Blue Ink Tech Blog

Less Paperwork, More Driving

What is a DVIR in trucking and why is it so important?

Oct 1, 2021 8:10:14 AM / Written by: Tiffney Lopez

The Daily Vehicle Inspection Record (DVIR), typically known as a pre-trip inspection, is done each day that a commercial motor vehicle (CMV) is in use. The driver of that vehicle does this to ensure the safety of the truck before it hits the road.

The Federal Motor Carrier Safety Administration (FMCSA) says it is against the law to operate a commercial motor vehicle if its safety is not certified. This safety certification of the CMV lies solely on the driver.

The Interstate Commerce Commission began requiring drivers to attest to the safety of their CMV starting in 1939. Decades later, it turned into the DVIR.

While a post-trip inspection is not required, the FMCSA says a pre-trip inspection is a must. The driver "must include all defects in the parts and accessories listed in that were discovered by or reported to the driver during that day."

Even if a driver uses more than one CMV per day, a DVIR must be done for each truck before the driver can put it on the road.

The FMCSA says the pre-trip inspections must include "defects and deficiencies" on the CMV in a number of categories which include:

- Service brakes, including trailer brake connections

- Parking (hand) brake

- Steering mechanism

- Lighting devices and reflectors

- Windshield wipers

- Rear-vision mirrors

- Coupling devices

- Wheels and rims

- Emergency equipment

If a driver finds any part of his or her vehicle to be deficient they are required to get it fixed before they can use the CMV. The original pre-trip inspection with the deficiency must be kept for three months and the corrective actions taken must be noted on the original DVIR.

Why are pre-trip inspections important?

Since a truck can be used by multiple different drivers in a company, you will want to make sure that there was not any unreported damage to the equipment from the last driver. Taking the time to walk around the truck and trailer to make sure everything is working and there are no defects can keep you out of a serious accident.

Trucks are complex machines designed to haul heavy loads over long distances. It's essential for the safety of the drivers in the truck and on the road to make sure things are in working order.

Who is responsible for defects found during pre-trip inspections?

It is the driver's responsibility to make sure that the vehicle they will be operating is in a safe working condition. If any defects are found they should be logged and addressed immediately.

The carrier is responsible for making sure that all defects are fixed and a log is kept indicating when the defect was found, who found the defects, who fixed them, and when they were fixed. These logs must be kept for 1 year in case of a DOT audit to show proof that pre-trip inspections were performed. Also, if a truck is sold by a carrier, they must keep 6 months of records from the time it was in their possession.

If defects are found or a known defect has not been fixed, the vehicle should not be used until it is back in safe working order. Carriers put their drivers, and others on the road, at significant risk by not maintaining their equipment and dispatching drivers to take loads. A coercion report can be filed with the FMCSA against carriers who try to convince drivers to perform certain acts that are in direct violation of the FMCSA regulations.

What are the consequences of not doing the DVIR?

One of the first things a DOT officer will ask during an inspections is request the pre-trip inspection on the vehicle. The FMCSA says that a driver who does not certify their DVIR can be put out of service or fined. Not having a pre-trip inspection is a moderately severe violation that carries a severity weight of 4 and if an out-of-service order is issued an additional 2 points is added.

The severity of these violations has a direct impact on a carrier's CSA score which can affect things like insurance rates, trigger DOT audits , affect their ability to get work, and more.

DVIRs or pre-trip inspections fall under the FMCSA Vehicle Maintenance BASIC which is the most enforced BASIC and accounts for about 60% of all of the violations issued out of the FMCSA's 7 BASIC categories .

How long does it take to do a DVIR?

A pre-trip inspection will usually take about 15 - 30 minutes depending on your carrier requirements and other factors. This should be reflected in your hours-of-service logbook as "on duty not driving" time. If you do not have a period of time dedicated for a pre-trip inspection before you start driving this will throw red flags with the DOT.

Since the use of electronic logging devices that keep track of a driver's time, some areas of the daily vehicle inspection report get overlooked or shortcuts are made to reduce time on inspections. One area of the inspection that does not get performed is usually tire pressure monitoring. Many drivers use tire thumpers to hit the tire and listen to the sound to judge if the tire is properly inflated. Shortcuts like these can backfire in a level 1 DOT inspection that may results in fines and violations.

Topics: ELDs

Written by Tiffney Lopez

Most popular post this month, learn more about blue ink tech products.

- [email protected]

- 304.840.0142

- Terms of Service

- © 2019 Blue Ink Technology

Home → Apply Visa → Visa Type

OCI Information

You should submit your OCI (Overseas Citizen of India) application at the VFS India Consular Application Centre.

Important Notes:

- Read the information available on all the tabs thoroughly before applying.

- If you have ever held Indian Citizenship, then it is mandatory to complete Renunciation of Indian Citizenship or Surrender of Indian Passport/ is the first step to complete before applying for OCI Visa. If you have not yet renounced your Indian Citizenship, then you must apply for Renunciation before applying for the OCI.

- Once application is submitted to the Embassy/ CGI for processing , please track the progress on GOI link https://ociservices.gov.in/statusEnqury . VFS team cannot offer any additional update on status till the OCI card is received back at our office from the Embassy/ Consulate

Select the visa type that is right for you to see important information on visa fees, documents required, forms, photo specifications and processing times.

New OCI Registration

Oci fees & documents required.

- Processing Times

- Photo Specifications

- Processing Time

Apply for OCI Services

While applying for an OCI, it is mandatory for former Indian nationals to provide Certificate of Renunciation of Indian citizenship. If you do not have the Renunciation Certificate, please apply for it first and after getting the renunciation certificate, please apply for OCI.

Eligibility for registration as OCI Cardholder:

Following categories of foreign nationals are eligible for registration as Overseas Citizen of India (OCI) Cardholder:

Any person of full age and capacity:

- who is a citizen of another country, but was a citizen of India at the time of, or at any time after the commencement of the Constitution i.e. 26.01.1950; or

- who is a citizen of another country, but was eligible to become a citizen of India at the time of the commencement of the Constitution i.e. on 26.01.1950; or

- who is a citizen of another country, but belonged to a territory that became part of India after 15.08.1947; or

- who is a child or a grandchild or a great grandchild of such a citizen;

- A person, who is a minor child of a person mentioned in (a) above;

- A person, who is a minor child, and whose both parents are citizens of India or one of the parents is a citizen of India;

- Spouse of foreign origin of a citizen of India or spouse of foreign origin of an Overseas Citizen of India Cardholder registered under section 7A of the Citizenship Act, 1955 and whose marriage has been registered and subsisted for a continuous period of not less than two years immediately preceding the presentation of the application.

Following categories of foreign nationals are NOT eligible for registration as Overseas Citizen of India (OCI) Cardholder:

- Who or either of whose parents or grandparents or great grandparents is or had been a citizen of Pakistan, Bangladesh or such other country as the Central Government may, by notification in the Official Gazette, specify.

- Foreign Military/Police personnel either serving or retired.

Before you start “New OCI Registration” on Govt. Website

- Check your eligibility before you start your registration.

- If you are already an OCI Card Holder, kindly use OCI Miscellaneous Services.

- If you are a PIO Card Holder, kindly register through OCI Registration (In Lieu Of Valid PIO-Card).

- If you are a PIO Card Holder and card is in lost state, kindly register through OCI Registration (In Lieu Of Lost PIO-Card).

- To reprint your already registered application, kindly use 'Re-Print Submitted Application' service.

- In case of urgent travel, applicants may apply for appropriate visa.

Prerequisites

- The height and width of the Applicant Photo must be equal.

- The minimum dimensions are 200 pixels (width) x 200 pixels (height).

- The maximum dimensions are 1500 pixels (width) x 1500 pixels (height).

- The height and width of the Signature Photo must have aspect ratio 1:3.

- The minimum dimensions are 200 pixels (width) x 67 pixels (height).

- The maximum dimensions are 1500 pixels (width) x 500 pixels (height).

- Kindly be ready with supporting documents in PDF format (Max size 1000kb). NOTE: UPLOADING OF DOCUMENTS AS STATED IN THE DOCUMENT CHECKLIST IS A MUST. YOUR APPLICATION WILL BE REJECTED AND RETURNED UNPROCESSED, IF YOU DON’T UPLOAD ALL THE REQUIRED DOCUMENTS ON GOVT. PORTAL.

- New OCI Registration – Sample form

- Document checklist for Foreign national - previously Indian passport holder (adult) Document checklist for Foreign national by birth and never held Indian passport (adult)

- Document Checklist for Foreign national - previously Indian passport holder (minor) Document Checklist for Foreign national by birth and never held Indian passport (minor)

- Document Checklist - For Foreign Spouse

After Registration

- After submission of online application, a copy of the application form will be printed with an Online Registration Number.

- Application form, complete in all respects, along with all relevant enclosures and requisite fee should be paid to the VFS India Consular Application Centre as per the Consular Jurisdiction in whose jurisdiction the applicant is ordinarily residing irrespective of the fact whether the same Indian Mission/Post/Office has issued the original OCI documents or not.

Guidelines for Shipping Service & its packaging

- You can select and pay for VFS provided courier service at the time of paying the fee online on VFS website.

- Please enclose only one application per package. Don’t enclose multiple applications in the same package.

- If used VFS offered courier service via UPS, Max. weight limit per package should be less than 0.5 Lbs & its a signature not required service.

- Pick-up from home/ office service is not included in the price. If you use any additional service, please ensure you make a separate payment directly with UPS.

- Only UPS Pak, UPS envelope or or UPS reusable envelope packaging can be used while shipping your application to the VFS Indian Consular Application Centre. Do not use UPS box or tube. Additional charges will apply if any other type of packaging is used which must be paid before your application is processed.

- Your return shipping address must match with the proof of address submitted as part of your application.

- VFS won't be responsible for any delays or damages if packages are in transit for inbound or outbound couriers.

- FedEx pre-paid labels are not acceptable to return your documents.

- Return address on the shipping label must match the address on the application form. Do not provide shipping address of Courier stores or Hold at Location stations.

- We don’t accept USPS pre-paid labels having expiry date limitation.

- Since our agreement of services is with UPS only, we cannot guarantee collection of your shipment by any other service provider from our officeYou are responsible for tracking your package and schedule a pick up from the VFS Consular application Centre once ready.

Policy - Return of incomplete documents after 20 days.

Incomplete application: If the application is not completed within 20 calendar days, then VFS will return your application unprocessed. In this scenario, the Consular and ICWF fee will be refunded post deduction of applicable postal charges (if applicable). Photocopy documents received after 20 days will be shredded and originals if any received will be returned to the Embassy of India or Consulate General of India. Applicants should contact the Embassy of India or Consulate General of India directly to receive their original documents, once VFS returns the original documents to the Embassy of India or Consulate General of India. In this scenario, only the Consular and ICWF fee will be refunded post deduction of applicable postal charges (if applies).

Policy – Additional documents after 07 days.

Additional documents: If the additional documents are not completed within 07 calendar days then Embassy/Consulates may stop processing your application. In this scenario, no fees will be refunded.

Fees and Charges

Note: Online payment/ Payment by card (s) convenience charges @3.5% will be charged over and over the total payment. We accept Master Card, Visa only

If paying by Money order or Banker or Cashier check, then it should be made in favor of “VFS Services (USA) Inc.

Documents Required

Processing time is 6 weeks from the date application reaches to the Embassy/ Consulate.

OCI Registration (In Lieu of Valid PIO card)

Before you start.

- If you are an PIO Card Holder, kindly register through OCI Registration (In Lieu Of Valid PIO-Card).

- If you are an PIO Card Holder and card is in lost state, kindly register through OCI Registration (In Lieu Of Lost PIO-Card).

- Bureau of Immigration (BoI) was accepting PIO cards as valid travel document till 30th September, 2023 along with valid foreign passport. PIO cards are no longer valid to travel. You must apply for OCI .

- Kindly be ready with supporting documents in PDF format (Max size 1000kb). You must upload documents online as listed in the checklist. NOTE: UPLOADING OF DOCUMENTS IS A MUST. YOUR APPLICATION WILL BE REJECTED AND RETURNED UNPROCESSED, IF YOU DON’T UPLOAD ALL THE REQUIRED DOCUMENTS ON GOVT. PORTAL.

- Government Sample Form

- Application form, complete in all respects, along with all relevant enclosures and requisite fee should be sent to the VFS India Consular Application Centre as per the Consular Jurisdiction in whose jurisdiction the applicant is ordinarily residing irrespective of the fact whether the same Indian Mission/Post/Office has issued the original OCI documents or not.

- If used VFS offered courier service via FedEx- points to notethen max. weight limit per package should be less than 0.5 Lbs.

- Pick-up from home/ office service is not included in the price. If you use any additional service, please ensure you make a separate payment directly with FedEx

- Only FedEx Pak, FedEx envelope or or FedEx reusable envelope packaging can be used while shipping your application to the VFS Indian Consular Application Centre. Do not use FedEx box or tube. Additional charges will apply if any other type of packaging is used which must be paid before your application is processed.

- Since our agreement of services is with FedEx only, we cannot guarantee collection of your shipment by any other service provider from our officeYou are responsible for tracking your package and schedule a pick up from the VFS Consular application Centre once ready.

- Applicants for new OCI, must provide 2 return courier labels with your application

- User Manual - How to Generate courier Label for Incomplete Application

Note: Online payment/ Payment by card (s) convenience charges @3.5% will be charged over and over the total payment.We accept Master Card, Visa only

OCI Registration (In lieu of LOST/Damaged PIO card)

Before you start – oci registration (in lieu of lost/damaged pio card).

- Kindly register through OCI Registration (In Lieu Of Valid PIO-Card).

- Bureau of Immigration (BoI) was accepting PIO cards as valid travel document till 30th September, 2023 along with valid foreign passport. PIO cards are no longer valid to travel. You must apply for OCI.

- Kindly be ready with supporting documents in PDF format (Max size 1000kb). You must upload the below statedthe documents online as listed on the checklist. NOTE: UPLOADING OF DOCUMENTS IS A MUST. YOUR APPLICATION WILL BE REJECTED AND RETURNED UNPROCESSED, IF YOU DON’T UPLOAD ALL THE REQUIRED DOCUMENTS ON GOVT. PORTAL.

processing time is 6 weeks from the date application reaches to the Embassy/ Consulate.

OCI Miscellaneous services

OCI Card Reissue Guidelines

Please refer the advisory - OCI Card Re-issue Guidelines

Before you start – OCI Miscellaneous Services

- To avail Miscellaneous Service, you must be an existing OCI Card Holder

- In case of issuance of new passport.

- In case of change of personal particulars viz. name, father’sname, nationality etc.

- In case of change of address/occupation

In case of urgent travel, applicants may apply for appropriate visa. In case of urgent travel, applicants may apply for appropriate visa.

Prerequisite

- Kindly be ready with supporting documents in PDF format (Max size 1000kb). Documents stated on the checklist must be uploaded online. NOTE: UPLOADING OF DOCUMENTS IS A MUST. YOUR APPLICATION WILL BE REJECTED AND RETURNED UNPROCESSED, IF YOU DON’T UPLOAD ALL THE REQUIRED DOCUMENTS ON GOVT. PORTAL.

- Document Checklist

- OCI Sample Form

- Affidavit in lieu of Originals

- Parental Authorization for Minors

- Application form, complete in all respects, along with all relevant enclosures and requisite fee should be sent to the VFS India Consular Application Centre as per the Consular Jurisdiction in whose jurisdiction the applicant is ordinarily residing irrespective of the fact whether the same Indian Mission/Post/Office has issued the original OCI documents or not

OCI in lieu of Damaged/Lost OCI Card

Before you start – oci in lieu of damaged/lost oci card.

- To avail OCI in lieu of Damaged/Lost OCI card Service, you must be an existing OCI Card Holder and should select “OCI Miscellaneous services on Govt. Portal

- OCI in lieu of Lost or Damaged OCI Checklist – For Adult

- OCI in lieu of Lost or Damaged OCI Checklist – For Minor

OCI In lieu of Damaged/Lost OCI Card

Renunciation of OCI card

Before you start – Renunciation of OCI card

- To avail Renunciation of OCI card service, you must be an existing OCI Card Holder

If paying by Money order or Banker or Cashier check, then it should be made in favor of “VFS Services (USA) Inc..

CDL Pre-Trip Inspection Checklist

Studying this Class-A CDL pre-trip inspection checklist is an important part of truck driver training. Before getting your Class-A CDL and finding an entry level truck driving job , most states will require students to pass a DOT (department of transportation) pre-trip inspection test and a general knowledge test .

Each company’s pre-trip inspection varies slightly. Most likely you will have to do the coupling system, light check and in-cab inspections plus one of the remaining three sections.

Pre Trip Inspection Checklist

Download free and print it! Printable Pre Trip Inspection Checklist (PDF)

There are many sections to learn but the test is not as difficult as it may seem. Studying our simplified Class-A pre-trip inspection checklist and taking classes at your local CDL training school will get you prepared.

Engine Compartment

Driver door fuel area, coupling area, light check, in-cab inspection and brake tests, belt driven alternator, belt driven water pump, brake chamber, brake lining, caste nuts and cotter pins, coolant reservoir, gear box and hoses, gear driven air compressor, gear driven power steering pump.

- General Hoses

Leaf Springs

Power steering fluid reservoir, shock absorber, slack adjuster and push rod, spring hanger, steering column, what to check for:.

When checking the engine compartment, you will always want to make sure the following components are properly mounted and secured. You should also make sure they are not cracked, bent or broken. The items you will need to check for include:

- Make sure all of the wires are connected. The belt should not be cracked or frayed and the free play on the belt should be between ½ to ¾ of an inch.

- The free play on the belt should be between ½ to ¾ of an inch. Also check all the hoses running to and from the water pump to make sure nothing is leaking.

- The brake chamber should not be leaking air.

- The brake drum should be properly mounted and secure.

- The brake hose is rubber, so it is important to make sure it is not leaking air.

- Check for oil or debris on the lining. There should be at least ¼ of an inch of friction material.

- Make sure all three caste nuts and cotter pins are present.

- The reservoir should not leaking and must be filled to the manufacturer’s specifications.

- Make sure the drag link is properly mounted and secure, and not cracked, bent or broken.

- The gear box and hoses should have no abrasions, bulges or cuts, and should not be leaking.

- Although the air compressor is hard to see, you must make sure it is properly mounted and does not leak.

- The steering pump is located in the same place as the air compressor and is also gear driven. Ensure the steering pump is not leaking.

General Hoses (Passenger and Driver’s Side)

- The hoses should be secure at both ends. There should be no abrasions, bulges or cuts. Fluids run through these hoses, so it is important to make sure they are not leaking.

- The hub seal (or axle seal) should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure none of the leaf springs have shifted.

- Check for leaks under the truck.

- There should be no lug nuts missing. Look for rust trails, powder residue and cracks around the bolt holes.

- The oil level should be filled to the manufacturer’s specifications.

- Make sure the pitman arm is properly mounted and secure. It should be not cracked, bent or broken.

- Make sure this reservoir is not leaking and filled to the manufacturer’s specifications.

- The rim cannot have any unauthorized welds.

- Make sure the shock absorber is not leaking. If it is leaking, the leak will be at the point where the top and bottom portion of the shock meet.

- With the brakes released and pulled by hand, the push rod should never move more than one inch.

- The spring hanger should be properly mounted and secure.

- Make sure the steering column is properly mounted and secure. It should not be cracked, bent or broken.

- Look for abrasions, bulges or cuts on the tread or sidewalls. Tread depth should have a depth no less than 4/32 of an inch. Tires must be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- Make sure the tie rod is properly mounted and secure, not cracked, bent or broken.

- Make sure all are accounted for.

Back to top of Engine Compartment

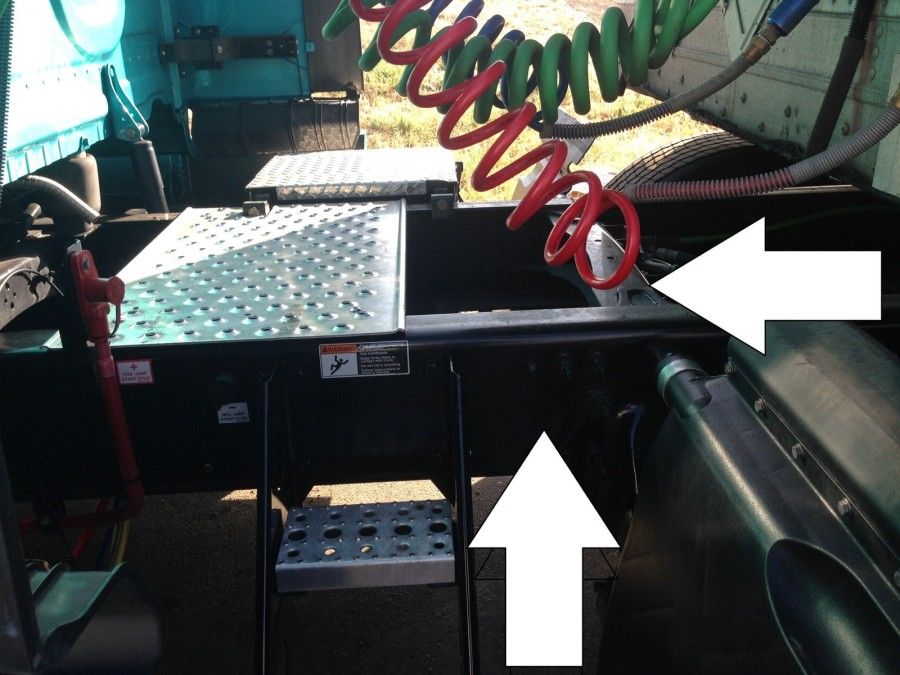

Catwalk and Steps

Door and hinges, drive shaft, exhaust system, frame and cross members, spring mount.

Again it is important to make sure these items are properly mounted and secure. Look for cracks, bends, and breaks.

- The actual airbag is rubber, so it is important to check for abrasions, bulges, cuts and leaks, in addition to any missing mounting bolts.

- The axle seal should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure to mention the brake chamber is not leaking air.

- Make sure the brake drum is secured properly. Also look for cracks, bends and breaks.

- Check the brake hose at both ends to make sure it is not leaking air.

- There should be no oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- The cat walk and steps should be clear of any loose objects.

- Physically demonstrate that the doors open, close and latch properly. Door seals should not be worn, torn or rotten.

- The drive shaft should not be twisted and the u-joints should be free of any debris.

- The tread and sidewalls should have no abrasions, bulges or cuts. The tread depth should be no less than 2/32 of an inch. Tires should be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- The exhaust system should show no signs of leaks.

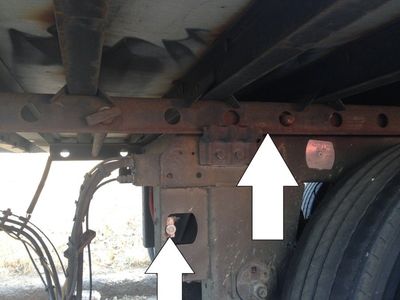

- There should be no unauthorized holes or welds. Bundle up the cross members to ensure none are missing.

- Fuel should not be leaking from the tank and the cap should always be on tight.

- Rust trails could indicate loose bolts, while powder residue and racks around the bolts could mean the bolts have been over-tightened.

- Mirrors should be clean for best visibility.

- Make sure the mud flap is secured properly. Also look for cracks, bends and breaks.

- Make sure to mention there should be never be any unauthorized welds.

- The shock absorber should be secure at both ends and not leaking. If it does leak, it will leak in the middle.

- With the brakes released and pulled by hand, the push rod should not move more than one inch.

- If you are equipped with duals, check to see there is proper spacing between the tires and there is nothing stuck.

- The spring arm should be secure at both ends.

- The spring mount should be secure at both ends.

- Make sure the torque arm is secured properly. Also look for cracks, bends and breaks.

- Make sure to check and mention that no U-bolts are missing.

Back to top of Driver Door Fuel Area

Electric Line

Locking jaws, mounting bolts, release arm, sliding fifth wheel locking pin.

- Air lines should be secure at both ends with no abrasions, bulges or cuts. They should not be leaking, dragging or tangled.

- Make sure the apron is properly mounted and secure. Look for cracks, bends and breaks.

- Make sure there is enough space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

- The electric line should be secure at both ends. There should be no abrasions, bulges, cuts or exposed wires.

- The gap is not an actual item, however there should be no space between the apron and the skid plate.

- The seals should be in good condition with no cracks, signs of rotting, or leaking air.

- Make sure the king pin is properly mounted and secure. Look for cracks, bends and breaks.

- You must physically check that the locking jaws is fully locked around the king pin.

- No mounting bolts should be missing.

- Make sure the platform is properly mounted and secure. Look for cracks, bends and breaks.

- The release arm should be in the fully locked position.

- The skid plate needs to be properly lubed.

- The pin must be in the fully locked position.

Back to top of Coupling Area

Header Board

Landing gear, rear door and hinges.

- Shock Absorbers

Tandem Frame and Release

Trailer tire.

- Again make sure the airbag has no abrasions, bulges, cuts or leakings. The airbag should not be missing any mounting bolts.

- The brake chamber should be properly mounted so that is does not leak air.

- The brake hose should be secure at both ends with no abrasions, bulges, cuts or leaks.

- Check for oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- There cannot be any missing cross members.

- The header board cannot have any holes or missing rivets.

- The landing gear must be fully raised and the cradle handle secure.

- Rust trails indicate loose bolts. Powder residue and cracks around the bolt holes could be an indication of over-tightened bolts.

- The rims cannot have any unauthorized welds.

- The rear door should open, close and latch properly. Door seals should not be worn, torn or dry rotten.

- The shock absorber should be checked at both ends for leaks.

- When the brakes are released and pulled by hand, the push rod should not move more than one inch.

- Release handle and locking pins should be in the fully locked position.

There should be no abrasions, bulges or cuts to the tread or sidewalls. Tread depth should be no less than 2/32 of an inch. The tire should be properly filled to manufacturer’s specifications and checked with an air gauge.

- Front of the truck

- Both sides of the truck

- Rear of the truck

- Both sides of the trailer

- Rear of the trailer

Back to top of Trailer

The five functions are:

- Left turn signal

- Right turn signal

- Four way flashers

- High/low beams

- Brake lights

Back to top of Light Check

- Airbrake Test

Air Pressure Gauges

Emergency equipment, heater and defroster, lighting indicators, oil pressure gauge, parking brake, service brake check, water temperature gauge, windshield and mirrors, windshield wipers and washers.

The last section is In-Cab Inspection and Brake Tests. For the In-Cab Inspection you will once again want to make sure all of the following components are properly mounted and secure. As well as the following:

Air Brake Test

There are three stages to an air brake test:

- Applied Pressure Test – When doing the Applied Pressure Test, you will want to build the air pressure to governor cut out. Put the truck in the lowest gear, turn the engine off and immediately turn it back on. Push in the tractor and trailer valves which will then release the parking brakes. Push and hold the brake pedal, allowing the gauges to stabilize. When the gauges have stabilized, announce the Primary and Secondary PSI. Listen for air leaks while doing this.

- Warning Light and Buzzer – Pump down on the brake pedal until the warning light and buzzer comes on. This is typically at or before 60 PSI.

- Tractor/Trailer Protection Valve Pop Out – Pump down on the brake pedal until the tractor and trailer protection valves pop out, this will be between 20 and 40 PSI.

- The air pressure gauges should build to governor cut out.

- Your truck should have a fire extinguisher, three red reflective triangles and spare electrical fuses.

- Demonstrate both the heater and defroster are working properly.

Horns (Air Horn and City Horn)

- Blow both horns to make sure they are working.

- Check the left turn, right turn, four way flashers and high beams; also point these out on the dashboard.

- Make sure transmission is in neutral and then fully depress the clutch. Turn the key on, check the ABS light, announce when it comes on and off, and start the engine.

- The seat belt should not be ripped or frayed and should adjust and latch properly.

- The engine oil pressure gauge should rise to normal operating range.

- Trailer Parking Brakes – Set the trailer brake, release the tractor brake, then tug lightly on the trailer.

- Tractor Parking Brakes – Set the tractor brake, release the trailer brake and tug lightly on the trailer.

- Release both the tractor and trailer brakes. Drive at idle speed. Apply the service brake to make sure you come to a complete stop and that it doesn’t pull to the left or right when applying the brakes.

- The voltmeter should be charging between 13 and 14 volts.

- The water temperature gauge should also rise to normal operating range.

- The windshield and mirrors must be clean, with no obstructions and in proper adjustment.

- Demonstrate the wipers and washers are working properly by spraying the windshield.

Back to top of In-Cab Inspection and Brake Tests

During a CDL pre-trip inspection, truckers inspect many aspects of their commercial vehicle, including the overall safety of the vehicle; major hoses, fluid levels, and vehicle belts; the clutch or gear shift; and emergency equipment. The driver demonstrates their knowledge by walking around the vehicle, checking various safety components and explaining why each part should be checked for safety.

Reference and practice tests:

- Printable Pre Trip Inspection Checklist (PDF)

- CDL General Knowledge Practice Test

- Pre Trip Inspection Practice Test

- CDL HAZMAT Endorsement Practice Test

Edited for 2024 on 12/5/23

- Register / Login

- Trucker's Forum

- Paid CDL Training

- Truck Driving Jobs

- CDL Practice Tests

- High Road Training

Pre-Trip Inspection Study Guide

Our Pre-Trip Inspection Study Guide has everything you need to prepare for the Class A CDL Pre-Trip Inspection Exam . Our study guide will cover the pre-trip inspection terminology as well as a thorough list of all of the parts you will be inspecting on the vehicle. For each part you will be inspecting there will also be a list of items you will be checking for. Our study guide is broken down into the following sections:

- What You Need to Know About Pre-Trip Inspection

Pre-Trip Inspection Practice Questions

- Pre-Trip Inspection Checklist

Pre-Trip Inspection Videos

Pre-trip inspection printable resources, what you need to know about the pre-trip inspection.

The Pre-Trip Inspection is a thorough inspection of the vehicle and all of its major systems. Inspecting the vehicle before driving each day is a Federal requirement and normally takes about 15 minutes. It must be logged in your logbook as "on duty not driving."

You will have to do thorough safety inspections of the coupling system, the vehicle lights, engine compartment, tires and brakes, the chassis, the fuel tanks, and an in-cab inspection.

The following information is a brief summary of Daniel's Complete Pre-Trip Inspection taken from our oustanding free PDF download:

Engine Compartment

You will be checking the engine compartment for any sort of leaks. You will also be checking to see if all components are properly mounted and secured. None of the mounts must be cracked, bent, or broken.

You will be checking all hoses to make sure they aren't leaking, frayed, or sliced and the fluid levels including the oil level, the coolant, and the power steering fluid.

You must check the components like the water pump, the power steering pump, and the alternator to make sure nothing is leaking, the belts are not frayed, and that everything is properly mounted and secured.

From inside the engine compartment you will also find the steering system, the front suspension system, and the front brake system. All components of these systems must be properly mounted and secured without anything being cracked, bent, or broken. Finally you will be checking the tires, rims, and axle seals to make sure the tires are properly inflated, the rim isn't bent or cracked, and the axle seals are not leaking.

Fuel Tank And Battery Area

You will be standing along the side of the tractor doing a series of checks on the mirrors, fuel tanks, batteries, exhaust system, and more. You will check to make sure nothing is bent, cracked, broken, or leaking.

Check the mirrors, door hinges, door handle to make sure nothing is cracked, bent, or broken. Check to make sure there is no fuel leaking and that the fuel cap is secured and the gasket is not missing.

Check the exhaust system to make sure nothing is cracked, bent, or broken. Check the driveshaft, cat walk, and steps to make sure nothing is cracked, bent, or broken.

Check the frame and crossmembers for structural integrity. Check the air lines going to the trailer to make sure they're properly connected and that there are no abrasions, bulges, or cuts. Make sure the gaskets are present.

Check the suspension system and brakes on the drive axles, making sure nothing is cracked, bent, or broken. Make sure the brake linings are the proper thickness and that the air bags and properly inflated. Inspect the brake chambers, slack adjusters, and pushrods are properly mounted and secure. Not Cracked, Bent, or Broken. With the brakes released and pulled by hand, the Push Rod should not move more than 1 inch.

Check the rims, tires, and axle seals of the drive tires for proper inflation, no leaks around the seal, and the lugs are all present and secured.

Coupling System

You will be standing where the tractor and trailer are connected and you'll start by checking the electrical line and air lines to make sure they're properly mounted and secure at both ends. No abrasions, bulges or cuts. Not leaking air. Make sure the electrical line has no wires exposed. Check the gladhands to make sure the seals are in good condition, no cracks or signs of dry rotting. Not leaking air.

Check the skid plate of the fifth wheel and the apron of the trailer to make sure there is no debris and nothing is cracked, bent, or broken. Make sure the fifth wheel is properly greased. Also make sure there is no gap in between the fifth wheel and the trailer apron once the tractor and trailer are coupled. Make sure the kingpin of the trailer is properly mounted and not cracked, bent, or broken and that the locking jaws of the fifth wheel are properly secured when the tractor and trailer are coupled.

Check the mounting bolts where the fifth wheel attaches to the tractor frame. Make sure there are no missing bolts and that everything is secured properly. Check the locking pin if you having a sliding fifth wheel to make sure it's properly locked into place.

Make sure that there is the proper clearance space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

You will start inspecting the trailer at the head board, which is the front wall of the trailer. Make sure there are no holes or missing rivets. Check the landing gear to make sure it is properly mounted and secure. Not cracked, bent, or broken. Make sure the fully raised and the handle is secure in the cradle when the tractor and trailer are coupled.

Check the frame and crossmembers under the trailer to make sure they're not cracked, bent, or broken. Check the tandem frame and release pins to make sure the frame is in good condition and the release handle and locking pins are in the fully locked position.

You will check the entire suspension and brake system for the trailer tandems the same way you did for the drive axles of the tractor. You will also make sure the mudflaps are properly secured. For dual tires check to see that there is proper space between the tires and there is nothing stuck between the tires.

Check the rear door and hinges to make sure they are properly mounted and nothing is cracked, bent, or broken. Make sure the door seals are not worn, torn, or dry rotted.

Light Check

You will be checking all of the lights and reflectors on both the tractor and the trailer. Check the reflectors and reflective tape to make sure they are properly mounted and secure, not cracked, bent, or broken, and clean and illuminated. Check that you have the proper color of amber to the front and sides, and red to the rear.

Start by turning on your marker lights and headlights. Now walk around the entire truck and trailer and point out the lights. Give the function of the light and the location. You should then ask your examiner to help you check your five functions.

While you're sitting in the drivers seat, the examiner will stand to the front of the truck, then behind the trailer. He will then check your Turn Signals, Four Way Flashers and Brake Lights. You must do each function at every location.

The five locations that you must check your lights:

- Front of the Truck

- Both sides of the Truck

- Rear of the Truck

- Both sides of the Trailer

- Rear of the Trailer

The Five Functions you are checking for:

- Left Turn Signal

- Right Turn Signal

- Four Way Flashers

- High Beams/Low Beams

- Brake Lights

In-Cab Inspection

The in-cab inspection and air brake check will cover the various gauges and systems inside the cab along with several tests to make sure you air brake system is working properly.

You will start by checking the following:

- Seat Belt- Properly Mounted and Secure. Not ripped or frayed Adjusts and latches properly.

- Fire Extinguisher- Properly Mounted and Secure. Fully charged

- Three Red Reflective Triangles- My three red reflective triangles are GIVE LOCATION

- Spare Electrical Fuses- My spare electrical fuses are GIVE LOCATION

- Volmeter, Oil Pressure Gauge, Water Temperature Gauge, and Air Pressure Gauge all show proper operation

- City horn and air horn functioning properly

- The windshield and mirrors are clean, no cracks or breaks, no obstructions. The mirrors are in proper adjustment.

- Windshield Wipers and Washers - Demonstrate that the washers work by spraying the windshield. The Wipers are: Properly Mounted and Secure and operate smoothly. The blades aren't cracked or dry rotten.

- Heater and Defroster - Demonstrate that both the Heater and Defroster are working properly.

- Lighting Indicators - Left Turn, Right Turn, Four Way Flashers, and High Beams.

Trailer Parking Brakes - Set the Trailer Brake, release the tractor brake, and then tug lightly on the trailer.

Tractor Parking Brakes- Then set the Tractor Brake, release the trailer brake, and then tug lightly on the tractor.

Service Brake Check - Release both Tractor and Trailer Brakes. Now drive at idle speed. Apply the Service Brake to make sure you come to a complete stop, and that it doesn't pull to the left or right when applying the brakes.

Air Brake Test

The air brake test will consist of a leakdown test to make sure your air brakes aren't leaking air and losing pressure. It will also test the warning lights and buzzer to make sure the driver gets the proper warning if the air pressure drops too low.

There are three stages to an Air Brake Test

#1: Applied Pressure Test

#2: Warning Light and Buzzer

#3 Tractor/Trailer Protection Valve Pop Out

Applied Pressure Test: Build the air pressure to governor cut out. Put the truck in the lowest gear. Then turn off the engine Immediately turn the engine back on. Push in both the tractor and trailer valves. (This will release the parking brakes.) Push and hold the Brake pedal fully. Allow the gauges to stabilize. Announce the gauges have stabilized and the Primary and Secondary PSI. With the Brakes fully pressed, you should not lose more than 4 PSI in one minute. Announce that you are listening for air leaks during that minute.

Warning Light and Buzzer Test: Pump down on the Brake pedal until the warning light and buzzer comes on, at or before 60 PSI.

Tractor/Trailer Protection Valve Pop Out Test: Pump down on the brake pedal until both the tractor and trailer protection valves pop out. They should both pop out between 40 and 20 PSI.

We have a ton of Pre-Trip Inspection Practice Questions along with the answers and a complete scoring system in our Free Online CDL Practice Tests :

The Engine Compartment Section will include questions about checking the oil level and coolant levels, inspecting belt-driven engine components (like the water pump, alternator, and air compressor), and the safety devices required in the cab. There will also be questions regarding the windshield wipers and free play in the steering wheel.

The Lights And Brakes Section will include questions about dashboard indicator lights, inspecting the parking brakes, and doing a leakdown test on the air brakes. It will also include questions about the low air pressure warning signal and testing your air horn and city horn.

The Suspension And Steering Section will include questions about the tractor protection valve, inspecting the steering box, and inspecting many suspension system parts. It will also include questions about welds being present on tire rims and the minimum tread depth required on steering axle tires.

The Tires And Coupling Devices Section will include questions about shiny trails or rusty threads on lug nuts, inspecting the battery box and cover, and inspecting electrical lines. It will also contain questions about inspecting the coupling devices and the fifth wheel skid plate.

The Emergency Equipment And Fifth Wheel Section will include questions about additional emergeny equipment required by school buses, inspecting the gap between the kingpin apron and the fifth wheel skid plate, and the landing gear securement. It will also contain questions about inspecting driver mirrors and the trailer frame.

Pre-Trip Inspection Checklist - Class A

Our pre-trip inspection checklist covers every part of the truck from front to back, both inside and outside of the truck. It covers the air brakes, suspension parts, steering components, wheels and rims, fuel tanks, batteries, lights, and more. It also covers the air brake tug test and checks for everything under the hood including alternator, water pump, fuel pump, fluids, and more.

This is a super handy checklist to study anytime you have a few minutes to spare:

Pre-Trip Inspection Checklist - Free Word Document Download (Editable Version)

Pre-Trip Inspection Checklist - Free PDF Download (Print Version)

Pre-Trip Inspection Video By Apex CDL Institute

Jeff from Apex Institute does an in-depth explanation of the entire pre-trip inspection process. This video is loaded with tips that go beyond the CDL test to help drivers really understand how to identify problems.

Pretrip Inspection Self-Test By CDL College

The Pretrip Inspection Self-Test By CDL College is really unique. It's a silent video which will show you the part you're inspecting and then gives you a few seconds to figure out what you should be checking for before giving you the answer. Definitely check this one out. Great for practicing before the CDL exam.

Pre-Trip Inspection Video By Averitt Express

This is a complete back to front pre-trip inspection of a truck and trailer by Averitt mainentance associate Kevin Breeding. This thorough pre-trip inspection covers all inportant points of inside the cab, lights, engine, the tractor itself and the trailer.

We have included two print versions of the pre-trip inspection process from Daniel. The first is the entire pre-trip inspection and the second is an abbreviated checklist for the inspection.

- PDF: Daniel's Pre-trip Inspection (Print Version)

- PDF: Daniel's Pre-trip Inspection Checklist (Print Version)

Why Join Trucking Truth?

- The High Road Training Program

- The High Road Article Series

- The Friendliest Trucker's Forum Ever!

- Email Updates When New Articles Are Posted

Apply For Paid CDL Training Through TruckingTruth

Did you know you can fill out one quick form here on TruckingTruth and apply to several companies at once for paid CDL training? Seriously! The application only takes one minute. You will speak with recruiters today. There is no obligation whatsoever. Learn more and apply here:

- Privacy Policy

- Optimization

- Safety & Security

- Truck/Vehicle

- Dry Trailer

- INTEGRATIONS

- Utilization

- Reefer Container

- Dry Container

- AIS DATA SERVICES

- VESSEL MONITORING SYSTEMS (VMS)

- Maintenance

- Construction

- Agriculture

- Customer Experience

- Customer Success Stories

- ORBCOMM University

- Customer Care

1-800-ORBCOMM

+1-804-404-8681

- Smart Terminals

- Satellite Modems

- Tools and Apps

- CONNECTIVITY

- Vessel Monitoring Systems

- White Papers

- Success Stories

- In the Media

- CargoWatch®

- Coldchainview

- Device Cloud

- FleetManager.com

- ORBCOMMconnect

- ORBCOMM Platform

- ReeferConnect

- ReeferTrak®

- Everything you need to know about pre-trip inspection checklists

- Transportation

- Jan 18, 2024

- Cody Lirette

Embarking on a safe and efficient journey as a truck driver begins long before hitting the road. The cornerstone of every successful trip is a thorough pre-trip inspection. This guide delves into the essential aspects of a pre-trip inspection checklist. These critical checkpoints can make all the difference in your driver’s safety and the efficiency and success of the journey.

What is a pre-trip inspection?

A pre-trip inspection is a proactive measure taken by truck drivers to ensure their vehicles are in optimal condition and adhere to safety standards and other relevant regulatory requirements. This assessment checks for signs of wear, damage or malfunction on critical components like the engine, brakes, lights, tires, fluid and more.

The goal of a pre-trip inspection is two-fold: safety and compliance . A thorough vehicle examination helps identify potential issues so they can be addressed promptly, minimizing the risk of breakdowns and accidents. The inspection is crucial for compliance with industry regulations and standards. Failure to do so could result in fines, penalties or suspensions.

The importance of a pre-trip inspection

Pre-trip inspections are more than a regulatory requirement; they can help keep drivers and the public safe, maintain cargo integrity and improve vehicle longevity. Here’s why this practice is essential:

- Enhanced safety: Identifies potential mechanical issues before they escalate. This means reduced risk of breakdowns and roadside emergencies.

- Improved efficiency: Addresses issues before they happen on the road to ensure fleets deliver on time.

- Better compliance: Helps meet legal requirements, avoid unnecessary fines and penalties and comply with industry standards and safety protocols.

- Protected cargo: Ensures cargo is secure and adequately loaded, preventing damage during transit.

- Maintain equipment health: Identifies wear and tear on components, allowing for timely maintenance, reducing long-term repair costs and prolonging the longevity of the vehicle and its critical systems.

- Boosted reputation: Demonstrates a commitment to professionalism and responsibility. This enhances a fleet’s reputation and builds stronger customer relationships.

- Driver confidence: Following a standardized pre-trip inspection checklist reassures drivers that their truck is in optimal condition.

Main components of a pre-trip inspection checklist

To ensure drivers cover all the essential components of pre-trip inspections, here are the main checkpoints to keep in mind:

Tire inspection

- Tread depth: Measure tire tread depth . Inadequate tread depth can compromise traction and vehicle stability, especially in unfavorable road conditions.

- Tire inflation: Verify that all tires meet the manufacturer’s specifications. Improper inflation poses safety issues and can lead to uneven wear and reduced fuel efficiency.

- Visible tire damage: Inspect each tire for cuts, bulges or other visible damage. Address these issues promptly to prevent blowouts and other safety concerns.

- Valve stem integrity: Inspect valve stems for damage or leaks and ensure caps are in place. Damaged stems can lead to pressure loss.

Lights and reflectors

- Headlights: Ensure both high and low beams work. Check for proper alignment to maximize visibility without blinding other drivers.

- Taillights: Verify that taillights work, including brake lights and turn signals.

- Clearance lights: Ensure clearance lights work. These enhance the visibility of the vehicle’s dimensions, especially in low-light conditions.

- Reflectors: Confirm the presence and condition of reflectors on all sides of the vehicle.

- Hazard lights: Ensure hazard lights work.

- Turn signals: Ensure the turn signals work on both sides.

Brake check

- Air brakes: Check air brakes for leaks by listening for hissing sounds. Confirm that air pressure builds within a reasonable time after starting the engine.

- Parking brake: Test the parking brake to ensure it holds the vehicle securely.

- Brake fluid levels: Check the fluid reservoir for proper fluid levels. Low levels may indicate a leak or wear.

- Brake pads and shoes: Inspect brake pads and shoes for visible wear. They may need replacing if they are too thin or show uneven wear patterns.

- Brake drums and rotors: Examine brake drums and rotors for signs of scoring, grooves or heat-related damage.

- Brake lines and hoses: Pay attention to visible damage, corrosion, bulging or leaks.

- Anti-lock braking system: Check the dashboard for warning lights.

Engine compartment

- Engine oil: Check the engine oil level. Ensure it falls within the recommended range.

- Coolant: Ensure the coolant reservoir has the appropriate amount to prevent engine overheating.

- Drive belts: Examine for signs of wear, fraying or cracking.

- Hoses: Inspect hoses for leaks, bulges or soft spots. Replace any damaged hoses to prevent leaks.

- Battery: Check battery terminals for corrosion and ensure they’re securely connected. Loose or corroded connections can lead to electrical issues.

- Air compressor: Inspect the air compressor for visible damage and ensure proper functioning for optimal brake performance.

- Power steering fluid: Ensure power steering fluid levels are within the recommended range.

- Air filter: Check for decay and debris. A clogged air filter can reduce engine efficiency and fuel economy.

- Fuel levels: Ensure the fuel tank is full.

- Fuel cap: Verify the fuel cap is tightly secured to prevent spillage and contamination.

- Fuel tank integrity: Inspect the tank for visible damage, rust or signs of leakage

Fluid inspection

- Transmission fluid: Check transmission fluid levels, ensuring they’re within the recommended range.

- Windshield washer fluid: Keep the washer fluid full.

- Differential fluid: Check differential fluid levels. Low levels can lead to differential damage and affect vehicle performance.

Windshield inspection

- Cracks and chips: Inspect the windshield for any cracks or chips. Address any large ones that affect visibility.

- Windshield wipers: Ensure the windshield wipers are functioning. Replace worn or damaged blades.

- Windshield washer jets: Confirm the windshield washer jets spray fluid evenly. Malfunctioning jets can result in uneven cleaning.

Emergency kit

A well-equipped kit ensures drivers are ready to handle unexpected situations on the road, promoting safety and efficiency:

- First aid supplies: Essential medical supplies including bandages, antiseptic wipes, pain relievers and any necessary personal medications.

- Reflective triangles or flares: Confirm that you have reflective triangles or flares to enhance visibility in case of roadside breakdowns.

- Fire extinguisher: Ensure the fire extinguisher has a valid inspection tag and is not expired.

- Essential tools: Check for the basics like a wrench, pliers and screwdrivers.

- Flashlights and batteries: Test the functionality of flashlights and ensure spare batteries are available.

- Blankets or sleeping bags: Essential for unexpected delays or overnight stops.

- Communication devices: Test radios or cell phones.

- Side mirrors: Confirm side mirrors are correctly adjusted for the driver’s line of sight and are securely attached.

- Convex mirrors: Verify the alignment of convex mirrors to provide an optimal wide field of view. Ensure they are not loose.

- Motorized adjustment: If mirrors have motorized adjustment capability, ensure these work.

Front suspension

- Shock absorbers: Inspect for leaks, visible damage or signs of wear.

- Springs: Pay attention to signs of sagging, damage or cracks.

- Bushings and mounts: Ensure bushings and mounts are in good condition and don’t have any significant wear, deterioration or damage.

- Alignment: Test steering stability to identify any abnormal vibrations or wandering.

- Tie rods and ends: Examine tie rods for signs of looseness, wear or damage.

Driver door

- Door Latches: Verify that door latches engage and disengage smoothly to maintain safety while driving.

- Hinges: Inspect door hinges for signs of wear, rust or damage.

- Seals and weatherstripping: Pay attention to any gaps, tears or deterioration of seals and weatherstripping. Proper seals prevent leakage and maintain a comfortable cabin environment.

- Mud flaps: Should be securely mounted.

- License plate: Ensure the license plate is securely attached and visible. A properly displayed license is crucial for regulatory compliance.

- Exhaust: Note any damage to the exhaust system, like rust or loose components.

- Rear doors or gates: If applicable, test the operation of rear doors or gates.

Coupling system

- Fifth wheel: Inspect for damage or misalignment.

- Kingpin: Ensure there is no wear or damage. A well-maintained kingpin ensures a secure attachment to the fifth wheel.

- Locking mechanism and safety latch: Test the locking mechanism to ensure it engages securely to help prevent accidental uncoupling during transit.

- Release handle: A properly functioning handle facilitates efficient coupling and decoupling.

- Connection hardware: Confirm that all connection hardware, such as bolts and brackets, is secure. Loose components can compromise the coupling system.

- Air and electrical lines: Inspect these lines for damage or leaks and ensure the trailer brake and light systems work.

- Structural integrity: Inspect the trailer for signs of structural damage, including rust, dents or wear.

- Lights and reflectors: Check that all lights and reflectors are functional.

- Brake system: Test the trailer brake system, including service and emergency brakes.

- Suspension components: Inspect suspension components for signs of wear.

- Tires and wheels: Ensure proper tire tread depth and pressure.

- Cargo: Confirm that cargo is securely fastened and within legal limits.

- Landing Gear: Check for proper functioning to ensure stability during loading and unloading.

In-cab inspection

- Steering wheel: Ensure the steering wheel is aligned and stable.

- Seat and seatbelt: Adjust the seat for comfort and confirm the seatbelt is in good condition.

- Pedals: Test the functionality of gas, brake and clutch pedals.

- Instrument panel: Inspect gauges on the instrument panel for proper readings about the truck’s status.

- Documentation: Ensure necessary documents like permits are present and up to date. This is essential for regulatory compliance.

- Electronic devices: Test GPS and communication systems.

How to properly report a pre-trip inspection

Reporting a pre-trip inspection is not just an industry requirement. It’s also a critical communication tool between drivers and fleet management . To effectively report results, it’s important to:

- Use a standardized form provided by the company or regulatory body.

- Record observations in an organized manner.

- Be specific and descriptive.

- Prioritize safety concerns in the report.

- Include suggestions for corrective actions.

- Submit the report promptly to allow swift resolution of issues and minimize the risk of operational delays.

- If available, leverage digital reporting platforms for efficiency. Digital reports can transmit information in real-time, streamlining communication between drivers and management.

- Confirm that the report has been received and acknowledged by the appropriate personnel.

What to do if there are issues in the pre-trip inspection

Encountering issues during a pre-trip inspection is common, and educating drivers on the importance of reporting is crucial for ensuring road readiness and compliance.

If issues arise, ensure they are documented thoroughly and reported promptly. If problems are safety-related, communicate these concerns to management immediately. Always practice clear communication, like concise and descriptive language, to ensure a shared understanding and quick resolution.

Frequently Asked Questions

When should a driver perform a pre-trip inspection.

A driver should perform a pre-trip inspection before embarking on each journey. This proactive examination of the vehicle’s mechanical and safety components ensures it’s in optimal condition for the road. Conducting an inspection daily or before the start of each trip is a regulatory requirement in many jurisdictions. Plus, it can enhance driver safety, limit the risk of mechanical failures and contribute to overall road safety.

What is the first step of the pre-trip inspection?

The first step of a pre-trip inspection should involve an external assessment of the truck or commercial vehicle. This includes visually inspecting the vehicle’s overall condition, ensuring no visible defects or safety hazards. Start with a walkaround to identify any significant issues. Then, break the inspection down into components. For example, start with the tires, then move on to the lights, brakes, mirrors, and under the hood.

What is the most overlooked part of pre-trip inspection reports?

Drivers may focus on more visible components, like tires and lights, neglecting critical elements like brake lines, suspension and the exhaust system. Checking for signs of leaks, loose parts, or damage underneath the vehicle is crucial for identifying hidden issues that could compromise safety and performance. Completing every part of the checklist ensures a comprehensive assessment, reducing the risk of overlooking these critical components.

What happens if I don’t perform the inspection?

Failing to perform a pre-trip inspection can have serious consequences, both legally and in terms of safety. Regulatory bodies often mandate these inspections, and non-compliance can lead to fines, penalties or even the suspension of driving privileges.

Beyond legal implications, neglecting the inspection jeopardizes safety. Without identifying potential issues before hitting the road, there’s an increased risk of mechanical failures, accidents, and breakdowns, posing a danger to the driver and others on the road.

Additionally, failure to perform pre-trip inspections may impact insurance claims and the overall reputation of the driver and transportation company.

What is a DOT pre-inspection checklist?

A DOT pre-inspection checklist is a comprehensive list of items and components that commercial vehicle drivers must inspect before embarking on their trip, as mandated by the United States Department of Transportation (DOT).

Where should the ignition key be during the pre-trip inspection?

During a pre-trip Inspection, the ignition key should be in the “off” position. This is a standard safety practice to prevent accidents during the inspection. Keeping the ignition key off allows the driver to thoroughly examine various components without the risk of moving parts or unexpected vehicle movement. This includes checking the vehicle’s lights, brakes, tires and other essential elements. It’s a precautionary measure that promotes the safety of the driver and those in the vicinity during the inspection process.

How long should a pre-trip inspection reports take?

The duration of a pre-trip Inspection can vary depending on factors such as the driver’s familiarity with the vehicle, the complexity of the truck itself, and the thoroughness of the inspection. On average, a comprehensive pre-trip inspection typically takes around 15 to 45 minutes.

Cody Lirette is Senior Content Marketing Manager at ORBCOMM. With over seven years of marketing and communications experience for both the public and private sector, he uses his passion for innovative technology and plain language to build compelling content that provides value.

- Mar 27, 2024

- Meghana Joshi

Cargo theft has been on the rise—reaching unprecedented highs in recent years. With a 57% increase in incidents in North America in 2023 compared to the previous year, it’s an alarming trend that isn’t showing signs of slowing down. According to the FBI, cargo theft losses in the United States are estimated to be $15-35…

- Value-Added Resellers

- Mar 15, 2024

While MWC 2024 is in the rearview mirror, there’s plenty of value to be taken from the three-day event in sunny Barcelona. Each panel discussion was unique in its own way but one key takeaway was this: the cellular and satellite space is heating up with new technological developments that are creating ample business opportunities….

- Feb 21, 2024

- Colin Withers

While it may be true that the whole is greater than the sum of its parts, the parts still matter. To build a powerful IoT solution, you need world-class hardware that can support your applications and deliver ROI for your customers. The ST 9101 dual-mode terminal does just that, providing all the same comprehensive features…

Get started with ORBCOMM

Serving your CDL Learner Permit requirement needs

- California CDL Permit Training Program

- | 2024 CA CDL Skills Tests

- CA CDL Pre-Trip Inspection

California CDL Pre-Trip Checklist Vehicle Inspection (Walk-Around) Skills Test

First of three california cdl skills tests - the california cdl vehicle checklist inspection skills test must be passed prior to being allowed to continue., there are three parts to the california cdl skills test.

- First Part: California CDL PreTrip Inspection on THIS page . . .

- Second Part: California CDL Basic Vehicle Control

- Third Part: California CDL Road Test

California CDL Pre Trip Inspection Diagram

Vehicle Pre-Trip Checklist Inspection - California CDL Skills Tests:

Quick study guide to california cdl pre-trip inspection.

- Engine Compartment

- Cab Check and Engine Start

- Brake Check

- External Cab

1. California CDL Engine Compartment Pre-Trip Inspection

- Look for puddles on the ground that would indicate a leak.

- Look for dripping fluids on the underside of the engine and transmission.

- Inspect hoses for "good" condition and leaks.

- Indicate the location of dipstick.

- Make sure the oil level is within safe operating range and above the refill mark.

- a) Checking the reservoir sight glass, or

- b) Removing the radiator cap if the engine is not hot and visually checking the coolant level.

- Indicate the location of the power steering fluid dipstick.

- Confirm that there is an adequate power steering fluid level that is above the refill mark.

- power steering belt

- water pump belt

- alternator belt

- air compressor belt

2. California CDL Cab Check and Engine Start - Pre-Trip Inspection

- Manual Transmissions:

- Depress the clutch.

- Place the gearshift lever in neutral.

- Start the engine and then slowly release the clutch.

- Automatic Transmissions:

- Confirm the vehicle is in �park� and start the engine.

- Confirm that the oil pressure gauge is functioning.

- Make sure that the pressure gauge shows increasing or normal oil pressure, otherwise that the warning light goes off.

- If equipped with an oil temperature gauge, it should begin to gradually rise to a normal operating range.

- Confirm that the temperature gauge is working.

- The temperature gauge should begin to climb to the normal operating range.

- The gauges should show the alternator and/or generator charging; otherwise the warning light should be set off.

- Check for proper operation and acceptable readings on the air and vacuum gauges.

- The speedometer should not be obscured or obviously broken.

- Mirrors should be clean and adjusted properly from the inside.

- Windshield should be clean with no illegal stickers, obstructions, or damage to the glass.

- Three red reflective triangles.

- One properly charged and rated fire extinguisher.

- Spare electrical fuses.

- Power steering equipped vehicles: With the engine running, play should not exceed 10 degrees (or about two inches on a 20-inch wheel) before the front left wheel barely moves when you turn the steering wheel back and forth.

- Non-power steering vehicles: Play should not exceed 10 degrees (or about two inches on a 20-inch wheel) when you turn the steering wheel back and forth.

- Check that the wiper arms and blades are not damaged and operate smoothly.

- Windshield washers must operate correctly if the vehicle is equipped.

- Left turn signal

- Right turn signal

- 4-way emergency flashers

- High beam headlight

- Check that air horn and/or electric horn are operational.

- Test that the heater and defroster works.

- Check that the safety belt is securely mounted, adjusts, and latches properly.

- Clearance lights (red on rear, amber elsewhere)

- Headlights (high and low beams)

- Turn signals

- 4-way flashers

- Brake lights

- Red reflectors (on rear) and amber reflectors (elsewhere)

3. California CDL Brake Check Pre-Trip Inspection

- Apply parking brake only and shift into a lower gear. Gently pull against the brake by releasing the clutch, and it should hold the vehicle.

- With the engine running, apply the foot brake and hold for five seconds. The pedal should not move (lose pressure) during those five seconds.

- If equipped with a hydraulic brake reserve system, with the key in the off position, depress the brake pedal and listen for the sound of the reserve system electric motor turning on.

- Check that the warning buzzer and light is off.

- Check the proper operation of the foot brake by moving the vehicle forward slowly at about 5 mph and applying the brake firmly.

- With a fully-charged air system, typically at 120 psi, turn the engine off, chock the wheels, release (push in) the parking brake button and trailer air supply button (for combination vehicles) and time the air pressure drop. After the initial drop, the rate of pressure loss should not be more than 2 psi per minute for single vehicles and no more than 3 psi per minute for combination vehicles

- Release (push in) the parking brake and trailer air supply button (for combination vehicles), and apply pressure to the foot brake. After the initial drop in pressure, the rate of pressure loss should be no more than 3 psi per minute for single vehicles and no more than 4 psi per minute for combination vehicles.

- Turn the key to the on position. Rapidly depress and release the foot brake to reduce air tank pressure. The low air pressure warning signal must come on before the pressure drops below 60 psi.

- Continue to rapidly apply and release the service brake pedal further reducing air pressure. The trailer air supply button (for combination vehicles) and parking brake button should pop out when the pressure falls to usually between 20 to 40 psi. This should activate the spring brakes.

- While the engine is operating at 1800 RPM, the pressure should rise from 85 to 100 psi within 45 seconds in dual air systems.

- With normal air pressure, release the parking brake and trailer air supply button (for combination vehicles), move the vehicle forward slowly at about 5 mph and apply the brakes firmly using the brake pedal. Test for any pulling to any one side or delayed stopping action.

4. California CDL External Cab | Truck | Bus Pre-Trip Inspection

- Check that the steering box is mounted securely and is not leaking.

- Check for damage to power steering hoses and power steering fluid leaks.

- Check that connecting links, arms, and rods from the steering box to the wheels are not worn and cracked.

- Check that the joints and sockets are not loose or worn and that there are no missing nuts, bolts, or cotter keys.

- Check for shifted, cracked, broken, or even missing leaf springs.

- Check for broken and distorted coil springs.

- If equipped, check the air ride suspension for damage and leaks.

- Look for cracked or broken spring hangers, missing or damaged bushings, and broken, loose, or missing bolts, U-bolts or other axle mounting parts.

- Confirm that the shock absorbers are secure and that there are no leaks.

- Look for missing, loose or broken parts.

- The angle between the adjuster arm and push rod should be not less than 90 degrees when the brakes are applied and when the brakes are released a little over 90 degrees.

- When pulled by hand, the brake rod should not move more than one inch with the brakes released.

- Check that brake chambers are not dented, cracked, or leaking and that they are mounted securely.

- Check for worn, cracked or leaking hoses, lines, and couplings.

- Check for dents, cracks or holes, and loose or missing bolts.

- Brake linings and pads should not be worn thin.

- Where visible, check that a reasonable amount of brake lining is showing.

- Check for damaged or bent rims. Rims cannot have welding repairs.

- Tread depth: need a minimum tread depth of 4/32 on steering axle tires, 2/32 on all other tires.

- Tire condition: Check that tread is evenly worn and without cuts or damage to tread or sidewalls. Valve caps and stems should not be missing, broken, or damaged.

- Tire inflation: Check for proper inflation with a tire gauge or by striking tires with a mallet.

- Check that hub oil/grease seals and axle seals are not leaking.

- Check for any missing lug nuts, cracks, distortions, and for signs of looseness such as rust trails or shiny threads.

- Check for cracked or distorted bolt holes.

- Spacers should not be bent, damaged, or rusted through.

- Spacers should be centered evenly.

- Check doors for any damage and that they open and close properly.

- Hinges should be secure with seals intact.

- Mirrors and mirror brackets should be mounted securely.

- Check for secure tanks, tight caps, and that the tanks or lines don�t leak.

- Check to see that batteries are secure, for tight cable connections, and that cell caps are present.

- Check for signs of excessive corrosion.

- Battery box and cover/door must be secure.

- The drive shaft should not be bent or cracked.

- Couplings should be secure.

- Check system for rust or carbon soot as they are signs of damage or leaks.

- System should be secure and connected tightly.

- Check the longitudinal frame members, cross members, box, and floor for cracks, broken welds, holes or other damage.

- If equipped with mud flaps or splash guards, check that they are mounted securely and not damaged.

- Doors and hinges must open, close, and latch properly from the outside, and should not be damaged.

- Check that any ties, straps, chains, and binders are secure.

- If equipped with a cargo lift, it must be fully retracted and latched securely, and should not be leaking, damaged or missing any parts.

- Check that electrical lines and air hoses are not cut, chafed, spliced, or worn, the steel braid should not show through its outer lining.

- Make sure the lines and hoses are not tangled or dragging against tractor parts.

- Make sure the catwalk is securely bolted to tractor frame.

- Check for loose or missing mounting brackets, clamps, bolts, or nuts. The fifth wheel and the slide mounting must be solidly attached.

- Other types of coupling systems should be inspected for missing or broken components.

- Check that the locking jaws fully close around the kingpin

- On other types of coupling systems the locking mechanism should not have missing or broken parts and should lock securely.

- The platform structure supporting the fifth wheel skid plate should be free of cracks or breaks.

- If equipped with a release arm, check that it engaged and that the safety latch is in place.

- The kingpin should not be bent.

- The visible part of the apron should not be bent, cracked, or broken.

- The trailer should be laying flat on the fifth wheel skid plate without any gap.

- Locking pins should be fully engaged.

- The fifth wheel should be positioned so the tractor frame will not strike the landing gear or the tractor.

5. California CDL Trailer Pre-Trip Inspection

- The trailer air connectors should be sealed and in good condition.

- Glad hands should be locked in place and free of damage or air leaks.

- The trailer electrical plug should be firmly seated and locked in place.

- If equipped with a header board, check to see that it is secure, damage-free and strong enough to contain cargo.

- If equipped with a canvas or tarp carrier, it should be mounted and fastened securely.

- Check the front area of enclosed trailers for cracks, bulges or holes.

- The landing gear must be fully raised. Check that it has no missing parts with a non-damaged support frame and that the crank handle is secure.

- Check for air or hydraulic leaks if power operated.