How Are Cruise Ships Powered?

Cruise ships require a lot of power. And rightfully so! As they carry close to 3000 passengers with 500-1000 crew members at any time.

Most of the power of the ship is consumed by the large air-conditioning plant that takes care of passenger comfort in suites and public spaces.

The propulsion plant of cruise ships, consisting of giant synchronous propulsion motors and associated equipment for speed and direction control is a large consumer too .

The tunnel thrusters, both forward and aft, stabilizers, machinery loads, galleys, the numerous lighting and hotel loads, ensure that there is a significant demand for power at any given time. The demand is especially more when the ship is sailing.

Cruise ships are equipped with multiple Diesel Generator sets to satisfy these power demands. These generator sets are larger and much more powerful than the DG sets found on a typical cargo vessel.

These are usually 5 or 6 in number and the power rating can be anywhere between 9-15 MW for each, which is approximately around 10 times the power rating of the DG’s on cargo ships.

Due to their large size, they command a separate compartment in the ship’s machinery space. This is called the DG room. Most modern passenger ships have two separate DG rooms, forward and aft, separated by a watertight bulkhead.

Each DG room has its independent air, fuel, lubrication and cooling water supply systems. This is for the purpose of safety and redundancy keeping in mind emergencies like fire and flooding.

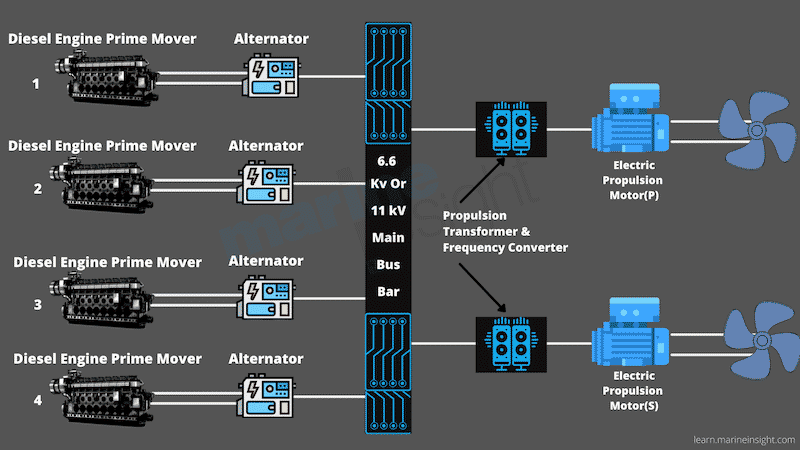

The diesel engine prime-mover drives the alternator. The alternator supplied 3-phase power usually of either 6.6 kV or 11 kV to the main HV busbar from where it is either used directly or stepped-down to lower voltages.

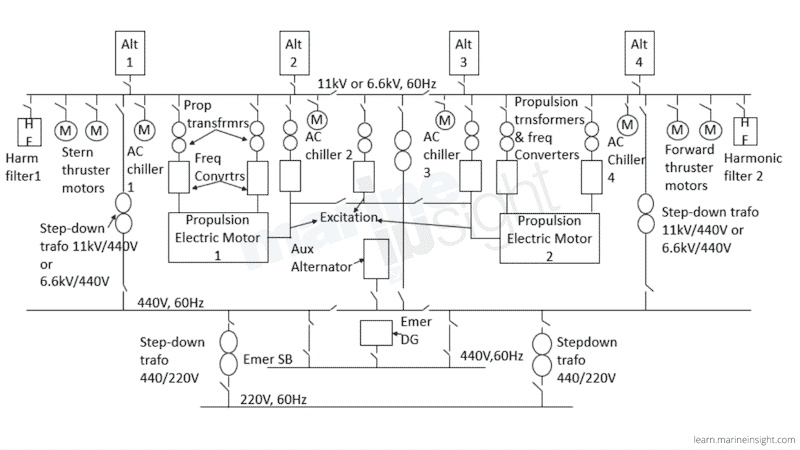

A typical passenger ship power distribution system is shown in the above illustration.

As we can see, the diesel generators (shown 4 in number) supply 3-phase high-voltage power to the HV busbar rated at either 6.6kV or 11kV.

There are different voltage demands on cruise ships according to the equipment. AC chillers, propulsion motors and tunnel thrusters typically have a high current demand. They get the supply from the HV busbar.

The Propulsion Electric Motors (PEMs) are a part of the diesel-electric propulsion powerplant. They require variable speed/torque in the case of fixed-pitch propellers. These are provided by thyristors or Silicon Controlled Rectifiers in the form of frequency convertors or cyclo-convertors.

Directional controls (ahead and astern movements) are obtained by changing the input phase sequence of the supply. This is by interchanging any two phases with the help of thyristors.

Each PEM has two separate stator windings known as half-drives. In case of failure of one half-drive, the other one operates the PEM, though at reduced power. Each half-drive has its own propulsion transformer and frequency converter.

Each PEM also has its separate excitation circuit. This is a direct current (DC) supply obtained from the main busbar after transformation and rectification. There are also two harmonic filters provided, at the port and starboard ends of the main HV busbar. These filter out unwanted harmonics generated by frequency converters and other HV components.

The 440V section takes care of most of the engine-room machinery loads such as pumps, compressors and fans. In addition, deck machinery and hotel loads are also supplied by it. The 440V busbar is fed from the HV busbar via step-down transformers.

In addition to this, there is also an additional auxiliary diesel generator for the restoration of power during blackout situations. This generator can be started to power the 440V busbar independent of the main supply, in order to prepare the plant for restart.

The auxiliary DG main breaker is automatically disconnected when the main DG starts and connects to the busbar.

An emergency generator is also available as per SOLAS , located above the uppermost continuous deck and away from the machinery spaces. This must start and come on load within 45 seconds of a power failure and supply power to the emergency switchboard. The switchboard provides power to selected critical equipment during blackout.

The emergency switchboard supplies power for the emergency lights, battery chargers, navigation and communication systems, a steering gear motor, sprinkler/hyper-mist pumps, a fire pump, a bilge/ballast pump, auxiliary DG pre-lube pumps, watertight doors , alarm and control systems and fire alarm system for a period of at least 36 hours on passenger vessels. On some vessels, power for one of the fuel oil supply pumps, booster pumps and starting air compressors are also supplied from the emergency SB.

In normal conditions, the emergency switchboard is supplied from the main bus bar. When there is a loss of main power, the supply breakers open and the emergency DG starts and takes over the supply to the ESB. On resumption of the main power, the EDG breaker is automatically disconnected. An interlock is available for this purpose.

The 220 V section takes care of the lighting loads and power outlets in accommodation and public areas. The 220V section is supplied from the 440V busbar by step-down transformers.

Diesel-Electric Propulsion

Most cruise ships are propelled by diesel-electric propulsion. The reason for this is that it has a lot of advantages over conventional propulsion system. These are: –

Flexibility of engine-room layout and huge space saving

DE propulsion does away with the need for the installation of a huge centralized 2-stroke main engine and auxiliary engines as on cargo ships.

Instead of this, the job of supplying electric power for the ship loads and for propelling the ship is carried out by the main generators. These generators allow for huge space saving and offers flexibility of location and arrangement.

The propulsion motors are themselves much more compact and lighter than conventional engines and being two in number. They allow for even distribution of weight athwartships.

This is even more amplification for DE propulsion fitted with azimuth podded propellers in which the need for shaft lines, stern tube, steering gear/rudder and stern thrusters is dispensed with.

Load diversity between ship service load and propulsion

The use of solid-state devices (diodes and thyristors) in the form of electronic converters for power circuits has enabled a single source of main electrical power (main DGs) to be used for all shipboard power requirements. This means doing away with the need for separate main and auxiliary generators.

The variable speed and torque requirements for the PEMs are handled by the convertors which convert fixed voltage and frequency to variable voltage and frequency for propulsion needs.

The other lower voltage ship loads are also supplied from the HV busbar through step-down transformers thus eliminating the need for additional gensets and reducing costs.

Higher propulsion redundancy

Two PEMs ensure redundancy as the failure of one does not render the ship to operate. Even each PEM has two separate drives or stator windings, known as half-drives which ensure redundancy. In case of failure of one of the windings, the other can be used to safely port the ship.

Economical part-load running

Slow-speed/part-load running does not affect the specific fuel oil consumption in DE drives in the same way as it affects conventional direct-drive engines. This is because the speed/torque is varied electrically by changing frequency and voltage.

The main DGs, irrespective of propulsion loads, always run at a constant speed and can be started or stopped as per load requirements. This ensures plant efficiency and results in considerable savings on fuel costs.

Ease of control

The electrical/electronic control of speed and direction (reversing), is quicker and smoother than conventional engines which largely rely on mechanical means for the same.

The lighter weight, even weight distribution and compactness of DE drives also contribute in the ease of control.

Low noise and vibration

On passenger ships, guest comfort is of utmost importance. A conventional direct-drive diesel engine comes with disadvantages of high noise and vibration, especially during starting, acceleration and deceleration.

This problem is done away with by employing diesel-electric propulsion. Starting, acceleration and deceleration is much quieter and smoother due to electrical control.

Emission Control

As a consequence of ergonomic design, lesser weight, efficient and optimized operation of the generators and reduced SFOC, emissions are also much less in a DE propelled vessel as compared to a conventional one.

Higher efficiency

The use of high voltage for DE propulsion is with the view of reducing current and conductor size. This also has the effect of considerably reducing copper, eddy and hysteresis losses.

The DE propeller efficiency is in the region of 87-90%.

Propulsion Electric Motor

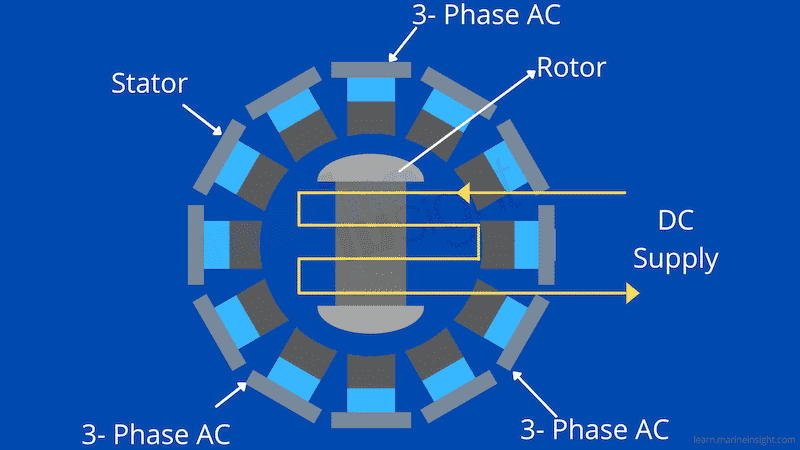

An AC synchronous motor is usually employed as a propulsion motor on passenger ships. It is not self-starting unlike an induction motor.

This is because when the rotor is excited with DC current, the magnetic flux produced interacts with the rotating magnetic field of the stator.

This interaction causes alternate attraction and repulsion due to a change of polarity every instant. Thus, it is unable to rotate because of its own inertia and requires additional help.

It is solvable by the use of either an external prime mover or a damper winding. An external prime-mover rotates the rotor to a speed close to synchronous speed after which DC is available for magnetic locking.

®A damper winding is an extra winding in the rotor provided in order for it to start as an induction motor. Once it starts and the speed nears synchronous speed, DC excitation is supplied and magnetic locking takes place.

Azimuth Podded propellers (Azipods)

This type of propulsion was pioneered by ABB in the late 1980s and has gone on to become a popular choice amongst passenger ship owners. It has become popular as AZIPOD, a name which has become synonymous with this type of propulsion, somewhat like XEROX for photocopiers.

Since then, apart from ABB, companies like Rolls-Royce and Schottel have also come up with their versions of the same.

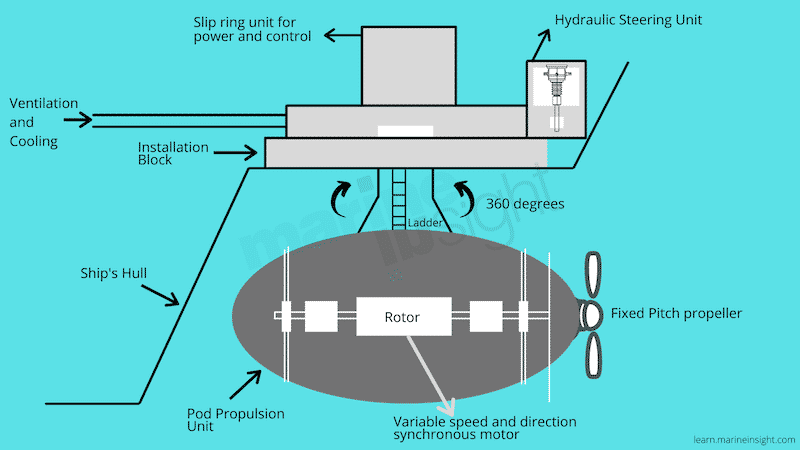

AZIPODS replace PEMs, thrust blocks, shaft lines & bearings, stern tube, steering gear & rudder, stern thrusters and stern bossing, hence simplifying casing, making engine-room smaller. It also creates more room for commercial space on cruise ships, thus enhancing earning capacity.

The AZIPOD is the first diesel-electric podded propulsion that is capable of azimuthing through 360 degrees. Their use has done away with rudders and stern thrusters.

There are around 100 cruise ships that have embraced this technology. These include Royal Caribbean International’s Oasis-class ships Oasis of the Seas, Symphony of the Seas, Harmony of the Seas and Allure of the Seas, to name a few.

Power cables from the HV switchboard connect to the PEM in a conventional DE propulsion system, which converts the electrical power to mechanical power. It then gets transmitted to the propellers with the help of lengthy shaft lines, bearings and thrust blocks.

These power cables instead go to a pod room at the stern where after getting converted to variable voltage and frequency by transformers and converters, they are fed to a slip-ring unit, rendering shaft lines and related equipment needless.

This slip-ring unit transmits this voltage and frequency-controlled power to the synchronous motor placed inside the pod.

A hydraulic steering unit aids in the 360 degrees turning capability which is useful during maneuvering. It is especially applied in many cruise destinations having smaller ports and limited tug assistance.

Reversing can be achieved either by reversing the propeller rotation or by rotating the pods 180 degrees. The latter helps to reverse the vessels without the need to reverse the prime-mover.

Advantages of podded propulsion:

- Increased energy efficiency (18-20%) with reduced fuel consumption.

- Improved crash-stop response.

- Reduced maintenance as it eliminates lengthy shaft lines and related equipment, steering gear/rudder, and stern thrusters.

- Reduced ship building time and expenditure as shaft installation and alignment works, bossing, stern thruster tunnels and installation works are not required.

- Excellent manoeuvrability even for large vessels.

- Efficient ice navigation.

- Enhanced space efficiency i.e., more flexibility of engine-room layout, smaller engine-rooms, more commercial and passenger space. This means more earnings.

- Increased redundancy because of the presence of multiple units (2 or even 3).

- Reduced emissions and enhanced energy efficiency due to lesser weight.

- Reduced noise and vibration and hence, enhanced passenger comfort.

- Reduced propeller size. This means cost saving, reduced maintenance and reduced chances of cavitation damage.

We saw how electric power is produced and distributed on cruise ships, how diesel-electric propulsion works, its advantages over convention 2-stroke engine driven centralized propulsion system and the latest avatar of DE propulsion (the podded propulsion system with its numerous advantages over both centralized propulsion system as well as traditional DE propulsion system).

Technological advancement in the design of ships is making rapid advancements and cruise ships are no exception to this. Each passing year, new technologies are being conceptualized, designed, experimented and fitted on new ships.

This makes the chips more efficient, powerful and environment-friendly than their predecessors. It also significantly reduces maintenance, man hours, costs and enhances the quality of life on board for guests and crew alike.

You might also like to read:

- How Do Cruise Ships Get Fresh Water?

- Top 10 Largest Cruise Ships in 2021

- Engineering Department Onboard Cruise Ships – A Detailed Guide

- How Much Fuel Does a Cruise Ship Use?

Do you have info to share with us ? Suggest a correction

Latest Marine Technology Articles You Would Like :

What is Eductor On a Ship?

What is an EchoSounder?

Practical Sample Kits by Normec MTS Allow the Crew to Take Water Samples Themselves

The Essential Guide to Bow Thruster Construction and Functionality

8 Biggest Ship Propellers in the World

Ballast Water Treatment System – A Boon For Many, A Menace For Some

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

One Comment

this is a really good article to read

Leave a Reply

Your email address will not be published. Required fields are marked *

Subscribe to Marine Insight Daily Newsletter

" * " indicates required fields

Marine Engineering

Marine Engine Air Compressor Marine Boiler Oily Water Separator Marine Electrical Ship Generator Ship Stabilizer

Nautical Science

Mooring Bridge Watchkeeping Ship Manoeuvring Nautical Charts Anchoring Nautical Equipment Shipboard Guidelines

Explore

Free Maritime eBooks Premium Maritime eBooks Marine Safety Financial Planning Marine Careers Maritime Law Ship Dry Dock

Shipping News Maritime Reports Videos Maritime Piracy Offshore Safety Of Life At Sea (SOLAS) MARPOL

The Shipyard

For Those Who Love Ships

- Cruise Ships

How Cruise Ships Work (Part 3): The Bridge and the Engine Room

It’s like back in the days when we were little children. Grandpaw’s almost mystical tool shed was strictly off limits, but we were just dying to have a peek, weren’t we? Now that we are all grown up, Grandpaw’s gadgets are old news, but there is still a place or two on a cruise ship that remains like a pie in the sky for all of us obsessed by ships.

It’s the heart of the matter, it’s where it all happens, it’s the real deal. And if you are anything like me, you would gladly give away a day at the spa, a dessert buffet and even two, or the latest Marvel flick in the movie theater, just to spend a precious hour down in the noisy engine room of your favorite cruise ship. But life being proverbially unfair, modern cruise lines rarely allow their passengers to enter the bridge or the engine rooms of their ships, unless the visit is part of a specially organized guided tour. Some cruise ships have a window from which passengers can observe what’s going on in the bridge, but only if they promise not to disturb the officers. Which is really hard, when you badly want to touch everything…

So until the next time someone lets me out of sight and I make my umptieth attempt at trespassing to the engine room, let’s have a quick virtual tour of a cruise ship’s most forbidden and exciting parts.

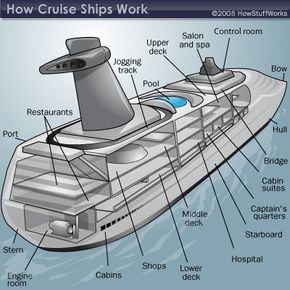

The bridge is the brain of the ship. It is from there that the captain and his officers command and maneuver the ship, keep watch for other vessels or potential hazards, and navigate through the oceans.

For twenty-four hours each day, the bridge is occupied by two Deck Officers and two Able Seamen, traditionally in four-hour shifts. The main job of the Officer of the Watch is to monitor the ship’s systems and surroundings, and to ensure that everything is running safely and smoothly. During extreme weather, docking, or other special cases, the Captain of the ship is also present on the bridge to guide the deck officers.

The term “bridge” comes from the time of the paddle steamers, where a bridge was built above the two paddle houses that used to hold the paddle wheels. This way the skipper could observe both wheels, while moving freely between the two and giving out commands. On today’s cruise ships, the bridge is usually on the upper deck in the forward part of the ship and extends over the sides of the superstructure, allowing deck officers a view to the sides of the ship as well as down to the waterline. The side extensions are called bridge wings and often have a glass flooring for better visibility.

The bridge houses a number of important nautical devices and information systems for command and navigation of the ship.

Satellite Navigation

The signals emitted by special navigation satellites are picked up by the cruise ship through a special antenna. On board, a computer converts these signals into the exact position of the ship at a given time. On large ships, the position indicator is constantly recorded in a so-called electronic nautical chart.

Satellites also enable automatic positioning systems on modern cruise ships. The positioning system is controlled from the bridge and it uses GPS to ensure that the ship stays at a defined location. When the captain defines a position where the ship needs to remain for a while without anchoring, the system automatically maintains the ship in position by using the bow and stern thrusters.

Modern cruise ships carry a gyro compass and a magnetic compass. The gyro compass consists of a fast-rotating disk, usually positioned in a gimbal. It is a non-magnetic compass oriented parallel to the axis of rotation of the earth and thus indicates the north-south direction.

The gyro compass is more accurate and reliable than the magnetic compass and is therefore the primary reference point for steering the ship. The magnetic compass on board is more prone to inaccuracies and it serves only as back-up.

The word radar stands for Radio Detection And Ranging. Radars are devices that allow us to locate distant objects from a given location, regardless of visibility and weather conditions. The radar emits electromagnetic waves to an object, then receives back the reflected echoes from that object, and interprets them based on distances and angles. These interpretations enable us to determine where an object lies, and in some cases even what its contours look like. In the shipping industry, radars are used for monitoring traffic in ports and coastal regions, for collision protection, for collecting weather data, and for navigation.

Speed logs are devices that measure the speed of the ship. There are two main types of speed logs: Doppler logs and electromagnetic logs.

The Doppler logs send out underwater sound signals. When the sound wave reaches the sea floor, it gets reflected and then returns to the receiver of the log. Due to the movement of the ship relative to the seabed, a Doppler effect occurs and is evaluated by the device. As long as the sound waves can reach the bottom of the sea and return to the receiver, the Doppler log measures the distance travelled over ground. However, if it is no longer possible to use the seabed as a reference, the device uses particles suspended in the water, such as plankton and minerals, to measure travel through the water.

The electromagnetic logs create an electromagnetic field in the water around the ship, with the aid of a small alternating current and a transducer. A voltage proportional to the speed of the ship is generated in the water and is picked up by special sensors, which then transfer the information to an electronic device for interpretation. From the electronic device, the speed is then transmitted onto the displays in the bridge.

Echo Sounder

Cruise ships also have an echo sounder, a device used for the electro-acoustic measurement of water depths (sounding). The depth is determined by measuring the time between the emission of a sound impulse (water sound) and the arrival of the sound waves reflected from the bottom of the sea. The main purpose of echo sounders in cruise ships is safe navigation through waters.

Electronic Chart Display and Information System

The Electronic Chart Display and Information System (ECDIS) is a console, built into the bridge of modern cruise ships, which incorporates the main engine safety system, fire control system, monitoring and control system, power management system, propulsion control system and navigation and maneuvering system. The ECDIS allows for navigation of the ship without the need of traditional paper charts. Navigation can be done manually, automatically, or through the Navigation and Command System (NACOS).

The NACOS is the main software used to coordinate all factors that need to be taken into consideration, in order to navigate and maneuver the ship safely. The console is composed of a number of displays showing information from the radars and compasses, data about the course of the ship and planned maneuvers, the current status of the pitch of the thrusters, the speed of the ship, and anything else concerning the steering of the ship. An intelligent autopilot tracks changes in the behavior of the ship through navigational sensors. If the ship drifts off its course due to strong winds, for example, the system automatically responds to correct the change by sending signals straight to the engine room. Once the signal is received by the engines, the rudder or thrusters of the ship are activated and move to the position given by the system. The displays on the bridge show both the angle of the rudder or thrusters, as well as the rate and the radius of the maneuver in progress.

The Engine Room

The engine room is the heart of a cruise ship. It is here that pistons hammer and crankshafts turn to propel the ship forward. It is the loud and oily place where the Chief Engineer and his team work around the clock to ensure that everything is running smoothly. It is the engine room of the ship that allows for the luxuries of air-conditioning, electricity, and plumbing on board cruise ships.

In future articles we will have the chance to explore the contents of the engine room in all the excruciating detail that they deserve, so to all the techies out there – I’ve got you covered. Just stay tuned.

Most larger ships have more than one engine room to house their machinery. The arrangement of the engine room can vary depending on the type, design, and size of the ship. For stability reasons, the engine machinery is typically placed as low as possible in the ship’s bowels and often takes up several decks in height. The machine rooms are split into watertight compartments, each housing different machinery.

Today’s cruise ships operate on diesel or diesel-electric engines. Their operating principle does not differ much from the old days of coal steamers, except for the medium used to generate power. While back in the day ocean liners used steam to move the engine’s pistons, modern cruise ships use diesel fuel. Today’s diesel engines are composed of the engine unit itself, gearboxes, shafts and generators. Some ships also have shaft generators which create electricity from the turning movement of the propeller shaft. The electricity is then used in the cabins, on deck and in the kitchens.

The latest generation of cruise ships are equipped with diesel electric engines. Instead of the more traditional engine-shaft-propeller arrangement, in this case the engines are connected to generators to create electricity. The generators power electric motors, and the electric motors move the propellers.

Aside from the engines and generators, the machinery that occupies the engine rooms includes pumps and heat exchangers for engine cooling, stabilizer fins and their motors, as well as the ship’s bow thruster system.

Since all of the equipment in the engine room is highly dependent on electricity, modern cruise ships also have back-up generators, usually located outside the main engine room, to protect them in case of fire. While these generators cannot produce enough power to keep the ship moving, they produce enough to keep some of the vital functions of the ship running, such as powering the emergency lights and the communication and navigation systems. In case the back-up generators fail, cruise ships are also equipped with a back-up battery that allows some of these functions to continue running for short periods of time.

All the machinery in the engine rooms is monitored in the Engine Control Room (ECR). The ECR is a room full of screens, lights, alarms, and switches from where the current operational status of every piece of equipment can be checked.

The main switchboard of the ECR is used to distribute the generated electricity to where it is needed on board. The ERC is also where the engineering team comes together to discuss and plan the safe running of the engine rooms, to take decisions in emergency situations, to consult the technical manuals and drawings of the ship, to restart certain pieces of machinery if necessary, and to maintain communication with the bridge. Communication between the ECR and the bridge is crucial for the safe operation of the ship, especially during docking, moving through shallow waters, maneuvering, and changes in the course or speed of the ship.

This concludes our three-part overview of how a cruise ship functions. Now that we have covered the basics, in future articles we can explore all the specifics to our hearts’ content. As always, don’t hesitate to leave your constructive comments below and feel free to suggest topics you want to know more about – chances are I want to know more about them too!

Stay in touch and I’ll see you next time!

Share this:

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Privacy Overview

Cruise Ship Engine Room (Everything You Want to Know)

Disclosure: This post may contain affiliate links. We may receive compensation when you purchase via my links at no cost to you. See my disclosure for more information.

Cruise ships require a lot of power to sail and operate. The cruise ship engine room is both mysterious and fascinating because it’s hidden from passengers.

Passenger ships have come a long way from sails and steam engines. Modern cruise ships use diesel-electric engines, while newer cruise ships are moving towards more environmentally friendly solutions like liquified natural gas.

Here’s everything you need to know about a cruise ship’s engine room.

Table of Contents

Where is the Cruise Ship Engine Room?

The engine rooms on cruise ships are located on the lower decks, between the midship and the aft. The engines aren’t quite at the back of the vessel but closer to midship.

There are several reasons for keeping the cruise ship engine room away from passenger areas.

- Stability : Placing the engines and heavy equipment below sea level helps keep the ship stable and prevents cruise ships from tipping over .

- Noise : Engine rooms are extremely noisy. Naval engineers compensate by incorporating sound reduction features and noise dampeners. However, the sound and vibration wouldn’t be pleasant for cruise ship passengers.

- Security : The engine room spaces are in crew-only areas for safety and security purposes.

Most of the heavy machinery on a cruise ship is located on the lower decks, just above the keel. The positioning of the engine room, other machines, and technical equipment give the massive vessels a lower center of gravity.

Although you might envision the engine room as a massive open room running the ship’s length, the lower decks are divided into several water-tight compartments. One compartment may house the cruise ship water fresh water systems , another for the main engines, and another for the air conditioning.

The division of the engine room into separate compartments is for safety. Dividing the engine room into different containers makes it easier for the ship to contain the damage if there’s a fire or leak in the hull.

Cruise ship fuel tanks are also on the lower decks, but they are kept separate from the main engines.

Crew members can monitor the ship’s systems from the engine control room. From the operation control center, crew members monitor the ship’s systems and act as a central area for maintaining the technical equipment on the cruise ship.

Every piece of equipment can be monitored from the engine control room to ensure the cruise ship runs smoothly.

The room is monitored 24/7 by watchkeeping teams. Each crew member is assigned specific machinery. For example, one person may be responsible for the freshwater generators and water pumps and another for the fuel oil systems.

How Big is a Cruise Ship Engine?

A cruise ship engine room spans several decks and holds the ship’s engines, fuel tanks, water systems, generators, control room, engine workshop, air conditioning, and other essential navigation systems.

Modern diesel-powered cruise ships have between four to six medium-speed (500 revolutions per minute) engines . Each engine can generate upwards of 25,000 horsepower or nearly 18.5 megawatts.

The engines on a cruise ship can be up to 45 feet long, 27 feet high, and weigh up to 275 tons .

These massive engines can propel cruise ships at an average speed of 18-22 knots .

Cruise Ship Engine Technology

Cruise ship engine technology has evolved from wind and sails to newer liquified natural gas technology.

We’ll cover some of the most popular technologies used by cruise ships.

Steam Engines

When the cruise industry began in the mid-1800s, vessels were propelled by steam engines.

Steam engines had boilers that used wood for fuel. Later steam engines used coal.

The boiler produced steam which created pressure in a pressurized system. The pressure moved pistons which drove the propeller shaft.

The Titanic was powered by two huge triple-expansion steam engines and a small propeller. ( Source )

Diesel Engine s

Diesel engines propel most modern ships. Cruise ships may have four to six medium-speed (500 rpm) engines producing 8-10MW each .

Diesel engines work on the same concept as steam engines. Rather than steam, the ignition of diesel fuel pushes the pistons up and down, turning the crankshaft attached to the propeller shaft.

Many of today’s diesel-engine cruise ships also employ a shaft generator to generate electricity for shipboard services, like lighting.

A shaft generator converts the circular motion of the propeller shaft into electricity. However, shaft generators only operate when the ship is moving. And can’t generate electricity while docked in port.

Diesel-Electric Cruise Ship Engines

Almost all new diesel-powered cruise ships use diesel-electric engines.

The engines work the same as a traditional diesel engine, but rather than connecting to the propeller shaft – diesel-electric engines connect directly to large generators .

A diesel-electric engine has one job, generating electricity.

The electricity produced by the engine is used to power the ship’s propellers.

These engines provide greater efficiency than traditional diesel engines.

While connected to a generator, the engines can run at their most efficient settings regardless of the travel speed . Whether the ship is sailing at 10 or 20 knots, the engines can operate a peak efficiency.

Diesel-electric engines are popular because of their ease of control, low noise, minimal vibration, and relatively compact size compared to other forms of propulsion.

Marine vessels that run on diesel power must carry exhaust-treatment systems and catalytic-reduction equipment to reduce the environmental impact of the ship.

Gas-Turbine Power System

Royal Caribbean Group was the first company to experiment with gas-turbine systems.

Compared to diesel engines, gas turbines offer several advantages, including:

- Lower environmental impact.

- More reliable.

- Take up less space.

- Gas engines require a smaller maintenance crew and less inventory.

The heat generated from the engine is recovered and used to produce electricity for other onboard systems, such as air conditioning and water heating.

Despite their advantages, gas propulsion is not widely used in the cruise industry. Gas-powered ships are faster, but most cruise ships don’t travel faster than 22-25 knots .

Diesel engines have greater fuel efficiency at slower speeds , and the high gas price compared to diesel makes them more costly to operate.

LNG Powered Ships

Many new cruise ships are propelled by liquified natural gas (LNG).

LNG is the cleanest fossil fuel currently produced. According to Cruise Critic , LNG-powered cruise ships can “reportedly reduce sulfur emissions by as much as 99 percent and nitrogen oxide emissions by up to 85 percent.” LNG can reduce carbon emissions by up to 20 percent .

The special engines of LNG-powered cruise ships use natural gas cooled to approximately -260°F. Once cooled, the liquid form of natural gas is about 600 times denser than natural gas , making it easier to transport.

Carnival Cruise Line announced the first LNG-powered vessels in 2015, using a “dual fuel” design. The ships can burn both liquified natural gas and marine fuel, reducing the required fuel storage space.

AIDAprima became the world’s first LNG-powered cruise ship on her debut in 2016.

Natural gas is purer, cleaner, more efficient, and cheaper than other fossil fuels . But it’s a relatively new technology, and not all ports have the facilities for refueling LNG-powered ships.

Because natural gas burns cleaner than other fossil fuels, the engines require less maintenance. But LNG has a lower fuel density than diesel, so LNG vessels need fuel tanks that are twice the size.

Emergency Generators

Every cruise ship has an emergency generator to maintain vital electrical power in case of engine failure.

The emergency generators are located away from the main engine room, usually on a higher deck. Their location isolates them from catastrophic damage in the engine room (for example, a fire).

The generators can operate critical navigation systems, emergency lights, and other vital equipment. But emergency generators can’t power the ship .

Larger ships may have multiple emergency generators. But due to the size constraints, they can’t produce the same power as the main engines and cannot propel the ship.

What happens if the generator fails?

Cruise ships have several redundant systems to ensure the safety and security of passengers. If the generators fail to work during an emergency, cruise ships have an emergency battery backup to power the most critical systems for up to 24 hours .

Shore-to-Ship Power Supply

Despite innovations in engine technology, cruise ships produce a lot of pollution.

To further reduce ships’ environmental impact, many cruise ships can connect to the cruise port’s power grid , known as “shore-to-ship power” or “cold ironing.”

In the past, cruise ships kept their engines running while docked to generate electricity for shipwide services.

But most of the energy produced by the ship’s engines goes towards powering the propellers, and running the engines while docked created massive energy waste.

Some cruise ships used smaller generators to power the hotel and amusement functions. The smaller generators allow cruise ships to shut off the main engines in port, reducing pollution.

Modern cruise ships are equipped with systems to “plug in” to the local power grid. Even some older cruise ships are being retrofitted to allow for shore-to-ship power.

Not all cruise ports have facilities to enable shore-to-ship energy. But many larger cruise ports have dockside electrical hookups that allow cruise ships to shut off their engines and run on the city’s electrical grid. The technology reduces harmful emissions by up to 95% while ships are docked .

Considering how much time cruise ships spend docked at port, it significantly reduces sulfur and carbon emissions.

How Loud is the Engine Room of a Cruise Ship?

A cruise ship engine room is incredibly noisy, exceeding 173 decibels . At this noise level, the noise in an engine room can cause immediate damage to your hearing without proper ear protection.

For reference, a gunshot is 130 decibels.

Engine rooms have insulation and sound-reducing technology, so it’s not as noisy. To prevent hearing damage, crew members must wear hearing protection when entering the multi-story engine room.

But guests don’t have to be concerned about the noise.

Thanks to the insulation and sound dampening, you’ll only hear a slight “purr” if you’re near the engine room.

You may feel the engine’s vibration if your cabin is on the lower decks, near the aft . On most ships, the noise isn’t enough to cause any annoyance or trouble sleeping.

But if you’re a light sleeper, accommodations near the engine room are among the worst cabins on a cruise ship .

Where are the Fuel Tanks?

The fuel tanks are located below the passenger decks , near the engine room. The fuel is stored in double bottom tanks.

How Much Fuel Can a Cruise Ship Hold?

A large cruise ship of 1,100 feet in length can hold between 1 to 2 million gallons of fuel .

It’s enough to power the cruise ship for up to two weeks of sailing without refueling.

Are There Cabins Near the Engine Room?

Newer cruise ships have a large gap between the cruise ship engine room and passenger cabins to minimize noise and vibrations.

However, you may still find cabins reasonably close to the engine room.

If you book a cabin near the engine room, you can expect to hear some noise and feel the vibrations caused by the engines . However, cruise ships use sound-dampening technology and insulation to minimize noise pollution.

The engines are typically cheaper because most passengers avoid booking cabins next to the engine room.

Cabins near the cruise ship engine room aren’t noisy enough to cause annoyance or sleeping issues.

If anything, the vibrations caused by the engines are more likely to cause annoyance over the sound of the engine .

How Much Fuel Do Cruise Ships Use?

It takes a lot of fuel to power a cruise ship.

The average cruise ship uses around 18.3 gallons of fuel per minute or 1100 gallons per hour . ( Source )

Marcello De Lio

Leave a Reply Cancel Reply

Your email address will not be published. Required fields are marked *

Name *

Email *

Add Comment *

Save my name, email, and website in this browser for the next time I comment.

Post Comment

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Trending now

This is How Cruise Ships Work

by Contractor | Nov 24, 2020 | resources , Travel Tips | 0 comments

Are you wondering how cruise ships work? Whether you’re planning a trip or just curious about a cruise ship’s technicality or even the logistics, it’s always intriguing to find out how massive ships like work. How does a cruise ship work?

First and foremost, a cruise ship’s heart is in the engine of the vessel. The engine’s design, paired with proper fueling, provides the power for the ship’s mobility and all the entertainment aboard. The ship’s engineering and the logistics of running a cruise company play a role in shaping how a cruise ship works overall

If you are an engineer curious about a ship’s mechanics, this is an article for you. Fortunately, if you’re just a curious traveler wondering how a cruise vessel will shape your next trip, this is also for you, so read on. There is so much to a cruise ship other than the cocktails and fun parks on top. This will be an eye-opening article for all audiences.

How Do Cruise Ships Work

To the ultimate question, “how a cruise ship works,” let’s dive into how it works mechanically. What are the technical and mechanical aspects of a cruise ship? What does an engine do? How does a massive ship provide light, food, entertainment in the middle of an ocean? Is the water safe to drink?

Then, after reviewing how the cruise ship’s mechanics work, the answer to how a cruise ship works logistically can be answered. How do companies make a profit from these vast ships? How do the ships prepare for new passengers?

Technical Aspects of Cruise Ships

The technical aspects are a vital part of a cruise ship, so it will be first visited. Not to state the obvious, but the ship’s heart is shaped by the crew and the engineers that have put many hours and dedication into making a cruise ship work.

This is article will reveal the true hidden layers of what makes it all work starting from ground zero, the heart.

Technical Aspects

If you want one thing in a cruise ship aside from the cocktails and a nice tan, it’s the vessel’s stability and durability. Whether you are traveling through an unexpected storm or cruising on a gentle wave, your cruise ship should be the most stable in all situations.

How are cruise ships stabilized? The general idea for balancing and maintaining buoyancy is distributing the weight throughout the ship correctly, and of course, displacing the right about of water as it moves. So, let’s first talk about one of the most massive machinery onboard, the engine. Where does it sit and how does it run the cruise ship?

Engine Rooms

Where are the engines located? You guessed it, most heavyweights, such as engines, are found as low as possible in the lower decks, ground zero. For most cruise ships, the engines are close to the keel. The structural keel is the most closes to the bottom of the vessel and the ship’s wide hull. It runs the length of the vessel down its centerline and in most ships, you won’t have to go far to find the engine rooms.

Just because it’s placed low in the ship doesn’t mean it doesn’t take a lot of space. For all the ship’s power, the engine rooms can take up several decks high and are generally divided into several compartments. It may not feel like an open massive space, but it is truly the heart of the ship and the design of the rooms and placement are critical.

Usually, the primary concern for most ships is have engines and machinery compartmentalized for safety and avoiding fire hazards. Compartmentalized and labeled rooms make maintenance simpler and enhances safety for unprecedented accidents.

New legislations also support the requirement for compartmentalization. Ships are required to have at least a duplicate of equipment and at least two separate spaces for engines. So, what about these engines? Why are they so important and why do ships need so many of them?

Power and Engines

Just to answer those questions, we’ll have to visit more fundamental questions such as: How do the engines power a giant cruise ship? How does it help the ship propel forward? Are there specific engines that power different parts of the cruise? Out of many questions regarding the engines, the answer starts with the main engines.

The main engines are the engines that produce the majority of the power for the cruise ship to move. Depending on the type of vessel, the main engine connects to different parts of the propelling power. From traditional steamboats, to diesel electric, the engine is the fundamental powerhouse for the entire ship on the sea.

The following table is a general overview of how engines on different types of vessels are connected to the ship’s requirements.

So How Do These Engines Make the Ship Move?

As shown in the table, depending on the vessel type, the engine will provide power to different aspects of the ship. More or less, everything is distributed to operating proportions, but the key mechanics differ from one to another.

Diesel may be something more familiar to what we saw in old movies with steamboats. Even in modern days, we use similar mechanisms, if not labeled the same. The main difference is the source of pressure, which can be the traditional steam, or a fuel ignition.

Whether it is steam (traditional) or fuel ignition, the pressure generated from either push the pistons up and down in the vessel. These pistons connect to crankshafts through gears, which turns the pistons.

The crankshaft connects to the propeller through a long propeller shaft and gears, which further determines its speed in traditional diesel-powered vessels by steam pressure. Generally, the faster the pistons move up and down from the pressure, the quicker the propeller shifts would move.

With modern designs that control the propeller speed, engineers placed the gears in between the propeller and the engines which further enhances efficiency for both engines and propellers.

Again, although the majority of the engine provides electricity to the propeller shaft, electricity must be provided to the rest of the ship for entertainment. Often, options such as a shaft generator offer power to outlets such as lighting the dining and general appliances onboard while in motion.

Diesel-Electric

Diesel-electric is another form of vessels that are found commonly with conventional diesel vessels. Unlike the conventional diesel, diesel-electric engines are connected directly to the generators that provide the electricity for the propellers and main generators.

This electricity also provides direct power for the ship’s lights, appliances, and much more.

Environmentally Friendly Power

On a side note, if the thought of diesel in the ocean disturbs you, there is some good news! Thankfully, more and more environmentally friendly options are appearing for cruise ships. For example, liquified Natural Gas (LNG) is an alternative method for powering ships that burns natural gas for power.

Using natural gas could reduce nitrogen oxide and carbon dioxide emissions significantly! With green-oriented companies, more green cruises have been released in the past few years.

That being said, if you are looking to book a trip, be on the lookout for green cruising opportunities! Onboard, you can also find environmentally conscious crew members and less-waste policies.

Source: CruiseCritic , Windstar Cruises , Green Cruises

Fuel Consumption

So, how does fuel play a part in powering the engine and the cruise ship? Let’s go back and visit what an engine does. An engine generates electricity to the propellers by supplying power the propulsion motors. How do they get the electricity and what makes an engine work? Most likely fuel and ignition (besides the steamboat example from before).

How much Fuel?

In general, a large cruise ship can consume up to 250 tons of fuel a day, which is close to 80,000 gallons a day. For medium size cruise ships, consumption can still range up to 150 tons of fuel a day.

Onboard, a ship may carry up to 1 to 2 million gallons of fuel, depending on the vessel size. Most of the power, which can be close to 85%, goes to the propellers, while the rest goes to keeping the cruise lit and comfortable for the passengers and crew members.

While passengers dine and enjoy their cruise aboard, crew members are constantly maintaining the proper fuel levels and providing proper power for the ship. As for the captain of the ship, he also has several variables to keep in mind to control fuel consumption and safety.

Fuel consumption may vary for several reasons, just like when we are driving our cars (but with more variability). For example, depending on where the wind is hitting the ship, the fuel consumption can go 1 – 5% over the average consumption rate.

Here is a short list of variables that the captain is keeping track of:

- Speed of the cruise

- Sea conditions (vs. sailing direction)

- Weather (including the direction of the wind)

- Size of the ship

- Engine (Gas turbines, diesel-electric, diesel, or electric)

Source: Windstar Cruises , Cruise Mapper

Overall, the fuel, power, and engine, are all functions of making the magic happen. Starting from the design of the engine, to the crewmembers and captain maintaining the fuel and power consumption, a lot of action happens behind the scenes while passengers are onboard during vacation.

Floating and Buoyancy

Now that the ship is powered, how do we ensure that it floats? How do these massive machineries, ice-skating rinks, restaurants, and bars float on water while keeping thousands of passengers safely onboard?

While the cruise ship constantly pushes the water out of its way when moving forward, the water being pushed will try to come back to its place. This displaced water pushes back with a force on the vessel which lets the cruise ship stay afloat.

This is the general idea when engineers designed the hull of the ship. This ratio has to be calculated when designing a ship and has to be correct. If you get a chance to see the hull of most ships, they have a wide U-shape hull at the front to maintain the displacement.

In addition to basic buoyancy principles, an engineer must also consider the ship’s average density. This means that the ship’s general open spaces must be considered on top of the vessel’s average weight, so the vessel remains “less dense” than the ocean’s (usually salty) water. A great example is a rock sinking vs. a beach ball floating on water.

Source: Express

Water Onboard

So the power, fuel, engine, and buoyancy are the fundamentals of the ship. What about the details of the cruise ship such as the water in your shower? Is it salty? Is it fresh? Where and how does that come to your room without running out.

In general, most cruise ships have a steam-evaporation system. Water is pumped and desalinated before going to your room. During this process, your water is distilled and desalinated using a reverse-osmosis system and filtration system.

Distillation and desalination process uses a purification system to take all contents out of the water. This is generally not healthy to drink, so this water is mineralized and chlorinated for taste and safety.

Additionally, some ships have water brought onboard for laundry and other maintenance purposes. Generally speaking, the water onboard available for drinking are tested and checked for purification. If you are ever in doubt, check with a crew member to ensure the water is safe for consumption.

Is the Water Safe?

The answer to your ultimate question is, no, the water you are drinking is not toilet water. Regulated by the Maritime Organization laws, all “toilet water” must be treated and discharged into the ocean at a specific distance from the land. This water is never treated and recycled for passengers to use again.

On a side note, if you feel uncomfortable drinking this water, bottled water will most likely be available onboard for purchase. If you need special water for medical needs, you will most likely be able to bring a few bottles on board by notifying them ahead of time.

Now that we have reviewed how cruise ships work mechanically, let’s dive into the ship’s logistics. How do they work? Who’s working, how is it supplied, and how are they so cheap? Or perhaps, why are they so expensive? All of these questions come down to logistics.

General Logistics

Depending on your opinion and type of cruise you may have signed up for, you may think that your cruise is way under or over-budget. The cruise companies measure these decisions and prices to minimize cost and maximize returns (of course).

For example, cruise ships avoid fines by taking specific lines. They must often save fuel and hiring a knowledgeable captain who can make these decisions and keep passengers aboard safe is essential.

So, what are the different divisions of a cruise vacation? Are some better than others?

Mainstream, Premium, and Luxury

If we broke down cruises into 3 main categories, we could look at the mainstream, premium, and luxury lines of cruise types. You will often see categories within each of these types, but let’s break them down into the major categories for simplicity.

First, we will start with the mainstream cruise lines. These are cruises that are readily available, common, and well-known by the public with reasonable ticket costs.

Generally, these cruises’ primary business is through the onboard casinos, spas, shopping, and drinks. They suit the needs of most passengers. To make maximum profit, companies design these cruises by providing readily available entertainment on board. Most passengers are estimated to use 500$ onboard for their vacation experience.

Onboard, you will find general amenities, restaurants, bars, pubs, nightclubs, shopping, theaters, cinemas, swimming pools, gyms, karaokes, libraries, and even museums! These are great for big parties and are generally the biggest ships at sea.

Examples of Mainstream Cruise Lines that are known as “floating resorts”:

- Carnival Cruise Line

- Royal Caribbean International

- Norwegian Cruise line

- Lindblad Expeditions

- Amawaterways

Mainstream cruises are great for

- Group of friends

Source: NancyandShawnPower , Fodors , and Wind Rose Network

Premium lines are perfect for adults or those that are retiring. The brilliant catch is that many have policies of “no kids allowed,” making it an excellent selling point for adults who need some peace and quiet. These cruises make money upfront by offering more access to ports and offering the serene luxury.

Premium cruises generally have a refined style in comparison to mainstream cruise lines. Activities are more focused on lifestyles. For example, you may find computer classes or a language-learning class. Besides, these ships still offer resort-style pools, game nights, bingo, spas, gyms, and maybe even a jazz night.

The perks for a premium in comparison to the mainstream is the higher quality of cuisine. Usually offering specialty restaurants and quality chefs, the price may be higher, but the overall quality is higher. The rooms at premium cruise lines are also superior, often offering suites and rooms with balconies.

Examples of Premium Cruise Lines

- Princess Cruises

- Celebrity Cruises

- Holland America Line

The popular audience for Premium cruise lines:

- Older Adults

- Sometimes family-oriented

Source: Fodors

Luxury lines are pricier yet offer the best-selling point, fewer people onboard with a luxurious experience from beginning to end. The more expensive tickets provided to only a few hundred passengers make a profit for the company with the much higher ticket prices.

There are abundant space and a deluxe ship that will greet you as a valued guest from beginning to end for the high price. No doubt, one will fall for such an exquisite experience that starts from fine dining of caviar and foie gras to personal service available at one’s fingertips.

Course meals are offered from a full restaurant menu in your stateroom and served with limitless wine. Most interiors are luxurious and elegant, with rooms that are large and overlooking the sea.

Amenities range from gyms, spas, pools, and low-key entertainment. Generally targeting a niche group, most luxury cruise lines do not allow children.

Examples of luxury cruise lines:

- Windstar Cruises

- Paul Gauguin

- Silversea Cruises

- Crystal Cruises

- Oceania Cruises

Source: Cruise Critic

Many corporations own several of these different targets to make the most profit. Additionally, by corporations owning various cruise types, they can also hand down older ships throughout their other brands.

Logistics throughout the year

In addition to managing several types of cruises, there are numerous ways cruises have to operate to maintain their profits and not waste money through resting and selecting the wrong routes.

For example, cruise lines generally have high sales in November through April by Americans. The cold Americans usually take a warm vacation away from winter for a trip to the Caribbean.

What about other times of the year? Staying on seas without business is a considerable loss in revenue and usually unheard of. So, what do they do? They sell repositioning one-way tickets in April!

Generally, towards the end of April, you will start seeing two-week trips from the Caribbean to Europe. Typically, these trips can range from any state on the Eastern Coast of the United States to European countries.

Switching over/Cleaning

When there are one-way trips, there also needs to be exceptional coordination for a short turnaround between trips. When the cruise ships get to the destination, all hotels, theaters, dining, laundromat, and parks are cleaned and reset for the next people to come on board within half a day!

How do they do it?

During night-time, luggage and bags are ready ashore for passengers to check out. Meanwhile, all the trash is dumped, and the trash containments are cleaned, crew members switch, fuels are refilled, and food is refreshed with new inventory.

Remember the 1 to 2 million gallons of fuel to refill? This process, called bunkering, is a whole-team effort and is completed before the ship is ready to travel again.

A small boat, a “barge,” brings fuel to the 400 ports fueling for ships.

- Barge secures to the side of the cruise ship

- Connects a hose between the ship tanks

- Pumps fuel while watching guard

When passengers load off, then the cleaning crew comes to clean the rooms. While the ship is pampering, they complete paperwork from the first trip, fulfill any necessary maintenance, redecorate rooms, and start preparing and cooking food and lunch for the next set of passengers coming on board.

Soon, the ship is reloaded with happy passengers and starts to move again. They make their profits from when the Casinos start, and food is served.

Crew Members

This brings light to the less noticed crew members. The ones that make all the magic happen. Generally, a cruise will have 1 crew for 2 passengers. Most of the crew members are working very long hours for several months.

In general, these crew ships are in their rooms when not on duty and do not get in the passengers’ way. How do cruises afford these crew members and their extended hours of work? The trick is that cruises can register in any country to abide by their labor laws. This is how they keep costs low, but there is a catch to that.

Crews and Destination

So, there is a catch, but it impacts your travel too. Did you ever wonder why cruises took less than expected stops? Not necessarily detours or emergency stops, but maybe a cruise led you to Ensenada or the Tabuaeran. This is due to the Passenger Vessel Services Act of 1886.

Why do cruises take weird detours?

Generally, a cruise ship can register any Labor law, as stated above. This makes it easy for cruise ships to pick a non-American country since it is cheaper and easier to fulfill (for business purposes). Unfortunately, if they choose this option, they must also abide by the Passenger Vessel Services Act of 1886. This act states that “No foreign vessel shall transport passengers between the United States.”

This means that if the cruise ship is registered under another country, they can never directly stop at an American stop if their initial take-off was in the United States. This is why you see stopes in Ensenada, for example.

For example, before Norwegian registered as American, if their cruise trip was to Hawaii from the motherland, they had to stop at Tabuaeran, a small island nearby.

When Norwegian registered as American, this let them bypass the Passenger Vessel Services Act. Unfortunately, this led the crew members’ service fees to rise, which led to higher ticket prices. If you want to watch how the above logistics work, check out this video !

A Cruise Ship Overview

Starting from the engine, fuel, and engineering to the logistics of companies, crewmembers, and governing policies, a cruise ship works in a marvelous way to shape every passengers’ experience abroad.

Thousands of crewmembers across various cruise ships, engineers of several centuries, and many hours of dedicated personnel make a cruise vacation work. Next time you are enjoying a cocktail on deck, remember that there is so much more behind the meaning of your cruise. There are so many parts that worked to make it happen! Enjoy and bon voyage!

Related Posts:

Submit a Comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Privacy Overview

How Do Cruise Ship Engines Work?

By Robert Palmer

Cruise ship engines are what make the entire vessel move, and as such, they are vitally important pieces of technology. Cruise ships rely on either diesel or gas turbine propulsion systems to travel from port to port. These propulsion systems use fuel sources such as diesel oil, bunker oil, heavy fuel oil, and natural gas.

Diesel Engines

Cruise ships that use diesel engines have a prime mover that is responsible for rotating the propeller shaft. The prime mover can be either a slow-speed two-stroke engine or a medium-speed four-stroke engine.

Slow-speed two stroke engines burn fuel at a lower rate than four stroke engines for the same amount of power output and require less maintenance. Meanwhile, medium-speed four stroke engines provide better fuel efficiency at higher speeds and are more reliable than two stroke engines.

Gas Turbine Engines

Gas turbine propulsion systems are also used in some cruise ships and work by using an air compressor to force large amounts of air into combustion chambers where it is then heated and mixed with fuel before being ignited by spark plugs. The resulting hot gases are then expelled out of the exhaust nozzle at high speeds, which creates thrust and propels the vessel forward. Gas turbine propulsion systems are more efficient than diesel engine systems but require more maintenance due to their highly complex design.

5 Related Question Answers Found

What do cruise ship engines run on, what engine does a cruise ship use, what kind of engine does a cruise ship have, how powerful is a cruise ship engine, how much engines does a cruise ship have, backpacking - budget travel - business travel - cruise ship - vacation - tourism - resort - cruise - road trip - destination wedding - tourist destination - best places, london - madrid - paris - prague - dubai - barcelona - rome.

© 2024 LuxuryTraveldiva

How ships float, avoid icebergs, & other questions from our not-so-scientifically-inclined writers.

Our virgin voyages engineers are dishing on what actually makes cruise ships work..

As a Sailor on one of our cruises, there’s some stuff we don’t want you to worry about. Cooking for yourself, for example. Stressing about work. And we certainly don’t want our Sailors to be preoccupied wondering, “how do cruise ships work?” or “no seriously, how do they stay afloat like that?” Our engineers worry about these things so you don’t have to. But even if you’re not contemplating the Archimedes Principle of positive buoyancy while you’re soaking up rays on the pool deck, you might have always wanted to know how cruise ships stay afloat, or how they avoid obstacles at night. These are interesting questions, even for the non-mechanically inclined.

Since we’re in the cruising business, we find this stuff fascinating, too. That’s why we interviewed Chief Engineer Rhea Wilson and her team to get the inside scoop on everything related to ship mechanics and operations. They break down how cruise engines work, where the water you’re drinking comes from, how cruise ships detect icebergs, how they avoid icebergs, and — yeah, a lot of other iceberg-related questions. If you knew nothing about ship mechanics before, that’s about to change. This one’s for all the nerds out there.

How cruise ships work: An interview with our Chief Engineer

Maybe a stupid question, but how does such a massive boat stay afloat, anyway?

Engineers : Science. Archimedes Principle to be exact, positive buoyancy. Basically the bit of the ship in the water weighs less than the weight of water it replaces (lots of tanks to create buoyancy). Why a tree trunk will float but a brick will sink despite the tree trunk weighing more.

Where is the engine located, and how are cruise ships powered?

Engineers : Cruise ship engines are located near the bottom of the ship as they are heavy, and they are usually towards the aft of the ship. Cruise ships use Diesel-Electric propulsion systems. The main engines are generators which produce electricity which then powers the azipods. VV ships have 4 engines and 2 azipods. There are 3 bow thrusters to provide maneuverability when arriving/departing a port.

Azipods are a motor with a built in propeller and rudder. The electrical power created by the engines drives this big azipod motor which turns the propellers, and pulls the ship forward. Basically think of how a jet engine pushes air across a plane wing — that's how an azipod and propeller pushes water across the rudder and drive/steer the ship. They can turn 360 degrees for maneuverability, and the rpm of the propeller varies depending on the required ship speed.

People tend to imagine engine rooms looking like the one on Titanic, with sweaty laborers shoveling coal into the engine. What does a cruise ship engine room actually look like?

Engineers : Well it can be a hot working environment, there is a lot of heat generating machinery in the engine rooms. However a modern engine room is bright and clean and nothing like Titanic. The engines are a large part of the engine room, but the whole lower part of the ship is the engine rooms and compartments with auxiliary equipment used to supply a whole ship. So fresh water generators, a wastewater treatment plant, stabilizers for minimizing ship movement etc, not only the engines like you see in the movies.

Speaking of Titanic, what technology is in place to keep cruise ships from hitting icebergs?

Engineers : Much better equipment for detecting objects in the water. Be it small craft, other large ships, or icebergs. That and proper binoculars for the lookouts.

Cruise ships are pretty huge. How quickly could it change direction and navigate around an iceberg, if one was detected?

Engineers : As above, the azipods make a large ship really maneuverable for it's size, much more so than a ship with conventional propellers and rudders.

If the ship did hit an iceberg, and started taking on water, what would happen?

Engineers : There are 5 main vertical zones along the ship, and split further into compartments. Every one of these compartments are capable of being fully isolated in case water came in and the ship would still be operational. There are regulations in place for essential services to stay functional in case certain sections were lost to fire or flooding.

Okay, enough about icebergs. We don’t even sail near them. People are more aware now than ever of their carbon footprint. What are cruise ships doing to reduce emissions ?

Engineers : There are stringent rules and regulations on emissions globally and locally to the ports the ships visit. There are advanced gas cleaning systems always in use to comply with these rules.

If someone fell overboard and the ship needed to stop, how long would that take? No one will, but I just have to ask.

Engineers : The requirement for a complete stop from full speed is 15 ship lengths, but the Virgin Voyages ships take less than half that for a stop from full speed.

Where do the ship engineers (and other essential ship operating staff) sleep when they’re not working?

Engineers : The majority of ship engineers/essential staff have accommodations close to the Engine Control Room, so they are close to their workplace. Most engine officers have an alarm fitted in their cabins which is activated from the ECR in case of technical emergency. Usually the deck below the main passenger decks, so with a porthole for daylight :)

Is there a giant 12,000,000,000 lb anchor like you see in movies?

Engineers : Not so much. There are two anchors by the bow, but they're not comically large. An anchor's “weight” to keep a ship in place is in the chain, not the anchor itself.

Where does the drinking water come from on a cruise ship (please tell us it’s not toilet water)?

Engineers : There are large Reverse Osmosis plants which take in heavily filtered sea water, and then after many processes produce fresh water. This fresh water is then treated to public health requirements and standards. So no, it's not from the toilet water. That water never goes anywhere near the potable fresh water.

Sometimes I’ll see the ship captain dining in a restaurant, or wandering around the boat. When he’s gone, who’s keeping the ship away from icebergs?

Engineers : Well there is a whole team for deck and engine departments, and the Captain can't be navigating the whole time. There is a watchkeeping team – consisting of deck officers on the bridge and technical officers in the ECR – 24/7 keeping the ship away from icebergs and the lights on while the Captain is out having dinner.

Wow, we certainly learned a lot about cruise ships!

Take that curiosity a step further and check out our Ships page to see more about our lady ships.

Related Articles

Come aboard our adults-only cruises for a kids-free getaway at sea., we’re all about the best “ships,” from friendship to partnerships, to cruise ships and beyond., cruises vs. all inclusive resorts: why one is the clear victor….

- CruiseMapper

- Ships and Lines

Cruise Ship Design Construction Building

Information on cruise ship construction and design and how cruise ships are built. Learn what is the cost of building a cruise ship, where are cruise ships built, which are the major cruise shipbuilders/yards and building companies . Plus some other shipbuilding stuff and fun facts, like who built the Titanic ship, who built the most expensive cruise ship in the world, who built the most expensive yacht in the world, who is responsible for making the best cruise vessels of the world. This survey is integrated with our cruise ship engines-propulsion-fuel and cruise safety articles.

The actual cruise shipbuilding takes 2 to 3 years (the design plans are usually started a year ahead). Shipbuilding takes place in specialized facilities called shipyards. The cruise ship hull is designed by the shipyard, while the interiors and all the special features are designed by architects. Shipbuilders (also called shipwrights) do shipbuilding, as well as ship repairs, both services being also referred to as "naval engineering". The reverse process (dismantling of ships) is called ship breaking/demolition . The world's biggest ship-breaking scrap yards are in India (Alang) , Bangladesh (Chittagong) , Pakistan (Gadani) , and Turkey (Aliaga).

Cruise ship construction and design

The cruise shipbuilding process involves numerous complex research and testing procedures. The cruise ship design company (whose work is also called naval architecture) analyses and provides solutions to meet the Marine and Shipbuilding Industry's requirements, submitting the basic and detailed designs, ship equipment designs and production drawings to the shipbuilding company. The design firm also provides engineers with analysis, simulations, diagnosis, manufacture, repair and other data by using the latest CAE (Computer-Aided Engineering) technology. The ship cabins manufacturer is able to design and produce various types of ready-to-install ship cabins and bathrooms for virtually all passenger ships - big and small, luxury, ferries, Ro-Ros, research, etc. The shipbuilder also hires a company to provide the so-called "Lifecycle Services", pertaining mostly to the industry's rules and regulations. Some of these services are retrofitting and refurbishing and keeping regular updates regarding new rules and requirements.

It's a common modern practice big cruise ships to be built of pre-made huge sections. Entire multi-deck segments are built at another place, transported or slipway to the shipyard and lifted into place. The sections often feature even pre-installed equipment, cables, pipes, and other components - it saves a lot of shipbuilding time, and it surely saves lots of money. This technique was used for the first time in the construction of Cunard's Queen Mary 2 (2002-2004) by the French "Chantiers de l'Atlantique" company.

The next photo shows a pre-made section for the Symphony Of The Seas ship construction.

The ice-going cruise shipbuilding is so expensive as to hull strength and engine power, that the best option is to buy an unfinished vessel or to refit an existing Ice-class ship (often an ex-navy vessel), like the case of the Regent Seven Seas Navigator ship. Constructed as a naval support ship and strengthened for navigation in ice, the Navigator ship's hull was purchased from the former USSR (now Russia), while its superstructure was finished later at the T. Mariotti shipyards in Genoa, Italy.

The following YouTube timelapse video shows the Japan-made AIDAprima cruise ship construction process (shipyard Nagasaki Japan ). Next YouTube video shows the Aqua Mekong riverboat construction (time-lapse).

Cruise ship design

This is an amazingly detailed cruise ship design infographic showing what is what and where on a typical cruise passenger vessel. Note: Click on image to enlarge, backspace/back button to return to the article page.

Marine design solutions for cruise ships are truly amazing and unique, using the latest innovations, technologies, and materials to ensure difference from other existing passenger ships. Special onboard features, such as the Royal Caribbean ships' rock-climbing walls, ice-skating rinks, surf simulators, wave pools, and the 9-deck high Zip-line are an irresistible temptation and a true allure for all the ship vacation fun fans. As to the common features, all big-capacity passenger ships have a several decks-high Atrium, at least 3 huge swimming pools, a Spa-Fitness complex, a grand casino, a library, duty-free shops, 2 huge capacity main restaurants, grand theatre, disco nightclub, kids and teen areas, numerous bars and lounges, and all-new big ships feature an open wraparound Promenade.

Cruise ship interior design

What about cruise ship interior designs? An example is SMC Design, which was appointed by Cunard Line to lead the development of the interior spaces on RMS Queen Mary 2 in preparation for liner's drydock refit in 2016. Cunard's flagship had a multi-million 25-day extensive refurbishment (May 27-June 21, 2016) that boasted new interior designs. The most iconic liner in the world opened the next chapter in her illustrious career. The announcement of the designer company followed the news that QM2 will gain 15 brand new single cabins and an additional 30 Britannia Club rooms during the refit. The popular onboard kennels were expanded in order to cater to the high demand this extraordinary facility already attracts.

SMC Design was established in 1994. The London -based design consultancy specializes in the maritime sector. SMC Design's team has worked on many cruise vessels - from small yachts to some of the biggest ships ever built. It also has a working history with Cunard liners, leading previous refits of QE2, Cunard Princess and Cunard Countess, while also being involved in its current fleet design: Queen Victoria , Queen Elizabeth and Queen Mary 2. Andy Collier, SMC Managing Director, was part of the launch design team of QM2 at the beginning of the Century. She was then the first Atlantic liner being built for more than 35 years.

New Russian cruise ship designs

In August 2016, at Lotus shipyard (Astrakhan, Russian) part of ASC (United Shipbuilding Company), the keel was laid for the 1st Russian passenger cruise ship in decades. Support for the new class of even vessel is coming from Russian Federation president Vladimir Putin, who expressed hope that this will be the first but not the last of a series of such ships.