ACGIH Digital Library

- Subscription Center

- Not a Subscriber?

ACGIH is a 501(c)(3) charitable scientific organization that advances occupational and environmental health.

- News Articles

- Copyright Policy

- ACGIH Copyright Permission Request

- Past Board of Directors & Annual Meeting Locations

- Scientific Committees

- Committee Operations Manuals

- Volunteer Spotlight

- 2021–2024 Strategic Plan

- ACGIH Sponsorship

- Organizational Subscriptions

- FIV On-The-Road

- Allied Industry Partners

- Collaborating Scientific Organizations

- Subscriptions

ACGIH advances the careers of professionals working in the occupational and environmental health, industrial hygiene, and safety communities interested in defining their science.

- Subscriber Benefits

- Emerging Career Professionals

- Awards Nominations Form

- Election Nominations Form

- John J. Bloomfield Award

- Robert T. Hughes Memorial Award

- Meritorious Achievement Award

- Philip R. Morey Memorial Award

- William Steiger Memorial Award

- Herbert E. Stokinger Award

- William D. Wagner Award

- Member Ethical Principles

This section has been established to help educate industry, government, and the public on what TLVs and BEIs are, and how TLVs and BEIs may best be used.

- Notice of Intended Changes

- Under Study

- Substances and Agents Listing

- Importance of TLV and BEI Documentation

- Compressed Schedule to TLV Development Process

- TLV/BEI Development Process

- TLV/BEI Policy Statement

- TLV/BEI Position Statement

- Conflict of Interest Policy

- Procedures for Commenting on TLVs and BEIs

- Guidelines and Services for Authors

- Career Development

ACGIH is committed to providing its members and other occupational and environmental health professionals with the training and education they need to excel in their profession.

- Access to ACGIH Online Learning

- Journal of Occupational and Environmental Hygiene

- Industrial Ventilation Resources

- In-Person Learning

- Noise Resources

- Learning Passes

- Submit 2024 Webinar Presentations

- Webinar Series Packages

- Professional Development Courses (PDCs)

- ACGIH Exhibits

- Submit a Job Posting

- Certification Resources

- Publications

ACGIH has publications in many different areas that fit your needs in your field.

- New Releases

- ACGIH Signature Publications

- Digital Publications

If you need to purchase the Digital Library, click here .

If you have purchased and need to access the Digital Library, click here .

- 2024 Documentation

- COVID-19 Resources

- Link to JOEH Articles

- The Action Level Program

The Foundation for Occupational Health & Safety (FOHS) is a 501(c)(3) corporation fostering the expanded establishment of occupational exposure values throughout the world.

- Board of Trustees

- FOHS Terms of Access

- Jeffrey S. Lee Lectureship Program

- Sustainable TLV/BEI Program

- Worldwide Outreach Program

TLV Chemical Substances Introduction

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec faucibus tempus eros eu fermentum.

Introduction to the Chemical Substances TLVs ®

General Information

The TLVs ® are guidelines to be used by professional industrial hygienists. The values presented in this book are intended for use only as guidelines or recommendations to assist in the evaluation and control of potential workplace health hazards and for no other use (e.g., neither for evaluating or controlling community air pollution; nor for estimating the toxic potential of continuous, uninterrupted exposures or other extended work periods; nor for proving or disproving an existing disease or physical condition in an individual). Further, these values are not fine lines between safe and dangerous conditions and should not be used by anyone who is not trained in the discipline of industrial hygiene. TLVs® are not regulatory or consensus standards.

Editor’s note: The approximate year that the current Documentation was last substantially reviewed and, where necessary, updated may be found following the CAS number for each of the adopted entries in the alphabetical listing, e.g., Chromium [7440-47-3] and inorganic compounds (2017). The reader is advised to refer to the “TLV ® Chronology” section in each Documentation for a brief history of the TLV ® recommendations and notations.

Definition of the TLVs ®

Threshold Limit Values (TLVs ® ) refer to airborne concentrations of chemical substances and represent conditions under which it is believed that nearly all workers may be repeatedly exposed, day after day, over a working lifetime, without adverse health effects.

Those who use the TLVs ® MUST consult the latest Documentation to ensure that they understand the basis for the TLV ® and the information used in its development. The amount and quality of the information that is available for each chemical substance varies over time.

Chemical substances with equivalent TLVs ® (i.e., same numerical values) cannot be assumed to have similar toxicologic effects or similar biologic potency. In this book, there are columns listing the TLVs ® for each chemical substance (that is, airborne concentrations in parts per million [ppm] or milligrams per cubic meter [mg/m 3 ]) and critical effects produced by the chemical substance. These critical effects form the basis of the TLV ® .

ACGIH ® recognizes that there will be considerable variation in the level of biological response to a particular chemical substance, regardless of the airborne concentration. Indeed, TLVs ® do not represent a fine line between a healthy versus an unhealthy work environment or the point at which material impairment of health will occur. TLVs ® will not adequately protect all workers. Some individuals may experience discomfort or even more serious adverse health effects when exposed to a chemical substance at the TLV ® or even at concentrations below the TLV ® . There are numerous possible reasons for increased susceptibility to a chemical substance, including age, gender, genetic factors (predisposition), lifestyle choices (e.g., diet, smoking, abuse of alcohol and other drugs), medications, and pre-existing medical conditions (e.g., aggravation of asthma or cardiovascular disease). Some individuals may become more responsive to one or more chemical substances following previous exposures (e.g., sensitized workers). Susceptibility to the effects of chemical substances may be altered during different periods of fetal development and throughout an individual’s reproductive lifetime. Some changes in susceptibility may also occur at different work levels (e.g., light versus heavy work) or at exercise — situations in which there is increased cardiopulmonary demand. Additionally, variations in temperature (e.g., extreme heat or cold) and relative humidity may alter an individual’s response to a toxicant. The Documentation for any given TLV ® must be reviewed, keeping in mind that other factors may modify biological responses.

Although TLVs ® refer to airborne levels of chemical exposure, dermal exposures may possibly occur in the workplace (see “Skin” on page 73 of the Definitions and Notations section).

Four categories of TLVs ® are specified: time-weighted average (TWA); short-term exposure limit (STEL); surface limit (SL); and ceiling (C). For most substances, a TWA alone or with a STEL is relevant. For some substances (e.g., irritant gases), only the TLV–STEL or TLV–C is applicable. If any of these TLV ® types are exceeded, a potential hazard from that substance is presumed to exist.

Threshold Limit Value–Time-Weighted Average (TLV–TWA)

The TWA concentration for a conventional 8-hour workday and a 40-hour workweek, to which it is believed that nearly all workers may be repeatedly exposed, day after day, for a working lifetime without adverse effect. Although calculating the average concentration for a workweek, rather than a workday, may be appropriate in some instances, ACGIH ® does not offer guidance regarding such exposures.

Threshold Limit Value–Short-Term Exposure Limit (TLV–STEL)

A 15-minute TWA exposure that should not be exceeded at any time during a workday, even if the 8-hour TWA is within the TLV–TWA. The TLV–STEL is the concentration to which it is believed that nearly all workers can be exposed continuously for a short period of time without suffering from 1) irritation, 2) chronic or irreversible tissue damage, 3) dose-rate-dependent toxic effects, or 4) narcosis of sufficient degree to increase the likelihood of accidental injury, impaired self-rescue, or materially reduced work efficiency. The TLV–STEL will not necessarily protect against these effects if the daily TLV–TWA is exceeded. The TLV–STEL usually supplements the TLV–TWA where there are recognized acute effects from a substance whose toxic effects are primarily of a chronic nature; however, the TLV–STEL may be a separate, independent exposure guideline. Exposures above the TLV–TWA up to the TLV–STEL (15-min TWA) should be less than 15 minutes, should occur no more than four times per day, and there should be at least 60 minutes between successive exposures in this range. An averaging period other than 15 minutes may be recommended when this is warranted by observed biological effects.

*Threshold Limit Value–Surface Limit (TLV–SL)

The concentration on workplace equipment and facility surfaces that is not likely to result in adverse effects following direct or indirect contact. The TLV–SL is intended to supplement airborne TLVs ® , especially those with Skin, DSEN and RSEN notations, to provide quantitative criteria for establishing acceptable surface concentrations expressed as mg/100 cm 2 . For systemic effects, consistent with the use of the Skin notation, the TLV–SL will often correspond to the dose permitted by the TLV–TWA over an 8-hour period, unless chemical-specific data are available linking adverse effects with surface sample results. For certain dermal sensitizers, the surface limit may be established using potency estimates from animal studies, such as the effective concentration causing a 3-fold increase in lymphocyte proliferation (EC3) and applying an appropriate adjustment factor (Naumann and Arnold, 2019). For other sensitizers, including some respiratory sensitizers that cause induction of sensitization via dermal exposure, professional judgment may be required to supplement available surface and airborne monitoring results.

Threshold Limit Value–Ceiling (TLV–C)

The concentration that should not be exceeded during any part of the working exposure. If instantaneous measurements are not available, sampling should be conducted for the minimum period of time sufficient to detect exposures at or above the ceiling value.

ACGIH ® believes that TLVs ® based on physical irritation should be considered no less binding than those based on physical impairment. There is increasing evidence that physical irritation may initiate, promote, or accelerate adverse health effects through interaction with other chemical or biologic agents or through other mechanisms.

Peak Exposures

The TLV ® Committee recommends consideration of a TLV–STEL if there are supporting data. For many substances with a TLV–TWA, there is no TLV–STEL. Nevertheless, short-term peak exposures above the TLV–TWA should be controlled, even where the 8-hour TLV–TWA is within recommended limits. Limiting short-term high exposures is intended to prevent rapidly occurring acute adverse health effects resulting from transient peak exposures during a workshift. Since these adverse effects may occur at some multiple of the 8-hour TWA, even if they have not yet been documented, it is prudent to limit peak exposures. Therefore, the following default short-term exposure limits apply to those TLV–TWAs that do not have a TLV–STEL:

Transient increases in workers’ exposure levels may exceed 3 times the value of the TLV–TWA level for no more than 15 minutes at a time, on no more than 4 occasions spaced 1 hour apart during a workday, and under no circumstances should they exceed 5 times the value of the TLV–TWA level when measured as a 15-min TWA. In addition, the 8-hour TWA is not to be exceeded for an 8-hour work period.

This guidance on limiting peak exposures above the value of the TLV–TWA is analogous to that for the TLV–STEL, and both represent 15-minute exposure limits. The consistency in approach is intended to encourage minimizing process variability and ensuring worker protection. Good design and industrial hygiene practice ensures that processes are controlled within acceptable ranges. Historically, guidance on peak exposures (formerly excursion limits) has been based purely on statistical considerations: if log-normally distributed, short-term exposure values for a well-controlled process have a geometric standard deviation of 2.0, then 5% of all values will exceed 3.13 times the geometric mean. Processes that display greater variability are not under good control, and efforts should be made to restore control. Higher exposure levels also increase the possibility that acute health effects may occur, which were probably not factored into the TLV–TWA if it was based on prevention of chronic effects. The maximum peak exposure factor of 5 also reflects this concern about undesirable health effects. Limiting peak exposures reduces the probability of exceeding the TLV–TWA. When initial samples indicate peak exposures beyond these recommendations, more careful assessment is needed, especially when dealing with unusual work schedules.

The so-called “3 by 5 Rule”, as described above, should be considered a rule of thumb, and a pragmatic precautionary approach. It is recognized that the geometric standard deviations of some common workplace exposures may exceed 2.0. If such distributions are known, and it can be shown that workers are not at increased risk of adverse health effects, recommended peak exposure guidelines may be modified based on workplace-specific and compound-specific health effects data. For example, consideration should be given to dose-rate effects and elimination half-times for the particular substance and for similar compounds. Special consideration should also be given to unusual work schedules and whether the peak exposure factors should be applied to the TLV–TWA (e.g., if concerns for acute health effects predominate) or the adjusted TWA (e.g., if the concern is with exceeding the adjusted TWA). The practicing hygienist must use judgment in applying this guidance on peak exposures. When a TLV–STEL or a TLV–C is available, this value takes precedence over the above guidance for peak exposures.

TWA and STEL versus Ceiling (C)

A substance may have certain toxicological properties that require the use of a TLV–C rather than a TLV–STEL or peak exposure guidance above a TLV–TWA. The amount by which the TLVs ® may be exceeded for short periods without injury to health depends upon a number of factors such as the nature of the contaminant, whether very high concentrations — even for short periods — produce acute poisoning, whether the effects are cumulative, the frequency with which high concentrations occur, and the duration of such periods. All factors must be taken into consideration in arriving at a decision as to whether a hazardous condition exists.

Although the TWA concentration provides the most satisfactory, practical way of monitoring airborne agents for compliance with the TLVs ® , there are certain substances for which it is inappropriate. In the latter group are substances that are predominantly fast-acting and whose TLV ® is more appropriately based on the concentration associated with this particular response. Substances with this type of response are best controlled by a TLV–C that should not be exceeded. It is implicit in these definitions that the manner of sampling to determine noncompliance with the TLVs® for each group must differ. Consequently, a single, brief sample that is applicable to a TLV–C is not appropriate to the TLV–TWA; here, a sufficient number of samples are needed to permit determination that the TLV-C is not exceeded at any time during a complete cycle of operation or throughout the workshift.

Whereas the TLV–C places a definite boundary that exposure concentrations should not be permitted to exceed, the TLV–TWA requires an explicit limit to the number and duration of peak exposures which are acceptable above the recommended TLV–TWAs.

Special consideration should also be given to the application of the TLVs ® in assessing the health hazards that may be associated with exposure to a mixture of two or more substances. A brief discussion of basic considerations involved in developing TLVs ® for mixtures and methods for their development, amplified by specific examples, is given in Appendix E.

Deviations in Work Conditions and Work Schedules

Application of TLVs ® to Unusual Ambient Conditions

When workers are exposed to air contaminants at temperatures and pressures substantially different than those at 25°C and 760 torr, care should be taken in comparing sampling results to the applicable TLVs ® . For aerosols, the TWA exposure concentration (calculated using sample volumes not adjusted to conditions at 25°C and 760 torr) should be compared directly to the applicable TLVs ® published in the TLVs ® and BEIs ® book . For gases and vapors, there are a number of options for comparing air-sampling results to the TLV ® , and these are discussed in detail by Stephenson and Lillquist (2001). One method that is simple in its conceptual approach is 1) to determine the exposure concentration, expressed in terms of mass per volume, at the sampling site using the sample volume not adjusted to conditions at 25°C and 760 torr, 2) if required, to convert the TLV ® to mg/m 3 (or other mass per volume measure) using a molar volume of 24.4 L/mole, and 3) to compare the exposure concentration to the TLV ® , both in units of mass per volume.

A number of assumptions are made when comparing sampling results obtained under unusual atmospheric conditions to the TLVs ® . One such assumption is that the volume of air inspired by the worker per workday is not appreciably different under moderate conditions of temperature and pressure as compared to those at 25°C and 760 torr (Stephenson and Lillquist, 2001). An additional assumption for gases and vapors is that absorbed dose is correlated to the partial pressure of the inhaled compound. Sampling results obtained under unusual conditions cannot easily be compared to the published TLVs ® , and extreme care should be exercised if workers are exposed to very high or low ambient pressures.

Unusual Work Schedules

Application of TLVs ® to work schedules markedly different from the conventional 8-hour day, 40-hour workweek requires particular judgment to provide protection for these workers equal to that provided to workers on conventional workshifts. Short workweeks can allow workers to have more than one job, perhaps with similar exposures, and may result in overexposure, even if neither job by itself entails overexposure.

Numerous mathematical models to adjust for unusual work schedules have been described. In terms of toxicologic principles, their general objective is to identify a dose that ensures that the daily peak body burden or weekly peak body burden does not exceed that which occurs during a normal 8-hour/day, 5-day/week shift. A comprehensive review of the approaches to adjusting occupational exposure limits for unusual work schedules is provided in Patty’s Industrial Hygiene (Paustenbach, 2000). Other selected readings on this topic include Lapare et al. (2003), Brodeur et al. (2001), Caldwell et al. (2001), Eide (2000), Verma (2000), Roach (1978), and Hickey and Reist (1977).

Another model that addresses unusual work schedules is the Brief and Scala model (1986), which is explained in detail in Patty’s Industrial Hygiene (Paustenbach, 2000). This model reduces the TLV ® proportionately for both increased exposure time and reduced recovery (i.e., non-exposure) time, and is generally intended to apply to work schedules longer than 8 hours/day or 40 hours/week. The model should not be used to justify very high exposures as “allowable” where the exposure periods are short (e.g., exposure to 8 times the TLV–TWA for 1 hour and zero exposure during the remainder of the shift). In this respect, the general limitations on peak exposures above the TLV–TWA and TLV–STELs should be applied to avoid inappropriate use of the model with very short exposure periods or shifts.

The Brief and Scala model is easier to use than some of the more complex models based on pharmacokinetic actions. The application of such models usually requires knowledge of the biological half-life of each substance, and some models require additional data. Another model developed by the University of Montreal and the Institute de Recherche en Sante et en Securite du Travail (IRSST) uses the Haber method to calculate adjusted exposure limits (Brodeur et al., 2001). This method generates values close to those obtained from physiologically based pharmacokinetic (PBPK) models.

Because adjusted TLVs ® do not have the benefit of historical use and long-time observation, medical supervision during initial use of adjusted TLVs ® is advised. Unnecessary exposure of workers should be avoided, even if a model shows such exposures to be “allowable.” Mathematical models should not be used to justify higher-than-necessary exposures.

TLV ® Units

TLVs ® are expressed in ppm, mg/m 3 or mg/100 cm 2 . An inhaled chemical substance may exist as a gas, vapor, or aerosol.

- A gas is a chemical substance whose molecules are moving freely within a space in which they are confined (e.g., cylinder/tank) at 25°C and 760 torr. Gases assume no shape or volume.

- A vapor is the gaseous phase of a chemical substance that exists as a liquid or a solid at 25°C and 760 torr. The amount of vapor given off by a chemical substance is expressed as the vapor pressure and is a function of temperature and pressure.

- An aerosol is a suspension of solid particles or liquid droplets in a gaseous medium. Other terms used to describe an aerosol include dust, mist, fume, fog, fiber, smoke, and smog. Aerosols may be characterized by their aerodynamic behavior and the site(s) of deposition in the human respiratory tract.

TLVs ® for aerosols are usually established in terms of mass of the chemical substance in air by volume. These TLVs ® are expressed in mg/m 3 .

TLVs ® for gases and vapors are established in terms of parts of vapor or gas per million parts of contaminated air by volume (ppm), but may also be expressed in mg/m 3 . For convenience to the user, these TLVs ® also reference molecular weights. Where 24.45 = molar volume of air in liters at 25°C and 760 torr, the conversion equations for gases and vapors [ppm:mg/m 3 ] are as follows:

When converting values for volatile forms of inorganic compounds (e.g., as Fe, as Ni), the molecular weight of the element should be used, not that of the entire compound.

In making conversions for substances with variable molecular weights, appropriate molecular weights should be estimated or assumed (see the TLV ® Documentation ).

User Information

Each TLV ® is supported by a comprehensive Documentation . It is imperative to consult the latest Documentation when applying the TLV ® .

Additional copies of the TLVs ® and BEIs ® book and the multi-volume Documentation of the Threshold Limit Values and Biological Exposure Indices , upon which this book is based, are available from ACGIH ® . Documentation of individual TLVs ® is also available. Consult the ACGIH ® website ( acgih.org/store ) for additional information and availability concerning these publications.

ACGIH ® disclaims liability with respect to the use of TLVs ® .

References and Selected Readings

- Brief RS; Scala RA: Occupational health aspects of unusual work schedules: a review of Exxon’s experiences. Am Ind Hyg Assoc J 47(4):199-202 (1986).

- Brodeur J; Vyskocil A; Tardif R; et al.: Adjustment of permissible exposure values to unusual work schedules. Am Ind Hyg Assoc J 62:584-594 (2001).

- Buringh E; Lanting R: Exposure variability in the workplace: its implications for the assessment of compliance. Am Ind Hyg Assoc J 52:6-13 (1991).

- Caldwell DJ; Armstrong TW; Barone NJ; et al.: Lessons learned while compiling a quantitative exposure database from the published literature. Appl Occup Environ Hyg 16(2):174-177 (2001).

- Eide I: The application of 8-hour occupational exposure limits to non-standard work schedules offshore. Ann Occup Hyg 34(1):13-17 (1990).

- Hickey JL; Reist PC: Application of occupational exposure limits to unusual work schedules. Am Ind Hyg Assoc J 38(11):613-621 (1977).

- Lapare S; Brodeur J; Tardif R: Contribution of toxicokinetic modeling to the adjustment of exposure limits to unusual work schedules. Am Ind Hyg Assoc J 64(1):17-23 (2003).

- Leidel NA; Busch KA; Crouse WE: Exposure measurement action level and occupational environmental variability. DHEW (NIOSH) Pub. No. 76-131; NTIS Pub. No. PB- 267-509. U.S. National Technical Information Service, Springfield, VA (December 1975).

- Paustenbach DJ: Pharmacokinetics and Unusual Work Schedules. In: Patty’s Industrial Hygiene, 5th ed., Vol. 3, Part VI, Law, Regulation, and Management, Chap. 40, pp. 1787-1901. RL Harris, Ed. John Wiley & Sons, Inc., New York (2000).

- Roach SA: Threshold limit values for extraordinary work schedules. Am Ind Hyg Assoc J 39(4):345-348 (1978).

- Stephenson DJ; Lillquist DR: The effects of temperature and pressure on airborne exposure concentrations when performing compliance evaluations using ACGIH TLVs and OSHA PELs. Appl Occup Environ Hyg 16(4):482-486 (2001).

- Verma DK: Adjustment of occupational exposure limits for unusual work schedules. Am Ind Hyg Assoc J 61(3):367-374 (2000).

Privacy Overview

The Law Dictionary

Your Free Online Legal Dictionary • Featuring Black’s Law Dictionary, 2nd Ed.

EXCURSION LIMIT Definition & Legal Meaning

Definition & citations:.

Specified, time-bound (typically 30 minutes), restricted exposure allowed to something unhealthy, even deadly. Meaningful especially in health and safety regulations.

This article contains general legal information but does not constitute professional legal advice for your particular situation. The Law Dictionary is not a law firm, and this page does not create an attorney-client or legal adviser relationship. If you have specific questions, please consult a qualified attorney licensed in your jurisdiction.

Browse Legal Articles

Business Formation

Business Law

Child Custody & Support

Criminal Law

Employment & Labor Law

Estate Planning

Immigration

Intellectual Property

Landlord-Tenant

Motor Vehicle Accidents

Personal Injury

Real Estate & Property Law

Traffic Violations

Browse by Area of Law

Powered by Black’s Law Dictionary, Free 2nd ed., and The Law Dictionary .

About The Law Dictionary

Terms and Conditions

Privacy Policy

- Skip to primary navigation

- Skip to main content

- Skip to primary sidebar

- Skip to footer

A Legal Dictionary

Black’s Law Online Dictionary

What is EXCURSION LIMIT

Specified, time-bound (typically 30 minutes), restricted exposure allowed to something unhealthy, even deadly. Meaningful especially in health and safety regulations.

What Are U.S. Standards and Regulations for Asbestos Levels?

- Learning Objectives

- Introduction

- Occupational Standards

- Environmental Standards

- Progress Check

Download Printer-Friendly Version [PDF – 843 KB]

Upon completion of this section, you will be able to

- Explain the Occupational Safety and Health Administration (OSHA) permissible exposure limit for asbestos and

- Explain the U.S. Environmental Protection Agency’s (EPA) maximum contaminant level for asbestos in drinking water.

The earliest evidence of asbestos-associated disease in workers was found in the 1930s by British studies [Lee and Selikoff 1979]. We now know that the toxic effects of asbestos depend on the nature and extent of exposure, particularly on the:

- Concentration of asbestos fibers involved in the exposure,

- Duration of exposure,

- Frequency of exposure,

- Type of asbestos fibers involved in the exposure, and

- Dimensions and durability of the asbestos fibers.

The Center for Disease Control and Prevention/National Institute for Occupational Safety and Health (NIOSH) and OSHA began establishing standards for asbestos in the 1970s. U.S. regulatory agencies such as EPA and OSHA recognize six asbestos and asbestiform minerals, i.e.,

- Actinolite asbestos,

- Amosite asbestos,

- Anthophyllite asbestos,

- Chrysotile asbestos,

- Crocidolite, and

- Tremolite asbestos

as legally regulated forms of asbestos out of the group of asbestiform minerals.

Asbestiform minerals are defined as crystal aggregates displaying these characteristics: groups of separable, long, thin, strong, and flexible fibers arranged in parallel [ATSDR 2001a].

Currently there is discussion underway to include asbestiform minerals that may have similar health effects to the previously mentioned forms of asbestos as regulated substances. However, nothing has been finalized at this time [OSHA 1992; NIOSH 2011a].

Currently, there are standards for asbestos in

- Drinking water,

- Some consumer products, and

- Workplace air.

In 1986, OSHA in Standard 29 CFR 1910.1001 established the current permissible exposure limit (PEL) for asbestos in the workplace: (0.1 fibers/cc of air as a time weighed average) [OSHA 2012]. PELs are allowable exposure levels in workplace air averaged over an 8-hour shift of a 40 hour workweek. There are also OSHA standards (29 CFR 1915.1001) for shipyards and construction (1926.1101).

Additionally, OSHA standards (1915.1001 and 1926.1101) requires employers of all workers whose work exposes them to asbestos above the PEL or excursion limit (1.0 f/cc over 30-minute period) to

- Provide training in the engineering controls, work practices, and proper use of personal protective equipment (PPE),

- Train workers in safety before beginning work and annually,

- Train workers regarding the health effects of asbestos exposure, and

- Inform workers of the relationship between smoking, asbestos exposure and increased risk of lung cancer.

In addition, OSHA requires employers of workers who are exposed to asbestos above the PEL and who are employed in certain asbestos industries to

- Provide and make sure of correct use of PPE (respirators, protective clothing like coveralls and goggles),

- To undergo medical surveillance in order to identify those with signs of asbestos-associated disease, remove them from further exposure,

- Comply with regulations requiring documentation for work-related injury claims, and

- Provide information to workers about where they can go for help to stop smoking.

Components of the required medical surveillance include

- Chest radiograph,

- Physical examination,

- Spirometric test, and

- Standard questionnaire.

Further information about OSHA requirements is available at http://www.osha.gov/SLTC/asbestos/standards.html .

For further information about protection guidelines, contact NIOSH via 1-800-CDC-INFO or via http://www.cdc.gov/niosh/contact/ .

ATSDR does not consider the use of OSHA’s PEL for workplace exposures to be appropriate for environmentally exposed populations since residential and/or environmental exposures are 24 hours a day year round, much longer than the typical 8-hour day and 40-hour workweek exposures of workers. Children and the elderly, who are not typically exposed in the workplace, may be more susceptible to exposure.

EPA has established a maximum contaminant level (MCL) for asbestos in drinking water of 7 MFL (million fibers per liter > 10 µm in length) in drinking water [EPA 2011]. Asbestos in drinking water comes from two main sources:

- Decay of water mains constructed of asbestos-containing cement, and

- Erosions of naturally occurring asbestos deposits into watersheds [EPA 2012a].

In addition, EPA has

- Banned spraying of asbestos in building interiors (for fireproofing and ceilings),

- Developed guidelines for proper treatment of in-place asbestos in old buildings,

- Recommended “no visible emissions” of asbestos,

- Regulated demolition of buildings with asbestos (NESHAP rules), and

- Regulated uses of asbestos in industrial products and construction.

More information on EPA rules and regulations regarding asbestos is available at http://www2.epa.gov/asbestos/asbestos-laws-and-regulations

The Asbestos Hazard Emergency Response Act of 1982 (CFR 40, Part 763, Subpart E) requires that local education agencies

- Inspect schools for asbestos-containing material using certified inspectors,

- Analyze these materials for asbestos content,

- Post results and notify parents and employees if asbestos is found,

- Test air levels following clean-up,

- Develop appropriate management plans,

- Communicate openly about any asbestos abatement needed, and

- Maintain appropriate records [EPA 2012c].

EPA also warned school authorities that power buffing and power stripping of asbestos-tile floors in schools produces significant airborne asbestos levels. Floor maintenance must be performed by hand to prevent release of asbestos fibers.

- OSHA’s PEL for asbestos in the workplace is 0.1 fibers/cc of air (8-hour TWA).

- OSHA requires all asbestos-exposed workers to be trained in PPE; they must undergo medical surveillance if exposed above the PEL.

- EPA’s MCL for asbestos in drinking water is 7 MFL greater than 10um in length (million fibers per liter) of drinking water.

- Local education agencies must inspect schools and analyze friable material for asbestos content, communicate results, and maintain records.

- Case Studies in Environmental Medicine

- Grand Rounds in Environmental Medicine

- Pediatric Environmental Health Training

- Patient Education

- Community Education

Exit Notification / Disclaimer Policy

- The Centers for Disease Control and Prevention (CDC) cannot attest to the accuracy of a non-federal website.

- Linking to a non-federal website does not constitute an endorsement by CDC or any of its employees of the sponsors or the information and products presented on the website.

- You will be subject to the destination website's privacy policy when you follow the link.

- CDC is not responsible for Section 508 compliance (accessibility) on other federal or private website.

The Federal Register

The daily journal of the united states government, request access.

Due to aggressive automated scraping of FederalRegister.gov and eCFR.gov, programmatic access to these sites is limited to access to our extensive developer APIs.

If you are human user receiving this message, we can add your IP address to a set of IPs that can access FederalRegister.gov & eCFR.gov; complete the CAPTCHA (bot test) below and click "Request Access". This process will be necessary for each IP address you wish to access the site from, requests are valid for approximately one quarter (three months) after which the process may need to be repeated.

An official website of the United States government.

If you want to request a wider IP range, first request access for your current IP, and then use the "Site Feedback" button found in the lower left-hand side to make the request.

- Chinese, Simplified

- Português, Brasil

Notice of Intent to Revise: <1079.2> Mean Kinetic Temperature in the Evaluation of Temperature Excursions During Storage and Transportation of Drug Products

Type of Posting: Notice of Intent to Revise Posting Date: 27-Jan-2023 Expert Committee: Packaging and Distribution Expert Committee

Mean Kinetic Temperature (MKT) cannot be used to normalize storage conditions situations that are out of control but can be a valuable tool to evaluate a temperature excursion. Thus, the use of MKT in evaluating a short-term excursion and the time frame used to calculate MKT as recommended by USP can allow for responsible management of excursion risk. Currently, <1079.2> Mean Kinetic Temperature in the Evaluation of Temperature Excursions During Storage and Transportation of Drug Products contains temperature excursion limits for climatic zone II.

The United States Pharmacopeia is pre-posting a revision to General Chapter <1079.2> where the inclusion of temperature excursion limits for climatic zone IVb is being proposed and a Stimuli Article: The Use of Mean Kinetic Temperature and the Need of Allowable Excursion Limits for Climatic Zone IVb which outlines the rationale for the revision, prior to its PF 49(2) [Mar.-Apr. 2023] publication.

This pre-posting is to allow stakeholders additional time for reading and understanding.

The chapter and Stimuli Article can be accessed here.

Questions may be directed to Desmond Hunt, Senior Principal Scientist, General Chapters ( [email protected] ).

CN-23-028-00

- Daily Crossword

- Word Puzzle

- Word Finder

- Word of the Day

- Synonym of the Day

- Word of the Year

- Language stories

- All featured

- Gender and sexuality

- All pop culture

- Grammar Coach ™

- Writing hub

- Grammar essentials

- Commonly confused

- All writing tips

- Pop culture

- Writing tips

a short trip or outing to some place, usually for a special purpose and with the intention of a prompt return: a pleasure excursion; a scientific excursion.

a trip on a train, ship, etc., at a reduced rate: weekend excursions to mountain resorts.

the group of persons making such a journey: an excursion of tourists.

a deviation or digression: excursions into futile philosophizing.

Physics . the displacement of a body or a point from a mean position or neutral value, as in an oscillation.

an accidental increase in the power level of a reactor, usually forcing its emergency shutdown.

Machinery .

the range of stroke of any moving part.

the stroke itself.

Obsolete . a sally or raid.

to go on or take an excursion.

of, relating to, or intended for use on excursions: an excursion fare; an excursion bus.

Origin of excursion

Other words from excursion.

- ex·cur·sion·al, ex·cur·sion·ar·y, adjective

- pre·ex·cur·sion, noun

Dictionary.com Unabridged Based on the Random House Unabridged Dictionary, © Random House, Inc. 2024

How to use excursion in a sentence

Should we cancel gatherings, reunions, excursions, or throw ourselves into them with even more gratitude for one another?

Lupher says vacationers are more worried about losing the $100 they paid for their excursions on Cozumel.

Aside from a vague tan after a handful of afternoon strolls, nothing came from those excursions.

These pages contain a record of the cost of our excursions abroad that is as illustrative as any culture can produce.

Hizbullah has in recent weeks increased its support of Assad and mounted more excursions across the border to fight Syrian rebels.

The night passed amid various excursions on the part of Aristide and alarms on the part of Jean.

The alarms and excursions of the past three weeks were naturally trying to a girl born and bred in a quiet Devon village.

I shall then give an account of my various excursions in an Appendix, and afterwards resume the thread of my journal.

If only they both come to realise it in their normal waking states his Double will cease these nocturnal excursions.

Owing to the extreme difficulty of getting about the city, we made but few short excursions from London such as I have described.

British Dictionary definitions for excursion

/ ( ɪkˈskɜːʃən , -ʒən ) /

a short outward and return journey, esp for relaxation, sightseeing, etc; outing

a group of people going on such a journey

(modifier) of or relating to special reduced rates offered on certain journeys by rail : an excursion ticket

a digression or deviation; diversion : an excursion into politics

(formerly) a raid or attack

a movement from an equilibrium position, as in an oscillation

the magnitude of this displacement

the normal movement of a movable bodily organ or part from its resting position, such as the lateral movement of the lower jaw

machinery the locus of a point on a moving part, esp the deflection of a whirling shaft

Collins English Dictionary - Complete & Unabridged 2012 Digital Edition © William Collins Sons & Co. Ltd. 1979, 1986 © HarperCollins Publishers 1998, 2000, 2003, 2005, 2006, 2007, 2009, 2012

An official website of the United States government.

Here’s how you know

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

Occupational Safety and Health Administration

- 中文(简体) (Chinese-Simplified)

- 繁體中文 (Chinese-Traditional)

- Kreyòl ayisyen (Haitian Creole)

- 한국어 (Korean)

- Español (Spanish)

- Filipino/Tagalog

- Tiếng Việt (Vietnamese)

- By Standard Number

- 1910.1001 App B - Detailed Procedures for Asbestos Sampling and Analysis - Non-mandatory

- Part Number: 1910

- Part Number Title: Occupational Safety and Health Standards

- Subpart: 1910 Subpart Z

- Subpart Title: Toxic and Hazardous Substances

- Standard Number: 1910.1001 App B

- Title: Detailed Procedures for Asbestos Sampling and Analysis - Non-mandatory

- GPO Source: e-CFR

Appendix B to § 1910.1001 - Detailed Procedures for Asbestos Sampling and Analysis - Non-mandatory

Analytical Procedure: A portion of the sample filter is cleared and prepared for asbestos fiber counting by Phase Contrast Microscopy (PCM) at 400X.

Commercial manufacturers and products mentioned in this method are for descriptive use only and do not constitute endorsements by USDOL-OSHA. Similar products from other sources can be substituted.

1. Introduction

This method describes the collection of airborne asbestos fibers using calibrated sampling pumps with mixed-cellulose ester (MCE) filters and analysis by phase contrast microscopy (PCM). Some terms used are unique to this method and are defined below:

Asbestos : A term for naturally occurring fibrous minerals. Asbestos includes chrysotile, crocidolite, amosite (cummingtonite-grunerite asbestos), tremolite asbestos, actinolite asbestos, anthophyllite asbestos, and any of these minerals that have been chemically treated and/or altered. The precise chemical formulation of each species will vary with the location from which it was mined. Nominal compositions are listed:

Asbestos Fiber : A fiber of asbestos which meets the criteria specified below for a fiber.

Aspect Ratio : The ratio of the length of a fiber to it's diameter (e.g. 3:1, 5:1 aspect ratios).

Cleavage Fragments : Mineral particles formed by comminution of minerals, especially those characterized by parallel sides and a moderate aspect ratio (usually less than 20:1).

Detection Limit : The number of fibers necessary to be 95% certain that the result is greater than zero.

Differential Counting : The term applied to the practice of excluding certain kinds of fibers from the fiber count because they do not appear to be asbestos.

Fiber : A particle that is 5 µm or longer, with a length-to-width ratio of 3 to 1 or longer.

Field : The area within the graticule circle that is superimposed on the microscope image.

Set : The samples which are taken, submitted to the laboratory, analyzed, and for which, interim or final result reports are generated.

Tremolite, Anthophyllite, and Actinolite : The non-asbestos form of these minerals which meet the definition of a fiber. It includes any of these minerals that have been chemically treated and/or altered.

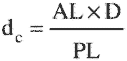

Walton-Beckett Graticule : An eyepiece graticule specifically designed for asbestos fiber counting. It consists of a circle with a projected diameter of 100 2 µm (area of about 0.00785 mm2) with a crosshair having tic-marks at 3-µm intervals in one direction and 5-µm in the orthogonal direction. There are marks around the periphery of the circle to demonstrate the proper sizes and shapes of fibers. This design is reproduced in Figure 1. The disk is placed in one of the microscope eyepieces so that the design is superimposed on the field of view.

1.1. HISTORY

Early surveys to determine asbestos exposures were conducted using impinger counts of total dust with the counts expressed as million particles per cubic foot. The British Asbestos Research Council recommended filter membrane counting in 1969. In July 1969, the Bureau of Occupational Safety and Health published a filter membrane method for counting asbestos fibers in the United States. This method was refined by NIOSH and published as P CAM 239. On May 29, 1971, OSHA specified filter membrane sampling with phase contrast counting for evaluation of asbestos exposures at work sites in the United States. The use of this technique was again required by OSHA in 1986. Phase contrast microscopy has continued to be the method of choice for the measurement of occupational exposure to asbestos.

1.2. PRINCIPLE

Air is drawn through a MCE filter to capture airborne asbestos fibers. A wedge shaped portion of the filter is removed, placed on a glass microscope slide and made transparent. A measured area (field) is viewed by PCM. All the fibers meeting defined criteria for asbestos are counted and considered a measure of the airborne asbestos concentration.

1.3. ADVANTAGES AND DISADVANTAGES

There are four main advantages of PCM over other methods:

(1) The technique is specific for fibers. Phase contrast is a fiber counting technique which excludes non-fibrous particles from the analysis.

(2) The technique is inexpensive and does not require specialized knowledge to carry out the analysis for total fiber counts.

(3) The analysis is quick and can be performed on-site for rapid determination of air concentrations of asbestos fibers.

(4) The technique has continuity with historical epidemiological studies so that estimates of expected disease can be inferred from long-term determinations of asbestos exposures.

The main disadvantage of PCM is that it does not positively identify asbestos fibers. Other fibers which are not asbestos may be included in the count unless differential counting is performed. This requires a great deal of experience to adequately differentiate asbestos from non-asbestos fibers. Positive identification of asbestos must be performed by polarized light or electron microscopy techniques. A further disadvantage of PCM is that the smallest visible fibers are about 0.2 µm in diameter while the finest asbestos fibers may be as small as 0.02 µm in diameter. For some exposures, substantially more fibers may be present than are actually counted.

1.4. WORKPLACE EXPOSURE

Asbestos is used by the construction industry in such products as shingles, floor tiles, asbestos cement, roofing felts, insulation and acoustical products. Non-construction uses include brakes, clutch facings, paper, paints, plastics, and fabrics. One of the most significant exposures in the workplace is the removal and encapsulation of asbestos in schools, public buildings, and homes. Many workers have the potential to be exposed to asbestos during these operations.

About 95% of the asbestos in commercial use in the United States is chrysotile. Crocidolite and amosite make up most of the remainder. Anthophyllite and tremolite or actinolite are likely to be encountered as contaminants in various industrial products.

1.5. PHYSICAL PROPERTIES

Asbestos fiber possesses a high tensile strength along its axis, is chemically inert, non-combustible, and heat resistant. It has a high electrical resistance and good sound absorbing properties. It can be weaved into cables, fabrics or other textiles, and also matted into asbestos papers, felts, or mats.

2. Range and Detection Limit

2.1. The ideal counting range on the filter is 100 to 1,300 fibers/mm 2 . With a Walton-Beckett graticule this range is equivalent to 0.8 to 10 fibers/field. Using NIOSH counting statistics, a count of 0.8 fibers/field would give an approximate coefficient of variation (CV) of 0.13.

2.2. The detection limit for this method is 4.0 fibers per 100 fields or 5.5 fibers/mm 2 . This was determined using an equation to estimate the maximum CV possible at a specific concentration (95% confidence) and a Lower Control Limit of zero. The CV value was then used to determine a corresponding concentration from historical CV vs fiber relationships. As an example:

Lower Control Limit (95% Confidence) = AC − 1.645(CV)(AC)

Where: AC = Estimate of the airborne fiber concentration (fibers/cc) Setting the Lower Control Limit = 0 and solving for CV: 0 = AC − 1.645(CV)(AC) CV = 0.61

This value was compared with CV vs. count curves. The count at which CV = 0.61 for Leidel-Busch counting statistics or for an OSHA Salt Lake Technical Center (OSHA-SLTC) CV curve (see appendix A for further information) was 4.4 fibers or 3.9 fibers per 100 fields, respectively. Although a lower detection limit of 4 fibers per 100 fields is supported by the OSHA-SLTC data, both data sets support the 4.5 fibers per 100 fields value.

3. Method Performance - Precision and Accuracy

Precision is dependent upon the total number of fibers counted and the uniformity of the fiber distribution on the filter. A general rule is to count at least 20 and not more than 100 fields. The count is discontinued when 100 fibers are counted, provided that 20 fields have already been counted. Counting more than 100 fibers results in only a small gain in precision. As the total count drops below 10 fibers, an accelerated loss of precision is noted.

At this time, there is no known method to determine the absolute accuracy of the asbestos analysis. Results of samples prepared through the Proficiency Analytical Testing (PAT) Program and analyzed by the OSHA-SLTC showed no significant bias when compared to PAT reference values. The PAT samples were analyzed from 1987 to 1989 (N = 36) and the concentration range was from 120 to 1,300 fibers/mm 2 .

4. Interferences

Fibrous substances, if present, may interfere with asbestos analysis.

Some common fibers are: fiberglass anhydrite plant fibers perlite veins gypsum some synthetic fibers membrane structures sponge spicules diatoms microorganisms wollastonite

The use of electron microscopy or optical tests such as polarized light, and dispersion staining may be used to differentiate these materials from asbestos when necessary.

5. Sampling

5.1. EQUIPMENT

5.1.1. Sample assembly (The assembly is shown in Figure 3). Conductive filter holder consisting of a 25-mm diameter, 3-piece cassette having a 50-mm long electrically conductive extension cowl. Backup pad, 25-mm, cellulose. Membrane filter, mixed-cellulose ester (MCE), 25-mm, plain, white, 0.4 to 1.2-µm pore size.

Notes: (a) Do not re-use cassettes. (b) Fully conductive cassettes are required to reduce fiber loss to the sides of the cassette due to electrostatic attraction. (c) Purchase filters which have been selected by the manufacturer for asbestos counting or analyze representative filters for fiber background before use. Discard the filter lot if more than 4 fibers/100 fields are found. (d) To decrease the possibility of contamination, the sampling system (filter-backup pad-cassette) for asbestos is usually preassembled by the manufacturer. (e) Other cassettes, such as the Bell-mouth, may be used within the limits of their validation.

5.1.2. Gel bands for sealing cassettes.

5.1.3. Sampling pump.

Each pump must be a battery operated, self-contained unit small enough to be placed on the monitored employee and not interfere with the work being performed. The pump must be capable of sampling at the collection rate for the required sampling time.

5.1.4. Flexible tubing, 6-mm bore.

5.1.5. Pump calibration.

Stopwatch and bubble tube/burette or electronic meter.

5.2. Sampling Procedure

5.2.1. Seal the point where the base and cowl of each cassette meet with a gel band or tape.

5.2.2. Charge the pumps completely before beginning.

5.2.3. Connect each pump to a calibration cassette with an appropriate length of 6-mm bore plastic tubing. Do not use luer connectors -- the type of cassette specified above has built-in adapters.

5.2.4. Select an appropriate flow rate for the situation being monitored. The sampling flow rate must be between 0.5 and 5.0 L/min for personal sampling and is commonly set between 1 and 2 L/min. Always choose a flow rate that will not produce overloaded filters.

5.2.5. Calibrate each sampling pump before and after sampling with a calibration cassette in-line (Note: This calibration cassette should be from the same lot of cassettes used for sampling). Use a primary standard (e.g. bubble burette) to calibrate each pump. If possible, calibrate at the sampling site.

Note: If sampling site calibration is not possible, environmental influences may affect the flow rate. The extent is dependent on the type of pump used. Consult with the pump manufacturer to determine dependence on environmental influences. If the pump is affected by temperature and pressure changes, correct the flow rate using the formula shown in the section “Sampling Pump Flow Rate Corrections” at the end of this appendix.

5.2.6. Connect each pump to the base of each sampling cassette with flexible tubing. Remove the end cap of each cassette and take each air sample open face. Assure that each sample cassette is held open side down in the employee's breathing zone during sampling. The distance from the nose/mouth of the employee to the cassette should be about 10 cm. Secure the cassette on the collar or lapel of the employee using spring clips or other similar devices.

5.2.7. A suggested minimum air volume when sampling to determine TWA compliance is 25 L. For Excursion Limit (30 min sampling time) evaluations, a minimum air volume of 48 L is recommended.

5.2.8. The most significant problem when sampling for asbestos is overloading the filter with non-asbestos dust. Suggested maximum air sample volumes for specific environments are:

Caution: Do not overload the filter with dust. High levels of non-fibrous dust particles may obscure fibers on the filter and lower the count or make counting impossible. If more than about 25 to 30% of the field area is obscured with dust, the result may be biased low. Smaller air volumes may be necessary when there is excessive non-asbestos dust in the air.

While sampling, observe the filter with a small flashlight. If there is a visible layer of dust on the filter, stop sampling, remove and seal the cassette, and replace with a new sampling assembly. The total dust loading should not exceed 1 mg.

5.2.9. Blank samples are used to determine if any contamination has occurred during sample handling. Prepare two blanks for the first 1 to 20 samples. For sets containing greater than 20 samples, prepare blanks as 10% of the samples. Handle blank samples in the same manner as air samples with one exception: Do not draw any air through the blank samples. Open the blank cassette in the place where the sample cassettes are mounted on the employee. Hold it open for about 30 seconds. Close and seal the cassette appropriately. Store blanks for shipment with the sample cassettes.

5.2.10. Immediately after sampling, close and seal each cassette with the base and plastic plugs. Do not touch or puncture the filter membrane as this will invalidate the analysis.

5.2.11. Attach and secure a sample seal around each sample cassette in such a way as to assure that the end cap and base plugs cannot be removed without destroying the seal. Tape the ends of the seal together since the seal is not long enough to be wrapped end-to-end. Also wrap tape around the cassette at each joint to keep the seal secure.

5.3. SAMPLE SHIPMENT

5.3.1. Send the samples to the laboratory with paperwork requesting asbestos analysis. List any known fibrous interferences present during sampling on the paperwork. Also, note the workplace operation(s) sampled.

5.3.2. Secure and handle the samples in such that they will not rattle during shipment nor be exposed to static electricity. Do not ship samples in expanded polystyrene peanuts, vermiculite, paper shreds, or excelsior. Tape sample cassettes to sheet bubbles and place in a container that will cushion the samples in such a manner that they will not rattle.

5.3.3. To avoid the possibility of sample contamination, always ship bulk samples in separate mailing containers.

6. Analysis

6.1. SAFETY PRECAUTIONS

6.1.1. Acetone is extremely flammable and precautions must be taken not to ignite it. Avoid using large containers or quantities of acetone. Transfer the solvent in a ventilated laboratory hood. Do not use acetone near any open flame. For generation of acetone vapor, use a spark free heat source.

6.1.2. Any asbestos spills should be cleaned up immediately to prevent dispersal of fibers. Prudence should be exercised to avoid contamination of laboratory facilities or exposure of personnel to asbestos. Asbestos spills should be cleaned up with wet methods and/or a High Efficiency Particulate-Air (HEPA) filtered vacuum.

Caution: Do not use a vacuum without a HEPA filter - It will disperse fine asbestos fibers in the air.

6.2. EQUIPMENT

6.2.1 . Phase contrast microscope with binocular or trinocular head.

6.2.2 . Widefield or Huygenian 10X eyepieces (Note: The eyepiece containing the graticule must be a focusing eyepiece. Use a 40X phase objective with a numerical aperture of 0.65 to 0.75).

6.2.3 . Kohler illumination (if possible) with green or blue filter.

6.2.4 . Walton-Beckett Graticule, type G-22 with 100 ± 2µm projected diameter.

6.2.5 . Mechanical stage.

A rotating mechanical stage is convenient for use with polarized light.

6.2.6 . Phase telescope.

6.2.7 . Stage micrometer with 0.01-mm subdivisions.

6.2.8 . Phase-shift test slide, mark II (Available from PTR optics Ltd., and also McCrone).

6.2.9 . Precleaned glass slides, 25 mm X 75 mm. One end can be frosted for convenience in writing sample numbers, etc., or paste-on labels can be used.

6.2.10 . Cover glass #1½.

6.2.11 . Scalpel (#10, curved blade).

6.2.12 . Fine tipped forceps.

6.2.13 . Aluminum block for clearing filter (see appendix D and Figure 4).

6.2.14 . Automatic adjustable pipette, 100- to 500-µL.

6.2.15 . Micropipette, 5 µL.

6.3. REAGENTS

6.3.1 . Acetone (HPLC grade).

6.3.2 . Triacetin (glycerol triacetate).

6.3.3 . Lacquer or nail polish.

6.4. STANDARD PREPARATION

A way to prepare standard asbestos samples of known concentration has not been developed. It is possible to prepare replicate samples of nearly equal concentration. This has been performed through the PAT program. These asbestos samples are distributed by the AIHA to participating laboratories.

Since only about one-fourth of a 25-mm sample membrane is required for an asbestos count, any PAT sample can serve as a “standard” for replicate counting.

6.5. SAMPLE MOUNTING

Note: See Safety Precautions in Section 6.1. before proceeding. The objective is to produce samples with a smooth (non-grainy) background in a medium with a refractive index of approximately 1.46. The technique below collapses the filter for easier focusing and produces permanent mounts which are useful for quality control and interlaboratory comparison.

An aluminum block or similar device is required for sample preparation.

6.5.1 . Heat the aluminum block to about 70 °C. The hot block should not be used on any surface that can be damaged by either the heat or from exposure to acetone.

6.5.2 . Ensure that the glass slides and cover glasses are free of dust and fibers.

6.5.3 . Remove the top plug to prevent a vacuum when the cassette is opened. Clean the outside of the cassette if necessary. Cut the seal and/or tape on the cassette with a razor blade. Very carefully separate the base from the extension cowl, leaving the filter and backup pad in the base.

6.5.4 . With a rocking motion cut a triangular wedge from the filter using the scalpel. This wedge should be one-sixth to one-fourth of the filter. Grasp the filter wedge with the forceps on the perimeter of the filter which was clamped between the cassette pieces. DO NOT TOUCH the filter with your finger. Place the filter on the glass slide sample side up. Static electricity will usually keep the filter on the slide until it is cleared.

6.5.5 . Place the tip of the micropipette containing about 200 µL acetone into the aluminum block. Insert the glass slide into the receiving slot in the aluminum block. Inject the acetone into the block with slow, steady pressure on the plunger while holding the pipette firmly in place. Wait 3 to 5 seconds for the filter to clear, then remove the pipette and slide from the aluminum block.

6.5.6 . Immediately (less than 30 seconds) place 2.5 to 3.5 µL of triacetin on the filter (Note: Waiting longer than 30 seconds will result in increased index of refraction and decreased contrast between the fibers and the preparation. This may also lead to separation of the cover slip from the slide).

6.5.7 . Lower a cover slip gently onto the filter at a slight angle to reduce the possibility of forming air bubbles. If more than 30 seconds have elapsed between acetone exposure and triacetin application, glue the edges of the cover slip to the slide with lacquer or nail polish.

6.5.8 . If clearing is slow, warm the slide for 15 min on a hot plate having a surface temperature of about 50 °C to hasten clearing. The top of the hot block can be used if the slide is not heated too long.

6.5.9 . Counting may proceed immediately after clearing and mounting are completed.

6.6. SAMPLE ANALYSIS

Completely align the microscope according to the manufacturer's instructions. Then, align the microscope using the following general alignment routine at the beginning of every counting session and more often if necessary.

6.6.1 . Alignment

(1) Clean all optical surfaces. Even a small amount of dirt can significantly degrade the image.

(2) Rough focus the objective on a sample.

(3) Close down the field iris so that it is visible in the field of view. Focus the image of the iris with the condenser focus. Center the image of the iris in the field of view.

(4) Install the phase telescope and focus on the phase rings. Critically center the rings. Misalignment of the rings results in astigmatism which will degrade the image.

(5) Place the phase-shift test slide on the microscope stage and focus on the lines. The analyst must see line set 3 and should see at least parts of 4 and 5 but, not see line set 6 or 6. A microscope/microscopist combination which does not pass this test may not be used.

6.6.2 . Counting Fibers

(1) Place the prepared sample slide on the mechanical stage of the microscope. Position the center of the wedge under the objective lens and focus upon the sample.

(2) Start counting from one end of the wedge and progress along a radial line to the other end (count in either direction from perimeter to wedge tip). Select fields randomly, without looking into the eyepieces, by slightly advancing the slide in one direction with the mechanical stage control.

(3) Continually scan over a range of focal planes (generally the upper 10 to 15µm of the filter surface) with the fine focus control during each field count. Spend at least 5 to 15 seconds per field.

(4) Most samples will contain asbestos fibers with fiber diameters less than 1µm. Look carefully for faint fiber images. The small diameter fibers will be very hard to see. However, they are an important contribution to the total count.

(5) Count only fibers equal to or longer than 5µm. Measure the length of curved fibers along the curve.

(6) Count fibers which have a length to width ratio of 3:1 or greater.

(7) Count all the fibers in at least 20 fields. Continue counting until either 100 fibers are counted or 100 fields have been viewed; whichever occurs first. Count all the fibers in the final field.

(8) Fibers lying entirely within the boundary of the Walton-Beckett graticule field shall receive a count of 1. Fibers crossing the boundary once, having one end within the circle shall receive a count of ½. Do not count any fiber that crosses the graticule boundary more than once. Reject and do not count any other fibers even though they may be visible outside the graticule area. If a fiber touches the circle, it is considered to cross the line.

(9) Count bundles of fibers as one fiber unless individual fibers can be clearly identified and each individual fiber is clearly not connected to another counted fiber. See Figure 1 for counting conventions.

(10) Record the number of fibers in each field in a consistent way such that filter non-uniformity can be assessed.

(11) Regularly check phase ring alignment.

(12) When an agglomerate (mass of material) covers more than 25% of the field of view, reject the field and select another. Do not include it in the number of fields counted.

(13) Perform a "blind recount" of 1 in every 10 filter wedges (slides). Re-label the slides using a person other than the original counter.

6.7. FIBER IDENTIFICATION

As previously mentioned in Section 1.3., PCM does not provide positive confirmation of asbestos fibers. Alternate differential counting techniques should be used if discrimination is desirable. Differential counting may include primary discrimination based on morphology, polarized light analysis of fibers, or modification of PCM data by Scanning Electron or Transmission Electron Microscopy.

A great deal of experience is required to routinely and correctly perform differential counting. It is discouraged unless it is legally necessary. Then, only if a fiber is obviously not asbestos should it be excluded from the count. Further discussion of this technique can be found in reference 8.10.

If there is a question whether a fiber is asbestos or not, follow the rule:

"WHEN IN DOUBT, COUNT."

6.8. ANALYTICAL RECOMMENDATIONS - QUALITY CONTROL SYSTEM

6.8.1 . All individuals performing asbestos analysis must have taken the NIOSH course for sampling and evaluating airborne asbestos or an equivalent course.

6.8.2 . Each laboratory engaged in asbestos counting shall set up a slide trading arrangement with at least two other laboratories in order to compare performance and eliminate inbreeding of error. The slide exchange occurs at least semiannually. The round robin results shall be posted where all analysts can view individual analyst's results.

6.8.3 . Each laboratory engaged in asbestos counting shall participate in the Proficiency Analytical Testing Program, the Asbestos Analyst Registry or equivalent.

6.8.4 . Each analyst shall select and count prepared slides from a "slide bank". These are quality assurance counts. The slide bank shall be prepared using uniformly distributed samples taken from the workload. Fiber densities should cover the entire range routinely analyzed by the laboratory. These slides are counted blind by all counters to establish an original standard deviation. This historical distribution is compared with the quality assurance counts. A counter must have 95% of all quality control samples counted within three standard deviations of the historical mean. This count is then integrated into a new historical mean and standard deviation for the slide.

The analyses done by the counters to establish the slide bank may be used for an interim quality control program if the data are treated in a proper statistical fashion.

7. Calculations

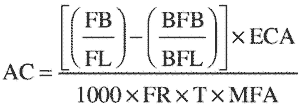

7.1. Calculate the estimated airborne asbestos fiber concentration on the filter sample using the following formula:

AC = Airborne fiber concentration

FB = Total number of fibers greater than 5µm counted

FL = Total number of fields counted on the filter

BFB = Total number of fibers greater than 5µm counted in the blank

BFL = Total number of fields counted on the blank

ECA = Effective collecting area of filter (385 mm 2 nominal for a 25-mm filter.)

FR = Pump flow rate (L/min)

MFA = Microscope count field area (mm 2 ). This is 0.00785 mm 2 for a Walton-Beckett Graticule.

T = Sample collection time (min)

1,000 = Conversion of L to cc

Note: The collection area of a filter is seldom equal to 385 mm 2 . It is appropriate for laboratories to routinely monitor the exact diameter using an inside micrometer. The collection area is calculated according to the formula:

Area = π(d/2) 2

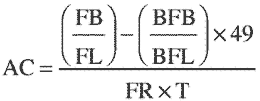

7.2. SHORT-CUT CALCULATION

Since a given analyst always has the same interpupillary distance, the number of fields per filter for a particular analyst will remain constant for a given size filter. The field size for that analyst is constant ( i.e . the analyst is using an assigned microscope and is not changing the reticle).

For example, if the exposed area of the filter is always 385 mm 2 and the size of the field is always 0.00785 mm 2 , the number of fields per filter will always be 49,000. In addition it is necessary to convert liters of air to cc. These three constants can then be combined such that ECA/(1,000 X MFA) = 49. The previous equation simplifies to:

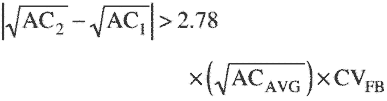

7.3. RECOUNT CALCULATIONS

As mentioned in step 13 of Section 6.6.2., a "blind recount" of 10% of the slides is performed. In all cases, differences will be observed between the first and second counts of the same filter wedge. Most of these differences will be due to chance alone, that is, due to the random variability (precision) of the count method. Statistical recount criteria enables one to decide whether observed differences can be explained due to chance alone or are probably due to systematic differences between analysts, microscopes, or other biasing factors.

The following recount criterion is for a pair of counts that estimate AC in fibers/cc. The criterion is given at the type-I error level. That is, there is 5% maximum risk that we will reject a pair of counts for the reason that one might be biased, when the large observed difference is really due to chance.

Reject a pair of counts if:

AC1 = lower estimated airborne fiber concentration

AC2 = higher estimated airborne fiber concentration

ACavg = average of the two concentration estimates

CV FB = CV for the average of the two concentration estimates

If a pair of counts are rejected by this criterion then, recount the rest of the filters in the submitted set. Apply the test and reject any other pairs failing the test. Rejection shall include a memo to the industrial hygienist stating that the sample failed a statistical test for homogeneity and the true air concentration may be significantly different than the reported value.

7.4. REPORTING RESULTS

Report results to the industrial hygienist as fibers/cc. Use two significant figures. If multiple analyses are performed on a sample, an average of the results is to be reported unless any of the results can be rejected for cause.

8. References

8.1. Dreesen, W.C., et al, U.S. Public Health Service: A Study of Asbestosis in the Asbestos Textile Industry , (Public Health Bulletin No. 241), US Treasury Dept., Washington, DC, 1938.

8.2. Asbestos Research Council : The Measurement of Airborne Asbestos Dust by the Membrane Filter Method (Technical Note), Asbestos Research Council, Rockdale, Lancashire, Great Britain, 1969.

8.3. Bayer, S.G., Zumwalde, R.D., Brown, T.A., Equipment and Procedure for Mounting Millipore Filters and Counting Asbestos Fibers by Phase Contrast Microscopy , Bureau of Occupational Health, U.S. Dept. of Health, Education and Welfare, Cincinnati, OH, 1969.

8.4. NIOSH Manual of Analytical Methods , 2nd ed., Vol. 1 (DHEW/NIOSH Pub. No. 77-157-A). National Institute for Occupational Safety and Health, Cincinnati, OH, 1977. pp. 239-1-239-21.

8.5. Asbestos , Code of Federal Regulations 29 CFR 1910.1001. 1971.

8.6. Occupational Exposure to Asbestos, Tremolite, Anthophyllite, and Actinolite. Final Rule , FEDERAL REGISTER 51:119 (20 June 1986). pp. 22612-22790.

8.7. Asbestos, Tremolite, Anthophyllite, and Actinolite , Code of Federal Regulations 1910.1001. 1988. pp 711-752.

8.8. Criteria for a Recommended Standard -- Occupational Exposure to Asbestos (DHEW/NIOSH Pub. No. HSM 72-10267), National Institute for Occupational Safety and Health NIOSH, Cincinnati,OH, 1972. pp. III-1-III-24.

8.9. Leidel, N.A., Bayer,S.G., Zumwalde, R.D.,Busch, K.A., USPHS/NIOSH Membrane Filter Method for Evaluating Airborne Asbestos Fibers (DHEW/NIOSH Pub. No. 79-127). National Institute for Occupational Safety and Health, Cincinnati, OH, 1979.

8.10. Dixon, W.C., Applications of Optical Microscopy in Analysis of Asbestos and Quartz , Analytical Techniques in Occupational Health Chemistry, edited by D.D. Dollberg and A.W. Verstuyft. Wash. DC: American Chemical Society, (ACS Symposium Series 120) 1980. pp. 13-41.

Quality Control

The OSHA asbestos regulations require each laboratory to establish a quality control program. The following is presented as an example of how the OSHA-SLTC constructed its internal CV curve as part of meeting this requirement. Data is from 395 samples collected during OSHA compliance inspections and analyzed from October 1980 through April 1986.

Each sample was counted by 2 to 5 different counters independently of one another. The standard deviation and the CV statistic was calculated for each sample. This data was then plotted on a graph of CV vs. fibers/mm 2 . A least squares regression was performed using the following equation:

CV = antilog1 10 [A(log10(x)) 2 + B(log 10 (x)) + C]

x = the number of fibers/mm 2

Application of least squares gave:

A = 0.182205 B = -0.973343 C = 0.327499

Using these values, the equation becomes:

CV = antilog(10)[0.182205(log(10)(x)) 2 -0.973343(log(10)(x))+0.327499]

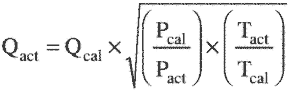

Sampling Pump Flow Rate Corrections

This correction is used if a difference greater than 5% in ambient temperature and/or pressure is noted between calibration and sampling sites and the pump does not compensate for the differences.

Q act = actual flow rate

Q cal = calibrated flow rate (if a rotameter was used, the rotameter value)

P cal = uncorrected air pressure at calibration

P act = uncorrected air pressure at sampling site

T act = temperature at sampling site (K)

T cal = temperature at calibration (K)

Walton-Beckett Graticule

When ordering the Graticule for asbestos counting, specify the exact disc diameter needed to fit the ocular of the microscope and the diameter (mm) of the circular counting area. Instructions for measuring the dimensions necessary are listed:

(1) Insert any available graticule into the focusing eyepiece and focus so that the graticule lines are sharp and clear.

(2) Align the microscope.

(3) Place a stage micrometer on the microscope object stage and focus the microscope on the graduated lines.

(4) Measure the magnified grid length, PL (µm), using the stage micrometer.

(5) Remove the graticule from the microscope and measure its actual grid length, AL (mm). This can be accomplished by using a mechanical stage fitted with verniers, or a jeweler's loupe with a direct reading scale.

(6) Let D = 100 µm. Calculate the circle diameter, d c (mm), for the Walton-Beckett graticule and specify the diameter when making a purchase:

Example: If PL = 108 µm, AL = 2.93 mm and D = 100 µm, then,

(7) Each eyepiece-objective-reticle combination on the microscope must be calibrated. Should any of the three be changed (by zoom adjustment, disassembly, replacement, etc.), the combination must be recalibrated. Calibration may change if interpupillary distance is changed. Measure the field diameter, D (acceptable range: 100 ± 2 µm) with a stage micrometer upon receipt of the graticule from the manufacturer. Determine the field area (mm 2 ).

Field Area = Δ(D/2) 2

If D = 100 µm = 0.1 mm, then

Field Area = Δ(0.1 mm/2) 2 = 0.00785 mm 2

The Graticule is available from: Graticules Ltd., Morley Road, Tonbridge TN9 IRN, Kent, England (Telephone 011-44-732-359061). Also available from PTR Optics Ltd., 145 Newton Street, Waltham, MA 02154 [telephone (617) 891-6000] or McCrone Accessories and Components, 2506 S. Michigan Ave., Chicago, IL 60616 [phone (312)-842-7100]. The graticule is custom made for each microscope.

[57 FR 24330, June 8, 1992; 59 FR 40964, Aug. 10, 1994; 60 FR 33972, June 29, 1995]

Dust Collectors for Every Situation

Search for your industry or application..

- Dust Collector Cartridge Filters

- Industrial Replacement Filters

- Endurex Filters

- PleatLock Filters

- Aftermarket Cartridge Filters

- Baghouse Filter Styles

- Paint & Spray Booth Filters

- Oil Mist Filters

- All Filters

PREVENTATIVE MAINTENANCE SERVICES

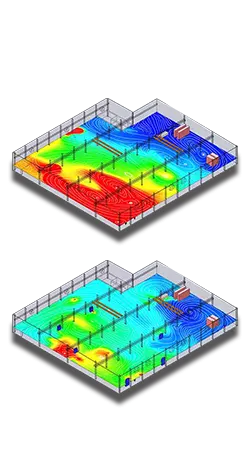

VENTMAPPING SERVICES

- Facility Testing & Engineering

- Project Management & Installation

- Preventive Maintenance & Repair

- Case Studies