- You are here:

- Home »

- Blog »

- » Lug Nut Torque For Trailers: What Should Tires Be Torqued To?

Lug Nut Torque For Trailers: What Should Tires Be Torqued To?

- May 16, 2022 /

- By James V.

When you leave home with a travel trailer, it is always good to be prepared for almost everything that can happen. One of the most important places to prepare will be your tires. Make sure they have the right air pressure and the right torque on the lug nuts

The amount of pound-foot torque will depend on the type of lug nuts, wheels, and tires you have on your trailer. Not every tire will be different as the 1/2- inch coned lug nuts on 15 & 16-inch tires with steel wheels the torque will be 90 to 120 lb-ft.

To learn more about this important topic just continue to read our article. It has the information you want to know about so you can drive safely with your trailer to your next destination. Take a few minutes to get the lug nut torque for your tires

What Should Trailer Tires Be Torqued To

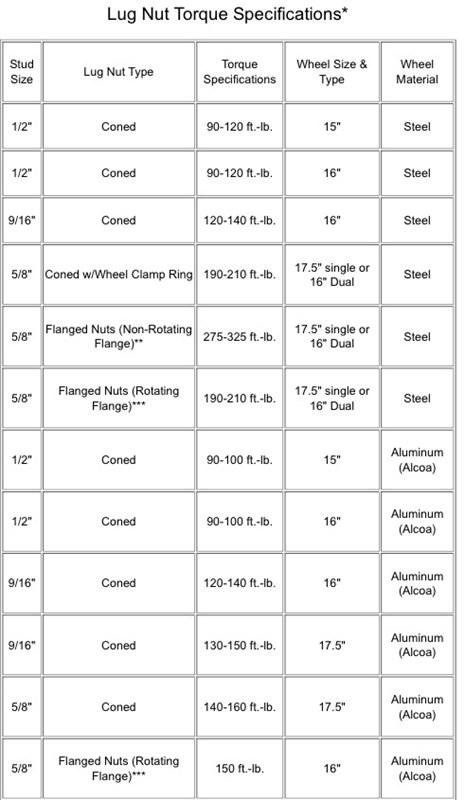

We are going to insert a chart of the different torque ratings for different tires. We came across it during our research and it comes from an e-trailer web page. This chart is to get you on the right track and do not be alarmed if your tires are not mentioned.

There are plenty of tire experts who can help you find yours:

Lug Nut Torque For Trailers

If you are towing a trailer with aluminum wheels, you can feel safe using the torque settings, listed in the chart above. As you can see those settings include aluminum wheels and their ratings are basically the same as they are for the steel wheels.

You may see some difference in torque ratings when you are towing a trailer whose wheels have 5 lug nuts. Those ratings go like this:

1/2-inch- 75 - 85 lb-ft

9/16-inch- 135 - 145 lb-ft

The key to torquing your wheels is to avoid using an impact wrench or any other tool that does not give you a gauge to measure the amount to the tightness of the lug nuts. When wanting to torque your wheels correctly, you need to use a torque wrench. That way you know exactly how tight your lug nuts are.

If your tires are not covered in the chart above, make sure to ask a tire expert what amount of torque you will need to keep those tires nice and safe.

Travel Trailer Lug Nut Torque

It is important to have the right torque on each wheel as there is some risk when you do not. According to one warning label, the wrong torque runs the risk of loose wheels, broken studs, and possibly wheel separation from the axle.

This is not to say these things will happen to you but to warn you that the risk is there. If you are not sure about how to do the torque, many owner’s manuals should have complete information within their pages.

When torquing your wheels, make sure to follow the star pattern. If it is possible you should double-check the torque somewhere around 25, 50, or 100 miles. Keeping the tires safe will help keep you and your loved ones safe.

There are different models of torque wrenches you can use. This is not the time to go cheap and buy a simple model that doe snot have an accurate gauge or no gauge.

13/16 Trailer Lug Nut Torque

This size of lug nut is not mentioned in the chart above. Usually, this lug nut size is used on smaller trailers, for example, cargo, utility, and boat trailers. They may be stamped already with the correct torque rating.

One owner said his lug nuts were pre-stamped and the rating was 85 to 95 lb-ft of torque. There are owners who go with the higher rating and have not had many problems. Check your trailer’s wheels to see if they have pre-stamped lug nuts.

If they do, that extra effort should save you some time and trouble. You won’t have to use the chart above to guide you. Again, we will caution you about the type of wrench you use to tighten your tires on the wheels.

Impact wrenches are quick and very easy to get the job done. However, there is no guarantee that you will stop at the right torque rating when the lug nuts can’t be turned any further.

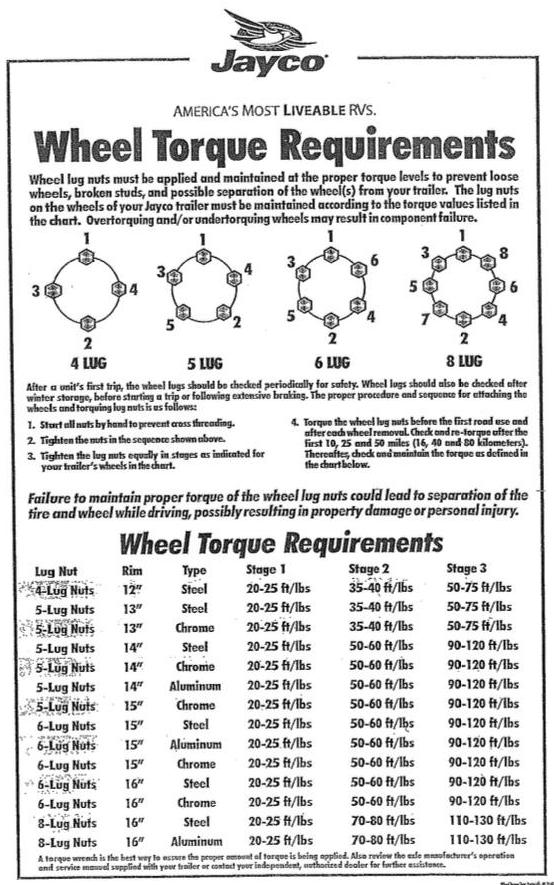

Jayco Wheel Nut Torque Settings

The following image will give you the best information as it is straight from Jayco. The chart covers 4 to 8 lugs and even tells you how to torque your lug nuts:

If you have any questions, you can go to the Jayco RV discussion forums and talk to the many members there. Some of those members are quite knowledgeable about tires and their requirements.

Another tool you should not totally rely on will be the 4-way lug nut wrench. While it will get your lug nuts nice and tight, it will not give you the correct torque rating. After using this wrench to secure your tire, switch to an actual torque wrench to complete the task.

This is the only way to be sure your tires are on correctly. While we make a point about the right wrench to use, we also have to mention that most people do not have a problem with not using a torque wrench. But you do not want to be the exception to this rule.

Some Final Words

Being safe when you are on the road is important. There have been many horror stories about trailers that have lost their tires due to the lack of proper toque. Unfortunately, those stories happen to be true in most cases.

One RV owner saw a trailer on the side of the road missing a tire. A few minutes later, he spotted the tire down the road a ways. Be safe and torque properly.

Related Posts

How Long Do 22.5 Tires Last? (Truck Tire Life Expectancy)

Are Freedom Hauler Tires Any Good? (Trailer Tires Reviews)

Best Tires For E450 Motorhome (Tire Size and Pressure)

Leave a Comment:

Typical Lug Nut Torque Specifications for Aluminum Trailer Wheels

The torque that is to be applied to lug nuts on a typical aluminum trailer wheel varies with the size of the stems on your trailer. Common size stems on a trailer often are 1/2", 9/16" or 5/8". Below is a table to guide you as you are installing the wheels on your trailer.

Lug nut torquing.

Ensuring the tightness and proper torquing of lug nuts on trailer wheels is a critical responsibility for trailer owners and users. Inadequate wheel nut torque is a leading cause of lug nut loosening, which, if not addressed, can result in wheel separation, posing serious safety risks. The Trailer Safety Industry Coalition (TSIC) emphasizes the importance of eliminating wheel separations and seeks assistance from trailer owners in achieving this goal.

Understanding Maintenance Responsibilities:

To begin with, it is essential for trailer owners to have a clear understanding of the specific wheel maintenance responsibilities outlined by the vehicle manufacturer. These responsibilities must be diligently performed to guarantee the safe upkeep of wheel equipment. Regularly checking lug nut tightness, especially during the initial few hundred miles of trailer use and at least biannually, is crucial. Additionally, it is advisable to check torque before embarking on long trips and whenever a wheel is removed. Consult the owner's manual and communicate with the dealer if there are any uncertainties regarding proper torque practices.

Importance of Torque Wrench:

The only foolproof method to ensure the lug nuts are torqued to the proper specification is by using a torque wrench . While four-way wrenches, ratchets, and similar tools may serve for short-term emergency repairs, they are not suitable for accurately checking lug nut torque. Employing a torque wrench provides an accurate indication of the torque applied to the lug nuts, promoting optimal safety standards.

Documentation and Investigation:

Maintaining a record of the date and approximate mileage when checking lug nut torque is a recommended practice. If any lug nuts have lost torque, thorough investigation is imperative. If torque is not sustained after one re-torque application, it signals an underlying issue with the lug nuts , nut studs, wheels , or hubs, necessitating correction. In such cases, prompt communication with the dealer or vehicle manufacturer is essential.

Immediate Action for Persistent Issues:

Persistent issues with lug nut loosening or any other lug, wheel, or axle problems should be promptly addressed. Contacting the dealer or vehicle manufacturer immediately is crucial for a timely resolution. Timely intervention can prevent potential safety hazards associated with wheel separation.

Dealing with Wheel Separation Incidents:

In the unfortunate event of a wheel separation incident, swift action is necessary. Notifying the vehicle manufacturer and dealer is the first step. Seeking professional assistance to assess the trailer and its components is crucial for understanding the extent of the damage. It is advised to retain, but not re-use, the lugs, wheels, and studs involved in the incident. Attempting to repair or service the trailer independently is discouraged; instead, a trained technician should be called upon to address the issue.

The meticulous torquing of lug nuts is a fundamental aspect of trailer maintenance that directly impacts safety on the road. Trailer owners play a pivotal role in ensuring the proper torquing of lug nuts, which is vital for preventing wheel separation incidents. By adhering to manufacturer recommendations, using the appropriate tools, documenting torque checks, and taking swift action in case of issues, trailer owners contribute to a safer and more secure towing experience. Prioritizing lug nut torquing is not just a responsibility; it is a proactive measure to safeguard lives on the road.

- #Lug Nut Torquing

- #trailer lug nut

Recent Posts

Maintenance Tips For Your Lawn Tractor

Getting Your Camper Ready For Adventure - A Guide to Camper and RV Trailer Maintenance

Trailer Bearing Grease Guide

What Do I Need To Torque My Trailer Lug Nuts To?

When you are installing tires or using a trailer for the first time, it's important to have the lug nuts torqued to the proper torque specs. Incorrect torque can cause loosening, cracking, and breaking.

Different trailer wheels and materials and stud sizes require different foot-pounds of torque. This chart is from the Lippert Components manual, check your axles manual for the torque specs of your trailer.

It's important to torque and check torque after the first install and periodically up to at least 50 miles of use.

Make sure to start tightening by hand to prevent cross-threading.

- Maintenance

Recent Posts

Trailer Brakes Aren't Braking

View our trailers

%202020-12-23.png)

Find the guide in your email!

HOW TO AVOID GETTING DUPED BY A TRAILER SALES PERSON

We build trailers that last.

Travel Trailer Lug Nut Torque: The Key to Safe and Smooth Journeys

John Little

When you’re getting ready to go on a fun trip with your travel trailer, there’s something important to remember: checking the lug nuts! What’s a lug nut, you ask? It’s like a special puzzle piece that keeps the wheels on your trailer nice and tight. Now, imagine this: you’re about to leave, and you check to make sure these lug nuts are not too loose or too tight. That’s what we call the “travel trailer lug nut torque.”

It’s a fancy way of saying, “making sure the wheels are just right for a safe trip.” So, next time you’re getting your trailer ready, don’t forget this important step. It’s like giving your trailer a quick health check before a big adventure. Keep reading to get a more clear idea of this.

Travel Trailer Lug Nut Torque

To tighten lug nuts on a travel trailer, use a wrench to turn them until they are firm. Do this in a star pattern for even tightness. Check the owner’s manual for the right tightness. It’s important to do this to keep the wheels safe.

Key highlights:

- Always check the lug nuts on your travel trailer before you go on a trip.

- A torque wrench is the best tool for this.

- Different wheel sizes need different amounts of tightness.

- Keep checking the lug nuts regularly, especially after driving a bit, to make sure they stay just right.

Travel Trailer Lug Nut Torque Chart

A Travel Trailer Lug Nut Torque Chart helps you know how tight to make the lug nuts on your trailer’s wheels. It’s important to use the right torque (tightness level) for safety. Here’s a simple chart:

You can decide how tight should trailer sway bar be besed on this chart. Because it needed to be tight enough to control swaying but not so tight that it’s hard to drive in tight parking lots or U-pick farms

Factors That Influence Trailer Nut Torque Weight

When you tighten the nuts on a trailer, how tight should they be? This is called “torque.” The right torque keeps the wheels safe on your trailer. Factors like the trailer’s weight and the size of the wheels change the torque needed.

- Trailer Weight: Heavier trailers need more torque. This keeps the wheels secure.

- Wheel Size: Bigger wheels often need more torque.

- Nut Size: Different nut sizes need different torque.

- Trailer Use: How you use your trailer can change the torque. If you drive in tight places or on bumpy roads, check the torque often.

- Material: What the trailer and nuts are made of matters. Some materials need more or less torque.

- Weather: Hot or cold weather can change how tight the nuts should be.

- Age of Trailer: Older trailers might need different torque settings.

For specific trailers, like a Jayco travel trailer or a camper trailer, the torque is different. You can find this in the owner’s manual. It tells you the exact torque. This is measured in “lbs of torque.” A tool called a torque wrench helps you get this right.

For example, a Jayco might say “80 lbs of torque.” This means you use the torque wrench to tighten the nuts until it measures 80 lbs. Each trailer type, like a travel trailer, has its own setting.

Risk Factors Of Wrong Travel Trailer Lug Nut

Travel trailers have lug nuts that need the right torque. This means how tight the lug nuts are. Getting it wrong can be risky. Let’s learn about these risks and how to do it right.

1. Understanding Torque Specs

Torque specs tell how tight the lug nuts should be. If they’re too loose or tight, it’s not safe. Your owner’s manual has this info. It’s key to check this first.

2. Using A Torque Wrench

A torque wrench helps get the right tightness. It’s a tool that shows how much force you use. Make sure to use it so your lug nuts are just right.

3. Lug Nut Torque Chart

This chart shows the right tightness for different trailers. It’s good to check this. Every travel trailer might need a different setting. This helps a lot.

4. Wheel Size And Lug Nut Torque

The size of your wheels affects lug nut torque. Bigger wheels might need more force. It’s important to know your wheel size for this.

5. Dexter Wheels And Stud Sizes

If you have Dexter wheels, they have special needs. Their stud sizes are important for setting the right torque. Check their specs for safe travel.

6. Avoiding Over-Torque

Too much torque can harm your wheels. It’s not just about being too loose. Too tight is bad too. Always follow the recommended torque.

7. Regular Checks

Always check your lug nuts before trips. Roads, like tight parking lots or bumpy paths, can change how tight they are. It’s good to check often.

8. Air Pressure and Lug Nut Torque

Your tires’ air pressure can affect lug nuts. Make sure your tires are right, then check the lug nuts. This keeps everything safe and sound.

How Do I Check The Lug Nut Torque On My Trailer?

To check the lug nut torque, you need a torque wrench. This tool will help you make sure the lug nuts are just tight enough. Not too tight, not too loose.

Get a Torque Wrench

First, find a torque wrench . This tool helps you measure how tight the lug nuts are. It’s a must-have for this job.

Find the Right Torque Spec

Check your owner’s manual or look for a lug nut torque chart torque spec for trailer lug nut. It tells you the correct torque for your trailer. This is often called the “lug nut torque spec.”

Check Each Lug Nut

Put the torque wrench on a lug nut. Turn it until it clicks. This click means the lug nut is just right, like in the story of Goldilocks. Not too tight, not too loose.

Follow A Star Pattern

Tighten the lug nuts in a star pattern . This means you don’t tighten the ones next to each other right away. It helps make the wheel sit evenly.

Repeat For All Wheels

Do the same steps for all the wheels on your trailer. Each wheel needs the same careful check.

Recheck Regularly

Lug nuts can get loose over time. Check them often, especially before a big trip.

Remember Other Maintenance

While you’re at it, think about other trailer care, like cleaning it oftern. And not put over pressure on it. It’s good to keep everything in tip-top shape.

For your trailer, the torque spec for the lug nut is important. It’s how tight your lug nuts should be. For example, you might ask, “What is the torque on a 1 2 inch trailer lug?” This info is in the owner’s manual or a lug nut torque chart. It’s measured in “lbs of torque.” The right torque keeps your wheels safe and secure, especially when you go to places like tight parking lots or U-pick farms.

How Tight Should Travel Trailer Lug Nuts Be?

Tightening the lug nuts on your travel trailer is essential. Think of it like making sure your shoes are tied well before a big run. If they’re too loose, they might come off. Too tight, and they could break. You want them “just right.”

Now, about that “just right” part. The lug nuts should be tightened to a certain tightness. This is called torque. A good way to remember is, “What torque should lug nuts be tightened to?” It’s like asking how tight your shoelaces should be.

When you pull trailer behind a camper , you want a smooth trip. The right torque makes sure your wheels stay on safely. To find the perfect tightness, check the owner’s manual of your trailer. It tells you the lug nut torque spec. This is a number, usually in lbs of torque. It’s like a secret code for how tight to make the nuts.

Use a torque wrench to get this right. It’s a tool that helps you tighten the nuts to the perfect level. Remember, the right torque keeps your travel happy and safe.

How Do You Tighten Travel Trailer Lug Nuts?

You need a torque wrench to tighten travel trailer lug nuts. Make sure it’s set to the right torque for your trailer. This torque is often in the trailer’s manual. Now, let’s go step by step.

Find The Right Torque

Check your owner’s manual for the lug nut torque spec. It tells you how tight the nuts should be. Even if you’re pulling a motorcycle trailer with car or bumper pull. This step is key for safety.

Get A Torque Wrench

Use a torque wrench, not just any wrench. It lets you tighten nuts to the exact right tightness. This step will help you adjust trailer brakes by backing up , too.

Loosen Nuts Slightly

If the nuts are very tight, loosen them a bit first. Then, you can properly tighten them.

Tighten In A Star Pattern

Tighten the lug nuts in a star pattern. This makes sure the wheel is evenly tight. It’s important for travel trailers.

Use the Correct Torque Setting

Set your torque wrench to the recommended torque from the manual. So, now you need to know What torque should trailer wheel nuts be?. Because the right setting is key.

Check All Nuts

After tightening, check each nut again. Make sure all are equally tight.

Recheck After A Drive

Drive a short distance, then recheck the nuts. They can loosen after a bit of driving.

Regular Checks Are Important

Always check your lug nuts before trips. It’s a good habit for safety.

Remember, the right torque and using a torque wrench are crucial. This keeps your travel trailer safe on the road.

Things To Avoid Doing With Travel Trailer Lug Nut

Lug nuts hold your wheels on. You must not over-tighten them. Use a torque wrench for this. The tool makes sure you use the right amount of force, called torque. Each trailer has a lug nut torque spec. This is a number saying how tight the nuts should be. You can find this number in the owner’s manual. It’s usually in lbs of torque.

For carry-on trailers, check the lug nut torque often. Use the carry on trailer lug nut torque spec as a guide. This keeps your wheels safe. Remember, too tight or too loose is not good. The right torque keeps you safe on the road.

Tips To Keep Trailer Lug Nut In Check

Follow these tips to keep your trailer’s lug nuts in good shape. They are easy to do and really helpful.

1. Check Lug Nut Torque Regularly

Every so often, check how tight your trailer’s wheel nuts are. This is called checking their torque. Use a torque wrench to do this. The right tightness for your trailer’s nuts can be found in the owner’s manual. It’s usually measured in pounds of torque.

2. Use a Torque Wrench for Accuracy

A torque wrench helps you tighten nuts just right. It’s better than guessing. The wrench will tell you when you’ve reached the recommended torque. This stops the nuts from being too loose or too tight.

3. Know the Correct Torque Rating

Your trailer’s manual will say how tight the nuts should be. This is the torque rating. It’s important to follow this to keep your wheels safe.

4. Regularly Inspect for Wear and Damage

Look at your lug nuts often. Check for signs that are worn out or damaged. If they look bad, replace them. This keeps your trailer safe.

5. Understand Your Trailer’s Wheel and Stud Sizes

Trailers have different wheel and stud sizes. This changes the torque needed. Know your trailer’s sizes to use the right torque.

6. Be Mindful of Changes and Repairs

If you change wheels or make repairs, recheck the lug nuts. They might need different torque after changes.

7. Keep a Lug Nut Torque Chart Handy

A chart shows the right torque for different trailers. Keep one handy for quick reference. This helps you make sure you’re using the right settings.

So, What torque should trailer wheel nuts be? Using the right torque for your trailer’s wheel lug nuts is crucial. It’s about safety and keeping your trailer in good shape. Remember, too much or too little torque can be bad. Always check the owner’s manual and use a torque wrench. This makes sure your trailer is ready for any road trip.

Frequently Asked Questions

How often should i check the lug nut torque on my travel trailer .

Check your travel trailer’s lug nut torque often. After the first 100 miles, then every 500 miles. Use a torque wrench. The correct torque is in the owner’s manual. It tells you how many lbs of torque to use. This keeps the wheels safe.

Is It Necessary To Torque Lug Nuts In Multiple Steps?

Yes, it’s important to torque lug nuts in steps. First, use a torque wrench to tighten them to half the recommended torque from your owner’s manual. Then, do it again to the full torque. This makes sure the wheel is balanced and tight. Check the lug nut torque spec for your wheel size and stud sizes.

Is It Risky To Drive A Travel Trailer With Loose Nut Torque?

Yes, driving a travel trailer with loose nut torque is risky. Lug nuts must be tight to the right torque specs. If they’re loose, wheels can come off. Always check with a torque wrench before trips. See the owner’s manual for the correct lug nut torque settings. Remember, safe torque keeps wheels secure.

What Torque For Boat Trailer Lug Nuts?

For boat trailer lug nuts, check the owner’s manual for the right torque spec. It varies based on wheel size and stud size. Generally, lug nut torque is between 90-120 lbs of torque. Use a torque wrench to get it right. If unsure, look at a lug nut torque chart or ask a professional.

Are There Any Laws About Trailer Lug Nuts?

Yes, there are laws about trailer lug nuts. It’s important to use the right torque specs from your owner’s manual. The manual will tell you how many lbs of torque to use. Use a torque wrench to tighten the lug nuts to the right setting. This is key for safe travel. It matches your wheel size and stud sizes.

Final Thoughts

When it comes to keeping your travel trailer safe, knowing about “travel trailer lug nut torque” is very important. Here’s what you need to know in simple words. First, always use a torque wrench to get the lug nut torque just right. This means tightening the nuts on your trailer wheels to a specific tightness, which you can find in the owner’s manual or a lug nut torque chart. Think about the size of your trailer and its wheels.

Bigger trailers and wheels often need more torque. And it’s not just about how tight the nuts are.

Meet John Little, the Tiny Living Guru. With two decades of hands-on experience and an architecture degree, he’s a Sustainable Housing Innovator and Tiny Home Ambassador. John’s mission: inspire eco-conscious, mobile living. Join him on this transformative journey.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

How To Charge Travel Trailer Battery At Home? | Mastering The Technique Easily

My family and I planned a big camping excursion. We packed everything but failed to check our travel trailer batteries. It was dead the morning we left. This was terrible because our trailer relied on the battery. I wondered how to charge travel trailer battery at home…

How To Paint A Trailer Home? (Tips For Paint Metal Trailer Home)

Today was a special day for me. I decided to give my trailer home a fresh look, so I set out on a journey to paint it. I wondered how to paint a trailer home. With a brush in hand and determination in my heart, I began.…

Can You Remodel a Trailer Home? How To Renovate A Trailer Home

Once upon a time, my friend had a trailer home that looked a bit old and tired. She always dreamed of making it look new and lovely again. She wondered, Can you remodel a trailer home? And guess what? She found out you really can! Remodel a…

- Trailer Wheel Information

Lug Nut Torque Specs

The torque that is to be applied to lug nuts on a typical aluminum trailer wheel varies with the size of the stems on your trailer. Common size stems on a trailer often are 1/2", 9/16" or 5/8". Below is a table to guide you as you are installing the wheels on your trailer.

Lug Nut Torquing

Being sure wheel mounting nuts(lug nuts) on trailer wheels are tight and properly torqued is an important responsibility that trailer owners and users need to be familiar with and practice. Inadequate and/or inappropriate wheel nut torque (tightness) is a major reason that lug nuts loosen in service. Loose lug nuts can rapidly lead to a wheel separation with potentially serious safety consequences.

- Be certain you have a clear understanding of the specific wheel maintenance responsibilities your vehicle manufacturer requires/recommends you, as the owner, must perform in order to insure your wheel equipment is safely maintained. Check the lug nut tightness often,especially during the first few hundred miles of the trailer's use, and at least twice per year. You should always check torque at the beginning of any long trip and every time a wheel is removed. Refer to the owner's manual and speak with your dealer if you have any questions about proper torque practices.

- The only way to be certain you have checked the torque or torqued the lug nuts to the proper torque is with a torque wrench . Four- way wrenches, ratchets, and similar tool can be useful for short-term emergency repairs but are not appropriate tools for accurately checking lug nut torque. You must use a torque wrench to accurately indicate the torque that you are applying to the lug nut.

- Keep a record of the date and approximate mileage when you check the lug nut torque. Note any lug nut that has lost torque. Investigate the reason(s) if the lug nut torque is not maintained after the one re-torque application, because this indicated there is something wrong with the lug nuts, nut studs, wheels and/or hubs and should be corrected.

- Contact your dealer or vehicle manufacturer immediately if you experience any persistent lug nut loosing or any other lug, wheel or axle problems.

- In the event of a wheel separation incident, notify the vehicle manufacturer and dealer. Seek prompt professional assistance in assessing the trailer and its gear, and retain, but don't re-use involved lugs, wheels and studs. Don't repair or service the trailer yourself. Call a trained technician.

Spin-transfer torque and specific features of magnetic-state switching in vacuum tunnel nanostructures

- Basic Research

- Published: 17 December 2015

- Volume 49 , pages 1679–1683, ( 2015 )

Cite this article

- G. D. Demin 1 ,

- A. F. Popkov 1 &

- N. A. Dyuzhev 1

44 Accesses

Explore all metrics

The specific features of spin-transfer torque in vacuum tunnel structures with magnetic electrodes are investigated using the quasi-classical Sommerfeld model of electron conductivity, which takes into account the exchange splitting of the spin energy subbands of free electrons. Using the calculated voltage dependences of the transferred torques for a tunnel structure with cobalt electrodes and noncollinear magnetic moments in the electrodes, diagrams of stable spin states on the current–field parameter plane in the in-plane geometry of the initial magnetization are obtained.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Effect of tunnel barrier thickness on spin-transfer torque, charge current, and shot noise in a magnetic tunnel junction nanostructure.

Physical Principles of Spin Torque

T. Shinjo, Nanomagnetism and Spintronics , 1st ed. (Elsevier Science, UK, 2009), p. 1.

Book Google Scholar

K. A. Zvezdin, M. Yu. Chinenkov, A. F. Popkov, et al., Inzh. Fiz.,No. 10, 27 (2012).

Google Scholar

A. F. Popkov, K. A. Zvezdin, M. Yu. Chinenkov, et al., Inzh. Fiz.,No. 9, 19 (2012).

A. Manchon, S. Zhang, and K.-J. Lee, Phys. Rev. B. 82 , 174420 (2010).

Article ADS Google Scholar

J. Zhang and R. M. White, J. Appl. Phys. 83 , 6512 (1998).

G. Herzog, S. Krause, and R. Wiesendanger, Appl. Phys. Lett. 96 , 102505 (2010).

H. F. Ding, W. Wulfhekel, J. Henk, et al., Phys. Rev. Lett. 90 , 116603 (2003).

H. Xi, J. Stricklin, H. Li, Y. Chen, et al., IEEE Trans. Magn. 46 , 860 (2010).

J. Slonczewski, Phys. Rev. B 71 , 024411 (2005).

P. Ogrodnik, M. Wilczyński, R. Świrkowicz, and J. Barnaś, Phys. Rev. B 82 , 134412 (2010).

J. Grollier, V. Cros, H. Jaffris, et al., Phys. Rev. B 67 , 174402 (2003).

J. Mathon and A. Umerski, Physics of Low Dimensional Systems, Ed. by J. L. Morán-López (Springer US, USA, 2001), p. 363.

D. Datta, B. Behin-Aein, S. Datta, and S. Salahuddin, IEEE Trans. Nanotech. 11 , 261 (2012).

Download references

Author information

Authors and affiliations.

National Research University of Electronic Technology “MIET”, Zelenograd, Moscow, 124498, Russia

G. D. Demin, A. F. Popkov & N. A. Dyuzhev

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to G. D. Demin .

Additional information

Original Russian Text © G.D. Demin, A.F. Popkov, N.A. Dyuzhev, 2015, published in Izvestiya vysshikh uchebnykh zavedenii. Elektronika, 2014, Vol. 108, No. 4, pp. 3–10.

Rights and permissions

Reprints and permissions

About this article

Demin, G.D., Popkov, A.F. & Dyuzhev, N.A. Spin-transfer torque and specific features of magnetic-state switching in vacuum tunnel nanostructures. Semiconductors 49 , 1679–1683 (2015). https://doi.org/10.1134/S1063782615130059

Download citation

Received : 12 December 2013

Published : 17 December 2015

Issue Date : December 2015

DOI : https://doi.org/10.1134/S1063782615130059

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- spin torque

- spin-polarized electron emission

- magnetic tunnel junction

- spin state switching

- Find a journal

- Publish with us

- Track your research

Moscow/Zelenograd and New Moscow

- 1.1 By plane

- 1.2 By train

- 4 Events, Festivals

Zelenograd and New Moscow are two large parts of Moscow city, that lie (often far) outside consolidated residential zone of the city, which lies within and just beyond the MKAD (Moscow Ring Road).

Zelenograd was added in Moscow in 1968 as one of the leading scientific centers. New Moscow was added to Moscow in 2012, forming Novomoskovky and Troitskiy Administrativniy Okrugs with plans of new vast expansion. New Moscow territory is yet to change according to its new city status. Even though suburbial kind construction intensifies in Novomoskovsky Administrativniy Okrug, Troitskiy Administrativniy Okrug still mostly has a rural feel.

Get in [ edit ]

By plane [ edit ]

Vnukovo and Ostafyevo airports are situated in New Moscow proper, though from Ostafyevo airport you still have to go through the "old" Moscow. It is possible to get from Sheremetyevo to Zelenograd without going to the old city - you have to change to 400 minibus on Leningrad highway or on local train on Planernaya. From Domodedovo airport you'll have to go through the old city anyway (the route through Domodedovo and Podolsk will take more time).

By train [ edit ]

Local trains connect Zelenograd with Leningrad Train Station, Tver, Klin and Konakovo. Local trains from Kiev Train Station pass through northern part of New Moscow between Novoperedelkino and Krekshino. To go to Zosimova Pustyn you may want to go all the way to Bekasovo, but trains there are infrequent. It is possible to get to New Moscow through Podolsk, but you'll have to change to bus there.

By bus [ edit ]

Most frequent bus to Zelenograd is bus 400 from Rechnoi Vokzal. It has special pricing. Buses are primary way of public transport to get to New Moscow, new buses are often added. Most buses start from Yugo-Zapadnaya and Tepliy Stan metroes, and Podolsk train station. Troitsk serves as a bus hub.

By car [ edit ]

Zelenograd is accessible by M10 highway. Major highways in New Moscow are M3, A101, Warsaw highway Podolsk - Kresty (joining with A101), first "Beton Ring" A107 and Borovsk highway Peredelkino - Vnukovo - to join with M3. M10 and A101 are often highly congested, M3 may be less prone to it, except Moscow vicinity, and crossing with A107, A107 is congested near M3 crossing, which is northwest of New Moscow; Warsaw highway is congested in Podolsk, and you'll have to pass congested M2 to get there from MKAD.

Connect [ edit ]

- Articles without Wikipedia links (via Wikidata)

- Has custom banner

- Has mapframe

- Has map markers

- All destination articles

- Outline districts

- Outline articles

- District articles

- Has Geo parameter

- Articles with no Wikidata coords

- Pages with maps

Navigation menu

IMAGES

VIDEO

COMMENTS

One of the most important places to prepare will be your tires. Make sure they have the right air pressure and the right torque on the lug nuts. The amount of pound-foot torque will depend on the type of lug nuts, wheels, and tires you have on your trailer. Not every tire will be different as the 1/2- inch coned lug nuts on 15 & 16-inch tires ...

For 9/16 inch studs, the typical lug nut torque will be 120-140 ft lbs based…. Wheel torque specs vary based on stud diameter, wheel diameter and wheel material. The linked chart shows you commonly recommended torque specs for a range of studs and wheels. For 1/2-inch wheel studs and a 14-inch steel trailer wheel you will use….

Steps to torque: We are using an adjustable click Torque Wrench. Unlock the handle and set the dial to your desired torque value. Lock the handle back in place. With the socket secure on the lug nut, with one hand, support the head of the wrench, and with the other hand, apply clockwise pressure. When the torque reaches the desired value, the ...

On here telling someone no matter if it is a single or dual wheel trailer torq specs are 75-85 ft lbs. i dont know how this guy is considered an expert. Sounds like an expert idiot to me. Most of the torq specs on 1/2 lug bolt depends on tire size. Most of the ones i do are a 16inch rim and are torqd to 120 ft lbs.

The torque that is to be applied to lug nuts on a typical aluminum trailer wheel varies with the size of the stems on your trailer. Common size stems on a trailer often are 1/2", 9/16" or 5/8". Below is a table to guide you as you are installing the wheels on your trailer. Lug Size.

A. Torque wheel lug nuts to the torque values listed in the Wheel Torque Requirement Chart. Wheel lug nuts should be torqued before first road use and after each wheel removal. A. Check and re-torque wheel lug nuts after 10, 25 and 50 miles. A periodic check during regular service is recommended. Wheel Size 14' 15' 16' 16.5' 14.5" Demount 16" 16.5'

This chart is from the Lippert Components manual, check your axles manual for the torque specs of your trailer. It's important to torque and check torque after the first install and periodically up to at least 50 miles of use. Make sure to start tightening by hand to prevent cross-threading. 20-25 ft-lbs. 50-60 ft-lbs. 20-25 ft-lbs. 50-60 ft-lbs.

Typical Lug Nut Torque Specifications for Aluminum Trailer Wheels. Lug Size FT/LBS Torque. 1/2" 90-120. 9/16" 120-140. 5/8" 140-160. How much torque is needed to tighten lug nuts? You're now twisting that nut with 10 ft-lb (distance times force, or 1 foot times 10 pounds). Use a 2-foot-long wrench and apply 50 pounds of force, and you'll have ...

For boat trailer lug nuts, check the owner's manual for the right torque spec. It varies based on wheel size and stud size. Generally, lug nut torque is between 90-120 lbs of torque. Use a torque wrench to get it right. If unsure, look at a lug nut torque chart or ask a professional.

Lug Nut Torque Specifications Must use a torque wrench for accurate results. Re-torque lug nuts at 10 miles, 25 miles, and 50 miles, and then periodically after that. Stud Size Lug Nut Type Torque Specifications Wheel Size & Type Wheel Material 1/2" Coned 90-120 ft.-lb. 15" & 16" Steel 5/8" Coned w/ Wheel Clamp Ring

What is lug nut torque on trailers? How Much Torque? 12" & 13" tire/rim (5-lug) 50 ft-lbs. min. 75 ft-lbs. max. ... What is the torque spec for aluminum wheels? Typical Lug Nut Torque Specifications for Aluminum Trailer Wheels Lug Size FT/LBS Torque 1/2" 90-120 9/16" 120-140 5/8" 140-160 How much torque is needed to tighten lug nuts?

One thing to remember is that for Class C and Class B RV motorhomes and for RV trailers, as with your car or pickup with 14″ to 16″ steel wheels, the torque spec is probably between 75 Ft-Lb and 85 Ft-Lb, while 19.5 tires run about 135-145 and 22.5 tires run 450-500 Ft-Lbs.

The torque that is to be applied to lug nuts on a typical aluminum trailer wheel varies with the size of the stems on your trailer. Common size stems on a trailer often are 1/2", 9/16" or 5/8". Below is a table to guide you as you are installing the wheels on your trailer. Lug Size.

Stage 1: Set your torque wrench to 20-30 ft/ lbs (50-60 ft/lbs for the Cambridge, which uses a 9/16" versus 1/2" inch stud). Begin with the appropriate bolt for your wheel. (12 o'clock position for 8 and 6 hole wheels and 2 o'clock position for 5 hole wheels, as illustrated) and apply torque to all lug nuts following the star pattern ...

Torque specs for trailer and vehicle wheels are based on the size of the wheel stud, the type of lug nut, and the material the wheel is made of, steel or aluminum. For example, the linked chart shows you the varying torque values for a range of larger wheel sizes based on these factors. Without knowing more about your hubs and wheels I cannot ...

Torque Specifications 2017 Tredit Tire and Wheel Company, Inc. 5 3 1 4 2 6 1 3 5 2 4 1 3 7 5 2 4 8 6 Using a properly calibrated torque wrench, all the lug nuts installed with any new tire/wheel assembly must have their torque values checked after the first 10, 25, and 50 miles (and periodically checked during normal use thereafter).

Lug Nut Type Torque Specifications Wheel Size & Type Wheel Material 1/2" Coned 120 ft-lb steel 9/16" Coned 140 ft-lb steel 5/8" Coned w/Wheel Clamp Ring 190-210 ft-lb 17.5 single or 16" dual ... TRAILERS . Title: LUG NUT TORQUE SPECIFICATIONS.xlsx Author: peter Created Date:

Looking for the wheel lug nut torque spec. I have a 2015 Rockwood A192HW with (5) 1/2" studs. Tires are 185/80R13 D load. I get conflicting information online, from Dexter axle manual, and the sticker on the side of the camper had a hand written torque spec, but is worn off. I called the dealer, and got 3 different specs ranging from 75 ft/lbs ...

The specific features of spin-transfer torque in vacuum tunnel structures with magnetic electrodes are investigated using the quasi-classical Sommerfeld model of electron conductivity, which takes into account the exchange splitting of the spin energy subbands of free electrons. Using the calculated voltage dependences of the transferred torques for a tunnel structure with cobalt electrodes ...

The torque rating depends on the lug size and type wheel you have on your trailer. I will list the torque specifications for 14 inch wheels. 7/16 inch lug steel wheel 55-65 ft-lb. 1/2 inch lug steel wheel 75-85 ft-lb. 9/16 inch lug steel wheel 95-115 ft-lb. 12 mm steel wheel 70-80 ft-lb. 14 mm steel wheel 85-95 ft-lb. expert reply by: Jeffrey L.

Zelenograd and New Moscow are two large parts of Moscow city, that lie (often far) outside consolidated residential zone of the city, which lies within and just beyond the MKAD (Moscow Ring Road).. Zelenograd was added in Moscow in 1968 as one of the leading scientific centers. New Moscow was added to Moscow in 2012, forming Novomoskovky and Troitskiy Administrativniy Okrugs with plans of new ...

Rome2Rio makes travelling from Moscow Domodedovo Airport (DME) to Zelenograd easy. Rome2Rio is a door-to-door travel information and booking engine, helping you get to and from any location in the world. Find all the transport options for your trip from Moscow Domodedovo Airport (DME) to Zelenograd right here.

Drive • 46 min. Drive from Zelenograd to Moscow 50.4 km. RUB 380 - RUB 600. Quickest way to get there Cheapest option Distance between.