,” said Manchin.

Mateo Jaramillo, CEO and Co-Founder of Form Energy, said, “We would not be where we are today – with eager customers waiting for our iron-air batteries, Form Factory 1 well under construction in Weirton, and already hiring for our manufacturing team – without the fantastic leadership of Senator Manchin and other federal, state, and local champions of Weirton. For so many decades, Weirton was the heart of iron and steelmaking in this country, enabling America to become a manufacturing powerhouse. We are so proud to now be building our first factory, and our first iron-air batteries, here in Weirton. Our hope is that Form Factory 1 will help place Weirton at the center of America’s new manufacturing boom, and America’s energy future.”

For the latest news, weather, sports, and streaming video, head to WTRF.

We've detected unusual activity from your computer network

To continue, please click the box below to let us know you're not a robot.

Why did this happen?

Please make sure your browser supports JavaScript and cookies and that you are not blocking them from loading. For more information you can review our Terms of Service and Cookie Policy .

For inquiries related to this message please contact our support team and provide the reference ID below.

IMAGES

VIDEO

COMMENTS

Hardest Working River Tour. Journey with Rivers of Steel up the Monongahela River and hear the stories about how this mighty river helped to shape Pittsburgh's early commercial and industrial success, helping to define the city we have today. The Hardest Working River Tour is a special tour offered several times in the spring season and again ...

The tour includes spectacular views of massive steel furnaces and great historical background. Our guide was a former steelworker and he shared his personal experiences working over 20 years at the mill. This was a great way to learn about the history of Bethlehem Steel and steel's role in US history. Read more.

Carrie Blast Furnaces. Towering 92 feet over the Monongahela River, constructed of 2.5″ thick steel plate and lined with refractory brick, Carrie Furnaces #6 and #7 are extremely rare examples of pre-World War II iron-making technology. Since the collapse of the region's big steel industry in the 1970s and 1980s, these are the only non ...

Rivers of Steel is a nonprofit that manages the Rivers of Steel National Heritage Area, an eight-country region in southwestern Pennsylvania linked by a shared cultural and industrial heritage. Rivers of Steel actively promotes education and heritage tourism through its attractions and programs, including tours of the Carrie Blast Furnaces ...

Carrie Furnace is the only example of a pre-World War 2 iron furnace left in Pittsburgh. Pittsburgh is known as "The Steel City," and for good reason. At its peak in 1910, the steel industry in Pittsburgh produced more than 60% of the total production in the US. The peak period of production at Carrie Blast Furnace was in the 1950s and ...

Rivers of Steel's attractions showcase the artistry and innovation of southwestern Pennsylvania's rich heritage. Hop on Rivers of Steel's Explorer riverboat for the Uniquely Pittsburgh Sightseeing Tour, a 90-minute sightseeing cruise of Pittsburgh's three rivers that seeks to answer the question "What makes Pittsburgh, Pittsburgh?"This tour shares the big stories of our region's past ...

The Carrie Furnaces are located southeast of Pittsburgh just outside of Rankin, PA. Tours are available during the summer months on Saturdays and Sundays and require advanced reservations. For those who want more, be sure to head over to Homestead after your tour to explore more historic sites associated with the steel industry, such as the ...

Philadelphia, Pennsylvania (Also Denver, Colorado): 45 minutes; free. View full post on Youtube. From a 40-foot observation deck you'll see coins—tens of millions each day—sliced from metal ...

Top 10 Best Factory Tours in Pittsburgh, PA - April 2024 - Yelp - Rivers of Steel:Carrie Blast Furnaces National Historic Landmark, Sarris Candies, Senator John Heinz History Center, The Pittsburgh Tour Company, Mattress Factory Art Museum, The Andy Warhol Museum, Duquesne Incline, Applelicious, Mon Aimee Chocolat, Jean-Marc Chatellier's French Bakery

Please see our Group Tours page. Steelworkers' Archives Tours. Every Saturday and Sunday from April through December, former steelworkers will lead sidewalk and Hoover-Mason Trestle tours through the Bethlehem Steel plant site. The tours start at 11:30 AM, rain or shine, and leave from the plaza outside the National Museum of History (NMIH ...

Bethlehem, PA, April 14, 2023 - The "Steelwalker' tours are back! Come take a multi-faceted journey led by former steelworkers on a sidewalk and Hoover-Mason Trestle tour through the former Bethlehem Steel plant site. Tours are available every Saturday and Sunday, from now to July 29, 2023. Tickets are priced at $15 per person (free for ...

Description. 1 session December 9th 1pm - 3pm. From the frying pan and into the fire! Get an up close and personal rare view of molten steel being produced. Tour takes up to 21/2 hours. Tour starts at 1pm meet up at the guard shack 10″ before. Late comers may be turned back….don't be late.

Dates: Friday - Saturday - Sunday 1 p.m. Adult 18+: $20. Child 7-17: $12. Tour begins outside the SteelStacks Visitor Center, 711 East First Street, Bethlehem, PA 18015. Combination tickets with National Museum of Industrial History can be used during their open hours. Value Ticket with National Museum of History.

A vestige of Pittsburgh's 20th-century domination of the steel industry. The Bost Building serves as the Visitors' Center for the Rivers of Steel National Heritage Area and offers exhibits on the region's industrial and cultural heritage. Rivers of Steel showcases southwestern PA's industrial and cultural heritage by fostering dynamic ...

Steelite Factory Tour. Open Fullscreen. Back

Witness passion forged in steel. Riders call our motorcycles legendary. When you take the H-D factory tour, you'll see just how legends are made. Established as an assembly facility in 1973, Harley-Davidson Vehicle Operations in York, PA, assembles the Touring, Softail®, CVO™ and Trike models. They also perform a variety of manufacturing operations - making parts like frames, fuel tanks ...

711 First Street, Bethlehem, PA 18020. Guests should meet the tour guide at the ArtsQuest Visitor Center at 10:30 a.m. If the building is closed, the guide will meet outside of the building. Bethlehem Steel, once the 2nd largest steel producer in the country, helped build some of America's greatest landmarks, including the Golden Gate Bridge ...

Discover the humble beginnings, monumental growth, and humbling decline of this 20th-century giant. The 90-minute walking tour features up-close views of the former steel plant and an in-depth look at the steel-making process and the roles the workers played in our country's history. Note: The Hoover Mason Trestle is closed due to snow/ice ...

In 1981, steel-making operations at the Rouge became part of a new independent company. When these operations were sold to Rouge Steel in 1989, Ford gave up ownership of all Rouge River frontage and boat docks, as well as about 45 percent of the original 2,000 acres. Over time, the number of operations and jobs at the Rouge dropped.

Steel in transition. Steel production is changing. thyssenkrupp Steel has set off - towards climate-neutral steel production. With the technological change, the plant of Germany's largest flat steel manufacturer is changing. We invite you to witness the transformation on a plant tour over the factory premises in the north of Duisburg.

Visit, learn, and experience all five of the Rivers of Steel attractions that showcase the artistry and innovation of southwestern Pennsylvania's rich heritage. Carrie Blast Furnaces Towering 92 feet over the Monongahela River, constructed of 2.5″ thick steel plate and lined with refractory brick, Carrie Furnaces #6 and #7 are extremely ...

47, Navnidhi Bhavan, Ground Floor, Shop No. 2, 5th Kumbharwada Lane, Near Moti Cinema, Mumbai 400 004, India. Mail: [email protected] [email protected] Fax: +91 22 2389 2178

Form Factory 1 is being constructed on a site that previously housed the Weirton Steel Mill. In less than a year, Form Energy has nearly completed building construction, started landing ...