- Weill Cornell Medicine

Slips, Trips, and Falls: Understanding, Preventing, and Mitigating Risks

By Gian Joseph, Safety Advisor

As we enter the rainy and cold season, we face several risks , which include slips , trips, and fall s in our day-to-day activities. It is important t o be aware of hazards around us and learn how to properly identify and assess any risks with each step.

Slips, trips, and falls (STFs) are common accidents that can lead to severe injuries. These incidents occur in various settings, from homes and workplaces to public spaces , and i t is essential to understand the causes, consequences, and , most importantly, strategies for prevention and mitigation.

1. Understanding the Dynamics of STFs. STFs are caused by the following .

Insu fficient friction between the shoe and the walking surface. Common causes include wet or greasy floors, spills, and loose debris (Slip and Fall Accidents, 2021).

When a person's foot collides with an object or an uneven surface, it caus es them to lose balance. Typical trip hazards include cluttered walkways, electrical cords, uneven flooring, and damaged or upturned mats (Slip and Fall Accidents, 2021).

2. The Impact of STFs

Slips, trips, and falls have far-reaching effects, affecting individuals and society . Personal i njuries range from minor cuts , bruises, sprains , and abrasions to fractures, dislocations, and head injuries (National Safety Council, 2021). The medical expenses associated with treating STF-related injuries can be substantial , including hospital stays, surgeries, rehabilitation, and ongoing care (National Safety Council, 2021). STFs can result in missed workdays and reduced productivity for both individuals and employers. Workers' compensation claims and absenteeism contribute to economic costs (National Safety Council, 2021). Lastly, t he physical and psychological consequences of STFs can limit mobility, independence, and overall quality of life, especially among older adults ( Sahyoun et al., 2020).

3. Prevention and Mitigation Strategies

Preventing and mitigating STFs involves a combination of awareness, environmental modifications, and education . H ere are some ways you can take precaution s against STFs in your daily activities;

Clear Pathways: Maintain clear, unobstructed walkways by removing clutter and tripping hazards such as cords, toys, and loose rugs (Occupational Safety and Health Administration [OSHA], 2002).

Adequate Lighting: Ensure proper lighting in all areas, both indoors and outdoors, to improve visibility and reduce the risk of tripping over obstacles (OSHA, 2002).

Slip-Resistant Flooring: Install slip-resistant flooring materials, especially in areas prone to moisture, like bathrooms and kitchens (OSHA, 2002).

Footwear: Encourage the use of proper footwear with good traction, especially in environments where slip hazards are prevalent ( Sahyoun et al., 2020).

Handrails and Guardrails: Install and maintain handrails and guardrails on stairs, ramps, and elevated platforms to provide support and prevent falls (OSHA, 2002).

Warning Signs: Use signage to alert individuals to potential hazards, such as wet floors or uneven surfaces (OSHA, 2002).

Education and Training: Promote awareness and provide training to individuals on recognizing and avoiding STF hazards (National Institute for Occupational Safety and Health [NIOSH], 2015).

Workplace Safety: Employers should implement safety protocols and conduct risk assessments in the workplace, addressing potential STF risks (NIOSH, 2015).

Regular Maintenance: Routinely inspect and maintain buildings, walkways, and outdoor areas to identify and address potential hazards promptly (NIOSH, 2015).

4. A Holistic Approach to STF Prevention

Preventing and mitigating STFs require a collaborative approach involving individuals, organizations, and communities:

Individuals : Exercise caution when walking, especially in unfamiliar or potentially hazardous environments. Wear appropriate footwear and take your time, especially in wet or slippery conditions ( Sahyoun et al., 2020).

Employers: Create a safe work environment by identifying and mitigating STF risks. Provide training to employees on safety protocols and the proper use of equipment (OSHA, 2002).

Property Owners and Managers: Ensure properties are well-maintained and free from hazards. Regularly inspect and address issues promptly (NIOSH, 2015).

Government and Local Authorities: Enforce building codes and regulations that promote safety, especially in public spaces and commercial buildings (OSHA, 2002).

Conclusion

Slips, trips, and falls are preventable accidents that carry substantial personal, economic, and societal costs. By comprehending the causes, consequences, and prevention strategies, we can significantly reduce the incidence of STFs and mitigate their impact. Whether at home, at work, or in public spaces, prioritizing safety and fostering awareness about STFs is crucial for the well-being of individuals and communities. Let us strive collectively to create environments where everyone can move safely and confidently, free from the fear of falling.

References:

National Institute for Occupational Safety and Health (NIOSH). (2015). Preventing Slips, Trips, and Falls in Wholesale and Retail Trade Establishments. https://www.cdc.gov/niosh/docs/2015-100/pdfs/2015-100.pdf

National Safety Council. (2021). Injury Facts. https://injuryfacts.nsc.org/work/overview/work-safety-introduction/work-...

Occupational Safety and Health Administration (OSHA). (2002). OSHA Publication 3151-12R. Preventing Slips, Trips, and Falls in Wholesale and Retail Trade Establishments. https://www.osha.gov/Publications/osha3151.pdf

Sahyoun , N. R., Pratt, L. A., & Lentzner , H. (2020). The Changing Profile of Nursing Home Residents: 1985-1997. Journal of Aging and Health, 12(3), 336-363.

Slip and Fall Accidents. (2021). InjuryClaimCoach.com. https://www.injuryclaimcoach.com/slip-and-fall-accidents.html

Please note that the sources cited are accurate as of the time of writing this article. For the most current information, consult authoritative sources and local health authorities.

Go to the staff directory for individual contacts within EHS. You may also use the Weill Cornell Medicine online directory to search for faculty and staff.

Create an EHS Incident

Weill Cornell Medicine Environmental Health and Safety 402 East 67th Street Room LA-0020 New York, NY 10065 Phone: (646) 962-7233 Fax: (646) 962-0288

Posted on: February 22, 2023

Slips, Trips, and Falls: Preventing Workplace Trip Hazards

When you think of a workplace accident, you probably think of something dramatic – an explosion or an amputation, for example.

But the second-most common cause of workplace injury is a trip or slip hazard that leads to a fall. And 20-30% of workplace falls result in a moderate or severe injury like deep bruising, broken bones, or concussions.

In fact, according to OSHA, slips, trips, and falls cause nearly 700 workplace fatalities per year – that's 15% of all workplace deaths.

The trouble is that the circumstances that lead to slips and trips tend to be spontaneous and changeable – they don't exist until suddenly they do. That means preventing slips, trips, and falls is an ongoing process that relies heavily on employees being able to recognize related hazards.

What Are OSHA's Trip Hazard Regulations?

OSHA's primary standard for slip, trip, and fall hazards is the General Industry Walking-Working Surface standard (29 CFR 1910 Subpart D, which includes §1910.21-30).

Related Construction Industry standards are scattered throughout §1926, including Subparts C, L, M, and X. However, OSHA's 2017 slip, trip, and fall revisions aligned Construction standards with General Industry wherever possible.

Finally, some specific slip, trip, and fall OSHA regulations ensure a safe exit route from any workplace. After all, the last thing you want during an emergency evacuation is a bottleneck at the exit. These Means of Egress regulations are found under §1910.36-37.

Walking and Working Surfaces

Definitions related to slips, trips, and falls.

The temporary nature of an OSHA tripping hazard makes a clear set of definitions even more critical.

What is a Walking-Working Surface?

When you first see the name of OSHA's main trip and slip hazard, you may wonder what a "walking-working surface" is.

But it's just a surface you walk on…or work on. Walking-working surfaces include floors, aisles, stairs, platforms, and more.

Slips vs. Trips

Slips and trips can lead to falls, but there's a pretty clear distinction between the two.

A slip happens when there's insufficient traction between your foot and the walking-working surface, causing a sudden loss of balance.

A trip happens when your leg or foot comes into contact with a hazard (either an object or an uneven surface) that arrests the movement of your lower body while momentum carries your upper body forward.

What are the Two Types of Falls?

A fall happens when your center of gravity shifts unexpectedly, but for workplace safety purposes, falls are divided into two different categories: same-level falls and elevated falls.

An elevated fall is when someone falls from one level to another, like from a ladder, scaffold, building, or through an opening in the floor.

A same-level fall is when someone falls to the floor they're standing on or against a nearby object or wall.

What are Examples of Slipping and Tripping Hazards?

There are many factors that can contribute to the likelihood of a slip or trip. Many slip or trip hazards are substances or objects that make a walking-working surface dangerous, but footwear and environmental conditions also play a part.

Examples of Slip Hazards

Basically, anything that decreases the amount of friction between your foot and the walking surface increases the risk of slipping.

This includes:

- Water, ice, snow, mud, grease, oil, food, or other wet products on smooth floors

- Dust, powders, plastic wrapping, granules, or other dry products that are slippery on smooth floors

- Freshly waxed surfaces

- Highly polished surfaces that remain slick when dry (like concrete, marble, or ceramic)

- Loose or irregular surfaces like gravel or unanchored flooring

- Sloped walking surfaces without slip- or skid-resistance

- Muddy terrain

- Wet or dry leaves, pine needles, or plant debris

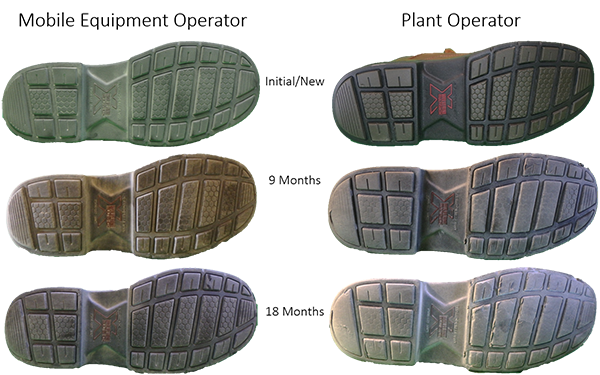

- Shoes with inadequate traction

- Soles that are wet, muddy, or greasy

As you can see, slip hazards can be found indoors or outdoors.

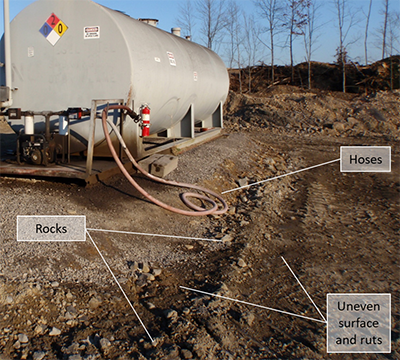

Workplace Trip Hazard Examples

Officially, OSHA's trip hazard height is a quarter inch. Any change in floor level that is ¼ inch or more constitutes a tripping hazard.

Examples of common tripping hazards include:

- Uncovered hoses, cables, wires, or cords across walking surfaces

- Obstacles or clutter on walking surfaces

- Furniture drawers/door left open

- Unmarked steps or ramps

- Damaged or irregular steps

- Rumpled carpets or mats (or curled edges)

- Thresholds, gaps, and other irregularities in walking surfaces

- Speed bumps and curb drops

Other factors can also contribute to the likelihood that you'll trip, including lack of coordination or an obstructed view of the walking surface. Many circumstances can contribute, including:

- Being under the influence

- Poor air quality

- Poor lighting

- Bulky loads

- Poor vision

Slips, Trips, and Falls Prevention

Some slip, trip, and fall prevention measures are permanent, including:

- Adequate lighting

- Slip-resistant surfaces in high-risk areas

- Effective drainage, ventilation, and other methods to keep surfaces dry

- Marking the edges of steps or elevation changes

Other methods for preventing slips, trips, and falls require ongoing participation from workers, including:

- Proper footwear

- Safe work practices

- Frequent cleaning

- Good housekeeping practices that keep walkways free of clutter

- Noticing and marking slip or trip hazards

As a result, a lot of slip, trip, and fall prevention relies on the ability of your workforce to recognize slipping and tripping hazards, understand how to mitigate them, and know how to use safe work practices to minimize their risk.

Even though there's no formal OSHA requirement for Slip, Trip, and Fall training, workers need education and regular refreshers in OSHA trip hazards and regulations to accomplish all of this correctly.

One of the easiest and most effective ways to keep your workforce fresh on this topic is to use online courses from an OSHA-authorized training provider like us. We have a Walking and Working Surface course that your employees can take at their own convenience and pace. Get started today!

OSHA Group Training Enrollment

Need to train your employees? Sign up today to set up a business account with OSHA.com. We offer an enhanced Learning Management System (LMS) and special discounts for large orders.

Group Enrollment Application

Indeed.com rating, trusted by industry leaders.

"The support team really helped me out! I really needed to get this training done for work and they definitely helped make it happen! Best support group I’ve ever dealt with! Thanks again!"

More testimonials

- +1 (800) 826-0777

- VIRTUAL TOUR

- Mass Notification

- Threat Intelligence

- Employee Safety Monitoring

- Travel Risk Management

- Emergency Preparedness

- Remote Workforce

- Location and Asset Protection

- Business Continuity

- Why AlertMedia

- Who We Serve

- Customer Spotlights

- Resource Library

- Downloads & Guides

Prevent Workplace Slips, Trips, and Falls—8 Safety Tips

Mopping up a spill or double-checking a guardrail might seem like simple common sense, but slips, trips, and falls are the second most common cause of death at work. These are life-saving procedures. Keep reading for practical tips to prevent workplace accidents.

- Slip, Trip, and Fall Hazards Listed

- Clarifying OSHA Standards

- Prevent Workplace Slips, Trips, and Falls

These are familiar scenarios at home: slipping on a wet floor in the kitchen and tripping over a toy left out by the kids. While annoying, these accidents are typically minor hazards in the home. You might stub your toe, but rarely are there severe consequences.

In the workplace, it’s a different and far more serious story. Slips, trips, and falls account for over 200,000 workplace injuries per year. In 2020, nearly one in five accidents leading to missed work was due to a slip, trip, or fall. They’re also the second-leading cause of workplace fatalities.

As a safety leader, you’re responsible for your company’s duty of care and for providing a safe workplace . This blog post will examine common hazards leading to slips, trips, and falls and the steps you can take to minimize injury risks for your team.

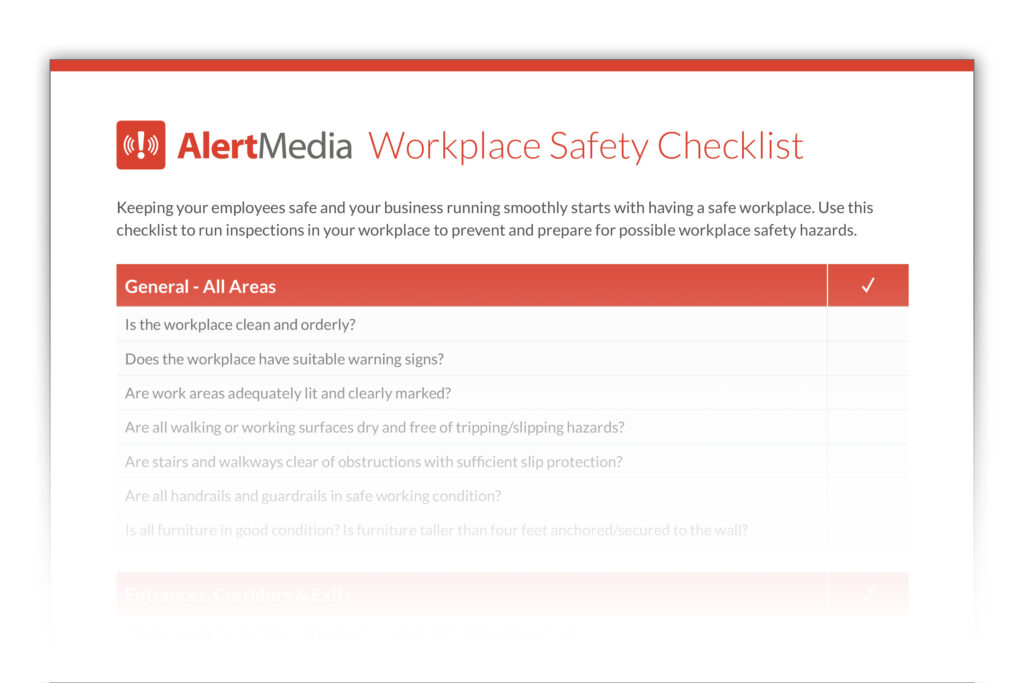

Download Our Workplace Safety Checklist

What are slip, trip, and fall hazards in the workplace.

Accidents involving slips, trips, and falls are often grouped together. While they’re similar, it’s important to understand the distinction since they each have different causes and consequences.

Slips occur when someone’s footwear loses traction with the surface they’re on, causing a loss of balance. Under some circumstances, slipping can lead to a fall.

Trips happen when someone hits their foot or lower leg on an object. As their upper body continues moving forward while their lower body remains stationary, the person may lose their balance in the process.

Falls often result from slips or trips, but they can also happen on their own. For example, a worker on a ladder or scaffolding can lose their balance and fall without slipping or tripping. Falls are also possible on flat surfaces and can still cause serious injuries.

Once you understand the hazards that lead to each type of accident, you can identify and mitigate risks in your workplace. Here are some of the most common causes of slips, trips, and falls in the workplace:

Slip Hazards

- Spills of wet or dry substances

- The cleaning process during spill removal

- Employees rushing or not paying attention to workplace conditions, especially while carrying objects

- Slippery floor surfaces such as marble or laminate

- Wet surfaces

- Poor lighting that obscures hazards

- Inappropriate footwear for the environment

- Transitioning between different types of surfaces

Trip Hazards

- Objects or obstructions in walkways

- Uneven surfaces on flooring or concrete

- Cables, cords, and hoses that aren’t properly secured or organized

- Unmarked steps or ramps

- Irregular stairs or stairs without railings

- Carpet, rugs, or mats with wrinkles or lifted edges

Fall Hazards

- Improperly used or poorly maintained ladders

- Elevated surfaces without guardrails

- Floor and wall openings

- Working in elevated environments without a safety harness

- Ill-fitting or improperly used PPE, such as helmets and safety lines

Preview the Workplace Safety Checklist

Are There OSHA Standards Related to Slips, Trips, and Falls?

Despite how common these injuries are, there is no specific OSHA standard on slips, trips, and falls. However, several OSHA rules indirectly address the same hazards.

The most important regulation to be aware of is 29 CFR 1910 Subpart D, which covers walking and working surfaces. OSHA updated the standard in 2017, introducing many upgrades to fall protection system requirements, improved employer-provided inspection guidelines, and a greater emphasis on safety training for employees.

For the construction industry, 29 CFR 1916 contains numerous fall-related regulations. Subpart M specifically addresses fall prevention, but other sections, such as Subpart L (scaffolds) and Subpart E (personal protective and lifesaving equipment), are also relevant. OSHA used 29 CFR 1916 as guidance when revising 29 CFR 1910, so the two guidelines now reflect many of the same OSHA violations .

As with any other workplace hazard or accident, OSHA recordkeeping requirements still apply in the event of a slip, trip, or fall incident. Internally, the reporting process is also an opportunity to review the details of the incident and determine how you can update your workplace safety policy to prevent similar accidents in the future.

How to Prevent Slips, Trips, and Falls in the Workplace

Many hazards that cause slips, trips, and falls are inevitable. However, injuries and accidents are not. To prevent slips, trips, and falls, train your employees to follow a three-step process:

- Recognize the hazard: Identify conditions that could lead to a slip, trip, or fall.

- Evaluate the hazard: Examine the situation and determine what level of risk it presents and who it affects.

- Control the hazard: Avoid the risk by removing the hazard (such as mopping up a spill) or implementing safety equipment and procedures (such as installing handrails on an elevated platform).

Here are eight workplace safety tips to prevent falls, trips, and slips.

1. Teach situational awareness

Since many causes of slips, trips, and falls are foreseeable, situational awareness in the workplace is one of the best preventative measures. Encourage your employees to pay attention to their surroundings and the risks they present:

- Look at walking surfaces for spills, obstacles, or other potential hazards

- Watch for signage that warns of increased hazards

- Be aware of conditions such as weather or time of day that might increase the risk of an accident

- Take shorter and more cautious steps on slippery surfaces

2. Encourage proper footwear

Like any other form of PPE, proper footwear can significantly reduce the risk of accidents. Research has found that slip-resistant shoes can reduce injury claims by 67% in environments with slippery work surfaces.

Employees should regularly inspect their shoes and make sure the soles aren’t worn out, as the lack of tread increases the danger of slipping. Additionally, anyone who works in conditions exposed to winter weather hazards should wear insulated boots. Cold temperatures can decrease muscle function, increasing the risk of slipping, tripping, or falling.

3. Utilize signage

Signage is an effective warning system for many workplace risks, but it can be especially effective in preventing slips, trips, and falls. There are two types of signs you can use to increase occupational safety:

- Temporary: Use warning signs while addressing a new hazard, such as cleaning up a spill, repairing a handrail, or replacing a ripped carpet. While temporary signage can help prevent injuries, you still need to address the actual hazard as quickly as possible.

- Permanent: For unavoidable hazards, such as slippery surfaces, a permanent sign can help warn employees to be careful. Use these sparingly, though, as it’s easy for people to ignore signs they see every day.

4. Keep floors clear and clean

Good housekeeping can help prevent most slips, trips, and falls. The details of keeping walking areas clean will vary widely by work environment, but there are a few common themes to encourage workplace safety:

- Report spills immediately, and warn nearby employees until someone can clean the contaminated surface

- Keep walkways clear of obstacles, loose objects, and anything that someone could trip over

- Place mats at entrances and exits so people can dry their shoes and avoid tracking water or other substances around the workplace

- Install handrails on stairways and elevated walkways

5. Apply non-slip mats and coatings

In some situations, keeping floors from becoming slippery is nearly impossible. Whether it’s liquid splashing or steam condensing, you must focus on mitigating the risk rather than avoiding it altogether.

For smaller or less demanding settings, non-slip mats can help employees maintain traction while walking around. In other cases, treating the floor with a permanent coating can help reduce slipping risks, even in the constant presence of liquids.

Who is at risk for slips, trips, and falls?

While all industries have some level of risk for a slip, trip, or fall, there are some industries where the risk is much higher, and the potential result could be much more dangerous. Here are some of the highest-risk industries:

- Construction

- Manufacturing

- Transportation/shipping/logistics

- Outdoor maintenance/groundskeeping

- Foodservice/hospitality

6. Ensure proper lighting

To identify slip, trip, and fall hazards, your employees need to be able to see their surroundings. Make sure that all of your work areas have proper lighting, especially in areas that are more prone to unsafe conditions.

While this can be a challenge in outdoor work environments, especially at night, it’s even more critical in those situations. Environmental conditions can lead to increased risks, and employees need to be able to see and avoid them. Adequate lighting should also extend to parking lots and walking areas around your facilities.

7. Develop safety programs

Your company’s safety plans and programs should include specific guidelines for preventing slips, trips, and falls. There are a few key topics to consider when developing these policies:

- The types of surfaces employees work and walk on and whether they present extra risks

- Seasonal or regional conditions that could heighten hazards, such as winter weather threats

- Specific OSHA regulations that apply to your workplace

- Potentially hazardous equipment training such as ladder safety

- Regular inspection plans to ensure your team is maintaining a safe work environment

- Policies to report hazards using your company’s two-way communication platform

- First aid training , so employees are prepared to respond safely should injuries occur

8. Provide Slips, Trips, and Falls Training

Lastly, training your employees to avoid slips, trips, and falls will help keep them safe. Provide specific guidance on the environments they’ll work in and the hazards they’ll face. For example, a slips, trips, and falls safety talk for food service workers should focus on wet floors and walking safely in crowded, fast-paced environments. Conversely, office workers could use extra reminders to watch for stray power cords and keep walkways clear of boxes, files, and other tripping hazards.

Working slips, trips, and falls into your safety topics for meetings is also helpful. Regular safety talks or safety moments are an excellent opportunity to remind your team about seasonal risks or update them on newly installed safety measures.

Don’t Let Your Safety Standards Slip

Slips, trips, and falls are some of the most common workplace injuries. Fortunately, you can usually prevent them with proper planning and safety measures.

By making slip, trip, and fall prevention a part of your company’s safety culture, you can ensure your employees are aware of their surroundings and ready to look out for each other’s safety. Enable them to report hazards easily, address risks quickly, and train them to avoid situations that are likely to cause injury.

With the right planning and prevention, even the most intense work environments can be as safe as a walk in the park.

More Articles You May Be Interested In

Workplace Safety Checklist

Please complete the form below to receive this resource.

Check Your Inbox!

The document you requested has been sent to your provided email address.

Cookies are required to play this video.

Click the blue shield icon on the bottom left of your screen to edit your cookie preferences.

Reducing slips, trips and falls

Hazard awareness and prevention strategies needed.

Fall hazards remain a common problem across multiple industries and workplaces. In 2019, worker deaths stemming from slips, trips and falls climbed 11.3% from the previous year, according to Bureau of Labor Statistics data. Meanwhile, OSHA’s standard on fall protection – general requirements (1926.501) has topped the agency’s Top 10 list of most frequently cited standards for 11 consecutive fiscal years.

Other standards related to inherent fall risks and that routinely populate the list include those regarding ladders (1926.1053), scaffolding (1926.451) and fall protection – training requirements (1926.503).

“Most workers have some safety knowledge, but how do we get people to consistently apply the safety practices that they know?” asked Bradley Evanoff, occupational health physician and professor of occupational and environmental medicine at Washington University in St. Louis. “How can an employer create a work culture where all employees take an active role in making the workplace safer and feel like they can speak up if they see a problem?”

Factors may overlap

During a December 2019 National Safety Council webinar on strategies for preventing slips, trips and falls, Amber Joseph, technical consultant at Liberty Mutual Insurance, identified several contributing factors. Among them:

- Walking surfaces

- People and activity

- Contaminants

“A lot of times, you’ll have overlap within these, so it may be a walking surface and a footwear discussion depending on the type of contaminant that you have in place,” Joseph said. “But really, it’s looking at this as a whole, and looking at it as, ‘All right, I need to address these areas as I move forward.’”

On the surface

Under OSHA’s standard on walking-working surfaces for general industry (1910.22), employers must ensure “all places of employment, passageways, storerooms, service rooms and walking-working surfaces are kept in a clean, orderly and sanitary condition.”

Walking-working surfaces also must be maintained free of hazards such as sharp or protruding objects, loose boards, corrosion, leaks, spills, snow, and ice. Additionally, hazardous conditions on surfaces must be “corrected or repaired before an employee uses the walking-working surface again.”

The standard adds that “if the correction or repair cannot be made immediately, the hazard must be guarded to prevent employees from using the walking-working surface until the hazard is corrected or repaired.”

NIOSH suggests that employers select flooring material based on the work that will be performed in the area. The agency also notes the importance of the factor of coefficient of friction – a measurement for the propensity to slip on a given walkway surface. The agency states that flooring with “a higher static coefficient of friction is safer” and recommends flooring with a CoF of 0.5 or greater for high-risk areas.

In November, the University of Pittsburgh announced that two researchers from its Swanson School of Engineering intend to use a NIOSH grant to develop a new model of flooring friction performance with the aim to prevent falls on the job. Citing data from Liberty Mutual, a Pitt press release notes that workplace slips and falls carry an annual expense of $10 billion in workers’ compensation claims.

Continued on page 2

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)

Report Abusive Comment

Facilities Management Advisor

Practical Facilities Tips, News & Advice.

Flooring, Safety

Slips, trips, and falls: some effective interventions.

Updated: Jun 23, 2021

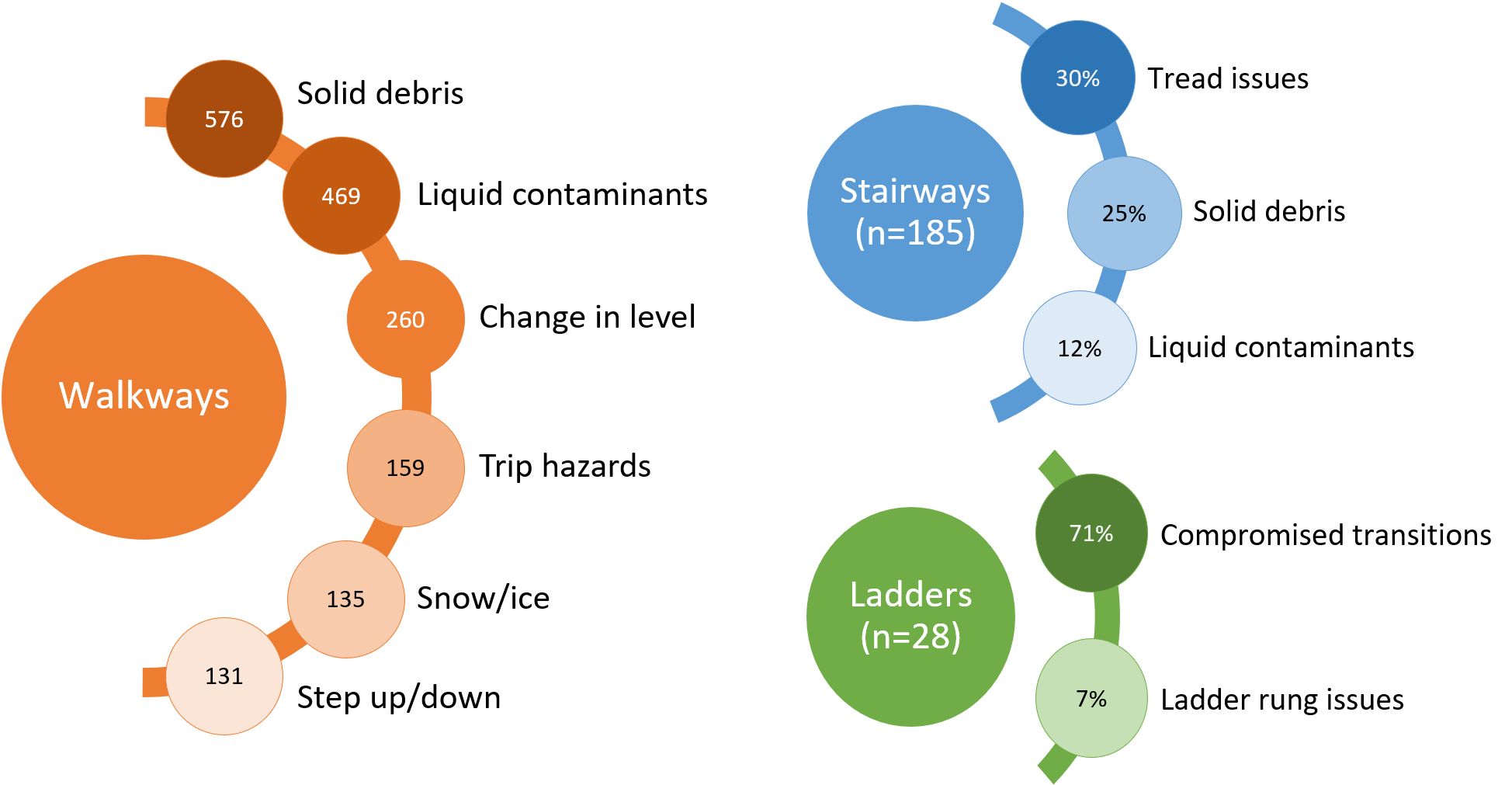

Walking Surface Issues

When it comes to slips, trips, and falls, healthcare workers are at higher risk than most workers, so that’s where the National Institute for Occupational Safety and Health (NIOSH) and the Centers for Disease Control and Prevention (CDC) went looking for causes—and solutions.

NIOSH conducted research on slips, trips, and falls in three acute care hospitals, and spent 10 years assessing the effectiveness of preventive measures. Over that 10-year period, workers’ compensation costs arising from slips, trips, and falls in the three hospitals declined by 59%. These preventive measures could help reduce your workers’ comp costs, too.

The specific causes of slips, trips, and falls may vary—the slick floors in your workplace might be created by a different substance than those in a hospital—but the prevention principles can be broadly applied. Major risk factors identified by NIOSH and the CDC include:

Contaminants on floors and walkways. Kitchens, bathrooms, building entrances, and other areas where floors and walkways are often wet or contaminated present this type of risk. Effective preventive measures include:

- Well-documented housekeeping procedures; the CDC suggests creating a written housekeeping program.

- Two-step mopping. This technique, in which a cleaning solution is applied, then removed, is more effective than traditional damp-mopping and may reduce slipping hazards.

- Slip-resistant shoes. In persistently slick areas, workers should wear appropriate footwear.

- Correctly aligning pipes with the drain they empty into, unclogging drains regularly, and redirecting downspouts away from sidewalks.

Indoor walking surface irregularities. Damaged, warped, buckled, or uneven flooring surfaces can cause employees to slip, trip, or fall. Control this risk by:

- Replacing or restretching loose or buckled carpeting;

- Removing, patching underneath, and replacing indented or blistered vinyl tile;

- Eliminating trip hazards over a quarter-inch high in all areas of pedestrian travel, using beveling or ramps;

- Replacing smooth flooring materials in areas normally exposed to water, grease, and/or particulate matter with rougher-surfaced flooring; and

- Making sure elevators are leveled properly so elevator floors line up evenly with hallway floors.

Outdoor walking surface irregularities. Outdoor falls can result from poorly maintained, uneven ground; protruding structures; holes; and rocks, leaves, and other debris. Improve safety by:

- Patching or filling cracks greater than a half-inch wide in walkways;

- Highlighting changes in elevation with Safety Yellow warning paint;

- Eliminating concrete wheel stops in parking lots; and

- Covering or highlighting underground watering system structures.

Weather conditions. Ice, snow, and rain can cause slips and falls. In areas where this is a problem, you can improve safety by:

- Providing additional mats when needed;

- Removing ice and snow from parking lots, garages, and sidewalks promptly;

- Placing freezing weather warning monitors at entrances to employee parking areas;

- Displaying contact numbers for the maintenance department so employees can report slick conditions; and

- Placing bins of ice-melting chemicals in outdoor areas of heavy pedestrian traffic.

Lights, Handrails, and Clutter

Slips and trips are often caused by problems with the floor surface itself—either by irregularities or slippery conditions. However, there are some issues not directly connected to the flooring surface that can also create a hazard, including:

Inadequate lighting. Inadequate lighting makes it harder to see hazards. Make hazards visible by:

- Installing more light fixtures and/or brighter bulbs in poorly lit areas; and

- Installing light fixtures that emit light from all sides.

Stairs and handrails. Poorly designed or maintained stairs and handrails can lead to falls. Make these safer with:

- Slip-resistant treads and nosing that cover the entire tread, especially on outside steps;

- Handrails at an appropriate height (34 to 38 inches from the stepping surface); and

- Handrails that extend the full length of the stairs plus 12 inches at top and one tread depth at bottom.

Tripping hazards. General clutter, loose cords, hoses, and wires pose a tripping hazard along with improperly used floor mats. Eliminate these by:

- Using wall-mounted storage hooks, shelves, and hose spools;

- Marking walkways and keeping them clear;

- Covering cords on the floor with a beveled protective cover;

- Using mats and runners large enough that users can take several footsteps on them, thereby cleaning contaminants off their shoes before the shoes contact the flooring;

- Using beveled-edge, flat, and continuous or interlocking mats; and

- Replacing mats that are curled, ripped, or worn (secure edges with carpet tape if needed).

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- Skip to main content

- Skip to site information

- Departments

Language selection

- Français

Scheduled maintenance - Thursday, July 12 at 5:00 PM EDT

We expect this update to take about an hour. Access to this website will be unavailable during this time.

Prevention of Slips, Trips and Falls

On this page, how do falls happen, how to prevent falls due to slips and trips, what can you do to avoid falling at work.

Statistics show that the majority (67%) of falls happen on the same level resulting from slips and trips. The remaining 30% are falls from a height. This document will summarize information on "falls on the same level" (slips and trips). Falls from an elevation, such as falls from ladders, roofs, down stairs or from jumping to a lower level, etc., is discussed in other documents since each type of fall must be assessed as part of a fall prevention program .

Slips happen where there is too little friction or traction between the footwear and the walking surface. Common causes of slips are:

- wet or oily surfaces

- occasional spills

- weather hazards

- loose, unanchored rugs or mats

- flooring or other walking surfaces that do not have the same degree of traction in all areas

Trips happen when your foot collides (strikes, hits) an object causing you to lose balance and, eventually fall. Common causes of tripping are:

- obstructed view

- poor lighting

- clutter in your way

- wrinkled carpeting

- uncovered cables

- bottom drawers not being closed

- uneven (steps, thresholds) walking surfaces

Both slips and trips result from unintended or unexpected change in the contact between the feet and the ground or walking surface. This fact shows that good housekeeping, quality of walking surfaces (flooring), selection of proper footwear, and appropriate pace of walking are critical for preventing fall incidents.

Housekeeping

Good housekeeping is the first and the most important (fundamental) level of preventing falls due to slips and trips. It includes:

- cleaning all spills immediately

- marking spills and wet areas

- mopping or sweeping debris from floors

- removing obstacles from walkways and always keeping walkways free of clutter

- securing (tacking, taping, etc.) mats, rugs and carpets that do not lay flat

- always closing file cabinet or storage drawers

- covering cables that cross walkways

- keeping working areas and walkways well lit

- replacing used light bulbs and faulty switches

Without good housekeeping practices, any other preventive measures such as installation of sophisticated flooring, specialty footwear or training on techniques of walking and safe falling will never be fully effective.

For more information about effective housekeeping, visit the OSH Answers document on Workplace Housekeeping - Basic Guide .

Changing or modifying walking surfaces is the next level of preventing slip and trips. Recoating or replacing floors, installing mats, pressure-sensitive abrasive strips or abrasive-filled paint-on coating and metal or synthetic decking can further improve safety and reduce the risk of falling. However, it is critical to remember that high-tech flooring requires good housekeeping as much as any other flooring. In addition, resilient, non-slippery flooring prevents or reduces foot fatigue and contributes to slip-prevention measures.

In workplaces where floors may be oily or wet or where workers spend considerable time outdoors, prevention of fall incidents should focus on selecting proper footwear. Since there is no footwear with anti-slip properties for every condition, consultation with manufacturers is highly recommended.

Properly fitting footwear increases comfort and prevents fatigue which, in turn, improves safety for the employee. For more information on footwear visit the OSH Answers document on Safety Footwear .

You can reduce the risk of slipping on wet flooring by:

- taking your time and paying attention to where you are going

- adjusting your stride to a pace that is suitable for the walking surface and the tasks you are doing

- walking with the feet pointed slightly outward

- making wide turns at corners

You can reduce the risk of tripping by:

- keeping walking areas clear from clutter or obstructions

- keeping flooring in good condition

- always using installed light sources that provide sufficient light for your tasks

- using a flashlight if you enter a dark room where there is no light

- making sure that things you are carrying or pushing do not prevent you from seeing any obstructions, spills, etc.

- Fact sheet last revised: 2023-03-28

Best Practices to Prevent Slips and Trips in the Workplace

Slip and trip injuries are some of the most common injuries employees experience on the job. These injuries are preventable. There are many safety best practices that can be implemented to reduce the risk of these injuries.

Slip and Trip Injury Statistics

As stated above, slip and trip injuries are extremely common in the workplace. It is difficult to find slip and trip injury fatal injury statistics without including falls in the data as well. The Bureau of Labor Statistics (BLS) reported that there were 805 fatal work injuries due to slips, trips, and falls in 2020. There were 30,160 non-fatal injuries due to slips and trips that required days away from work in 2020.

These numbers do not include the injuries that an employee had to get medical care for but did not miss work. It is safe to say that there are most likely hundreds of thousands of slips and trips occurring every single year.

10 Ways to Prevent Slips and Trips in the Workplace

There are many different ways slips and trips can be prevented in the workplace. These injuries can be difficult to prevent due to the sheer amount of exposure that is present due to employees walking around the workplace all day, but it is not impossible.

Browse the ten safety best practices provided below. Some of the ideas will be more applicable to your workplace than others. A combination of safeguards is the most effective way to prevent workplace injuries when completely eliminating a hazard is not possible.

Ensure Mats and Rugs Are Secure

Employees can slip or trip due to loose mats or rugs. It is vital that mats and rugs are secured to the floor. They should not move when someone steps on them. The edges should be secured so that they do not come up, which can result in an employee tripping over the mat or rug. This commonly occurs when opening doors causes the edge of the mat or rug to pull up.

Barricade Unsafe Areas

Many workplaces are extremely large and house a variety of work processes. There are many areas where pedestrians need to be, and there may be various areas where employees should not enter. Barricades are an example of an engineering control, which is one of the most effective safeguards that can be implemented. By barricading hazardous work areas, slips and trips are effectively eliminated since employees are no longer exposed to walking through the area.

Examples of areas that should be barricaded include areas with moving equipment, storage areas for materials that are not picked by hand, areas that are consistently wet, etc.

Clearly Mark Paths of Travel

For areas where employees are allowed to enter and walk through, marking paths of travel is a best practice. By clearly marking the paths of travel, employees know where they should and should not walk. These paths also communicate to equipment operators where pedestrians may be, as well as communicate that objects or materials should not be stored in these areas.

Organize Work Areas

Poor organization of work areas is one of the leading causes of trip injuries in the workplace. When the organization of a facility is poor, there is an increased risk of employees to trip over something. All tools, supplies, materials, and other objects should be neatly stored away from walking paths. Employees should understand where everything is kept in a workplace.

Practice Good Housekeeping

Good housekeeping is closely related to ensuring work areas are organized. Once the proper organization of a work area is set up, efforts need to be directed at maintaining the areas through proper housekeeping. Employees need to understand that everything needs to be put back into its place after use and that there should be nothing placed on the ground if it is not meant to be there. Holding employees accountable for the cleanliness of their work areas is vital to ensuring the workplace is well-maintained.

Keep Floors Dry

Keeping floors dry is part of the housekeeping process. For some workplaces, doing so can be difficult. Work processes can create slippery floors. Also, workplaces that are exposed to the weather may be frequently wet, resulting in slick surfaces. Any moisture or spills should be immediately marked and cleaned up whenever possible if employees are required to walk through them.

Install Anti Slip Tape Where Needed

Installing anti-slip tape is a great way to reduce the risk of slips and falls. It is commonly applied on stairs to ensure sufficient traction of employees’ shoes and the surface of the stairs. This tape can also be applied near entryways, where moisture may be present, or other work areas that tend to get slick.

Improve Lighting

Poor lighting contributes to many slips and trips in the workplace. When employees are not able to see where they are walking, they may not see changes in elevation, objects on the ground, or slick surfaces. All work areas where employees are required to enter or walk through should be adequately lit so that they can make it where they need to go safely. Any broken lights should be immediately replaced.

Ensure Employees Can Clean Footwear When Needed

For workplaces where employees must walk outdoors and indoors, they should be provided a way to clean their shoes and boots. It is common that there are mats present in entry doors at most workplaces, but additional safeguards may be needed. Mats should be placed at any entry and exit door so employees can wipe their footwear off when coming into the facility.

Additionally, water hoses, hand brushes, or boot brushes may be needed for workplaces where employees are walking through mud or other sticky substances and then coming indoors. Mats will not suffice to get these employees’ footwear clean.

Require Slip-Resistant Footwear in the Workplace

Personal protective equipment (PPE) is the last line of defense for preventing injuries. Slip-resistant footwear is an example of personal protective equipment that can be utilized to reduce the risk of slips in the workplace. NIOSH completed a study of 17,000 food services workers from 226 school districts across the United States, and it found that using 5-star rated slip-resistant shoes significantly reduced workers’ compensation claims for slip injuries.

The ASTM F2913 testing standard is most commonly referred to for measuring the slip resistance of footwear in action.

Slip and trip injuries can be difficult to prevent. After all, employees spend a lot of the work day walking around the workplace. By following the safety best practices mentioned in this post as well as other ones, these injuries can be prevented. Employees need to be trained on these safe work practices and held accountable for following these practices. Consistency in implementing and maintaining safeguards is vital for preventing any type of workplace injury.

Do you want downloadable PDFs of all of the talks? Join as a member and get all of the 250+ free talks as well as 300+ additional talks in PDFs that are easy to download and print!

Table of Contents

Identify all unsafe conditions, address unsafe behaviors, falls from elevated levels, we must do better, prevention: slips, trips and falls.

Preventative methods for reducing slips, trips and falls.

Falls are consistently the leading cause of death in construction followed by electrocution , struck by objects and caught in-between accidents (collectively known as OSHA's Fatal Four ). Furthermore, falls are one of the primary causes of lost days from work and the leading cause of worker compensation claims , according to the National Floor Safety Institute. It is also the No.1 injury for emergency room visits.

The largest percentages of injuries are from same-surface falls attributed to slips and trips. Let’s look at these first before addressing falls from elevated levels. Slipping occurs when there is not sufficient traction between the foot and the walking surface. The most common causes of slipping include:

- Wet or oily surfaces

- Loose or unfastened mats or rugs

- Smooth walking surfaces (insufficient traction)

- Gravel or sand (these equate to a moving walking surface)

- Improper footwear (smooth, slick shoe bottoms)

Tripping is caused by interruption to walking by striking an object. Common causes for tripping include:

- Obstructed view

- Poor lighting

- Objects in the walking path

- Un-level carpet or rug, flooring, etc.

- Cords/cables in walking path

- Uneven steps

Like a pre-flight checklist for an airplane pilot, you are having workers look over their work area for abnormal conditions. This is assuming their work area is normally free of exposed dangers such as slip, trip and fall hazards. Creating simple safety checkoff lists makes it a snap to uncover a potential slip/trip hazard before an accident occurs.

By involving all workers in daily safety inspections of their work areas, you reinforce safety with them (learn more about Creating a Workplace Safety Culture ). This may also help reduce unsafe behaviors by a daily focus on safety. Rotating the safety inspection between employees can be effective for uncovering unsafe conditions while sharing the workload and responsibility. Employees that work in the area being inspected will notice discrepancies fast, because it is a change to what they normally see and experience.

Another way to prevent slips is to ensure workers are only allowed to wear shoes that provide good traction and protection for their work environment .

We all look for shortcuts at work and home. The conservation of energy is always at work in our minds. Standing on a chair to change a lightbulb is common, even though a step ladder can be retrieved from a room down the hall. Safety often requires extra effort and we must encourage that effort. Safety should be rewarded and reinforced at every opportunity (see Your Incentives Are Compromising Safety Culture for advice on rewarding safety the right way).

Work leaders also need to be on the lookout for unsafe practices and address them quickly, yet politely. It sends a mixed signal when you get angry at someone while you’re concerned about their safety.

The best way to control behaviors that impact safety is by creating standard work procedures. This means taking the time to outline the safest, most efficient way to perform all identified work tasks. If you can’t or don’t want to take the time to write down each step of a process to make work instructions, just shoot a video of the correct procedure. Save these as video files and use for reference and training.

Once the area is free of identified hazards, standard work instructions and check lists help keep workers from inadvertently recreating them. By having the workers monitor and inspect their work area daily for safety, you help instill a safety mindset. This can help reduce all unsafe behaviors.

A proactive approach for preventing falls from elevated levels still centers on controlling unsafe conditions and unsafe behaviors. However, just as elevated levels can increase the hazard potential, we need to increase our attention and efforts. We must make sure we are compliant with all safety regulations for elevated work.

To protect from falls involving elevated levels, the same activities of hazard identification are used. A simple checklist and standard work instructions can flush out danger. Elevated surfaces need to meet safety regulation guidelines for proper railing, steps, ladders, scaffolding, and so on (find out whether you can use scaffold cross bracing instead of guard rails ).

Personal fall arrest systems must be used for fall protection when deemed necessary by OSHA or other regulatory agencies (learn more in Arrest or Protect: Your Guide to Choosing the Right Fall Protection System ).

This is still nothing more than identifying a potential fall hazard and making sure a control measure is in place. This requires attention that may not be given if safety is not valued.

Unsafe conditions and behaviors will not be an issue with elevated level working as long as all regulatory rules for elevated work are followed. Like buckling a seat belt in your car, the proper behavior is to insist all workers have the correct equipment and obey safety rules for elevated work.

In 2013, there were 291 fatal falls to a lower level out of 828 total fatalities in construction. These deaths are preventable .

Why is this type of accident so common if identifying fall hazards is so easy? There are many factors that lead to slips, trips and falls, including multi-tasking, rushing and lack of preparation.

Walking is what we do as we carry out routine activities. When we climb ladders, use steps, or work from scaffolding, we are focused on getting work tasks done.

After performing many accident investigations involving falls, I noticed a pattern: every slip, trip, or fall accident I have ever investigated included a chain of events. The worker was typically in a hurry or focused on the needed task and did not see the hazard that led to their fall until it was too late.

This pattern or "chain of events" is common for leading to falls. Workers are paid to perform tasks and activities. This is where their focus will be. Now throw in a little added burden such as:

- Being stressed due to deadlines, work targets, or meeting incentives

- Working short handed

- Reacting to a fast paced job where falling behind is not an option

You get the idea. We care about our work and want to do a good job. For that purpose, management needs to have a strong proactive safety focus. Without a safety focus you will have no counter balance. Safety may become an afterthought.

We know that slips, trips and falls are at the top of the list for injuries that impact workers. So, what are we doing about it? How proactive is your company? Are there efforts to control these hazards such as checklists in place? Do you have standard work instructions?

It is up to us safety professionals, managers, and work leaders to protect workers by providing a safe work environment. This includes proactively seeking unsafe conditions and behaviors that can lead to slips, trips, and falls.

Try These Tips From OSHA for Helping Prevent Injuries Associated With Falls:

- Plan ahead to get work done safely (make sure supplies and tools are delivered in a safe manner and in good shape—this is extremely important when working in jobs involving elevated levels)

- Provide the right equipment, including proper ladders and harnesses , working surfaces, lighting and footwear

- Train employees to use equipment and perform work safely

OSHA says it in three easy to remember words: Plan – Provide – Train.

Launch a fall prevention campaign to heighten awareness. Promote the Plan – Provide – Train formula. Set your goal for worker injuries from falls to be ZERO (see The Journey to Zero! for tips on reaching zero workplace accidents).

The next time I see a movie scene involving a fall from a banana peel, I will most likely still laugh. And I hope that this is the only place I will see a fall – on the movie screen, where it belongs.

Related Terms

- Accident Prevention

- Fall Arrest

- Non-Slip Mat

- Fall Protection Plan

- Anti-Slip Tape

- Short-Term Exposure Limit

- Ultraviolet

- Fatal Incident

Presented By

Written by Bryan McWhorter | Lead Safety Advisor, Author, Writer, Speaker

Bryan McWhorter is a safety professional with eight years of experience in driving and teaching safety. Bryan gained his knowledge and experience as the safety officer and Senior Trainer for Philips Lighting. Philips is a strong health and well-being company that promotes a safety first culture.

More From Tingley

What Can the Latest Statistics Tell Us About Slip, Trip, and Fall Prevention

Related questions.

- Why do I need an entrance mat?

- How can I know the footwear I’m buying has enough slip resistance for my workplace?

Let's Make Workplaces Safer!

Subscribe to the Safeopedia newsletter to stay on top of current industry trends and up-to-date know-how from subject matter authorities. Our comprehensive online resources are dedicated to safety professionals and decision makers like you.

Latest Articles

An Overview of Asset Management in Construction

By: Lindsey Walker | Marketing Manager

Best Practices for Preventing Heat Stress in Construction

By: Jack Shaw | Writer & Editor

A Primer on Arc Flash Boundaries

By: Safeopedia Staff

Washroom Safety: A Brief Guide to Safeguarding Your Health

Slips, Trips, and Falls Prevention Guide – Online Safety Trainer

The Importance of Preventing Slips, Trips, and Falls

As a society, we often take for granted the simple act of walking. But slips, trips, and falls can happen to anyone, anywhere, at any time. According to the National Safety Council (NSC), slips, trips and falls are the leading cause of workplace injuries and the second leading cause of accidental death. The Bureau of Labor Statistics reported that in 2019, slips, trips, and falls accounted for 24% of all nonfatal workplace injuries. The importance of preventing slips, trips, and falls cannot be overstated, especially in the workplace where they are a leading cause of injury.

Understanding the Risk Factors

Slips, trips, and falls can occur due to a variety of factors. Wet or oily surfaces, uneven surfaces, poor lighting, and obstructed walkways are common causes of slips. Trips can occur due to raised or uneven surfaces, electrical cords, and clutter on the floor. Falls can happen when working at heights, such as on ladders or scaffolding. It’s important to understand these risk factors in order to effectively prevent slips, trips, and falls in the workplace.

With a clear understanding of the risk factors that can lead to slips, trips, and falls, it’s important to take action to mitigate these hazards in the workplace. What follows next is a helpful guide to help reduce the risk of slips, trips, and falls in your workplace.

Conduct regular inspections of the workplace to identify hazards

Conducting regular inspections of the workplace is a crucial step in identifying hazards that can lead to slips, trips, and falls. These inspections should be conducted by a trained individual, who is familiar with the potential hazards and can recognize them in the workplace. The inspection should cover all areas of the workplace, including common areas such as hallways, stairways, and walkways, as well as specific areas where slips, trips and falls hazards are likely to occur such as near machinery and equipment, in storage areas, and near hazardous materials.

During the inspection, the inspector should look for hazards such as wet or oily surfaces, uneven surfaces, poor lighting, obstructed walkways, raised or uneven surfaces, electrical cords, and clutter on the floor. The inspector should also take note of any areas that are frequently used by employees and visitors, as they are more likely to be affected by slips, trips, and falls hazards. Once the inspection is complete, the inspector should document any hazards found and work with management to develop a plan to eliminate or control the hazards.

Regular inspections of the workplace can help to identify hazards before they cause accidents, and thus prevent injuries. This not only keeps the employees safe but also helps to reduce the costs associated with slip, trip and fall incidents. It is important to schedule regular inspections and follow up on any hazards identified to ensure that they are properly addressed. This will help to create a safer work environment for all employees and visitors.

Implement slip-resistant flooring and ensure walkways are clear of debris

One of the most effective ways to prevent slips, trips, and falls in the workplace is to implement slip-resistant flooring. Slip-resistant flooring is designed to provide a higher coefficient of friction, making it less likely for a person to slip or fall on the surface. There are different types of slip-resistant flooring, such as those made of rubber, vinyl, or concrete, that can be used in various settings, and it’s important to choose the right type of flooring for the specific environment.

In addition to implementing slip-resistant flooring, it’s important to ensure that walkways are clear of debris. Clutter on the floor, such as boxes, papers, or loose cables, can create tripping hazards and should be removed immediately. It’s also important to make sure that walkways are well lit and that any obstacles or changes in elevation are clearly marked. This will help to ensure that employees and visitors can safely navigate the workplace, reducing the risk of slips, trips, and falls.

It’s important to keep in mind that slip-resistant flooring and clear walkways are not a one-time solution, but rather a constant effort. Regular maintenance and cleaning are necessary to keep the flooring slip-resistant and walkways clear of debris. This includes regular cleaning, sweeping, and mopping of the flooring to remove any dirt, oil, or other materials that can make the surface slippery. Additionally, it’s important to address any potential hazards or changes in the workplace, such as spills or new equipment, as soon as they are identified, to minimize the risk of slips, trips, and falls.

Provide adequate lighting, including emergency lighting

Providing adequate lighting is an important aspect of preventing slips, trips, and falls in the workplace. Adequate lighting is essential for employees and visitors to be able to navigate the workplace safely and to recognize potential hazards. This includes not only the overall lighting level in the area, but also the distribution of light, which should be consistent and without shadows or glare.

In addition to general lighting, it’s also important to provide emergency lighting. Emergency lighting is essential in case of power outages or other emergency situations, to ensure that employees and visitors can safely evacuate the building. The emergency lighting should be placed in a way that it provides a clear path of egress, and it should be tested regularly to ensure that it is in proper working order.

It’s also important to consider the type of lighting that is used in the workplace. LED lights are energy-efficient and can provide a high level of lighting, while also reducing the heat output. This can be beneficial in areas where the temperature is critical such as in refrigerated areas or in areas where heat can be a hazard. Additionally, it’s important to make sure that the lighting is placed in a way that it does not create any glare or shadows that can create hazards.

In summary, providing adequate lighting is a crucial aspect of preventing slips, trips, and falls in the workplace. This includes not only providing general lighting but also emergency lighting, which is essential in case of power outages or other emergency situations. It’s important to regularly check the lighting levels, the distribution of light, and the type of lighting used, to ensure that it is appropriate and working properly. This will help to create a safer work environment for all employees and visitors.

Train employees on how to safely navigate the workplace and recognize hazards

Training employees on how to safely navigate the workplace and recognize hazards is an essential step in preventing slips, trips, and falls. This training should cover a variety of topics, including identifying common hazards, such as wet or oily surfaces, uneven surfaces, poor lighting, and obstructed walkways, as well as specific hazards that are unique to the workplace. It’s important to ensure that employees understand the importance of reporting hazards and incidents, and how to do so.

The training should also include the proper use of personal protective equipment (PPE), such as slip-resistant shoes, hard hats, and safety goggles, and any specific procedures that employees need to follow, such as how to safely use ladders or scaffolding. Additionally, it’s important to train employees on emergency procedures, such as how to evacuate the building safely in case of a fire or other emergency.

It’s also important to regularly review and update the training program to ensure that it is current and effective. This includes providing refresher training, especially after a significant change in the workplace, such as new equipment or layout changes. Additionally, it’s important to provide ongoing training and communication to employees, such as through safety bulletins or newsletters, to keep them informed of the latest hazards and best practices.

Training employees on how to safely navigate the workplace and recognize hazards is an essential step in preventing slips, trips, and falls. This includes not only providing training on identifying hazards but also providing training on emergency procedures, personal protective equipment and procedures that employees need to follow. It’s important to regularly review and update the training program to ensure that it is current and effective, this will help to create a safer work environment for all employees.

Use warning signs and barriers to alert employees and visitors of potential hazards

Using warning signs and barriers is an effective way to alert employees and visitors of potential hazards in the workplace and to prevent slips, trips, and falls. Warning signs can be used to indicate areas that are potentially hazardous, such as wet or oily floors, or areas that are under construction. These signs should be conspicuous and easily readable, and they should be placed in areas where they can be easily seen by employees and visitors.

Barriers can also be used to indicate potential hazards and to physically separate employees and visitors from the hazard. These barriers can be used to block off areas that are under construction, or to separate employees and visitors from hazardous materials or equipment. It’s important to ensure that the barriers are sturdy, and that they are placed in a way that they can’t be easily bypassed.

It’s also important to regularly inspect the warning signs and barriers to ensure that they are in good condition and that they are still needed. This includes checking that the signs are still legible and that the barriers are still in place and functional. If the signs or barriers are damaged or no longer needed, they should be repaired or removed immediately.

Using warning signs and barriers is an effective way to alert employees and visitors of potential hazards in the workplace and to prevent slips, trips, and falls. These signs and barriers should be conspicuous, easily readable and placed in areas where they can be easily seen by employees and visitors. Regular inspection of these signs and barriers is important to ensure that they are in good condition and that they are still needed, this will help to create a safer work environment for all employees and visitors.

Establish a reporting system for hazards and incidents

Establishing a reporting system for hazards and incidents is an important step in preventing slips, trips, and falls in the workplace. This system should allow employees and visitors to easily report hazards and incidents, such as slips, trips and falls, and should provide a clear process for how these reports are handled. This includes providing employees with multiple ways to report hazards, such as through a hotline, a web portal, or in-person reporting, and ensuring that the process is simple and easy to use.

When a hazard or incident is reported, it’s important to have a clear process for how it is handled. This includes assigning responsibility for investigating the report and determining the cause of the hazard or incident, as well as developing and implementing a plan to eliminate or control the hazard. This should be followed by a follow-up process to ensure that the hazard or incident has been effectively addressed, and that it is not likely to occur again in the future.

It’s also important to track and analyze the data on hazards and incidents, in order to identify trends and patterns that can be used to improve the overall safety of the workplace. This can help to identify problem areas and to target resources where they are needed most. Additionally, it’s important to communicate the outcome of the report and the actions taken to the employee who reported it and to all the employees, to ensure that everyone is aware of the hazards and how to avoid them.

Establishing a reporting system for hazards and incidents is an important step in preventing slips, trips, and falls in the workplace. This system should

Implement an emergency response plan

Implementing an emergency response plan is an essential step in preventing and managing slips, trips and falls incidents in the workplace. An emergency response plan is a set of procedures and protocols that are put in place to ensure that employees and visitors know what to do in the event of an emergency, such as a slip, trip or fall incident. It should include details on how to respond to the incident, who is responsible for taking action, and what resources are available.

The emergency response plan should be clearly communicated to all employees and visitors, and they should be trained on how to respond in the event of an emergency. This includes how to provide first aid if necessary, how to evacuate the building if necessary, and how to contact emergency services. The emergency response plan should also include procedures for reporting the incident, documenting it, and conducting an investigation to identify the cause.

It is also important to regularly practice and review the emergency response plan to ensure that it is up-to-date and that all employees are familiar with it. This includes conducting regular drills and exercises, so that employees know what to do in the event of an emergency and that they can respond quickly and efficiently. This will help to minimize the risk of injury and damage, and ensure that the incident is resolved as quickly as possible.

Implementing an emergency response plan is an essential step in preventing and managing slips, trips and falls incidents in the workplace. It’s important to clearly communicate the plan to all employees and visitors, and train them on how to respond in the event of an emergency. It’s also important to regularly practice and review the plan, to ensure that it is up-to-date and that all employees are familiar with it. This will help to minimize the risk of injury and damage, and ensure that the incident is resolved as quickly as possible.

Regularly review and update policies and procedures to ensure they are current and effective

Regularly reviewing and updating policies and procedures is an important step in preventing slips, trips and falls in the workplace. This includes reviewing and updating policies and procedures related to slips, trips and falls, such as those related to maintenance, housekeeping, and emergency response. It’s important to ensure that these policies and procedures are current and effective in addressing the hazards that may cause slips, trips and falls, and that they are consistent with industry best practices and regulations.

When reviewing and updating policies and procedures, it’s important to involve all relevant stakeholders, such as employees, management, and safety professionals. This will help to ensure that the policies and procedures are practical, effective and easy to understand for everyone. Additionally, it’s important to communicate any updates or changes to the policies and procedures to all employees and visitors, and to provide training on how to follow them.

It’s also important to monitor and evaluate the effectiveness of the policies and procedures. This includes tracking incidents and hazards, analyzing the data, and identifying patterns or trends. This information can be used to identify areas that need improvement and to develop strategies to address them. By regularly reviewing and updating policies and procedures, organizations can ensure that they are current and effective in preventing slips, trips and falls and to create a safer work environment for all.

Regularly reviewing and updating policies and procedures is an important step in preventing slips, trips and falls in the workplace. This includes involving all relevant stakeholders and communicating any updates or changes to the policies and procedures, it’s important to monitor and evaluate the effectiveness of the policies and procedures to ensure that they are current and effective in preventing slips, trips and falls. This will help to create a safer work environment for all.

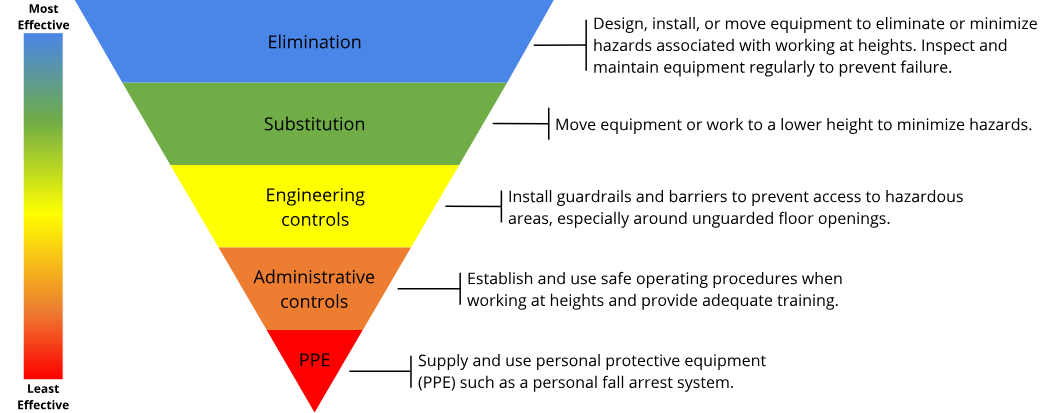

Slips, trips and falls are a leading cause of injuries in the workplace and it’s crucial that organizations take steps to prevent them. The Hierarchy of Controls framework is a powerful tool for identifying and implementing effective controls to prevent slips, trips and falls. It’s important to use the most effective controls first, eliminate hazards where possible, substitute less hazardous materials or processes, engineer controls to reduce exposure, implement administrative controls, provide personal protective equipment, monitor and evaluate controls, and implement a combination of controls. By following these steps and regularly reviewing and updating policies and procedures, organizations can effectively control the risk of slips, trips and falls and create a safer work environment for all

Share This Article

Related posts.

Controlling Silica Dust Exposure from Handheld Power Saws

Controlling Silica Dust Exposure from Handheld Grinders

Controlling Silica Dust from Handheld and Stand-Mounted Drills

Controlling Silica Dust Exposure from Stationary Masonry Saws

Preventing and Responding to Avian Influenza Outbreaks

Reducing Risks of Tick-Borne Diseases for Outdoor Workers

OSHA’s New Rules for Electronic Injury Reporting

Protecting Workers from Silica Dust during Hydraulic Fracturing Operations

Contact | Subscribe | Media centre

- Lifting, pushing and pulling

- Psychosocial hazards

- Working at heights

- Crystalline silica and silicosis

Managing health and safety

- Identify, assess and control hazards

- Safety data sheets

- Personal protective equipment

- Emergency plans and procedures

- Incident reporting

Industry and business

- Construction

- Small business

- Agriculture

- Gig economy

The Commonwealth, states and territories regulate and enforce WHS laws.

Find your Regulator

Model WHS Laws

We created the model WHS laws in 2011.

- Model WHS Act

- Model WHS Regulations

- Duties under Model WHS laws

- Codes of Practice

- Legislation

WHS laws in your jurisdiction

Contact your regulator

Data and Research

We collect, analyse and publish data and information on work health and safety and workers' compensation.

See our data

- Work-related fatalities

- Work-related injuries

- Work-related diseases

- Return to Work

- Explore our data

- About our data

- Industry benchmarking

- Research by industry or topic

See our latest Key work health and safety statistics

explore our data

Workers' Compensation

We develop national policy and strategy about workers' compensation.

- Workers’ compensation

- Comparing workers' compensation in Australia

- National Return to Work Strategy

- Deemed diseases

- Permanent impairment

- Workers' compensation for psychological injury

Read the Strategy

Resources and Publications

We publish a wide range of resources covering many work health and safety topics.

- Codes of practice

- Video and audio

- Corporate publications

Media centre

- Media releases

- News update

Read our Codes of Practice

read the codes

Slips, trips and falls

Each year slips, trips and falls cause thousands of preventable injuries.

- Safety by topic

The most common ones are:

- musculoskeletal injuries (injuries to muscles, nerves, tendons, joints, cartilage and spinal discs)

- dislocations.

More serious injuries and deaths can also happen.

Slip, trip and fall hazards

Some things that can cause you to slip are:

- the wrong footwear

- polished, wet or greasy floors.

In most cases, people trip on low obstacles that are hard to spot, such as:

- uneven edges in flooring

- loose mats

- open drawers

- untidy tools, or

- electrical cables.

Falls can result from a slip or trip, but many occur from low heights. For example:

- ditches, or

- wet or slippery surfaces.

WHS duties

As a person conducting a business or undertaking (PCBU), you must always aim to eliminate the risk of slips, trips and falls, so far as is reasonably practicable. If that is not possible, you must minimise risks so far as is reasonably practicable.

You must identify hazards, and assess and control risks. Think about your:

- work areas

- work procedures

- equipment.

Consulting with workers can help you find better and easier ways to identify and minimise risks. You should also review control measures to ensure they are working as planned.

Workers also have duties, including taking reasonable care for their own health and safety.

Managing risks

The best way to manage the risk of slips, trips and falls is to eliminate hazards at the design stage of the workplace.

If you can’t eliminate the risk, you must minimise it so far as is reasonably practicable.

Designing safe workplaces

In designing floors, stairs, lighting, drainage and storage:

- keep floors at a single level and use slip-resistant floor coverings

- install extra power points to avoid trip hazards from trailing cords