- Free Practice Tests

Commercial Driving

- Introduction

Getting a CDL

- Fees and costs

CDL Types & Permits

Endorsements & Restrictions

CDL Exam Preparation

Written exams

Practical exams

- Skills test

- Pre-trip inspection

- TSA background check

- Retake policy

CDL Maintenance

ELDT Training & Certification

CDL how-to guides

Mastering the CDL Pre-Trip Inspection Exam: A Complete Guide

Learn how to conduct thorough pre-trip inspections with our guide, a critical component for commercial vehicle safety.

Written by Andrei Zakhareuski. With over 16 years of expertise, Andrei leads Driving-Tests.org, a top online resource for driver education. His leadership has established vital partnerships with over 2,600 libraries, educational bodies, and state agencies.

The CDL Pre-Trip Inspection Exam is an integral part of obtaining your commercial driver’s license. This guide covers Class A and Class B pre-trip inspections, provides a checklist, and offers tips for memorizing the inspection process.

Start a free Pre-Trip Inspection practice test:

- Alabama - AL - Alabama Pre-Trip Inspection Practice Test

- Alaska - AK - Alaska Pre-Trip Inspection Practice Test

- Arizona - AZ - Arizona Pre-Trip Inspection Practice Test

- Arkansas - AR - Arkansas Pre-Trip Inspection Practice Test

- California - CA - California Pre-Trip Inspection Practice Test

- Colorado - CO - Colorado Pre-Trip Inspection Practice Test

- Connecticut - CT - Connecticut Pre-Trip Inspection Practice Test

- Delaware - DE - Delaware Pre-Trip Inspection Practice Test

- District of Columbia - DC - District of Columbia Pre-Trip Inspection Practice Test

- Florida - FL - Florida Pre-Trip Inspection Practice Test

- Georgia - GA - Georgia Pre-Trip Inspection Practice Test

- Hawaii - HI - Hawaii Pre-Trip Inspection Practice Test

- Idaho - ID - Idaho Pre-Trip Inspection Practice Test

- Illinois - IL - Illinois Pre-Trip Inspection Practice Test

- Indiana - IN - Indiana Pre-Trip Inspection Practice Test

- Iowa - IA - Iowa Pre-Trip Inspection Practice Test

- Kansas - KS - Kansas Pre-Trip Inspection Practice Test

- Kentucky - KY - Kentucky Pre-Trip Inspection Practice Test

- Louisiana - LA - Louisiana Pre-Trip Inspection Practice Test

- Maine - ME - Maine Pre-Trip Inspection Practice Test

- Maryland - MD - Maryland Pre-Trip Inspection Practice Test

- Massachusetts - MA - Massachusetts Pre-Trip Inspection Practice Test

- Michigan - MI - Michigan Pre-Trip Inspection Practice Test

- Minnesota - MN - Minnesota Pre-Trip Inspection Practice Test

- Mississippi - MS - Mississippi Pre-Trip Inspection Practice Test

- Missouri - MO - Missouri Pre-Trip Inspection Practice Test

- Montana - MT - Montana Pre-Trip Inspection Practice Test

- Nebraska - NE - Nebraska Pre-Trip Inspection Practice Test

- Nevada - NV - Nevada Pre-Trip Inspection Practice Test

- New Hampshire - NH - New Hampshire Pre-Trip Inspection Practice Test

- New Jersey - NJ - New Jersey Pre-Trip Inspection Practice Test

- New Mexico - NM - New Mexico Pre-Trip Inspection Practice Test

- New York - NY - New York Pre-Trip Inspection Practice Test

- North Carolina - NC - North Carolina Pre-Trip Inspection Practice Test

- North Dakota - ND - North Dakota Pre-Trip Inspection Practice Test

- Ohio - OH - Ohio Pre-Trip Inspection Practice Test

- Oklahoma - OK - Oklahoma Pre-Trip Inspection Practice Test

- Oregon - OR - Oregon Pre-Trip Inspection Practice Test

- Pennsylvania - PA - Pennsylvania Pre-Trip Inspection Practice Test

- Rhode Island - RI - Rhode Island Pre-Trip Inspection Practice Test

- South Carolina - SC - South Carolina Pre-Trip Inspection Practice Test

- South Dakota - SD - South Dakota Pre-Trip Inspection Practice Test

- Tennessee - TN - Tennessee Pre-Trip Inspection Practice Test

- Texas - TX - Texas Pre-Trip Inspection Practice Test

- Utah - UT - Utah Pre-Trip Inspection Practice Test

- Vermont - VT - Vermont Pre-Trip Inspection Practice Test

- Virginia - VA - Virginia Pre-Trip Inspection Practice Test

- Washington - WA - Washington Pre-Trip Inspection Practice Test

- West Virginia - WV - West Virginia Pre-Trip Inspection Practice Test

- Wisconsin - WI - Wisconsin Pre-Trip Inspection Practice Test

- Wyoming - WY - Wyoming Pre-Trip Inspection Practice Test

CDL Class A Pre-Trip Inspection

Engine Compartment Inspection

Includes checking for leaks, belt tension, and the condition of hoses, among other components.

Cab Check/Engine Start

Involves inspecting the cab’s interior, gauges, and starting the engine to check for abnormalities.

Brake Check

Focuses on air brake systems, including air brake checks and the parking brake test.

CDL Class B Pre-Trip Inspection

Vehicle Overview

Begin with a general overview of the vehicle, checking for obvious signs of damage or issues.

External Inspection

Inspect all external components, including tires, lights, and mirrors.

Internal Inspection

Check all internal controls, ensuring everything is functional and within reach.

Pre-Trip Inspection Checklist

- Lights and reflector s: Ensure all are clean and functional.

- Engine oil and coolant levels : Check for adequate levels.

- Steering mechanism : Ensure it’s secure and functioning.

- Horn : Test for functionality.

- Windshield wipers : Check for operability and condition.

- Mirror s: Adjust for optimal visibility.

- Emergency equipment : Ensure presence and accessibility.

- Air brake system : Test for leaks and proper pressure.

Tips for Memorizing the Pre-Trip Inspection for CDL

- Create a Routine : Develop a consistent order in which to conduct your inspection.

- Use Mnemonics : Create acronyms or phrases to help remember the steps.

- Practice Regularly : Hands-on practice is the most effective way to memorize the inspection process.

- Visual Aids : Use diagrams or checklists as visual reminders.

Pro Tip : Practice the pre-trip inspection in a real-world setting. The more you perform the inspection in a practical environment, the more natural it will become.

Remember, the pre-trip inspection is not just a test requirement – it’s a fundamental safety practice every commercial driver should master. For more resources and detailed guides, visit Driving-Tests.org .

Secure your CDL with confidence!

Our exclusive CDL Premium program offers comprehensive online training with an ELDT certificate, authentic exam questions, and a solid Pass Guarantee, starting at only $49. Ideal for first-time applicants, seasoned drivers, and those new to the U.S. road rules.

Explore CDL Premium

Was this page helpful?

- Start a free Pre-Trip Inspection practice test:

- CDL Class A Pre-Trip Inspection

- CDL Class B Pre-Trip Inspection

- Pre-Trip Inspection Checklist

- Tips for Memorizing the Pre-Trip Inspection for CDL

- Why Whip Around

- Maintenance

- Inspections

- Reporting & Analytics

- Fuel Management

- Integrations

- Executive/Owner

- Fleet Manager

- Case Studies

- Our Story & Leadership

Pre-trip Inspection Guide: Class B Commercial Driver Licenses

Table of contents.

There are numerous aspects that go into a pre-trip inspection depending on the class of commercial driver’s license obtained. Having a CDL or operating a fleet is a responsibility, therefore, it is critical to be educated on the different types of classes for CDL inspections to be fully prepared. There are specific pre-trip inspections that need to be completed in order to successfully operate a Class B vehicle. Knowledge is power in the fleet industry and forgetting important details can be consequential.

A Class B CDL allows the driver to operate a commercial vehicle greater than 26,000 pounds. Operating a vehicle of any kind is a responsibility, but operating a Class B vehicle requires specific pre-trip inspections.

Things to Consider Before Starting Your Inspection

Before starting a Class B CDL inspection it is important to identify the item under inspection by touching the vehicle part or pointing to the aspect under inspection. The driver will need to verify that the part under inspection is in good condition. Make notice of any and all defects caught during the inspection. Logging any defect is essential to the process so that the driver will receive proper credit.

Inspect the Outside of the Truck

- Hood and Doors : Make sure the hood is not damaged and is securely locked. Doors should open and close properly. Check that the hinges aren’t broken or bent and that the seal is in place and shows no signs of damage.

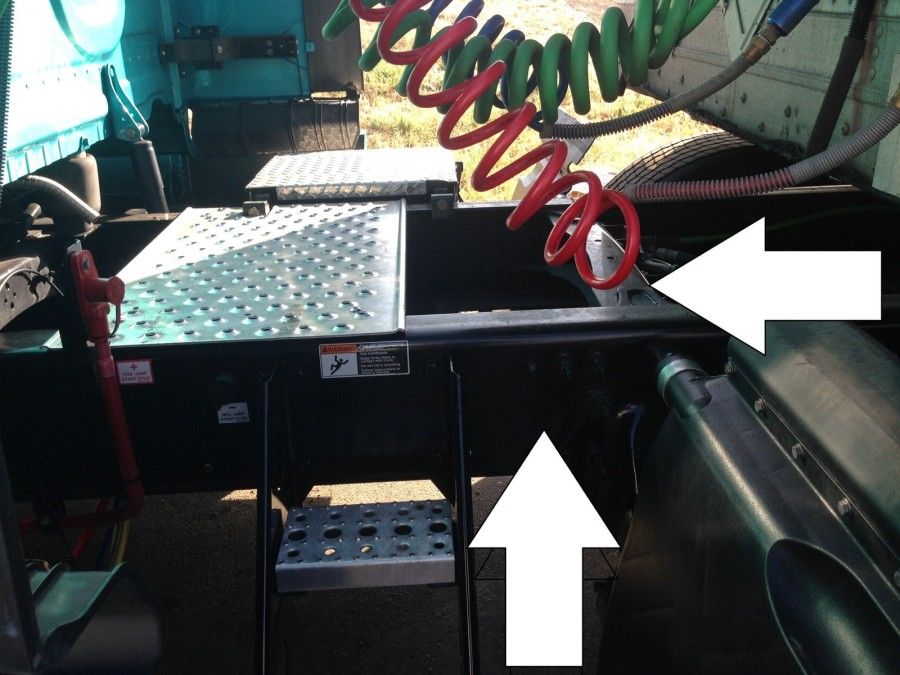

- Steps: These should be mounted securely, with no excessive debris and no missing hardware.

- Fuel Tank: Make sure the fuel tank is securely mounted and not leaking. The cap should be tight and the seal intact. Check to make sure the safety chain is in place.

- Windshield: The windshield, like the lights, should be clean and not cracked or broken in any way.

- Bumper: Lastly, the bumper should be well-mounted, and in good condition. A registration plate should also be clean and visible with a valid sticker to pass inspection.

Leaks, Leans, and Lights

- Leaks: Before opening the hood, inspect under the truck. When inspecting under the truck ensure there are no wirings hanging or out of place and that there is no leaks present. There are two types of leaks that can appear. The first leak is one from the transmission or engine. The other leak could be fluid from the power steering or cooling system.

- Leans: Once confirmed that nothing is leaking, check that the truck itself isn’t leaning. If it is, that could indicate a suspension problem or low tire pressure.

- Lights: Finally, it’s time to check the lights on the top and front of the truck. The lights should not only be in working order, but the lights should be the proper color, clean, and not broken or cracked.

- Tires: Inspecting tires is a visual assessment , but it’s important to pay close attention. First, ensure that no bubbles or cuts are present. Then check that there is no space between the tires and the rims. Lastly, make sure the air pressure is correct and that the tread is worn evenly.

- Rim: The rim should show not be bent or show signs of cracks or welding repairs.

- Lug Nuts : Lug Nuts should be tightly in place, with no shiny threads or rust trails. There should be no signs of cracks or breaks. All lug nuts must be present.

- Valve Stem: Finally, the valve stem should be securely mounted, with a metal cap, and should not be damaged in any way.

Fluid Check

- Coolant Reservoir : First, take a look at the coolant reservoir. Here, the inspector is checking to make sure the coolant is at a proper level, the reservoir is mounted securely, and there are no leaks. Check the hose for signs of damage, and make sure that it, too, is securely mounted.

- Oil: Next, move on to the oil. The inspector should describe the procedure for checking the oil . First, remove the dipstick, wipe it completely clean, then re-insert the dipstick into the oil, remove, and check the level. The correct oil level is at, or below FULL but above ADD.

- Power Steering Reservoir : Finally, the inspector should check the power steering reservoir. Indicate where the dipstick is located and make sure the power steering is at the proper level. Check that the reservoir is not leaking and is securely mounted. The hose should show no signs of leaks or damages, and it too should be properly mounted.

Engine Components

- Alternator: The alternator should be securely mounted without any signs of damage. No bolts or parts should be missing. Wires must have good connections, without any fraying. Belts should have no more than ¾ inch of play and should show no signs of fraying or cuts.

- Water Pump: To locate the water pump, follow the bottom radiator hose. The pump should be securely mounted without any signs of damage or leaks. Hoses should not be leaking and must be securely attached. Belts should show no signs of being cracked, frayed, cut, or damaged in any other way. Belts should have more than ¾ inch of play.

- Air Compressor: Finally, check to make sure the air compressor is securely mounted, without any signs of damage and no audible leaks. There should be no missing bolts or parts. The compressor belt should show no signs of damage or fraying. Make sure the best has no more than ¾ inch of play.

- The Steering Shaft: Ensure that the shaft is securely mounted without excessive play and shows no signs of damage.

- The Power Steering Box: The box should be mounted to the frame without damage. Check that no leaks are present.

- The Pitman Arm: The pitman arm should be securely mounted without damage or cracks. Castle nuts and cotter pins must be present and without damage.

- Drag Link: When inspecting the drag link, make sure it is properly secured, without damage, and that the rubber bushings show no signs of damage.

- Upper and Lower Control Arms and Tie Rod: Finally, check that these are not bent or broken and that all hardware is present and securely mounted.

- Spring Mounts: There are front and rear spring mounts. Both should be securely mounted to the frame with no signs of damage.

- Leaf Springs: It’s important that the leaf springs are not t missing, cracked, or broken, but the inspector should check to make sure the leaf springs are not shifting (scissoring) either.

- Shock Absorber: Make sure the shock absorber is mounted securely and not bent or dented. Check for leaks. Lastly, make sure the rubber bushings are not worn.

- U-Bolts: U-bolts t should not be broken, cracked, missing, or loose.

- Air Hose to Brake Chamber: Check to make sure the air hose to the brake chamber is mounted securely at both ends and shows no signs of splits or cuts. Also, check for leaks.

- Brake Chamber: Check to make sure that the brake chamber shows no damage, is mounted securely and is not leaking.

- Slack Adjuster: Check that the pushrod is at a 90-degree angle to the chamber and that there is no more than 1 inch of free play at the pushrod with the brakes released. Also check for dents, breaks, and loose or missing parts.

- Brake Pads: Brake pads should show no signs of breaks or cracks and should be mounted securely. Check that the brake pads have a minimum of ¼ inch pad depth. Also check for signs of heat, such as cracking or glazing.

- Brake Drums: Check for cracks or bending, and ensure that the brake drums are mounted securely. Next, check for oil leaking from an inner oil seal. Ensure that the brake drum is free of debris and that there is no blueing from excessive heat.

Check the Cab of the Truck

- Mirrors: Mirrors inside and outside the vehicle must be checked. All mirrors should be properly adjusted, clean, and damage free.

- Wipers: Both the arms and blades on the wipers should be securely mounted with no damage. Don’t forget to check the wiper fluid.

- Heater/Defroster: Simply make sure that the heater and defroster work properly.

- Dashboard Indicator Lights: Ensure that both left and right turn signals are functioning. Then check 4-way flashers and high beams.

- Learn More About Class B CDL Pre-Trip Inspections

It may seem exhausting, having to check so many items on a large truck for Class B CDL pre-trip inspection, but it’s vital for driver safety and the safety of others on the road. Having a DOT Pre-trip Inspection Checklist ensures that every step of the inspection is followed. To make inspecting fleet vehicles, equipment, and other assets a little easier and more manageable, please don’t hesitate to contact us today to start your free trial.

Start streamlining your fleet operations with Whip Around .

- Fleet Compliance

- Fleet Inspections

- Fleet Maintenance

- Fleet Reporting & Analytics

- Help Center

- Guides & Ebooks

- Professional Services

- Training Center

- Construction

- Landscaping

- Passenger Transportation

- Trucking & Delivery

- Waste & Recycling

Connect With Us

Download Whip Around

© 2023. Whip Around. All Rights Reserved. Privacy Policy | Terms of Service

CDL Pre-Trip Inspection Checklist

Studying this Class-A CDL pre-trip inspection checklist is an important part of truck driver training. Before getting your Class-A CDL and finding an entry level truck driving job , most states will require students to pass a DOT (department of transportation) pre-trip inspection test and a general knowledge test .

Each company’s pre-trip inspection varies slightly. Most likely you will have to do the coupling system, light check and in-cab inspections plus one of the remaining three sections.

Pre Trip Inspection Checklist

Download free and print it! Printable Pre Trip Inspection Checklist (PDF)

There are many sections to learn but the test is not as difficult as it may seem. Studying our simplified Class-A pre-trip inspection checklist and taking classes at your local CDL training school will get you prepared.

Engine Compartment

Driver door fuel area, coupling area, light check, in-cab inspection and brake tests, belt driven alternator, belt driven water pump, brake chamber, brake lining, caste nuts and cotter pins, coolant reservoir, gear box and hoses, gear driven air compressor, gear driven power steering pump.

- General Hoses

Leaf Springs

Power steering fluid reservoir, shock absorber, slack adjuster and push rod, spring hanger, steering column, what to check for:.

When checking the engine compartment, you will always want to make sure the following components are properly mounted and secured. You should also make sure they are not cracked, bent or broken. The items you will need to check for include:

- Make sure all of the wires are connected. The belt should not be cracked or frayed and the free play on the belt should be between ½ to ¾ of an inch.

- The free play on the belt should be between ½ to ¾ of an inch. Also check all the hoses running to and from the water pump to make sure nothing is leaking.

- The brake chamber should not be leaking air.

- The brake drum should be properly mounted and secure.

- The brake hose is rubber, so it is important to make sure it is not leaking air.

- Check for oil or debris on the lining. There should be at least ¼ of an inch of friction material.

- Make sure all three caste nuts and cotter pins are present.

- The reservoir should not leaking and must be filled to the manufacturer’s specifications.

- Make sure the drag link is properly mounted and secure, and not cracked, bent or broken.

- The gear box and hoses should have no abrasions, bulges or cuts, and should not be leaking.

- Although the air compressor is hard to see, you must make sure it is properly mounted and does not leak.

- The steering pump is located in the same place as the air compressor and is also gear driven. Ensure the steering pump is not leaking.

General Hoses (Passenger and Driver’s Side)

- The hoses should be secure at both ends. There should be no abrasions, bulges or cuts. Fluids run through these hoses, so it is important to make sure they are not leaking.

- The hub seal (or axle seal) should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure none of the leaf springs have shifted.

- Check for leaks under the truck.

- There should be no lug nuts missing. Look for rust trails, powder residue and cracks around the bolt holes.

- The oil level should be filled to the manufacturer’s specifications.

- Make sure the pitman arm is properly mounted and secure. It should be not cracked, bent or broken.

- Make sure this reservoir is not leaking and filled to the manufacturer’s specifications.

- The rim cannot have any unauthorized welds.

- Make sure the shock absorber is not leaking. If it is leaking, the leak will be at the point where the top and bottom portion of the shock meet.

- With the brakes released and pulled by hand, the push rod should never move more than one inch.

- The spring hanger should be properly mounted and secure.

- Make sure the steering column is properly mounted and secure. It should not be cracked, bent or broken.

- Look for abrasions, bulges or cuts on the tread or sidewalls. Tread depth should have a depth no less than 4/32 of an inch. Tires must be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- Make sure the tie rod is properly mounted and secure, not cracked, bent or broken.

- Make sure all are accounted for.

Back to top of Engine Compartment

Catwalk and Steps

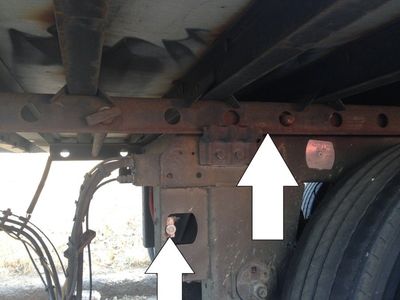

Door and hinges, drive shaft, exhaust system, frame and cross members, spring mount.

Again it is important to make sure these items are properly mounted and secure. Look for cracks, bends, and breaks.

- The actual airbag is rubber, so it is important to check for abrasions, bulges, cuts and leaks, in addition to any missing mounting bolts.

- The axle seal should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure to mention the brake chamber is not leaking air.

- Make sure the brake drum is secured properly. Also look for cracks, bends and breaks.

- Check the brake hose at both ends to make sure it is not leaking air.

- There should be no oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- The cat walk and steps should be clear of any loose objects.

- Physically demonstrate that the doors open, close and latch properly. Door seals should not be worn, torn or rotten.

- The drive shaft should not be twisted and the u-joints should be free of any debris.

- The tread and sidewalls should have no abrasions, bulges or cuts. The tread depth should be no less than 2/32 of an inch. Tires should be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- The exhaust system should show no signs of leaks.

- There should be no unauthorized holes or welds. Bundle up the cross members to ensure none are missing.

- Fuel should not be leaking from the tank and the cap should always be on tight.

- Rust trails could indicate loose bolts, while powder residue and racks around the bolts could mean the bolts have been over-tightened.

- Mirrors should be clean for best visibility.

- Make sure the mud flap is secured properly. Also look for cracks, bends and breaks.

- Make sure to mention there should be never be any unauthorized welds.

- The shock absorber should be secure at both ends and not leaking. If it does leak, it will leak in the middle.

- With the brakes released and pulled by hand, the push rod should not move more than one inch.

- If you are equipped with duals, check to see there is proper spacing between the tires and there is nothing stuck.

- The spring arm should be secure at both ends.

- The spring mount should be secure at both ends.

- Make sure the torque arm is secured properly. Also look for cracks, bends and breaks.

- Make sure to check and mention that no U-bolts are missing.

Back to top of Driver Door Fuel Area

Electric Line

Locking jaws, mounting bolts, release arm, sliding fifth wheel locking pin.

- Air lines should be secure at both ends with no abrasions, bulges or cuts. They should not be leaking, dragging or tangled.

- Make sure the apron is properly mounted and secure. Look for cracks, bends and breaks.

- Make sure there is enough space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

- The electric line should be secure at both ends. There should be no abrasions, bulges, cuts or exposed wires.

- The gap is not an actual item, however there should be no space between the apron and the skid plate.

- The seals should be in good condition with no cracks, signs of rotting, or leaking air.

- Make sure the king pin is properly mounted and secure. Look for cracks, bends and breaks.

- You must physically check that the locking jaws is fully locked around the king pin.

- No mounting bolts should be missing.

- Make sure the platform is properly mounted and secure. Look for cracks, bends and breaks.

- The release arm should be in the fully locked position.

- The skid plate needs to be properly lubed.

- The pin must be in the fully locked position.

Back to top of Coupling Area

Header Board

Landing gear, rear door and hinges.

- Shock Absorbers

Tandem Frame and Release

Trailer tire.

- Again make sure the airbag has no abrasions, bulges, cuts or leakings. The airbag should not be missing any mounting bolts.

- The brake chamber should be properly mounted so that is does not leak air.

- The brake hose should be secure at both ends with no abrasions, bulges, cuts or leaks.

- Check for oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- There cannot be any missing cross members.

- The header board cannot have any holes or missing rivets.

- The landing gear must be fully raised and the cradle handle secure.

- Rust trails indicate loose bolts. Powder residue and cracks around the bolt holes could be an indication of over-tightened bolts.

- The rims cannot have any unauthorized welds.

- The rear door should open, close and latch properly. Door seals should not be worn, torn or dry rotten.

- The shock absorber should be checked at both ends for leaks.

- When the brakes are released and pulled by hand, the push rod should not move more than one inch.

- Release handle and locking pins should be in the fully locked position.

There should be no abrasions, bulges or cuts to the tread or sidewalls. Tread depth should be no less than 2/32 of an inch. The tire should be properly filled to manufacturer’s specifications and checked with an air gauge.

- Front of the truck

- Both sides of the truck

- Rear of the truck

- Both sides of the trailer

- Rear of the trailer

Back to top of Trailer

The five functions are:

- Left turn signal

- Right turn signal

- Four way flashers

- High/low beams

- Brake lights

Back to top of Light Check

- Airbrake Test

Air Pressure Gauges

Emergency equipment, heater and defroster, lighting indicators, oil pressure gauge, parking brake, service brake check, water temperature gauge, windshield and mirrors, windshield wipers and washers.

The last section is In-Cab Inspection and Brake Tests. For the In-Cab Inspection you will once again want to make sure all of the following components are properly mounted and secure. As well as the following:

Air Brake Test

There are three stages to an air brake test:

- Applied Pressure Test – When doing the Applied Pressure Test, you will want to build the air pressure to governor cut out. Put the truck in the lowest gear, turn the engine off and immediately turn it back on. Push in the tractor and trailer valves which will then release the parking brakes. Push and hold the brake pedal, allowing the gauges to stabilize. When the gauges have stabilized, announce the Primary and Secondary PSI. Listen for air leaks while doing this.

- Warning Light and Buzzer – Pump down on the brake pedal until the warning light and buzzer comes on. This is typically at or before 60 PSI.

- Tractor/Trailer Protection Valve Pop Out – Pump down on the brake pedal until the tractor and trailer protection valves pop out, this will be between 20 and 40 PSI.

- The air pressure gauges should build to governor cut out.

- Your truck should have a fire extinguisher, three red reflective triangles and spare electrical fuses.

- Demonstrate both the heater and defroster are working properly.

Horns (Air Horn and City Horn)

- Blow both horns to make sure they are working.

- Check the left turn, right turn, four way flashers and high beams; also point these out on the dashboard.

- Make sure transmission is in neutral and then fully depress the clutch. Turn the key on, check the ABS light, announce when it comes on and off, and start the engine.

- The seat belt should not be ripped or frayed and should adjust and latch properly.

- The engine oil pressure gauge should rise to normal operating range.

- Trailer Parking Brakes – Set the trailer brake, release the tractor brake, then tug lightly on the trailer.

- Tractor Parking Brakes – Set the tractor brake, release the trailer brake and tug lightly on the trailer.

- Release both the tractor and trailer brakes. Drive at idle speed. Apply the service brake to make sure you come to a complete stop and that it doesn’t pull to the left or right when applying the brakes.

- The voltmeter should be charging between 13 and 14 volts.

- The water temperature gauge should also rise to normal operating range.

- The windshield and mirrors must be clean, with no obstructions and in proper adjustment.

- Demonstrate the wipers and washers are working properly by spraying the windshield.

Back to top of In-Cab Inspection and Brake Tests

During a CDL pre-trip inspection, truckers inspect many aspects of their commercial vehicle, including the overall safety of the vehicle; major hoses, fluid levels, and vehicle belts; the clutch or gear shift; and emergency equipment. The driver demonstrates their knowledge by walking around the vehicle, checking various safety components and explaining why each part should be checked for safety.

Reference and practice tests:

- Printable Pre Trip Inspection Checklist (PDF)

- CDL General Knowledge Practice Test

- Pre Trip Inspection Practice Test

- CDL HAZMAT Endorsement Practice Test

Edited for 2024 on 12/5/23

Complete CDL Pre-Trip Inspection Checklists for Class A and Class B Drivers

Your fleet is loaded, and the fuel tanks are full – you’re ready to move. Or are you?

If you haven’t completed a pre-trip inspection checklist, you might not be.

The Department of Transportation (DOT) requires all drivers holding a commercial driver’s license (CDL) to complete a pre-trip DOT inspection checklist before operating a commercial vehicle. Usually taking about 10-15 minutes, this inspection checks essential systems such as brakes and steering, as well as tires, mirrors, and emergency equipment.

So how can drivers know what to check? In this article, we’ll run down the DOT requirements for pre-trip inspection checklists, along with key differences between Class A and Class B inspections and even some useful tools that can help make the job easier.

What is a pre-trip inspection checklist?

A pre-trip inspection checklist is a list of items that CDL holders need to review before operating their vehicles. As you may have guessed, this process is known as a pre-trip inspection .

What is a pre-trip inspection?

Pre-trip inspections aren’t just an annoying routine – they’re an important and necessary safety measure that helps ensure that commercial vehicles are up to fleet safety operation standards .

While the scope and contents of a pre-trip inspection checklist vary according to the type of commercial vehicle and its use, you can complete most inspections in about 10-15 minutes. Checklist items generally include assessing the operational condition of anything the driver and vehicle need to operate the vehicle safely . This usually includes things like an air brake check, along with checking lights, tire pressure, couplings, and so on.

Drivers must also record their inspection results in a driver vehicle inspection report (DVIR), which is usually automated (or at least streamlined) in companies with established fleet management tools. Periodic inspection requirements require additional pre-trip inspections every 24 hours of continuous use or whenever the driver changes vehicles.

It may seem like a lot to review, but most of it boils down to common sense. Before you start crawling under the nearest truck, however, you may want to see whether you have to perform a pre-trip inspection in the first place!

Who needs to complete a pre-trip inspection?

Pre-trip inspections are mandatory for both Class A and Class B commercial driver’s license (CDL) holders.

If you’re a CDL holder, you probably already know which Class you fall into. But just in case, here’s a quick refresher on the types and weights of vehicles that different classes of CDL holders can operate.

- The Class A CDL applies to commercial vehicles weighing at least 26,001 pounds that can tow at least 10,000 pounds. This usually encompasses most towing commercial vehicles such as big rigs, tractor-trailers , and flatbeds.

- The Class B CDL applies to commercial vehicles weighing at least 26,001 pounds that can tow no more than 10,000 pounds. This usually encompasses most non-towing commercial vehicles, such as passenger buses, garbage trucks, and delivery trucks.

While there is also a Class C CDL, this usually extends to specialty vehicles not found under either Class A or Class B (such as hazardous waste transport). However, since their detailed inspection procedures are highly specific and beyond the scope of this article, we won’t cover them here.

But what’s involved in Class A and Class B inspections, and how can they differ?

Class A vs. Class B pre-trip inspections

While Class A and Class B vehicles share many of the same detailed inspection procedures (every commercial vehicle has brake lights, after all), each class and vehicle type has its own inspection procedures.

- Class A and Class B commercial vehicles share many common inspection items, such as front and rear suspension, brake lights, minimum brake pad thickness, oil level, etc. These are usually items that apply to any type of road vehicle.

- Class A inspection items are usually those related to towing systems in commercial vehicles, such as the trailer parking brake, coupling areas, etc. These inspection standards usually extend to the trailer, flatbed, or any other object that the truck is towing.

- Class B inspection items are usually those related to non-towing commercial vehicles. As this is a very broad category, some Class B vehicles may not require any additional inspections, while others may have several specific systems to inspect. In the case of the latter, these are usually items specific to the vehicle itself, such as checking for broken seat frames in passenger areas of a bus.

Of course, there’s much more to each pre-trip vehicle inspection than the handful of key differences we’ve listed here. In the next section, we’ll run down the pre-trip inspection process that applies to nearly every commercial vehicle and then detail more class-specific motor vehicle safety inspections.

CDL pre-trip inspection checklist

The standard CDL pre-trip DOT inspection checklist includes everything a commercial motor vehicle needs to navigate the road safely.

These are generally suspension- and engine-related items that would just as well apply to a regular car. As a general rule, a commercial pre-trip inspection test almost always includes the following motor vehicle safety inspections.

Brake system

There’s nothing more important than your vehicle’s air brakes. Note that the following air brake tests apply to both tractor brakes and trailer brakes on Class A commercial vehicles.

- Brake linings and brake pads: Brake pads should be no less than the minimum thickness of one-quarter inch (¼”). Also, be sure to check linings for oil and debris.

- Brake chamber: The brake chamber should be completely sealed with no audible air leaks.

- Air brake hose: No air should leak from the brake hose, and the line should be properly mounted and free of cuts or splits.

- Brake drum: Should not be blue from excessive heat.

- Hand brake: Push rods should have no more than one inch (1”) of play in either direction and stand up 90 degrees when pulled.

Depending on the vehicle, these items are usually checked with a 9-step, 7-step, or 5-step brake test. These tests usually involve pressing the brake pedal, service brake, hand brake, or foot brake under various conditions and seeing whether air pressure recovers to the proper level in time (see your vehicle’s operating guide).

For example, drivers can check for low air pressure by pressing the brake pedal to fan off the pressure. If repeatedly pressing the brake pedal results in a low pressure buzzer or light indicator, the brake system will require repair.

Engine compartment

Engine compartment inspection items include:

- Fluids: The coolant hose, power steering hose, and any tanks or reservoirs should all be securely mounted and have no leaks. Similarly, a dipstick should indicate that all fluid levels (including oil level and coolant level) are at their proper levels.

- Belts: All belts for compressors, pumps, and alternators should have no cracks or frays and give no more than one-half of an inch (½”) of play.

- Air compressor: Should be securely mounted and functional with no cracks or leaks.

- Water pump: Pump hoses must be properly connected with no leaks.

- Alternator: Wires and belts must be properly connected.

Front of vehicle

Front-of-vehicle inspection items usually include steering equipment such as:

- Steering column or steering shaft: The steering column should be straight and unbroken.

- Steering box: The steering gearbox should be intact, and all connected hoses should be securely mounted with no power steering fluid leaks.

- Tie rod and control arms: Both should be straight.

- Drag link: The rubber should be greased and uncracked.

- Pitman arm: All cotter pins and caste nuts are present, secure, and tight.

Front suspension

Front suspension inspection items include springs, spring mounts, shocks, and suspension airbags.

- Spring mounts and spring hangers: Spring mounts should hold spring hangers securely in place with no signs of wear, cracks, or breakage.

- Leaf springs: Should be secured to hangers with no cracks or breakage.

- Shock absorbers: Should have no leaks, splits, or dry rot in the rubber. Leaks are typically located where the top and bottom pieces overlap.

- U-bolts: Should all be securely fastened around the spring and axle.

Rear of vehicle

The rear of tractor or truck inspection items include the following.

- Driveshaft: Should be straight with unbroken U-joints.

- Exhaust: Should be free of rust with no leaks or excessive soot.

- Frame: Structurally sound with no damages or unauthorized repairs/welds.

- Steps: Structurally sound and mounted properly.

- Mud Flaps: Should be clean, unbroken, and secured at the right height.

Wheels and tires

Wheel and tire inspections check for both proper inflation and overall tire condition, specifically tread depth. Note that this also extends to trailers on Class A vehicles.

- Drive and steer tires: Tire tread should be even with a minimum tread depth of 2/32” on drive tires and a minimum tread depth of 4/32” on steering axle tires. Use an air pressure gauge to check inflation levels against manufacturer inflation levels. Treads and sidewalls should be free of cracks, bulges, and abrasions.

- Wheel rims: No unauthorized repairs or illegal welds.

- Hub seal and axle seals: Should show the axle and hub seal intact with no visible leaks or play.

- Dual spacing: Any dual tires must have enough spacing between them.

- Lug bolt holes: All lug bolt holes should have all lug bolts and lug nuts.

- Valve stem: No audible air leaks.

Lights and reflectors

Light and reflector inspections include everything from running lights to DOT tape and 4-way emergency flashers.

- High and low beams: Ensure both are functional on all forward lights.

- Turn signals: Make sure all are functional for both tractor and trailer.

- Brake lights: Make sure all are functional for both tractor and trailer.

- Running lights and license plate lights: Walk around the truck and make sure all are on.

- 4-way emergency flasher function: Walk around the truck to make sure the 4-way flasher rear and front lights are fully operational.

- Reflector tape and DOT tape: All DOT tape and reflector tape should be clean with no signs of excessive wear.

Driver door and fuel tanks

Cab doors and fuel tanks are often located in the same area on commercial vehicles. Be sure to check the following:

- Door and door hinges: Should be intact and latch completely. The rubber door seal should be clean and uncracked.

- External mirrors and mirror brackets: All external mirrors should be firmly attached to their mirror brackets. External mirrors should also be clean and uncracked. Also, be sure to adjust external mirrors and mirror brackets to provide an adequate rear view.

- Steps: Should be securely mounted and able to support the weight.

- Fuel tank: No leaks, with cap and seal unbroken and intact.

In-cab items

Cab inspection usually covers the following items:

- Steering wheel: Fully attached to steering column.

- Gauges: Check that air gauges, oil pressure gauges, and any other gauges for operation function normally within their operating range. Air pressure gauges should build pressure to the governor cut out during an applied pressure test.

- Warning lights: Lights should show clearly for any lighting indicators, such as ABS lights or oil pressure indicators.

- Windshield: Cracks beyond one inch (1”) are not permitted. Windshield wipers should be clean and work properly, and the truck should have enough windshield washer fluid.

- Seat belt: Should fasten securely.

- City horn and air horns: Both air and city horn should sound properly.

- Heater and defroster: Should heat and function properly.

Special checks for Class A and Class B inspections

As we mentioned earlier, a Class A pre-trip truck inspection will usually have different periodic inspection requirements than, say, a Class B pre-trip school bus inspection.

While periodic inspection requirements ultimately come down to the exact type of vehicle (a Class B garbage truck, for example, may require additional inspections for its armature and compactor), the main differences usually come down to trailers vs. passenger areas .

- Trailers share many of the same inspection checklist items as the tractor, specifically the wheels and tires, suspension, and rear of trailer lights and reflectors. Also, make sure that the landing gear is not broken and can be fully raised.

- Coupling area inspections include checking air connectors, electrical lines, and nearby glad hands. All mounting equipment, such as the fifth-wheel plate, kingpin, mounting bolts, skid plate, release arm, and locking jaw and pins, should be present, secure, and in good condition.

- Rear of truck suspension inspections share many of the same items as those of front inspections but with special attention paid to the torque arm (or radius rod), which should be mounted securely with intact brushings.

- Passenger items such as seating, passenger doors, and any wheelchair lifts should all be secure and in working order. Emergency exits should also be clearly labeled and sound an alarm when opened.

- School bus items include all of the passenger items listed above, with the addition of checking student loading lights, stop arm, student rear-view mirror, and a recent first aid and body fluid cleanup kit.

Pre-trip inspections made easy with CalAmp

With fleet management software from CalAmp, you can spend less time filling out pre-trip inspection reports and more time on the road. Request a demo today to see just how easy it is to use CalAmp’s pre-trip inspection tools!

Recent Related Stories

Connect with us.

Complete pre-trip inspection checklist for truck drivers

By The Schneider Guy

Estimated reading time: 4 minutes

As a truck driver, performing a CDL pre-trip inspection is one of the most common and repeated tasks you will complete. Pre-trip inspections help truck drivers ensure their tractor and trailer are safe to operat e before hitting the road.

Keep reading to learn what a p re -trip inspection is and what should be on a p re -trip inspection checklist .

What is a pre-trip inspection?

A pre-trip inspection includes checking over the tractor and trailer a truck driver will be operating . A pre-trip should be completed before the operation of a vehicle :

- At the beginning of a driver’s shift.

- Any time a new trailer is picked up.

- After a 10-hour break.

A thorough inspection usually takes anywhere from 30 minutes to one hour and should be logged as on-duty, not driving (line 4) .

How to complete a CDL pre-trip inspection

CDL pre-trip inspection checklist

1. passenger-side engine: .

- Air filter housing: Secure mounting, cover in place.

- Windshield washer fluid reservoir: No leaks, proper fluid level.

- Turbocharger: No oil or exhaust leaks.

- Engine air ductwork: No cuts, clamps secured.

- Alternator: Mounting secured, no broken or loose wire.

- Accessory drive belt: Not cracked or frayed.

- Air conditioner compressor: Secure m ounting .

2. Front brakes (covers all five brake components):

- Brake drum: No cracks.

- Brake lining: No cracks or damage.

- Slack adjuster: Proper angle to the brake chamber, clevis and cotter pin intact.

- Brake air line: No bulges or cuts, fitting tight .

- Brake chamber: Mounting bolts secured, band clamp secured.

3. Front wheel:

- Tire: ABCs (abrasions, bulges, cuts), pressure = 120 PSI, tread depth = 4/32 min ( DOT ) .

- Wheel: Not cracked or bent.

- Hub oil: Not leaking, at proper level – if it’s a sealed unit, can’t check level.

- Oil seal (outer): Not leaking.

- Valve cap: Not missing.

- Lug nuts: None missing, no streaks or shiny areas, none loose.

4. Driver side of engine:

- Radiator brace: No cracks or missing bolts.

- Radiator: Not leaking, secure mounting.

- Water pump: No cracks, not loose or leaking.

- Fuel water separator/filter: Not leaking, secure mounting.

- Pitman arm/drag link: Not cracked, castle nut secured with cotter pin.

- Steering gear box: Secure to frame, not leaking.

- Power steering reservoir: Secure mounting , no leaks, proper level.

- Dipstick: Right level, secured after check.

- Steering shaft: Secure, not loose or damaged.

- Fuel pump: No cracks, not loose or damaged.

- Oil filler cap: Secure, no cracks.

- Engine coolant reservoir: No leaks, proper fluid level.

5. Steer axle suspension:

- U-bolts: No cracks, no loose or missing nuts.

- Leak spring: No cracks, not loose or shifting.

- Tie rod: Secured with castle nuts and cotter pins.

- Shock absorber: Secure mounting, not leaking oil.

- Axle: Not cracked.

6. Rear suspension:

- Spring mount: No cracks, secure mounting.

- Tire: ABCs (abrasions, bulges, cuts), pressure = 110 PSI, tread depth = 2/32 min ( DOT ) .

- Airbag (bellows): Fully inflated, secure mounting, not ruptured.

7. Side of cab:

- Mirrors: Secure m ounting , no broken glass.

- Doors: No damage, glass not broken, hinges secured, opens and closes well.

- Lights and turn signals: Working, not cracked.

- Steps: Mounted, secured to skirting.

- Battery box: Secure m ounting , cover latched.

- DEF cap: Cap secured.

- Fuel cap/tank: Gasket in place, vent in place, chain secures the cap to the tank.

- Side skirting: No damage, panels secure.

- Side box: Secured, safety triangles present.

- Side of sleeper berth: No body damage.

- Sleeper berth window: No cracks.

8. Rear of cab:

- Electrical cord: No bare wire, no corrosion, check the plug at the end of the cord.

- Air line: Not tangled or worn, rubber grommets not worn, fittings tight.

- Cab shock absorber: Secure mounting, not leaking oil.

- Cab airbag (bellows): Not ruptured, securely mounted.

9. Driveshaft/rear frame:

- Driveshaft: Not cracked.

- Universal joint: Not cracked, not missing bolts, no shiny areas.

- Differential: Not leaking oil.

- Frame: Straight, no non-factory welds.

10. Fifth wheel area:

- Pivot pin: Keeper pin and cotter key intact.

- Slider lock pins: Fully engaged.

- Release arm: Not bent.

- Slider rail: No broken welds or missing bolts.

- Slider stop blocks: Welds not broken, not missing bolts.

- 5th wheel platform: Well-greased, tilted down.

11. Front of trailer:

- Top rail: No cracks or collision damage.

- Clearance lights: Not broken, working properly.

- Registration: Not missing, readable.

- Document box: Not missing or loose.

- Air line /glad hands: No bulges or cuts in air lines, rubber grommets not damaged on glad hands.

- Electric hook up: No broken pins, cover intact.

- PM sticker: Current, legible.

- Height sticker: Legible, legal for route.

- Placard holder: Not broken or missing rivets.

- Tracking device: No cracks or collision damage.

12. Side of trailer:

- Top rail: Not cracked, no collision damage.

- Clearance light: Not broken, operational.

- Bottom light: Not cracked, no collision damage, no missing bolts.

- Landing gear: Legs straight, no broken welds in bracing, sand pads secured and clean handle in cradle.

- Reflector tape: Clean.

- Side panels: No holes or cuts, no missing rivets.

13. Rear of trailer:

- Latches: Secured, not damaged.

- Lights: Not broken or missing, operational.

- Splash guard: Brackets and guard secured.

- License plate: Secure and clean, light is working.

- Bumper: Not damaged, no broken welds.

- Door hooks: Not loose, no missing bolts.

- Hinges: Not cracked, no missing bolts on both sides.

- Door seals: No separation, no rubber tubing sticking out.

14. Trailer suspension:

- Air line: No bulges or cuts, fittings are tight and not rubbing.

- Axle: Not bent or broken.

- Clevis pin/cotter key: Not missing.

- Slack adjuster: Proper angle, clevis pin and cotter pin intact.

- Brake linings: Minimum of ¼ inch thick, not cracked.

- Brake drum: Not cracked.

- Tire: (ABCs), tread depth = 2/32 , air pressure = 110 PSI.

- Spring: Not broken, not shifted.

- Spring mount: No broken welds.

- U bolts: Not loose, not cracked.

- Torque rod: Secure mounting, bushings intact.

- Spring brake chamber: Secure m ounting , band clamp secure.

15. Gauges/inside the truck:

- Fuel: Matches visual when looking in the tank.

- Def level: Maintain a minimum of one light bar.

- Oil pressure: 25-50 PSI.

- Speedometer: 0-60 MPH.

- Air pressure: 90-120 PSI.

Please note that the list above is just an example. It is important to remember the type of driver you are, the company you work for and the type of truck you drive can impact your CDL pre-trip inspection . Be sure to consult your company guidelines or speak with your leader for more information on your post-trip inspection requirements.

Get more great driving tips and guides.

Schneider Guy loves the "Big Orange." He's passionate about the trucking industry and connecting people to rewarding careers within it. He's been the eyes and ears of our company since our founding in 1935, and he's excited to interact with prospective and current Schneider associates through "A Slice of Orange."

Related posts

8 CDL Road Test tips to help you pass

How hard is it to get a CDL?

How to get your CDL – 7 simple steps for new truck drivers

- Register / Login

- Trucker's Forum

- Paid CDL Training

- Truck Driving Jobs

- CDL Practice Tests

- High Road Training

Pre-Trip Inspection Study Guide

Our Pre-Trip Inspection Study Guide has everything you need to prepare for the Class A CDL Pre-Trip Inspection Exam . Our study guide will cover the pre-trip inspection terminology as well as a thorough list of all of the parts you will be inspecting on the vehicle. For each part you will be inspecting there will also be a list of items you will be checking for. Our study guide is broken down into the following sections:

- What You Need to Know About Pre-Trip Inspection

Pre-Trip Inspection Practice Questions

- Pre-Trip Inspection Checklist

Pre-Trip Inspection Videos

Pre-trip inspection printable resources, what you need to know about the pre-trip inspection.

The Pre-Trip Inspection is a thorough inspection of the vehicle and all of its major systems. Inspecting the vehicle before driving each day is a Federal requirement and normally takes about 15 minutes. It must be logged in your logbook as "on duty not driving."

You will have to do thorough safety inspections of the coupling system, the vehicle lights, engine compartment, tires and brakes, the chassis, the fuel tanks, and an in-cab inspection.

The following information is a brief summary of Daniel's Complete Pre-Trip Inspection taken from our oustanding free PDF download:

Engine Compartment

You will be checking the engine compartment for any sort of leaks. You will also be checking to see if all components are properly mounted and secured. None of the mounts must be cracked, bent, or broken.

You will be checking all hoses to make sure they aren't leaking, frayed, or sliced and the fluid levels including the oil level, the coolant, and the power steering fluid.

You must check the components like the water pump, the power steering pump, and the alternator to make sure nothing is leaking, the belts are not frayed, and that everything is properly mounted and secured.

From inside the engine compartment you will also find the steering system, the front suspension system, and the front brake system. All components of these systems must be properly mounted and secured without anything being cracked, bent, or broken. Finally you will be checking the tires, rims, and axle seals to make sure the tires are properly inflated, the rim isn't bent or cracked, and the axle seals are not leaking.

Fuel Tank And Battery Area

You will be standing along the side of the tractor doing a series of checks on the mirrors, fuel tanks, batteries, exhaust system, and more. You will check to make sure nothing is bent, cracked, broken, or leaking.

Check the mirrors, door hinges, door handle to make sure nothing is cracked, bent, or broken. Check to make sure there is no fuel leaking and that the fuel cap is secured and the gasket is not missing.

Check the exhaust system to make sure nothing is cracked, bent, or broken. Check the driveshaft, cat walk, and steps to make sure nothing is cracked, bent, or broken.

Check the frame and crossmembers for structural integrity. Check the air lines going to the trailer to make sure they're properly connected and that there are no abrasions, bulges, or cuts. Make sure the gaskets are present.

Check the suspension system and brakes on the drive axles, making sure nothing is cracked, bent, or broken. Make sure the brake linings are the proper thickness and that the air bags and properly inflated. Inspect the brake chambers, slack adjusters, and pushrods are properly mounted and secure. Not Cracked, Bent, or Broken. With the brakes released and pulled by hand, the Push Rod should not move more than 1 inch.

Check the rims, tires, and axle seals of the drive tires for proper inflation, no leaks around the seal, and the lugs are all present and secured.

Coupling System

You will be standing where the tractor and trailer are connected and you'll start by checking the electrical line and air lines to make sure they're properly mounted and secure at both ends. No abrasions, bulges or cuts. Not leaking air. Make sure the electrical line has no wires exposed. Check the gladhands to make sure the seals are in good condition, no cracks or signs of dry rotting. Not leaking air.

Check the skid plate of the fifth wheel and the apron of the trailer to make sure there is no debris and nothing is cracked, bent, or broken. Make sure the fifth wheel is properly greased. Also make sure there is no gap in between the fifth wheel and the trailer apron once the tractor and trailer are coupled. Make sure the kingpin of the trailer is properly mounted and not cracked, bent, or broken and that the locking jaws of the fifth wheel are properly secured when the tractor and trailer are coupled.

Check the mounting bolts where the fifth wheel attaches to the tractor frame. Make sure there are no missing bolts and that everything is secured properly. Check the locking pin if you having a sliding fifth wheel to make sure it's properly locked into place.

Make sure that there is the proper clearance space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

You will start inspecting the trailer at the head board, which is the front wall of the trailer. Make sure there are no holes or missing rivets. Check the landing gear to make sure it is properly mounted and secure. Not cracked, bent, or broken. Make sure the fully raised and the handle is secure in the cradle when the tractor and trailer are coupled.

Check the frame and crossmembers under the trailer to make sure they're not cracked, bent, or broken. Check the tandem frame and release pins to make sure the frame is in good condition and the release handle and locking pins are in the fully locked position.

You will check the entire suspension and brake system for the trailer tandems the same way you did for the drive axles of the tractor. You will also make sure the mudflaps are properly secured. For dual tires check to see that there is proper space between the tires and there is nothing stuck between the tires.

Check the rear door and hinges to make sure they are properly mounted and nothing is cracked, bent, or broken. Make sure the door seals are not worn, torn, or dry rotted.

Light Check

You will be checking all of the lights and reflectors on both the tractor and the trailer. Check the reflectors and reflective tape to make sure they are properly mounted and secure, not cracked, bent, or broken, and clean and illuminated. Check that you have the proper color of amber to the front and sides, and red to the rear.

Start by turning on your marker lights and headlights. Now walk around the entire truck and trailer and point out the lights. Give the function of the light and the location. You should then ask your examiner to help you check your five functions.

While you're sitting in the drivers seat, the examiner will stand to the front of the truck, then behind the trailer. He will then check your Turn Signals, Four Way Flashers and Brake Lights. You must do each function at every location.

The five locations that you must check your lights:

- Front of the Truck

- Both sides of the Truck

- Rear of the Truck

- Both sides of the Trailer

- Rear of the Trailer

The Five Functions you are checking for:

- Left Turn Signal

- Right Turn Signal

- Four Way Flashers

- High Beams/Low Beams

- Brake Lights

In-Cab Inspection

The in-cab inspection and air brake check will cover the various gauges and systems inside the cab along with several tests to make sure you air brake system is working properly.

You will start by checking the following:

- Seat Belt- Properly Mounted and Secure. Not ripped or frayed Adjusts and latches properly.

- Fire Extinguisher- Properly Mounted and Secure. Fully charged

- Three Red Reflective Triangles- My three red reflective triangles are GIVE LOCATION

- Spare Electrical Fuses- My spare electrical fuses are GIVE LOCATION

- Volmeter, Oil Pressure Gauge, Water Temperature Gauge, and Air Pressure Gauge all show proper operation

- City horn and air horn functioning properly

- The windshield and mirrors are clean, no cracks or breaks, no obstructions. The mirrors are in proper adjustment.

- Windshield Wipers and Washers - Demonstrate that the washers work by spraying the windshield. The Wipers are: Properly Mounted and Secure and operate smoothly. The blades aren't cracked or dry rotten.

- Heater and Defroster - Demonstrate that both the Heater and Defroster are working properly.

- Lighting Indicators - Left Turn, Right Turn, Four Way Flashers, and High Beams.

Trailer Parking Brakes - Set the Trailer Brake, release the tractor brake, and then tug lightly on the trailer.

Tractor Parking Brakes- Then set the Tractor Brake, release the trailer brake, and then tug lightly on the tractor.

Service Brake Check - Release both Tractor and Trailer Brakes. Now drive at idle speed. Apply the Service Brake to make sure you come to a complete stop, and that it doesn't pull to the left or right when applying the brakes.

Air Brake Test

The air brake test will consist of a leakdown test to make sure your air brakes aren't leaking air and losing pressure. It will also test the warning lights and buzzer to make sure the driver gets the proper warning if the air pressure drops too low.

There are three stages to an Air Brake Test

#1: Applied Pressure Test

#2: Warning Light and Buzzer

#3 Tractor/Trailer Protection Valve Pop Out

Applied Pressure Test: Build the air pressure to governor cut out. Put the truck in the lowest gear. Then turn off the engine Immediately turn the engine back on. Push in both the tractor and trailer valves. (This will release the parking brakes.) Push and hold the Brake pedal fully. Allow the gauges to stabilize. Announce the gauges have stabilized and the Primary and Secondary PSI. With the Brakes fully pressed, you should not lose more than 4 PSI in one minute. Announce that you are listening for air leaks during that minute.

Warning Light and Buzzer Test: Pump down on the Brake pedal until the warning light and buzzer comes on, at or before 60 PSI.

Tractor/Trailer Protection Valve Pop Out Test: Pump down on the brake pedal until both the tractor and trailer protection valves pop out. They should both pop out between 40 and 20 PSI.

We have a ton of Pre-Trip Inspection Practice Questions along with the answers and a complete scoring system in our Free Online CDL Practice Tests :

The Engine Compartment Section will include questions about checking the oil level and coolant levels, inspecting belt-driven engine components (like the water pump, alternator, and air compressor), and the safety devices required in the cab. There will also be questions regarding the windshield wipers and free play in the steering wheel.

The Lights And Brakes Section will include questions about dashboard indicator lights, inspecting the parking brakes, and doing a leakdown test on the air brakes. It will also include questions about the low air pressure warning signal and testing your air horn and city horn.

The Suspension And Steering Section will include questions about the tractor protection valve, inspecting the steering box, and inspecting many suspension system parts. It will also include questions about welds being present on tire rims and the minimum tread depth required on steering axle tires.

The Tires And Coupling Devices Section will include questions about shiny trails or rusty threads on lug nuts, inspecting the battery box and cover, and inspecting electrical lines. It will also contain questions about inspecting the coupling devices and the fifth wheel skid plate.

The Emergency Equipment And Fifth Wheel Section will include questions about additional emergeny equipment required by school buses, inspecting the gap between the kingpin apron and the fifth wheel skid plate, and the landing gear securement. It will also contain questions about inspecting driver mirrors and the trailer frame.

Pre-Trip Inspection Checklist - Class A

Our pre-trip inspection checklist covers every part of the truck from front to back, both inside and outside of the truck. It covers the air brakes, suspension parts, steering components, wheels and rims, fuel tanks, batteries, lights, and more. It also covers the air brake tug test and checks for everything under the hood including alternator, water pump, fuel pump, fluids, and more.

This is a super handy checklist to study anytime you have a few minutes to spare:

Pre-Trip Inspection Checklist - Free Word Document Download (Editable Version)

Pre-Trip Inspection Checklist - Free PDF Download (Print Version)

Pre-Trip Inspection Video By Apex CDL Institute

Jeff from Apex Institute does an in-depth explanation of the entire pre-trip inspection process. This video is loaded with tips that go beyond the CDL test to help drivers really understand how to identify problems.

Pretrip Inspection Self-Test By CDL College

The Pretrip Inspection Self-Test By CDL College is really unique. It's a silent video which will show you the part you're inspecting and then gives you a few seconds to figure out what you should be checking for before giving you the answer. Definitely check this one out. Great for practicing before the CDL exam.

Pre-Trip Inspection Video By Averitt Express

This is a complete back to front pre-trip inspection of a truck and trailer by Averitt mainentance associate Kevin Breeding. This thorough pre-trip inspection covers all inportant points of inside the cab, lights, engine, the tractor itself and the trailer.

We have included two print versions of the pre-trip inspection process from Daniel. The first is the entire pre-trip inspection and the second is an abbreviated checklist for the inspection.

- PDF: Daniel's Pre-trip Inspection (Print Version)

- PDF: Daniel's Pre-trip Inspection Checklist (Print Version)

Why Join Trucking Truth?

- The High Road Training Program

- The High Road Article Series

- The Friendliest Trucker's Forum Ever!

- Email Updates When New Articles Are Posted

Apply For Paid CDL Training Through TruckingTruth

Did you know you can fill out one quick form here on TruckingTruth and apply to several companies at once for paid CDL training? Seriously! The application only takes one minute. You will speak with recruiters today. There is no obligation whatsoever. Learn more and apply here:

- Privacy Policy

Passenger Bus CDL Class B Pre-Trip Inspection

Pre-trip inspection passenger bus class b.

The commercial driver’s license (CDL) pre-trip inspection for a passenger bus includes 71 items to be checked.

You must name and point to or touch each item, and fully explain what you are inspecting (you must ensure the tester knows what you are referring to). You are getting graded that you know what to check each part for, not that you know the names of the parts. You will have to check each axle as outlined. There is no order or sequence to the test. If you miss a part, you can go back and identify it.

At the end of this checklist (scroll to the bottom of this page), you will find procedural videos to assist you in understanding the requirements for successfully completing the Class B (Passenger bus) Pre-Trip Inspection.

Engine Compartment

This order starts in the engine compartment and inspects only the axles on the driver’s side of the bus. The test requires you to only inspect the driver side unless the item is only on the passenger side (parts in engine compartment, exhaust).

- make sure level is between add and full

- level is sufficient for operation, between hot and cold mark

- level is between add and full

- must say that it is gear powered, working properly

- not leaking, securely mounted

- securely mounted, bolts tight, not leaking

- belt, not cracked or frayed, tension is between ½” and ¾”

- securely mounted, bolts tight

- wire secure into back of alternator

- secure to engine, bolts tight, hoses secure, not leaking

- must say that it is belt driven

- works properly

- check under vehicle for oil puddles

- check bottom of motor for leaks

- check hoses for splits, cuts

- make sure all clamps are tight

- check all hoses for leaks

- make sure to check both sides of engine for leaks/hoses

Front Truck Axle

- secure, bolts tight

- not leaking

- not cut, pinched or leaking

- fittings are secure not cracked or broken

- not bent, bolts tight, no cracks, cotter pins in place

- sockets are not worn or loose

- must check from steering box to wheel

- none broken

- all in alignment

- not shifted

- not broke or rusted

- check front and rear mount for cracks, rust

- check for tight or missing bolts

- make sure bushings are not torn or missing

- bolts tight

- not kinked, cut, swollen or leaking

- fittings secure

- not bent, broke or leaking

- not cracked dented, rusted or leaking

- clamp is secure, tight and in place

- pins in place holding slack adjuster to push rod

- straight, not broken

- no more than 1”adjustment (movement) on the push rod

- no holes, cracks or dents

- smooth surface

- no signs of grease or oil

- shoes are sufficient, more than ¼” pad

- no cracks, no chipped pads

- no fluid, grease or oil

- 4/32” tread depth

- no cuts or bubbles on side walls

- check top of tire for even wear and flat spots

- check pressure with gauge

- check valve stem is not cracked, broke, leaking or twisted and secured with cap

- none missing

- no signs of rust trails

- no cracks or distortion from lug bolt holes

- no loose or missing bolts

- proper fluid level (if sight glass)

Side of Cab

- door hinges are secure, bolts tight

- handle works, no damage to side

- seal is in tack and not torn

- opens and closes properly

- securely mounded, brackets not damages, bolts in place

- mirror is not broke and clean

- straps are secure

- cap is on tight

- must check tank & cap for leaking

Under Vehicle

- no signs of soot (leaking)

- securely mounded

- all clamps are tight

- must check hole exhaust system from turbo to top of stack

- bolts are all tight

- must also check cross members for same

- straight, no cracks, bolts are tight

- must check u-joint bolts and u-joint is free of foreign objects

- no holes, cracks, chipped and flat

Rear Truck Axle

- check front and rear mount for cracks

- fitting is secure

- not cracked or rusted or leaking

- no more than 1” adjustment (movement) on the push rod with brakes released (double chamber)

- no holes, cracks, or dents

- no cracked or chipped pads

- 2/32” tread depth

- check pressure with a gauge

- check valve stem is not cracked, secure, leaking or twisted and cap is in place

- no cracks, no rust or welded

- none missing, not loose, no signs of rust trails

- must check there is no debris between tires

- tires are evenly spaced

- rims flush (butted) together

Rear of Vehicle

- opens and closes

- no damage, holes, broken glass

- hinges are secure, no missing bolts

- seal is not missing or torn

Cab Compartment/Engine Start (need to demonstrate all mechanisms)

- push in clutch & make sure shifter is in neutral before starting engine

- if automatic transmission make sure vehicle is in neutral

- check temperature gauge for operation and in safe range

- check voltmeter for operation and in safe range

- needle indication charging

- check oil pressure gauge for operation and in safe range

- working properly, pressure builds to 120 psi or governor cut out or purge

- check steering play for no more than 10 degrees or 2”

- check parking brake by applying and putting truck in low gear and try to move (lug engine)

- must check both tractor and trailer parking brake individually

- pull forward at 5 mph and stop with foot brake, check for no pull left or right

- must be clean

- no cracks, chips or stickers

- seal is secure with no leaks

- no stickers

- mirrors are adjusted

- operate properly (must turn on)

- rubber blades are not cracked with good contact to windshield

- medal arms are secure, no damage

- washer fluid operates (squirts)

- on dash, check left & right turn arrow

- 4 way flashers

- high/low beam indicator

- blow air and electric horn

- must turn to hot and feel for air from vents

- turn on defroster to make sure they work properly

- feel for air to blow from vent at windshield

- spare fuses or breakers (which ever truck is equipped with)

- not cut, frayed or torn

- securely mounded at seat, shoulder and floor ( all points )

- build air pressure to 120, governor cut out or purge

- turn off engine then turn key to on position

- release parking brake, push in

- apply foot brake & keep pressure and listen , applied for 1 minute-cannot lose more than 3 pounds in 1 minute (must hold for full, timed minute)

- after leak test, say that low air buzzer will come on at 60 PSI, pump foot brake (fan) so buzzer will sound

- after checking the low air warning device, say that parking brake will pop out at approximately 30 PSI, pump foot brake (fan) so buttons pop

Passenger Items

- securely mounted

- walk through bus and check

- buzzer sounds when open (key on)

Lights—Amber on Front, Red on Rear (all lights, must say color and describe light condition)

- Lights (front of vehicle AMBER )-head lights (high & low beam), right/left turn signal, 4 way flashers, clearance, must turn on, clean, not broken, operating properly

- Lights (front side of vehicle AMBER )-right/left turn signal, put on emergency, flashers, make sure working, amber lenses, not broken, clean

- Lights (rear of vehicle RED )-right/left turn signal, put on 4 way flashers, clearance and brake lights, red lenses, not broken, clean

CDL Class B Passenger Bus Pre-Trip Inspection Video

A procedural training video demonstrating the requirements and best practices to help prepare you for successfully completing the Pre-Trip Inspection portion of the CDL Class B (Passenger Bus).

Site Navigation

- SMG of Crystal River

- CDL Testing

CDL Testing and Prep

- Steps to Getting Your CDL

- Class A CDL Pre-Trip Inspection w/Air

- Class A CDL Pre-Trip Inspection w/o Air

- Dump Truck CDL Pre-Trip Inspection Class B

- Passenger Bus CDL Pre-Trip Inspection Class B

- Driver's On-road Practical Test

- Commercial Driving Behavior

- CDL Driver Control Skills Test

- Instructional Videos

All CDL Testing & Training

All SMG CDL testing and training is initiated and completed at Interstate Commercial Driving School (ICDS) located at:

SMG Contact Information:

Tel: (352)795-7170

Fax: (352)795-8723

© SMG, Inc . All Rights Reserved.

Platform Overview

The Connected Operations Cloud

Apps & Driver Workflows

Messaging, dispatch, documents, ELD

Video-Based Safety

AI cameras, driver coaching, safety reports, in-cab alerts

Equipment Monitoring

Location tracking, utilization, continuous diagnostics

Vehicle Telematics

Real-time GPS, routing, fuel, maintenance, electrification

Site Visibility

Remote visibility, proactive alerting, on-the-go access

Integrations

Developer API

Start building with our API

App Marketplace

Install turnkey integrations

OEM Integrations

Unlock embedded telematics data

Experts Marketplace

Find certified Samsara experts

By Business Need

Reduce costs across your business

Automate regulatory compliance

Ensure safety wherever you operate

Identify and eliminate risks

Sustainability

Prepare for transition to renewables

Customer Experience

Build customer loyalty and retention

By Industry

Transportation & Logistics

Food & Beverage

Field Services

Construction

K-12 Schools

Higher Education

Passenger Transit

Customer Success

Customer Stories

Education & Training

Customer Support

Help Center

Developer Portal

Customer Tips

Case Study Highlight

DHL consolidates 7 separate point solutions with Samsara’s integrated platform

Read more ➔

Nutrien Ag Solutions

Nutrien Ag Solutions cuts distracted driving in half 90 days after installing AI Dash Cams

Video Library

Product Tours

Fleet Safety Guide

Business Resilience

State of Connected Operations

See how leaders are adopting cutting-edge technologies, empowering their workforce, and unlocking new revenue streams.

Optimization

Make More Possible

Find ways to make more possible across your organization to empower your workers, increase efficiency, and reduce operational costs.

Build Your EV Fleet

Get the essentials on fleet electrification and better understand how an EV fleet can benefit your business.

Investor Relations

Samsara Ventures