- CruiseMapper

- Ships and Lines

Cruise Ship Engine Power, Propulsion, Fuel

These are some of the most interesting cruise ship technology-related data and facts - engines , power , marine propulsion systems , fuel consumption of cruise ships , and something about pollution (in-article navigation links).

In 2020, IMO (International Maritime Organization) implements its global 0,5% sulfur cap on marine fuels. If not using scrubbers (pollution control devices), owners of older vessels must use as ship fuels either MGO (marine gas oil), ECA Category Fuels (low sulfur MGO), new modified fuels and blends, LNG (liquefied natural gas) or electric/battery power . Each fuel option is based on vessel type and age, routes/itineraries and powerplant. Most newbuild passenger ships are LNG-powered . World's largest seaports plus numerous smaller ports already have installed shoreside power capabilities providing shore-to-ship power supply to berthed vessels. In many ports, shorepower is in addition to LNG bunkering capabilities.

Cruise Ship Engine

Without a source of power, these huge cruise vessels would be nothing more than drifting aimlessly hotels. A large number of older ships use diesel reciprocating engines for generating power for propulsion. Cruise ship engine power is supplied through the transmission to the propeller shafts. These transmissions determine the revolutions of propellers. Modern ships use either diesel-electric engines or gas turbines as a source of power for propulsion, and for ship's systems. Some of the larger ships depend on two power sources - one for electrical power and one for propulsion.

Gas turbine engines (being aero-derivative) generate heat which is transformed from mechanical energy into electricity. To achieve this, compressed air is fired in a combustion chamber. Hot exhaust is made over a turbine that spins to drive mechanically a shaft. The power can be used to spin the generators. The same way works diesel-electric engines, yet they use a direct drive system, not a turbine. The output shafts, to produce electrical power, are connected to generators.

Both engine types need a lot of fuel. Cunard QE2 , for example, consumes daily 380 tons of fuel when traveling at 29 knots speed and carries fuel enough to sail for 12 days. Usually, ships fill up at various seaports and use fueling barges as floating gas stations. Vessels use lower-grade diesel which tends not to burn as purely as diesel-powered road-going vehicles.

All ships rely on propellers/screws to be pushed through the water, providing forward and reverse motion. Airplanes, for example, require tremendous propeller speeds to provide the forward motion, but ship propellers don't need to turn so fast and rely on torque power. Therefore, ships travel slowly and rarely top 30 knots (for more info follow our speed-link above).

Cruise ship engine room

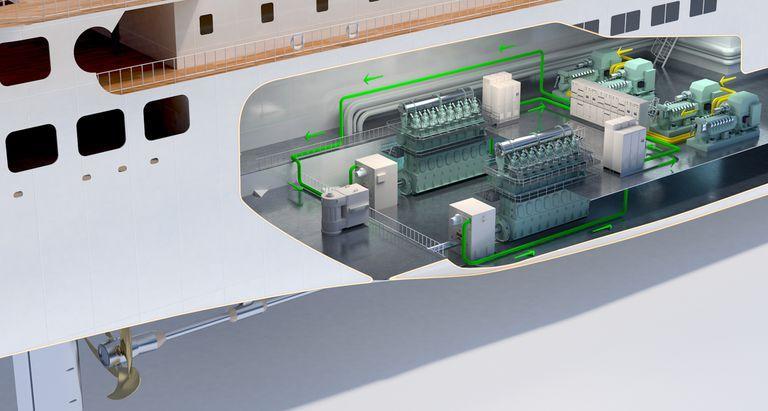

The basic detail about the cruise ship engine room is its location. For stability, the ship's heaviest weights are at its lowest possible deck, and usually, engines are mounted above the keel. Ship's lowest decks are almost entirely full of machinery. An area creating enough power for driving such an enormous vessel through water needs to be really big - very often engine rooms occupy at least three decks. Rather than long halls stretching the length of hulls, machinery is almost always divided into smaller compartments - one for the main engines, another for the heating/air-conditioning system. This compartmentalization is for safety reasons. If a penetration to the hull or fire happens, multiple compartments help contain the damage. The next photo shows the engine room of RCI's Oasis-Class vessels.

Rarely, engines are not placed at the ship's bottom. RMS Queen Mary 2's four main diesel engines are above the keel, with two smaller gas turbines on top-deck (aft of the funnel). It was not unusual for older liners to have 2 engine rooms. Gradually, technology allowed the consolidation of these spaces. However, current maritime legislation requires vessels to have equipment duplication and 2 engine rooms.

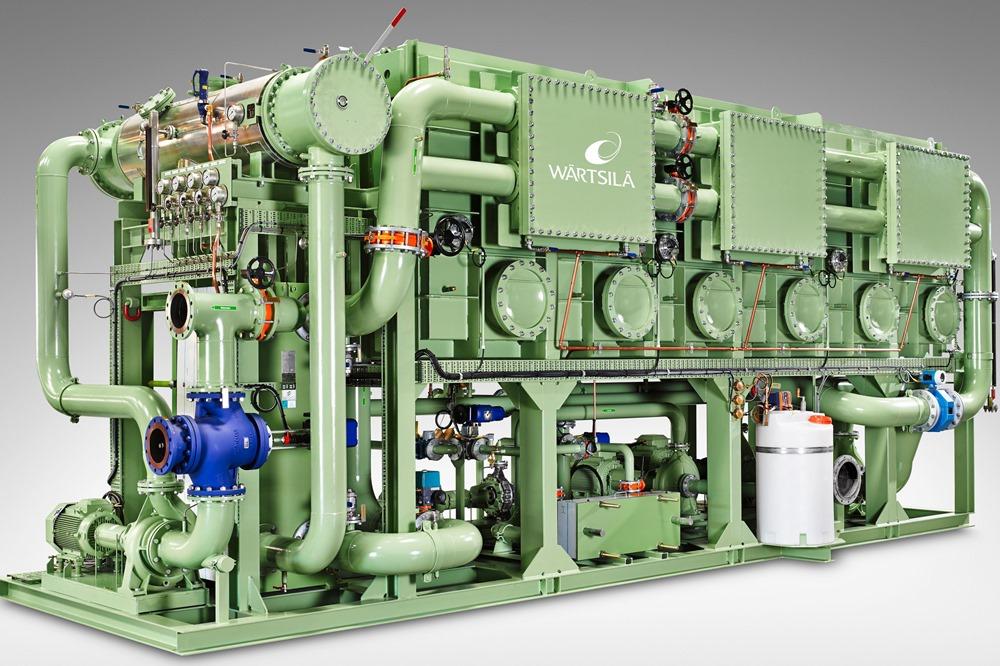

In May 2015, Wartsila Corporation and Carnival Corporation partnered to optimize cruise ship engine room operations of all 101 ships across the corporation's 9 brands. The deal was signed by Micky Arison (Carnival's Chairman) and Bjorn Rosengren (Wartsila's President and CEO). The plan included installing Wartsila's latest marine solutions, first tested on several Carnival Cruise Line vessels in pilot projects. The new systems and technologies included engine control and monitoring systems, safety and fuel efficiency equipment.

Wartsila's "Asset Performance Optimization Solution" package allows obtaining optimal performance from Wartsila marine diesel engines, recommends how to deal with potential issues, maximizes ship performance, ensures full-capacity systems operations, increases the predictability of fuel management and maintenance needs. Wartsila's fuel engine package was specifically designed to reduce fuel consumption.

Wartsila Marine technologies aim to optimize ship performance, but also allow to locate deviations from normal parameters of equipment and engines. This allows emerging problems and engine fault sources to be fixed before they occur.

Conventional diesel cruise ship engine

Today's direct-drive diesels feature one main advantage - the option to use a shaft generator, which is a device using the circular motion of the propeller shaft in order to generate the electricity needed for hotel services, like cooking and lighting.

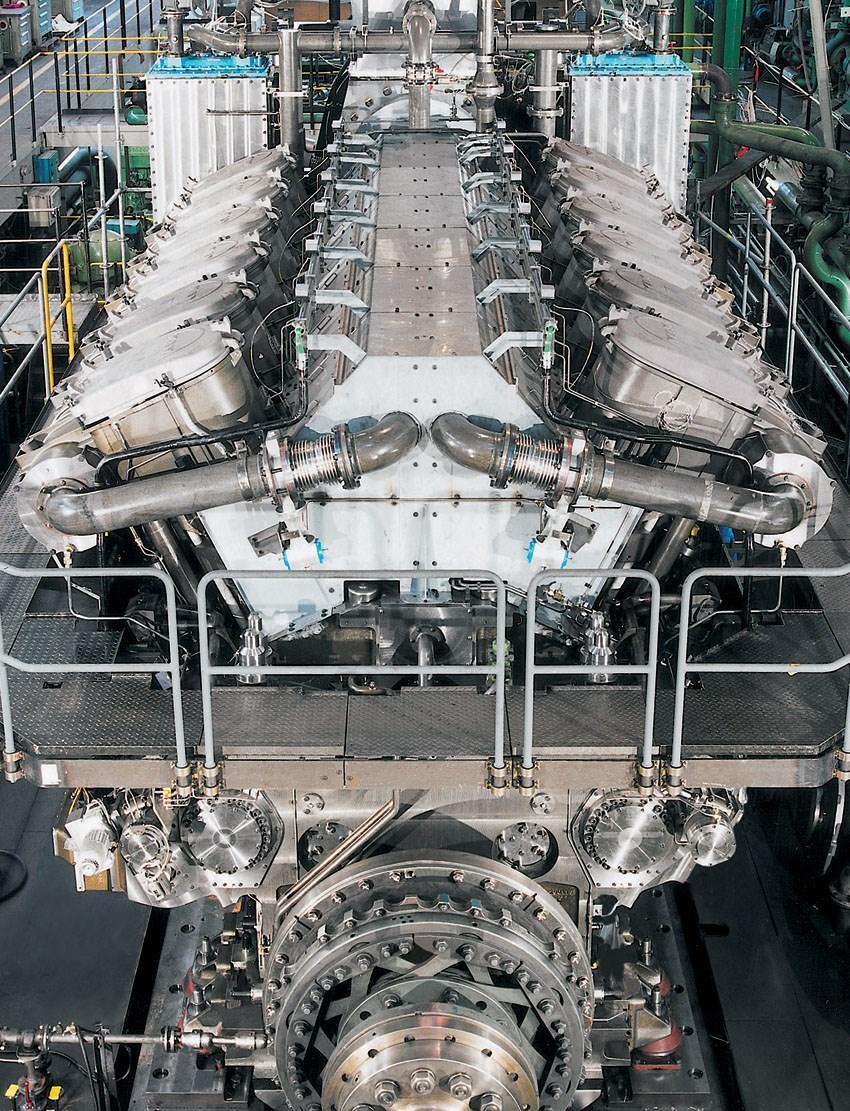

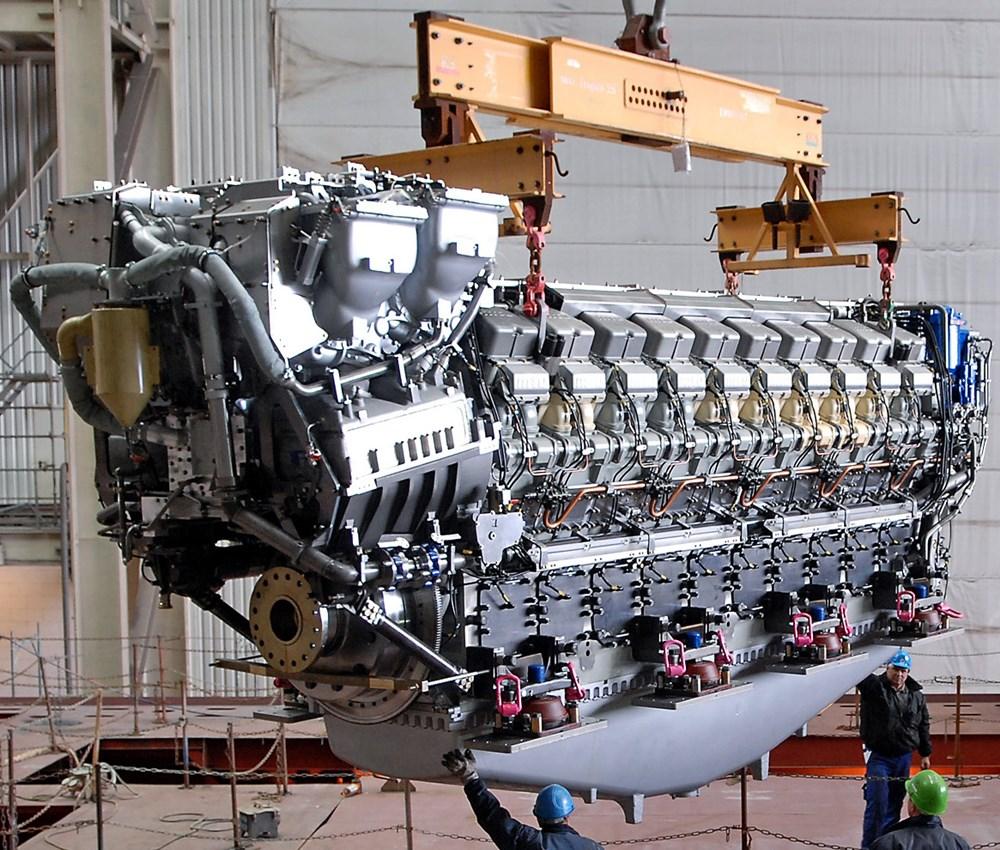

Shaft generators can be used only while the ship is moving with a fairly constant cruising speed. This is what the NCL Epic cruise ship engine looks like:

Diesel-electric cruise ship engine

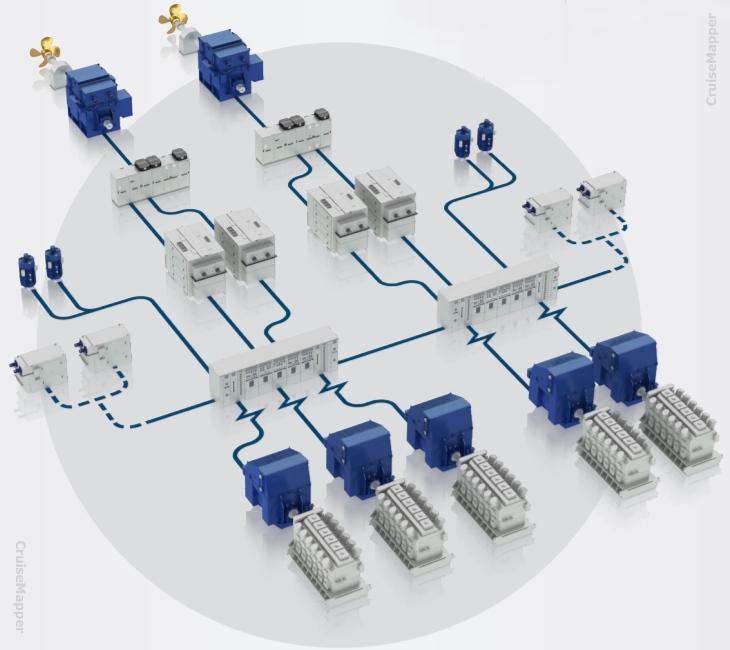

Almost all new ships feature a diesel-electric propulsion form. On these ships, main engines are not connected to propeller shafts, and instead of it they are directly connected to big generators in order to produce electricity, which is sent in turn to electric motors, that then power and help turn the propellers. The main advantage of the diesel-electric cruise ship engine systems is efficiency as they allow main engines to operate near the most efficient speed, no matter if the ship is moving at 5 or 25 knots.

Losing electrical power is devastating to ships. Main engines and generators require electricity and it's needed to keep them going. Pumps that are driven electrically take in cold ocean water to cool the engines and electrical pumps get fuel from fuel tanks and supply it to the engine. Electrical power is vital for many operational functions - without it, ships come to a halt.

Large equipment (propulsion motor, bow thrusters) requires electricity of high voltage. As for smaller machinery (cabin lights, galley equipment), the electricity goes through the transformer and is thus stepped down into lower voltage. Large cables snake through all the ships to distribute electrical power. They carry power from generators to switchboards, through passageways, public rooms, crew and passenger cabins. Cabling can be a weak point in the distribution system. If the electrical cables aren't truly redundant, even ships that feature two engine rooms suffer power failure.

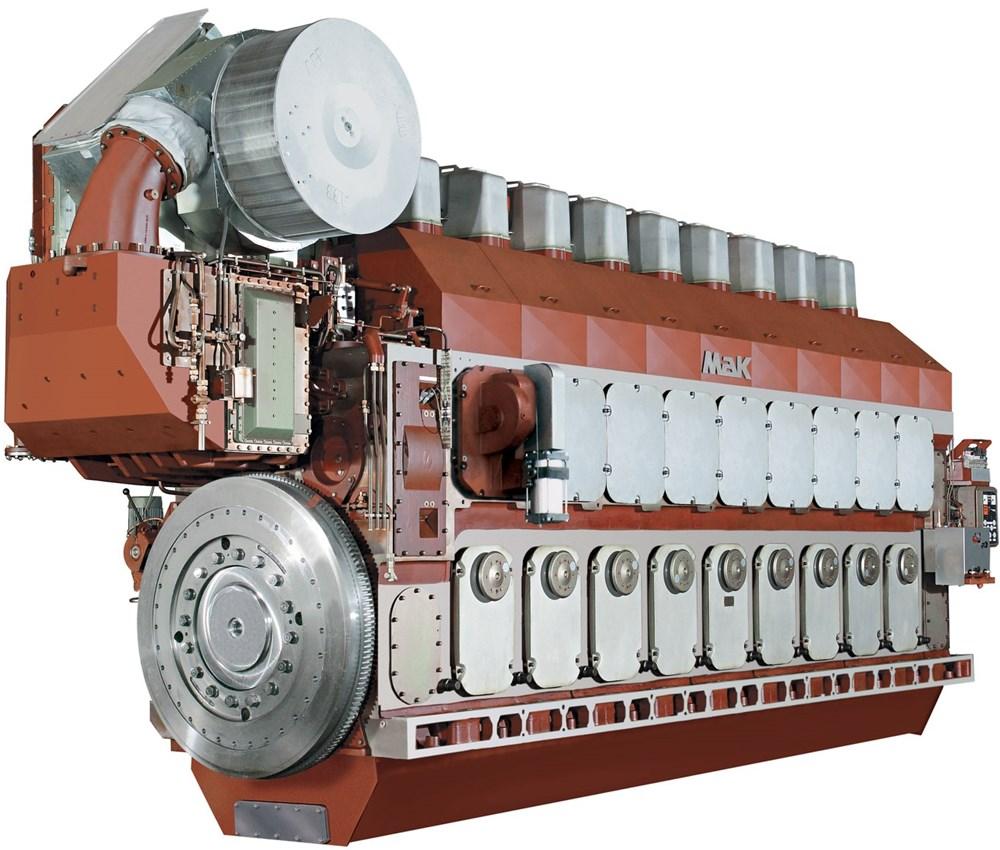

While ships are docked, generators and main engines produce more power than needed. They are turned off in port, and smaller generators supply "hotel" loads (lights, air-conditioning, galley, etc.). Moving through water takes up the vast majority of the ship's power needs - about 85% of all the diesel-electric powerplant production is consumed by the propulsion system. The above photo is of the Vista-class Carnival cruise ship engine room. The engine type is "MAN 2 times; 14V48/60CR" (common-rail diesel injection system):

Cruise ship Emergency Generators

All ships are supplied with emergency generators to maintain vital electrical power. Backup generators are located higher up and also outside engine room spaces to isolate them from damage or fire.

Big ships require much power, so they might have more than one emergency generator. Despite that, they don't have the capacity of main generators and engines, don't produce electricity enough to move the ship, and can't supply all the power needed in ports, because of constraints in space.

Emergency generators are instead used only for essential navigation systems - crucial communication equipment, critical pumps in the engine room, emergency lighting. Should they also fail, vessels are required to have a battery backup. 24 hours of power are at least provided by battery rooms to the smaller emergency equipment list.

Probably you've heard about Carnival cruise ship accidents related to power failures in 2013. At our Carnival Fun Ship 2.0 upgrades link you can learn how CCL battled with this "unmaintained ships" image and implemented revolutionary new technology initiatives fleetwide - including an additional emergency backup generator on each of their vessels.

Cruise Ship Propulsion

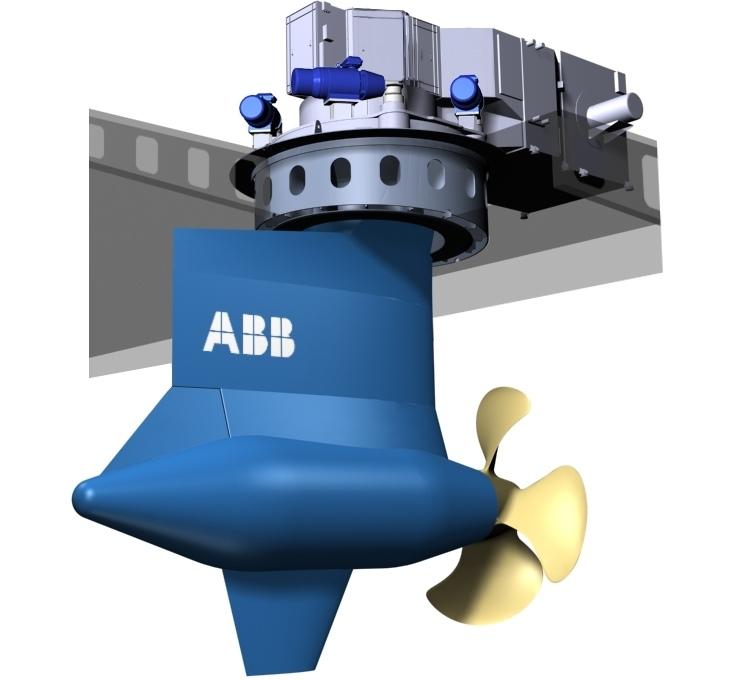

The new cruise ship propulsion systems ABB Azipods XO (below photo) are more fuel-efficient than traditional systems, also providing better maneuverability, maximizing speed, reducing bad emissions, which as a whole optimizes ship's performance and enhances passenger safety.

ABB Azipod propulsion systems have a major impact on the vessel's operating efficiency - reducing energy consumption and bad emissions by up to 20%.

In 2019, ABB signed a deal with Oldendorff Carriers (1921-founded, Germany's largest bulk shipping company with a fleet of ~700 ships) for the supply and installation of Azipod propulsion systems on two newbuild carriers. Both self-unloading dry bulk vessels were China-built (by Chengxi Shipyard Co Ltd / subsidiary of CSSC) and scheduled for deliveries in 2021. Each vessel was fitted with two Azipods (power output 1,9 MW per unit) plus various related electric and digital solutions (powerplant, diesel-electric generators, bow thruster motors, transformers, switchboards, power management system, ABB Ability global ABB real-time monitoring).

Azipod cruise ship propulsion system

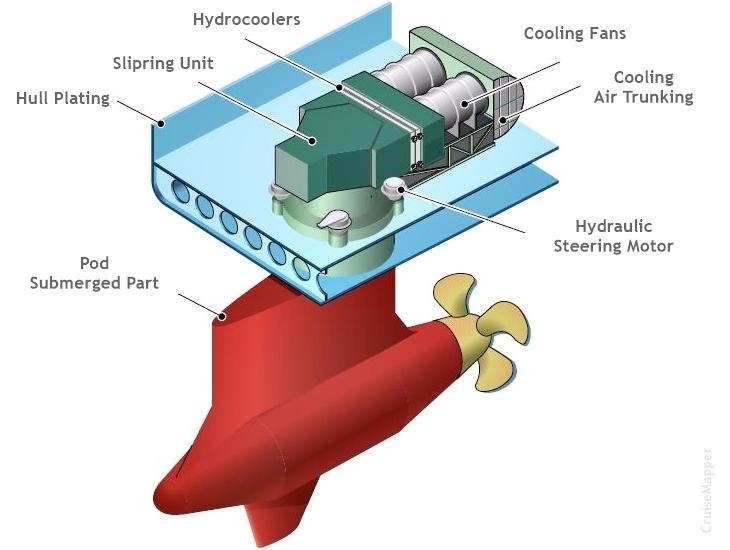

Azipod cruise ship propulsion system is situated outside the hull in the aft of the ship. Azipod turns in all directions (360 degrees) by a rudder, providing thrust in any directions, not possible for conventional systems.

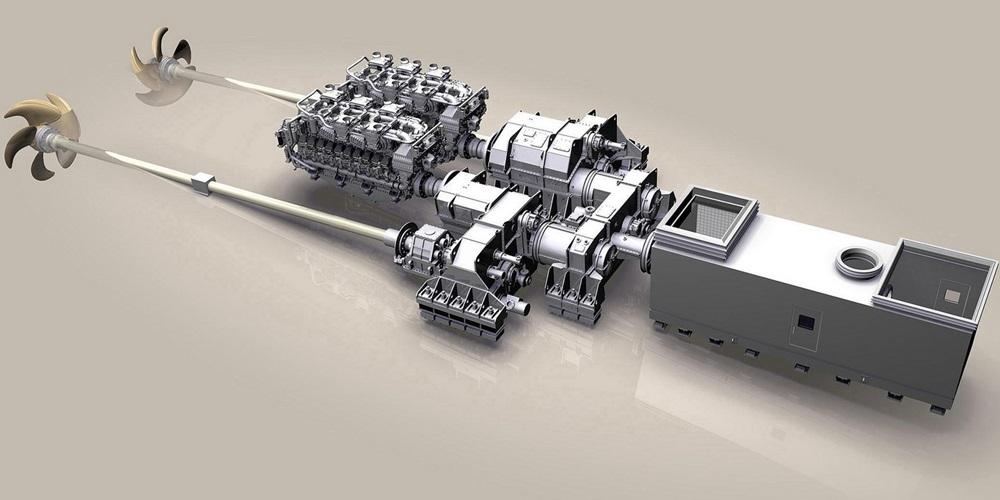

See at the first photo at right RMS Queen Mary 2 's propulsion system scheme.

QM2's Azipod is actually an electric propulsion system consisting of the following main components:

- Propulsion motor - used to produce or drive thrust. The propeller's rotating is powered by an electric motor.

- Supply transformer - power produced by generators is 6600 KV, which is stepped down to the necessary voltage by supply transformer and is provided to the motor in the pod.

- Frequency controller - used to change the frequency of supplied power so that the rotating motor speed can be controlled.

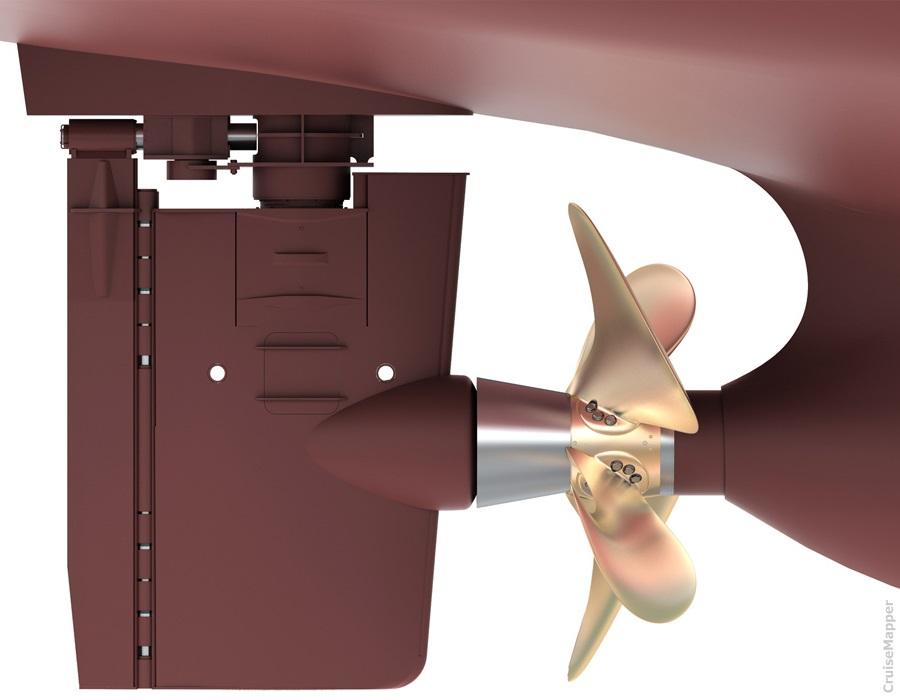

Azipod marine ship propulsion is a combination of both steering and propulsion systems. Conventional marine propulsion systems use a two-stroke engine connected to a shaft, that passes through a stern tube and shaft tunnel to connect to the propeller outside the hull in the ship's aft/stern. This system's steering is done by a rudder (in the propeller's aft).

The above photo shows Oasis-class ship propulsion Azipods (2 units) before being mounted onto the hull. The next photo shows the Azipods (both units) mounted on the hull.

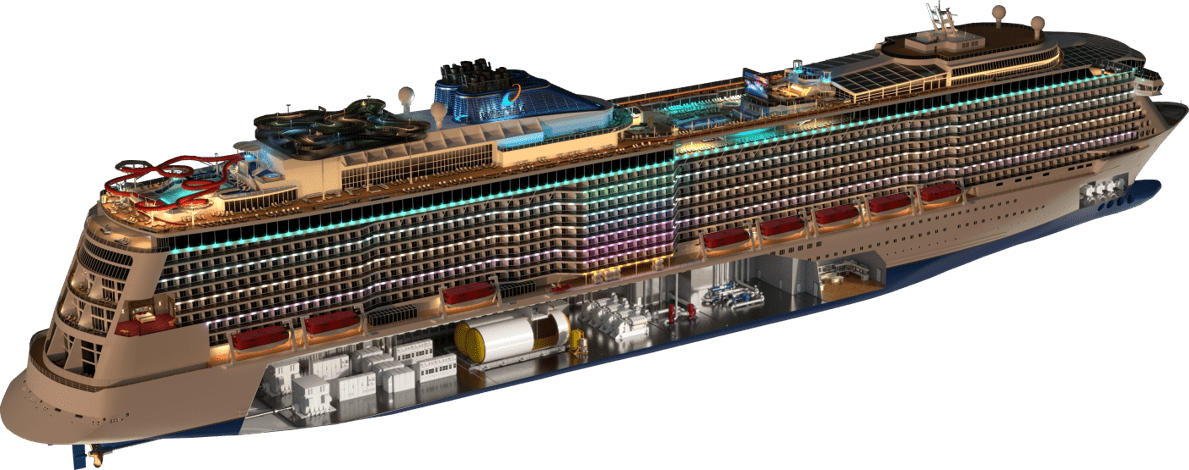

The 3rd Oasis-class ship - Harmony of the Seas, is currently the most technologically advanced and energy-efficient cruise vessel ever built. It is equipped with a new-generation exhaust gas cleaning system (multi-stream scrubbers) and also features a hull lubrication system allowing the ship to float on air bubbles (created around the hull) thus reducing drag and increasing fuel efficiency.

However, the steering and propulsion systems in Azipod arrangement, are combined into one part and the system consists of a propeller (driven by an electrical motor) turned by a rudder connected to the azipod system. The motor is inside the sealed pod and connected to the propeller.

The following YouTube video is about ABB Azipods installed on the new Genting Hong Kong vessels (Star Cruises' new ships and on Crystal Cruises' polar-class boats).

These ships incorporate a complete ABB propulsion - Azipods, electric power plant, computer automation, and software. Crystal cruise ships are powered by two "Azipod D" units allowing navigation in polar destinations. Each of the Star Cruises "Global-Class" vessels have three "Azipod XO" thrusters. All ships have installed ABB's "Intelligent Maneuvering Interface" and the "OCTOPUS" software optimizing fuel consumption and energy management. All these ships were constructed by the German shipbuilder MV Werften. Currently, almost 2/3 of all large-sized cruise vessels, icebreaking ships, and high ice-class cargo ships are with Azipod propulsion.

Advantages of Azipod propulsion marine systems

- A lot of space is saved by the Azipod cruise ship propulsion system in the engine room - there is no propeller, engine, shafting or other arrangements. This saved space can be used for storing cargo.

- Great maneuverability - the propeller can turn in all directions and enables crash maneuvering stop distance that is better than the conventional systems.

- Azipod cruise ship propulsion system can be placed below the ship's height and provide more efficiency than conventional systems.

- In case the ships have large breadth, two (or more) azipod systems, independent from one another, can be used to provide subtle maneuvering.

- Side thruster's use is eliminated as pods can be used to provide side thrust.

- Low lube oil and fuel consumption.

- Lower vibrations and noise than conventional systems.

- Because emissions are low, it's environment-friendly.

Disadvantages of the Azipod marine propulsion

- It requires great initial cost.

- Many diesel generators are needed for producing power.

- The power produced by the motor is limited - the maximum available power now is 21 MW.

- Azipod cruise ship propulsion systems can't be installed in heavy cargo ships that need large motors and a lot of power.

Royal Caribbean Quantum-class cruise ships propulsion

In April 2012 ABB made a USD 60-million contract to provide the Azipod propulsion systems for the new Royal Caribbean ships of the Quantum-class (Quantum, Anthem, Ovation) and Quantum Plus-class (Pulse, Passion). The former name of this vessel design was "Project Sunshine". Builder is Meyer Werft (Papenburg, Germany).

ABB also supplies the power generation, distribution systems, bow thrusters, and of course, the 2 x 20,500 kW propulsion Azipod XO units (at the photo at right), transformers and drives.

NCL Epic ship pod-propulsion

When entering service in 2004, the Cunard's QM2 was the biggest in the world at 150,000 GR tonnes. Her designer Stephen Payne showed the advantages of pod-propulsion giving vessels increased maneuverability. The propellers (screws) of the QM2 ship are mounted on the pods which rotate 360 degrees and provide advanced maneuverability. He made the choice to put pods - though relatively new and yet untested for big ships. Royal Caribbean vessels of Oasis, Freedom, and Voyager classes have pod-propulsion as many other big ships, which is opposed to the fixed traditional screws which push in one direction only.

An interesting fact about cruise ship propulsion is that Norwegian Epic doesn't have pods, though slightly bigger than Queen Mary 2 (at 153,000 GR tonnes), because of NCL concerns about the new technology. Some of the lines (including Celebrity and Cunard) have suffered vessel breakdowns due to pod-bearing failures. Lots of voyages had to be canceled, extensive dry-docking periods were required for pod bearings to be replaced, and NCL didn't want to take the risk.

Currently, NCL Norwegian Epic has two rudders with conventional non-Azipod screws. But how does she manage to maneuver if they can push in one direction only? One option is to make them bigger and more effective when maneuvering, another is to add additional mini-pods or install full-sized pods. Only time will tell if any of these will actually ever happen.

Rolls-Royce cruise ship propulsion system "Promas Lite"

In November 2013, the manufacturing giant Rolls-Royce upgraded Hurtigruten's ship MS Richard With its new "Promas Lite" propulsion system (integrated propeller-rudder system). This is an older ship, and Promas Lite was the perfect choice as it is a combined "propeller-rudder" system increasing the efficiency of older passenger vessels with lesser tonnage. The upgrade significantly reduced Hurtigruten's operating costs on this vessel. The improved propeller efficiency was estimated to be between 11-14% at a cruising speed of 15 knots (17 mph / 28kph).

Promas propulsion integrates propeller, hubcap, rudder bulb and the rudder into a single unit which can increase propulsion's efficiency by 3-8% (1-screw vessels) and by 2-6% (2-screw vessels). It also improves maneuverability, reduces fuel consumption and bad emissions. The new modular technology allows efficient and cost-effective custom-made systems to be built up from various existing and standard parts - mooring winches, anchor cable lifters, warping heads.

Hurtigruten was compensated with ~80% of its total investment in Promas Lite marine propulsion upgrades as the Norwegian Government has this NOx fund encouraging shipowners and operators to upgrade their vessels and invest in new marine technologies that reduce NOx emissions. The Promas Lite propulsion future clients, besides passenger ships, are marine vessels like fishing and freighter ships.

After Norwegian Spirit (the first ship in NCL fleet with installed Promas Lite in 2011), in May 2014 the Star Cruises ship SuperStar Virgo became Southeast Asia's first passenger liner with RR's Promas Lite propulsion. Fincantieri used Promas Lite propulsion for all Viking Ocean liners.

Cruise Ship Power

The cruise ship engine power is responsible for driving propellers, and the other possibility is producing electricity that is used subsequently to drive propellers. The engine's effectiveness depends not only on the design but also the ship's shape, weight, and size. Power is measured in horsepower traditionally - one horsepower equals 746 watts. The next photo shows the world's largest passenger ships' engine that powers each of the Royal Caribbean Oasis-class vessels.

Marine steam engines

The cruise industry began in 1844, when ships were propelled by steam engines, performing the driving of propellers by using steam as working fluid. The largest passenger steamship (before hitting an iceberg on April 14, 1912) was the Titanic, powered by both reciprocating engines and turbines, able to generate 50,000 horsepower (37 megawatts).

Marine diesel engines

Usually, ships are powered by four or five generator sets (medium-speed, 500 revolutions per minute), fueled by diesel and creating 8-10 MW energy each. The power density of marine diesel medium-speed engine is 80 kilowatts per cubic meter. Ships that use diesel engines are required to carry exhaust-treatment systems and catalytic-reduction equipment to reduce the environmental impact.

Marine nuclear power engines

The building of the US first and only merchant nuclear-powered ship was commissioned in the 1950s by President Eisenhower. Of total cost $46.9 million, on the fuel core and nuclear reactor was spent more than $28 million. The ship operated only for five years (1965-1970) but due to the high running costs, its service was terminated.

Marine gas turbines

The first company that fitted cruise vessels with gas turbines, was Royal Caribbean. Gas turbines are greener than diesel engines and allow ships to sail with reduced inventory and smaller maintenance crew. Gas turbines drive generators which in turn provide electricity to propeller motors. They recover heat from gas turbines' exhaust, which then is used to produce the electricity needed for onboard services (air conditioning, water heating).

Rolls Royce is the manufacturer of the world's largest GAS marine turbine "Rolls-Royce MT30". The turbine will provide the immense 109 MW of power for the 2 propellers, all the weaponry, radars, command sys, etc. of the new generation UK aircraft carriers of the Queen Elizabeth class. To this class belong HMS Queen Elizabeth (2017-commissioned) and HMS Prince of Wales (2019-commissioned), each of them with a total power consumption of 80 MW.

Gas-turbine cruise ship power system

The first large vessel to use a new gas-turbine cruise ship propulsion system was Celebrity Millennium . This system will be more frequently used in new cruise ship buildings . It's innovative and, besides new activities available, the economy of scale, marketing, represents an important element of ship design. System's advantages include:

- lower vibrations and noise level, better comfort, lower probability of failure;

- lower exploitation costs because of the easier maintenance;

- nocive emissions reduction, which is partially owed to gas oil instead of fuel (-90% oxide of sulfur, -80% oxide of azote).

- considerable gain of weight and volume, especially when with Azipod marine propulsion system (900 tons, 70 cabins added).

Gas turbines at this time are only interesting in the building of high-speed ships (warships, and especially aircraft carriers, or fast passenger vessels - Millennium max speed is 25kn), because of the better diesel output in lower speeds and higher price of gasoil instead of fuel for diesel engines.

Gas turbine cruise ship propulsion systems are able to avoid pre-heating systems needed for fuel in classic installations (risk of fire!), as they use gasoil, Celebrity's Millenium-class and RCI's Radiance-class use such turbine powerplants. The next photo shows Celebrity's Solstice-class ship propulsion (the 4 aft azipods, and the underwater hull shape).

LNG-powered cruise ships

In June 2015, Carnival Corporation announced the company's contract with Fincantieri to build four LNG-powered vessels with the industry's largest passenger capacity. This was part of the order with Meyer Werft and Fincantieri for a total of 9x units to be built in the period 2019-2022.

The four newbuilds became the industry's first LNG (Liquefied Natural Gas) powered vessels using LNG in their hybrid engines. The gas is stored in the ship and used to generate all needed power at sea. The engines are not exclusively LNG, but "dual fuel" (capable of burring both liquid marine fuel and natural gas). This design is for saving onboard space (reducing fuel storage space required).

LNG is natural gas, which consists of 90% methane and 10% ethane. When cooled to -160 C, it passes from gas to liquid, and its volume decreases over 600 times, making it very efficient for distribution. Long-distance LNG transportation is via dual-hull gas carriers. Short-distance LNG transportation is via trucks or smaller vessels (also barges) fitted with high-pressure tanks.

Gas fuel eliminates all the bad emissions - soot and sulfur oxides. In April 2016 MSC Cruises announced its contract with STX France for up to four LNG-powered ships with GT over 200,000 tons each. For comparison, the Oasis of the Seas is 225,000 GT tons. The new MSC ships have 5400 passengers capacity at double occupancy each. The first one is scheduled for delivery in 2022. Its power plant will be based on a new prototype engine.

Using LNG to power large cruise ships is a relatively new (2016) concept. Due to LNG tanks' large sizes, this fuel is used usually on smaller passenger shipping vessels ( ferries ) operating on short crossing itineraries. LNG bunkering facilities available in ports are very few. Compared to other fuels (including MGO / marine gas oil), LNG is purer (no unburned residues, fewer greenhouse gases), more efficient, stable and cheaper (reduces fuel costs). LNG technology also advances due to IMO's future maritime emissions regulations, especially in ports and while operating in environmentally sensitive destinations.

In comparison to pipeline gas, LNG is superior in quality - purer, with more methane and other energy content. Its chemical structure also has a stable composition that doesn't generate unburned residues, soot or any particulates. In addition, because the fuel is so clean, on LNG-powered ships maintenance intervals are doubled (over 25,000 hours / ~10140 days), as opposed to the standard MDO-powered 12,500 hours (520 days).

- All the world's major environmental organizations and the marine shipping industry joined for an explicit prohibition on the carriage of non-compliant fuels when the 0,5% sulfur cap takes effect in 2020.

- In January 2018, IMO announced that starting January 1, 2020, the marine fuels' max allowed sulfur content (outside Emission Control Areas) is reduced from the previous 3,5% to 0,5%. Unless marine vessels are using approved equivalent compliance methods, after Jan 2020 there is no reason for ships to use non-compliant diesel fuels.

- IMO's new sulfur cap's goal is to provide substantial health benefits by reducing marine fuels' sulfur content (SOx gases). At the same time, IMO's lowered cap significantly increases ships' operating costs.

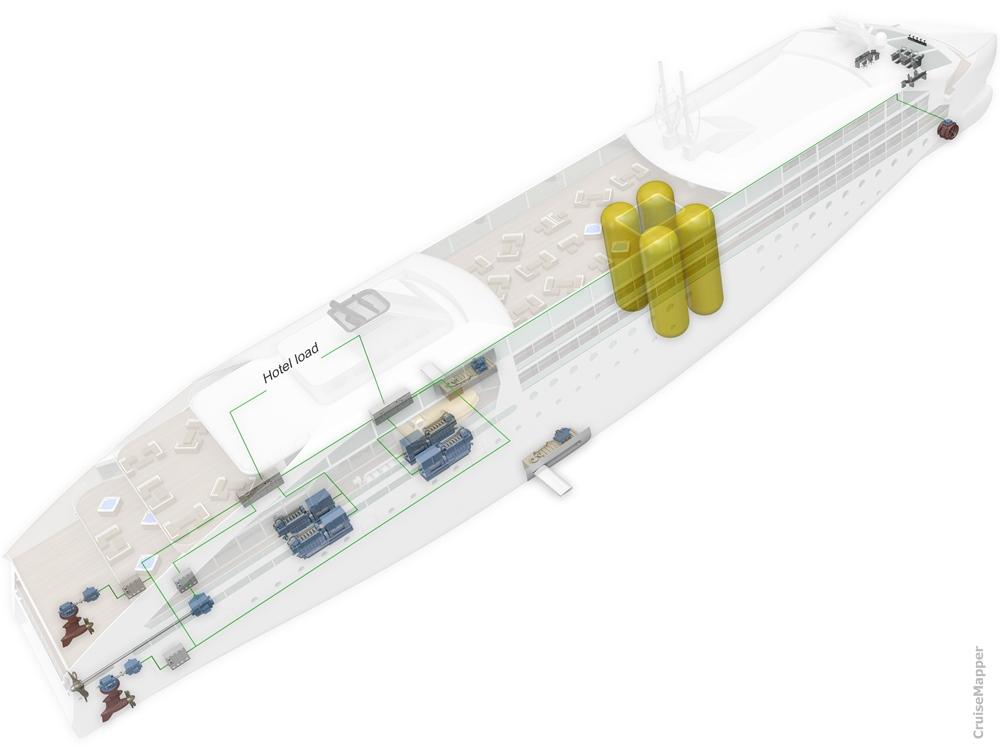

The LNG cruise ship concept was first introduced by Wartsila (Finnish manufacturing company) and is based on drive shaft propulsion instead of azipods. The LNG tanks' location is in the upper deck area (right below the funnels). The Rolls Royce concept is based on azipods.

AIDAprima (2016) is one of the world's most technologically advanced cruise vessels. The ship rides on a cushion of air, thus reducing frictions and fuel consumption, The new technology is called MALS ("Mitsubishi Air Lubrication System"), allowing the liner to glide on an air bubbles carpet.

The ship's 4 main engines are dual-fuel (heavy oil and LNG gas oil) thus reducing fuel consumption. The ship has an advanced filtering system that reduces stack emissions (greenhouse gases). The ship's propulsion features 1 pair of stabilizers and 2x ABB-pod drives (new XO-Pod series, power output per unit: is 3 MW). The total power output is 48 MW. AIDAprima is also the world's first-ever "LNG cruise ship" as it uses LNG fuel supply while berthed in ports.

For its LNG-bunkering operations in Florida (at homeports PortMiami and Port Canaveral ), CCL-Carnival partnered with Royal Dutch Shell plc as fuel supplier for the liners Mardi Gras (2021) and Celebration (2022).

AIDA's LNG-powered cruise ships

The AIDAprima ship's first successful test run for LNG supply was in Hamburg Germany on May 7, 2016. While berthed, the ship was successfully provided with LNG at all the itinerary's ports of call (Hamburg, Rotterdam, Le Havre, Southampton, Zeebrugge).

- The company's statistics show that the AIDA ship spends about 40% of its operating time in ports. Compared to using conventional marine diesel (0,1% sulfur content), by using LNG, the vessel's emissions were considerably reduced even further. Sulfur oxides and soot particles were prevented completely (while in port), nitrogen oxide emission was reduced by up to 80%, CO2 emissions were lowered by 20%.

- AIDA ships (produced by Shipyard Papenburg ) are 100% LNG-powered. AIDA invested in research and testing of LNG cruise ship technologies since 2015. In 2013, AIDA collaborated on LNG hybrid barges with Becker Marine Systems. The innovative and flexible solution is used on ships moored in Port Hamburg.

- Since May 30, 2015, AIDAsol is regularly supplied with low-emission LNG power at Hamburg's Hafencity Cruise Terminal.

- AIDA ships use just 3 liters (0,8 US gallons) of fuel on average per person on board for a 100 km (62 ml) trip. This was confirmed by an independent expert study in 2012. Following the implementation of new technologies and economical handling of resources, the company's statistics for 2016 (over 2012) showed reduced energy consumption (9% per person onboard), reduced water consumption (7,2% pp) and reduced CO2 emissions (7,7% pp).

Hurtigruten ships

In April 2018, the Norwegian cruise and ferry company Hurtigruten announced a USD 150 million fleet renovation project. Almost all vessels will be upgraded with new hybrid powerplants that combine LNG-engines and batteries.

For the project was contracted Rolls-Royce Marine, initially for 6 ships plus optional another 3. The program's completion was scheduled before January 1, 2021. The project also includes all vessels to be upgraded with shore power capabilities.

Dual-engine ferries (LNG-MDO)

The next scheme shows the dual-engine powerplant (Wartsila) and propulsion (Azipod) of the cruise ferry Tallink Megastar . This ship is the biggest "floating superstore" on the Baltic Sea, featuring a 2-deck retail shopping complex and the unique self-service option called "Q-shopping". The RoPax vessel uses LNG as prime fuel and MDO (marine diesel oil) as secondary fuel.

The ship is powered by a total of five Wartsila dual-fuel engines - three 12-cylinder (model 12V50DF, combined output 34,2 MW) plus two 6-cylinder (model 6L50DF, combined output 11,4 MW). Ferryboat's total power output is 45,6 MW. Its propulsion system includes two Wartsila fixed-pitch propellers with twin propeller shafts. Navigation systems are also Wartsila-made, including NACOS Platinum (integrated vessel control system).

The power generated by the main engines/powerplant produces electricity that is used from the propulsion motors, as well as all auxiliary systems and hotel functions. This innovative maritime technology allows the engines to be started and stopped depending on the onboard electricity demand, which additionally improves fuel efficiency.

Vessel's hull is ice-strengthened (class 1A). Rudders are from Becker Marine Systems. When compared to traditional marine engines, in gas mode, the ship's engines produce 1/4 less COx, 2/3 less NOx, zero SOx and no soot particles.

The onboard LNG system consists of 2 bunker stations, 2 horizontal LNG storage tanks by Linde (cryogenic, vacuum-insulated, stainless steel, total gas volume 600 m3), double-walled bunkering lines, pipelines (acid-proof stainless steel), special pipe fittings, gas distribution system, steam boilers. All the ship's electrical equipment is certified "explosion-proof". The LNG is stored at temperatures -160 Celsius (-256 Fahrenheit) and under pressure 4-6 bars.

ABB supplied the vessel's power and electric propulsion systems, as well as the Octopus (smart energy management system). While mechanical propulsion is optimized for a single-speed, electric propulsion is based on rotating speed control resulting in energy efficiency at all speeds. ABB's propulsion also improves passenger comfort as the ship runs much more quietly and smoothly. ABB's Octopus marine technology allows real-time monitoring of the vessel's energy (and fuel) consumption. Based on the collected data, the software suggests optimal performance recommendations.

Spain's first LNG-powered cruiseferry was Hypatia de Alejandria (2019) owned by BALEARIA .

Wind-assisted propulsion

On April 12, 2018, the VIKING LINE -owned ferry Viking Grace became the world's first-ever passenger ship equipped with a rotor sail utilizing wind power. This also made it the world's first hybrid vessel that uses both wind power and dual-fuel (diesel-gas) engines.

"Rotor Sail Solution" is an innovative technology developed by the company Norsepower Ltd (Finland) in 5 years. It reduces fuel consumption and also COx emissions up to 900 tons per year (depending on wind conditions).

The cylindrical rotor sail has a height of 24 m (79 ft) and a diameter of 4 m (13 ft). The technology is based on the "Flettner rotor" (patented by Anton Flettner in 1922) and uses the so-called "Magnus effect" - the spinning rotor (rotating cylinder) drags airflow faster around one side. This creates pressure/speed difference that moves it in the direction of the opposite (lower-pressure) side, creating a force at a right angle to the direction of the wind. This wind-assisted propulsion power drives the ship forward. Unlike traditional cloth sails, the rotor needs no furling (stowing), reefing (reducing sail's area) or line-tending. The rotor sail system is automated and shuts down when unfavorable changes in wind force or direction occur.

Added to the dual-fuel engines, the new technology makes Viking Grace one of the world's most environmentally-friendly passenger ships, operating with very low levels of emissions and noise. Norsepower's wind propulsion system was also installed on VIKING LINE's newest vessel (still unnamed) scheduled for delivery in 2020. The China-built ferryboat is equipped with two Norsepower-produced rotor sails, doubling its wind power potential.

Ship's powerplant includes 4x Wartsila engines (model 8L50DF, total power output 30,4 MW). Propulsion is diesel-electric (2x shafts with fixed-pitch propellers) and wind-assisted (with 1x rotor sail). Engines are dual-fuel (MDO-LNG). As gas tanks are larger than marine fuel tanks. they need 6 times more space. To save hull space, LNG tanks are located on an open deck. LNG tanks are two (type C / vacuum insulated), each with capacity 200 m3 and weight 140 tons (LNG weight 85 tons per tank).

MS Viking Grace is also the world's first ship with the energy recycling system "Ocean Marine" (developed by Climeon AB / Stockholm-based company). The system converts the excess heat (generated by engines and exhausts) into clean (emission-free) electricity with an annual capacity of 700,000 kWh. This electricity is primarily used on cabin decks (including for heating, hot water, lighting). The technology uses heat exchangers that evaporate a carrier fluid circulating in a closed system. This gas (at 2-bar pressure) drives a turbine, then a 100 kW generator produces electricity. After that, the gas is cooled (in a vacuum chamber) and liquefied. Cooling is rapid, as the cold fluid is sprayed out. Then Heat exchangers cool the carrier fluid to temperatures around 20 C / 68 F.

Cruise Ship Fuel Consumption

How much fuel do cruise ships use.

Cruise ship fuel consumption depends on the ship's size. For most vessels, the average consumption is 30-50 miles on a fuel gallon. This will be also determined by other factors using fuel. Ships' gas mileage varies depending on the type and size of ship, the number of passengers on board, and other factors. Larger ships need more fuel to move through the water.

RMS Queen Mary uses 6 tons of marine fuel per hour. Celebrity Eclipse gets 56 feet to the gallon. MS Zuiderdam - .0130 miles per gallon (0.34 tons fuel per mile). This may not seem very good mileage at first glance, however, cruise ships are moving at once thousands of people whereas a car is moving a few.

Nearly all contemporary cruise ships are powered by electricity (motors turn propellers). It powers the air conditioning systems, lights and all other appliances aboard the ship. Most vessels produce the electricity they need by using diesel engines. Some use gas turbine engines. Others use a combination of the two. HFO (heavy fuel oil) is used by diesel engines, while MGO (marine gas oil) is used by gas turbine engines. The MGO is similar to the jet airplanes' fuel.

Speed affects cruise ship fuel consumption because to go faster, vessels must increase the electricity flow to motors. Thus more engines are employed, and it, in turn, increases fuel consumption. For example, Queen Mary 2 consumes 237 tons MGO and 261 tons HFO a day when at full speed. After a certain point, the rate of return decreases from adding engines, because if a ship can manage 17 knots by two engines, it doesn't mean that four engines are going to produce 34 knots.

Cruise companies employ new technologies in order to reduce fuel consumption. Ship's hull, for example, can be applied by silicon coating in order to reduce friction as the ship goes through the water. Friction reduction on Celebrity Eclipse is 5%. Another experiment is LED lighting, using less energy and producing less heat (thus is reduced the demand for electricity and air conditioning). Celebrity Solstice-class vessels have solar panels' field over the AquaSpa pool area. This not only provides shade for the pool area but produced by solar panels electricity is used to decrease the electricity demand from the engines.

RMS Queen Mary 2 is equipped with exhaust gas economizers, using waste heat from engines to produce steam. Then steam is used to heat fuel and QM2 hotel accommodations, laundry, galleys. This reduces the energy amount that has to be produced by ship's engines. The Promas Lite system (mentioned above) generates cruise ship fuel savings in the range of 5-15% depending on the operation type and the actual performance of the ship's existing propeller.

How marine ships fuel consumption increases at higher speeds? Next infographic shows the speed-fuel consumption relation on container ships (their sizes are measured in TEU-containers/20 ft equivalent units), which are similar by speeds and even gross tonnage to cruise passenger ships.

Cruise Ship Pollution

Today cruising is one of the most popular vacations, but there are significant environmental downsides. Mega-ships burn the dirtiest fuel in the world, even if they are sitting in port. Asthma, cancer, respiratory illness, heart disease, are the results of burned in ports nasty bunker fuel.

Shore-to-Ship Power Supply

Those who support the cruise industry point out that cruising has never been more popular. However, more ships generate more pollution. A solution is to have docked vessels plug into the port's shore power grid. Most of the world's largest cruise ports have such dockside electrical hookups, reducing bad emissions by up to 95%.

Aka "cold ironing" and "shore-to-ship power", shore power capability allows berthed cruise ships to shut down their diesel engines (main and auxiliary) and plug into city's electrical grid, using locally-produced electricity for all shipboard equipment and services - including cooling, heating, lighting, emergency, etc. The technology greatly reduces exhaust emissions in seaports. Next video animation reviews this technology.

TUI Cruises Ships Environmental Report

TUI published the company's environmental impact report (first of its kind) including environmental objectives and TUI strategy for a 5-years period. TUI said it planned to issue reports every 2 years. According to it, in 2012 TUI reduced by 3.7% per nautical mile its fuel consumption, and expects further 5% reduction, reducing CO2 emission at the same time by 0.5 kg to 0.55 kg per traveler.

Energy efficiencies are the key to reduce fuel consumption, CO2, and other emissions, and contribute to climate protection. Mein Schiff 3, for example, is expected to feature special energy management systems that help to consume 30% less energy than comparable size ships. TUI is focused on reducing recycling and waste, too. In 2012, TUI reduced the waste amount to 10,7 L (per passenger day), which is 27,8% less (over 2011). In 2012, TUI used 54,463 tons of fuel, including 9,732 tons LSFO (low sulfur fuel oil), 40,880 tons HFO (heavy fuel oil) and 3,851 tons MDO (marine diesel oil). Fuel consumption was 0,367 tons per nautical mile.

All new TUI ships are built to the latest standards with environmentally-friendly marine technologies. These vessels, both as design (hull and superstructure) and implemented technologies, are highly energy-efficient. Each consumes 1/3 less energy compared to most cruise liners. The advanced exhaust cleaning system uses a catalytic and scrubber converter. This technology allows sulfur emissions to be reduced by 99%, and NOx emissions - by 75%.

All-electric passenger ships

In May 2019, the US company "Maid of the Mist" ordered ABB two new all-electric vessels for the company's Niagara Falls tours. Both catamarans are 100% emission-free being powered by high-capacity batteries. Each ship is fitted with two battery packs (combined capacity 316 kWh / 563 HP output). The electricity is provided by 2 fully-independent power systems and split evenly between the 2 hulls.

Shoreside battery charging takes just 7 min (per ship). The powerplant is controlled by ABB's PEMS (Power and Energy Management System), which also optimizes the onboard energy use. Ships' batteries are charged using hydropower (water-generated electricity), which as of 2019 accounts for ~7% of the USA's total electricity production. In addition to the shoreside charging connection, ABB supplied the newbuilds with switchboards, motors, integrated control systems and ABB Ability's Marine Remote Diagnostic System (24-hour equipment monitoring and predictive maintenance).

Battery power is used during turnaround navigation in ports when the onboard diesel-electric generators are switched off. For ferry batteries (fabrication, delivery, and installation) is often contracted the Canadian company Corvus Energy (Richmond BC) - one of the world's largest manufacturers and suppliers of energy storage solutions (ESS) for the maritime industry. The company provides ESS to hybrid and all-electric ferries. As of 2019, Corvus Energy delivered its innovative product line "Orca ESS" to 200+ vessel conversion/upgrade projects, totaling 200+ MWh.

At the following tag-link can be found listed all CruiseMapper's news related to propulsion-power accidents .

This cruise vessel technology-related survey is integrated with our articles on passenger ships building and safety , and the statistical ones about registry/flag-states , cost to build , speed , passenger capacity . All ship links redirect to the vessel's "itinerary-schedule-current position" page.

The Shipyard

For Those Who Love Ships

- Cruise Ships

How Cruise Ships Work (Part 3): The Bridge and the Engine Room

It’s like back in the days when we were little children. Grandpaw’s almost mystical tool shed was strictly off limits, but we were just dying to have a peek, weren’t we? Now that we are all grown up, Grandpaw’s gadgets are old news, but there is still a place or two on a cruise ship that remains like a pie in the sky for all of us obsessed by ships.

It’s the heart of the matter, it’s where it all happens, it’s the real deal. And if you are anything like me, you would gladly give away a day at the spa, a dessert buffet and even two, or the latest Marvel flick in the movie theater, just to spend a precious hour down in the noisy engine room of your favorite cruise ship. But life being proverbially unfair, modern cruise lines rarely allow their passengers to enter the bridge or the engine rooms of their ships, unless the visit is part of a specially organized guided tour. Some cruise ships have a window from which passengers can observe what’s going on in the bridge, but only if they promise not to disturb the officers. Which is really hard, when you badly want to touch everything…

So until the next time someone lets me out of sight and I make my umptieth attempt at trespassing to the engine room, let’s have a quick virtual tour of a cruise ship’s most forbidden and exciting parts.

The bridge is the brain of the ship. It is from there that the captain and his officers command and maneuver the ship, keep watch for other vessels or potential hazards, and navigate through the oceans.

For twenty-four hours each day, the bridge is occupied by two Deck Officers and two Able Seamen, traditionally in four-hour shifts. The main job of the Officer of the Watch is to monitor the ship’s systems and surroundings, and to ensure that everything is running safely and smoothly. During extreme weather, docking, or other special cases, the Captain of the ship is also present on the bridge to guide the deck officers.

The term “bridge” comes from the time of the paddle steamers, where a bridge was built above the two paddle houses that used to hold the paddle wheels. This way the skipper could observe both wheels, while moving freely between the two and giving out commands. On today’s cruise ships, the bridge is usually on the upper deck in the forward part of the ship and extends over the sides of the superstructure, allowing deck officers a view to the sides of the ship as well as down to the waterline. The side extensions are called bridge wings and often have a glass flooring for better visibility.

The bridge houses a number of important nautical devices and information systems for command and navigation of the ship.

Satellite Navigation

The signals emitted by special navigation satellites are picked up by the cruise ship through a special antenna. On board, a computer converts these signals into the exact position of the ship at a given time. On large ships, the position indicator is constantly recorded in a so-called electronic nautical chart.

Satellites also enable automatic positioning systems on modern cruise ships. The positioning system is controlled from the bridge and it uses GPS to ensure that the ship stays at a defined location. When the captain defines a position where the ship needs to remain for a while without anchoring, the system automatically maintains the ship in position by using the bow and stern thrusters.

Modern cruise ships carry a gyro compass and a magnetic compass. The gyro compass consists of a fast-rotating disk, usually positioned in a gimbal. It is a non-magnetic compass oriented parallel to the axis of rotation of the earth and thus indicates the north-south direction.

The gyro compass is more accurate and reliable than the magnetic compass and is therefore the primary reference point for steering the ship. The magnetic compass on board is more prone to inaccuracies and it serves only as back-up.

The word radar stands for Radio Detection And Ranging. Radars are devices that allow us to locate distant objects from a given location, regardless of visibility and weather conditions. The radar emits electromagnetic waves to an object, then receives back the reflected echoes from that object, and interprets them based on distances and angles. These interpretations enable us to determine where an object lies, and in some cases even what its contours look like. In the shipping industry, radars are used for monitoring traffic in ports and coastal regions, for collision protection, for collecting weather data, and for navigation.

Speed logs are devices that measure the speed of the ship. There are two main types of speed logs: Doppler logs and electromagnetic logs.

The Doppler logs send out underwater sound signals. When the sound wave reaches the sea floor, it gets reflected and then returns to the receiver of the log. Due to the movement of the ship relative to the seabed, a Doppler effect occurs and is evaluated by the device. As long as the sound waves can reach the bottom of the sea and return to the receiver, the Doppler log measures the distance travelled over ground. However, if it is no longer possible to use the seabed as a reference, the device uses particles suspended in the water, such as plankton and minerals, to measure travel through the water.

The electromagnetic logs create an electromagnetic field in the water around the ship, with the aid of a small alternating current and a transducer. A voltage proportional to the speed of the ship is generated in the water and is picked up by special sensors, which then transfer the information to an electronic device for interpretation. From the electronic device, the speed is then transmitted onto the displays in the bridge.

Echo Sounder

Cruise ships also have an echo sounder, a device used for the electro-acoustic measurement of water depths (sounding). The depth is determined by measuring the time between the emission of a sound impulse (water sound) and the arrival of the sound waves reflected from the bottom of the sea. The main purpose of echo sounders in cruise ships is safe navigation through waters.

Electronic Chart Display and Information System

The Electronic Chart Display and Information System (ECDIS) is a console, built into the bridge of modern cruise ships, which incorporates the main engine safety system, fire control system, monitoring and control system, power management system, propulsion control system and navigation and maneuvering system. The ECDIS allows for navigation of the ship without the need of traditional paper charts. Navigation can be done manually, automatically, or through the Navigation and Command System (NACOS).

The NACOS is the main software used to coordinate all factors that need to be taken into consideration, in order to navigate and maneuver the ship safely. The console is composed of a number of displays showing information from the radars and compasses, data about the course of the ship and planned maneuvers, the current status of the pitch of the thrusters, the speed of the ship, and anything else concerning the steering of the ship. An intelligent autopilot tracks changes in the behavior of the ship through navigational sensors. If the ship drifts off its course due to strong winds, for example, the system automatically responds to correct the change by sending signals straight to the engine room. Once the signal is received by the engines, the rudder or thrusters of the ship are activated and move to the position given by the system. The displays on the bridge show both the angle of the rudder or thrusters, as well as the rate and the radius of the maneuver in progress.

The Engine Room

The engine room is the heart of a cruise ship. It is here that pistons hammer and crankshafts turn to propel the ship forward. It is the loud and oily place where the Chief Engineer and his team work around the clock to ensure that everything is running smoothly. It is the engine room of the ship that allows for the luxuries of air-conditioning, electricity, and plumbing on board cruise ships.

In future articles we will have the chance to explore the contents of the engine room in all the excruciating detail that they deserve, so to all the techies out there – I’ve got you covered. Just stay tuned.

Most larger ships have more than one engine room to house their machinery. The arrangement of the engine room can vary depending on the type, design, and size of the ship. For stability reasons, the engine machinery is typically placed as low as possible in the ship’s bowels and often takes up several decks in height. The machine rooms are split into watertight compartments, each housing different machinery.

Today’s cruise ships operate on diesel or diesel-electric engines. Their operating principle does not differ much from the old days of coal steamers, except for the medium used to generate power. While back in the day ocean liners used steam to move the engine’s pistons, modern cruise ships use diesel fuel. Today’s diesel engines are composed of the engine unit itself, gearboxes, shafts and generators. Some ships also have shaft generators which create electricity from the turning movement of the propeller shaft. The electricity is then used in the cabins, on deck and in the kitchens.

The latest generation of cruise ships are equipped with diesel electric engines. Instead of the more traditional engine-shaft-propeller arrangement, in this case the engines are connected to generators to create electricity. The generators power electric motors, and the electric motors move the propellers.

Aside from the engines and generators, the machinery that occupies the engine rooms includes pumps and heat exchangers for engine cooling, stabilizer fins and their motors, as well as the ship’s bow thruster system.

Since all of the equipment in the engine room is highly dependent on electricity, modern cruise ships also have back-up generators, usually located outside the main engine room, to protect them in case of fire. While these generators cannot produce enough power to keep the ship moving, they produce enough to keep some of the vital functions of the ship running, such as powering the emergency lights and the communication and navigation systems. In case the back-up generators fail, cruise ships are also equipped with a back-up battery that allows some of these functions to continue running for short periods of time.

All the machinery in the engine rooms is monitored in the Engine Control Room (ECR). The ECR is a room full of screens, lights, alarms, and switches from where the current operational status of every piece of equipment can be checked.

The main switchboard of the ECR is used to distribute the generated electricity to where it is needed on board. The ERC is also where the engineering team comes together to discuss and plan the safe running of the engine rooms, to take decisions in emergency situations, to consult the technical manuals and drawings of the ship, to restart certain pieces of machinery if necessary, and to maintain communication with the bridge. Communication between the ECR and the bridge is crucial for the safe operation of the ship, especially during docking, moving through shallow waters, maneuvering, and changes in the course or speed of the ship.

This concludes our three-part overview of how a cruise ship functions. Now that we have covered the basics, in future articles we can explore all the specifics to our hearts’ content. As always, don’t hesitate to leave your constructive comments below and feel free to suggest topics you want to know more about – chances are I want to know more about them too!

Stay in touch and I’ll see you next time!

Share this:

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Privacy Overview

Cruise ship engines, propulsion solutions and more

The ambition in the cruise industry is to go above and beyond – to exceed expectations. This is as true for the guest experience as it is for the industry’s drive to reduce emissions and decarbonise. When the goal is net zero operations, cruise ships need a range of sustainable engines, propulsion solutions, maritime technology, and services.

Wärtsilä offers a comprehensive portfolio to support cruise operators on their decarbonisation journey – for retrofit projects and for future-proof new builds.

How to succeed in decarbonisation

Wärtsilä has a five-step approach to ensure you remain competitive, compliant and profitable.

1. Lower carbon fuels

Adoption of LNG, bioLNG or Methanol

2. Electrification

Integration of additional power sources such as battery hybrid and shore power

3. Boosting efficiency

Highest engine efficiency, re-use of waste energy, energy savings devices

4. Digital innovation

Adoption of new digital solutions to improve voyage efficiency

5. Smart services

Optimised fleet decarbonisation services and guaranteed asset performance agreements

Cutting-edge solutions in a nutshell

How to future-proof your cruise vessels.

Cruise vessels being built today will still be sailing in 30 years or more. Over that time new, more sustainable technologies and fuels will become available so it is essential to build with the future in mind. How to keep up and invest wisely?

Download this paper now to learn more about the five steps that help ensure competitive, compliant, and profitable cruise operations.

Everything from engines to digital solutions and electric propulsion

Over the lifetime of a cruise ship, new technologies and fuels will become available. It is essential to have the future in mind to meet regulations, passenger demands and financiers’ preferences. Integrated solutions from Wärtsilä can give you just what you need to stay competitive and successful.

What could be the true cost of a single day’s delay?

Picture the scene: Your cruise ship is set to leave port with thousands of guest onboard. But there’s a problem which means your ship leaves port a day later than it should. What is the true cost of a day’s delay for a cruise operator? And how could you avoid such expensive problems? Open the infographic

Essential solutions and services for cruise ships

A handy tool that helps you plan, measure and report EUA costs. Accurately and easily!

Case Carnival Regal Princess

Watch this video! Chris Millman, Vice President Marine Technology for Carnival reveals how Carnival gets the critical data and insight that will help to decarbonise its existing vessels and newbuilds.

Ready to be inspired?

Watch now! In less than a minute, Maikel Arts, GM Technical Sales at Wärtsilä will reveal some interesting opportunities that hybrid systems can offer to the cruise industry.

Reducing plastic packaging

Watch and discover a personal look into a sustainability pilot project with Carnival and Wärtsilä. How did a switch from plastic packaging to eco-friendly packaging work?

Optimising ship lifecycle efficiency

Customer stories from the cruise industry

Discover the benefits others have already gained from choosing Wärtsilä.

Wärtsilä 31DF dual-fuel engines with custom flexible mounting guarantee comfortable cruising aboard The Ritz-Carlton Yacht Collection’s Ilma superyacht.

A digital model of the Regal Princess cruise ship has given Carnival data and insights that will help it decarbonise both existing vessels and newbuilds.

Close collaboration between Royal Caribbean Group, Wärtsilä & French yard Chantier de l’Atlantique was key to successful development and introduction of the first new Wärtsilä 46TS-DF engine.

When Silversea’s luxury cruise liner Silver Dawn needed a high-quality, reliable and quiet propulsion system, Fincantieri shipyard turned to Wärtsilä.

Princess Cruises relies on Wärtsilä’s propulsion system for minimal engine noise and vibrations and ultra-reliable operation on its vessel Discovery Princess.

Ship lengthening is a complex process, but with the right expertise – like that found at Fincantieri and Wärtsilä – the benefits were clear for Windstar

Le Commandant Charcot, the world’s only luxury icebreaker, uses the Wärtsilä 31DF engines for sustainable polar exploration

Essential webinars

What everyone in the cruise industry should know about future-proof maritime solutions. Register now! Or catch up on webinar recordings.

Important insights

Discover these hand-picked articles to learn about the many solutions for future-proof, sustainable cruise ship operations.

Latest news for the cruise industry

Wärtsilä and Royal Caribbean Group celebrate 15 years of collaboration on digital transformation

Extended Wärtsilä agreement continues support for Carnival Corporation’s fleet decarbonisation goals

Latest Wärtsilä engine to make its debut powering new luxury cruise ships

Wärtsilä’s expertise covers the full spectrum of solutions and services, from cruise ship engines to digital solutions and from hybrid ships to lifecycle services. Cruise ships can stay productive and competitive – and on the steady course towards net zero operations.

Take your easiest step to future-proofing your cruise operations – get in touch and let’s discuss your needs and options!

- Privacy notice

- Cookie notice

- Terms of Use

This is How Cruise Ships Work

by Contractor | Nov 24, 2020 | resources , Travel Tips | 0 comments

Are you wondering how cruise ships work? Whether you’re planning a trip or just curious about a cruise ship’s technicality or even the logistics, it’s always intriguing to find out how massive ships like work. How does a cruise ship work?

First and foremost, a cruise ship’s heart is in the engine of the vessel. The engine’s design, paired with proper fueling, provides the power for the ship’s mobility and all the entertainment aboard. The ship’s engineering and the logistics of running a cruise company play a role in shaping how a cruise ship works overall

If you are an engineer curious about a ship’s mechanics, this is an article for you. Fortunately, if you’re just a curious traveler wondering how a cruise vessel will shape your next trip, this is also for you, so read on. There is so much to a cruise ship other than the cocktails and fun parks on top. This will be an eye-opening article for all audiences.

How Do Cruise Ships Work

To the ultimate question, “how a cruise ship works,” let’s dive into how it works mechanically. What are the technical and mechanical aspects of a cruise ship? What does an engine do? How does a massive ship provide light, food, entertainment in the middle of an ocean? Is the water safe to drink?

Then, after reviewing how the cruise ship’s mechanics work, the answer to how a cruise ship works logistically can be answered. How do companies make a profit from these vast ships? How do the ships prepare for new passengers?

Technical Aspects of Cruise Ships

The technical aspects are a vital part of a cruise ship, so it will be first visited. Not to state the obvious, but the ship’s heart is shaped by the crew and the engineers that have put many hours and dedication into making a cruise ship work.

This is article will reveal the true hidden layers of what makes it all work starting from ground zero, the heart.

Technical Aspects

If you want one thing in a cruise ship aside from the cocktails and a nice tan, it’s the vessel’s stability and durability. Whether you are traveling through an unexpected storm or cruising on a gentle wave, your cruise ship should be the most stable in all situations.

How are cruise ships stabilized? The general idea for balancing and maintaining buoyancy is distributing the weight throughout the ship correctly, and of course, displacing the right about of water as it moves. So, let’s first talk about one of the most massive machinery onboard, the engine. Where does it sit and how does it run the cruise ship?

Engine Rooms

Where are the engines located? You guessed it, most heavyweights, such as engines, are found as low as possible in the lower decks, ground zero. For most cruise ships, the engines are close to the keel. The structural keel is the most closes to the bottom of the vessel and the ship’s wide hull. It runs the length of the vessel down its centerline and in most ships, you won’t have to go far to find the engine rooms.

Just because it’s placed low in the ship doesn’t mean it doesn’t take a lot of space. For all the ship’s power, the engine rooms can take up several decks high and are generally divided into several compartments. It may not feel like an open massive space, but it is truly the heart of the ship and the design of the rooms and placement are critical.

Usually, the primary concern for most ships is have engines and machinery compartmentalized for safety and avoiding fire hazards. Compartmentalized and labeled rooms make maintenance simpler and enhances safety for unprecedented accidents.

New legislations also support the requirement for compartmentalization. Ships are required to have at least a duplicate of equipment and at least two separate spaces for engines. So, what about these engines? Why are they so important and why do ships need so many of them?

Power and Engines

Just to answer those questions, we’ll have to visit more fundamental questions such as: How do the engines power a giant cruise ship? How does it help the ship propel forward? Are there specific engines that power different parts of the cruise? Out of many questions regarding the engines, the answer starts with the main engines.

The main engines are the engines that produce the majority of the power for the cruise ship to move. Depending on the type of vessel, the main engine connects to different parts of the propelling power. From traditional steamboats, to diesel electric, the engine is the fundamental powerhouse for the entire ship on the sea.

The following table is a general overview of how engines on different types of vessels are connected to the ship’s requirements.

So How Do These Engines Make the Ship Move?

As shown in the table, depending on the vessel type, the engine will provide power to different aspects of the ship. More or less, everything is distributed to operating proportions, but the key mechanics differ from one to another.

Diesel may be something more familiar to what we saw in old movies with steamboats. Even in modern days, we use similar mechanisms, if not labeled the same. The main difference is the source of pressure, which can be the traditional steam, or a fuel ignition.

Whether it is steam (traditional) or fuel ignition, the pressure generated from either push the pistons up and down in the vessel. These pistons connect to crankshafts through gears, which turns the pistons.

The crankshaft connects to the propeller through a long propeller shaft and gears, which further determines its speed in traditional diesel-powered vessels by steam pressure. Generally, the faster the pistons move up and down from the pressure, the quicker the propeller shifts would move.

With modern designs that control the propeller speed, engineers placed the gears in between the propeller and the engines which further enhances efficiency for both engines and propellers.

Again, although the majority of the engine provides electricity to the propeller shaft, electricity must be provided to the rest of the ship for entertainment. Often, options such as a shaft generator offer power to outlets such as lighting the dining and general appliances onboard while in motion.

Diesel-Electric

Diesel-electric is another form of vessels that are found commonly with conventional diesel vessels. Unlike the conventional diesel, diesel-electric engines are connected directly to the generators that provide the electricity for the propellers and main generators.

This electricity also provides direct power for the ship’s lights, appliances, and much more.

Environmentally Friendly Power

On a side note, if the thought of diesel in the ocean disturbs you, there is some good news! Thankfully, more and more environmentally friendly options are appearing for cruise ships. For example, liquified Natural Gas (LNG) is an alternative method for powering ships that burns natural gas for power.

Using natural gas could reduce nitrogen oxide and carbon dioxide emissions significantly! With green-oriented companies, more green cruises have been released in the past few years.

That being said, if you are looking to book a trip, be on the lookout for green cruising opportunities! Onboard, you can also find environmentally conscious crew members and less-waste policies.

Source: CruiseCritic , Windstar Cruises , Green Cruises

Fuel Consumption

So, how does fuel play a part in powering the engine and the cruise ship? Let’s go back and visit what an engine does. An engine generates electricity to the propellers by supplying power the propulsion motors. How do they get the electricity and what makes an engine work? Most likely fuel and ignition (besides the steamboat example from before).

How much Fuel?

In general, a large cruise ship can consume up to 250 tons of fuel a day, which is close to 80,000 gallons a day. For medium size cruise ships, consumption can still range up to 150 tons of fuel a day.

Onboard, a ship may carry up to 1 to 2 million gallons of fuel, depending on the vessel size. Most of the power, which can be close to 85%, goes to the propellers, while the rest goes to keeping the cruise lit and comfortable for the passengers and crew members.

While passengers dine and enjoy their cruise aboard, crew members are constantly maintaining the proper fuel levels and providing proper power for the ship. As for the captain of the ship, he also has several variables to keep in mind to control fuel consumption and safety.

Fuel consumption may vary for several reasons, just like when we are driving our cars (but with more variability). For example, depending on where the wind is hitting the ship, the fuel consumption can go 1 – 5% over the average consumption rate.

Here is a short list of variables that the captain is keeping track of:

- Speed of the cruise

- Sea conditions (vs. sailing direction)

- Weather (including the direction of the wind)

- Size of the ship

- Engine (Gas turbines, diesel-electric, diesel, or electric)

Source: Windstar Cruises , Cruise Mapper

Overall, the fuel, power, and engine, are all functions of making the magic happen. Starting from the design of the engine, to the crewmembers and captain maintaining the fuel and power consumption, a lot of action happens behind the scenes while passengers are onboard during vacation.

Floating and Buoyancy

Now that the ship is powered, how do we ensure that it floats? How do these massive machineries, ice-skating rinks, restaurants, and bars float on water while keeping thousands of passengers safely onboard?

While the cruise ship constantly pushes the water out of its way when moving forward, the water being pushed will try to come back to its place. This displaced water pushes back with a force on the vessel which lets the cruise ship stay afloat.

This is the general idea when engineers designed the hull of the ship. This ratio has to be calculated when designing a ship and has to be correct. If you get a chance to see the hull of most ships, they have a wide U-shape hull at the front to maintain the displacement.

In addition to basic buoyancy principles, an engineer must also consider the ship’s average density. This means that the ship’s general open spaces must be considered on top of the vessel’s average weight, so the vessel remains “less dense” than the ocean’s (usually salty) water. A great example is a rock sinking vs. a beach ball floating on water.

Source: Express

Water Onboard

So the power, fuel, engine, and buoyancy are the fundamentals of the ship. What about the details of the cruise ship such as the water in your shower? Is it salty? Is it fresh? Where and how does that come to your room without running out.

In general, most cruise ships have a steam-evaporation system. Water is pumped and desalinated before going to your room. During this process, your water is distilled and desalinated using a reverse-osmosis system and filtration system.

Distillation and desalination process uses a purification system to take all contents out of the water. This is generally not healthy to drink, so this water is mineralized and chlorinated for taste and safety.

Additionally, some ships have water brought onboard for laundry and other maintenance purposes. Generally speaking, the water onboard available for drinking are tested and checked for purification. If you are ever in doubt, check with a crew member to ensure the water is safe for consumption.

Is the Water Safe?

The answer to your ultimate question is, no, the water you are drinking is not toilet water. Regulated by the Maritime Organization laws, all “toilet water” must be treated and discharged into the ocean at a specific distance from the land. This water is never treated and recycled for passengers to use again.

On a side note, if you feel uncomfortable drinking this water, bottled water will most likely be available onboard for purchase. If you need special water for medical needs, you will most likely be able to bring a few bottles on board by notifying them ahead of time.

Now that we have reviewed how cruise ships work mechanically, let’s dive into the ship’s logistics. How do they work? Who’s working, how is it supplied, and how are they so cheap? Or perhaps, why are they so expensive? All of these questions come down to logistics.

General Logistics

Depending on your opinion and type of cruise you may have signed up for, you may think that your cruise is way under or over-budget. The cruise companies measure these decisions and prices to minimize cost and maximize returns (of course).

For example, cruise ships avoid fines by taking specific lines. They must often save fuel and hiring a knowledgeable captain who can make these decisions and keep passengers aboard safe is essential.

So, what are the different divisions of a cruise vacation? Are some better than others?

Mainstream, Premium, and Luxury

If we broke down cruises into 3 main categories, we could look at the mainstream, premium, and luxury lines of cruise types. You will often see categories within each of these types, but let’s break them down into the major categories for simplicity.

First, we will start with the mainstream cruise lines. These are cruises that are readily available, common, and well-known by the public with reasonable ticket costs.

Generally, these cruises’ primary business is through the onboard casinos, spas, shopping, and drinks. They suit the needs of most passengers. To make maximum profit, companies design these cruises by providing readily available entertainment on board. Most passengers are estimated to use 500$ onboard for their vacation experience.

Onboard, you will find general amenities, restaurants, bars, pubs, nightclubs, shopping, theaters, cinemas, swimming pools, gyms, karaokes, libraries, and even museums! These are great for big parties and are generally the biggest ships at sea.

Examples of Mainstream Cruise Lines that are known as “floating resorts”:

- Carnival Cruise Line

- Royal Caribbean International

- Norwegian Cruise line

- Lindblad Expeditions

- Amawaterways

Mainstream cruises are great for

- Group of friends

Source: NancyandShawnPower , Fodors , and Wind Rose Network

Premium lines are perfect for adults or those that are retiring. The brilliant catch is that many have policies of “no kids allowed,” making it an excellent selling point for adults who need some peace and quiet. These cruises make money upfront by offering more access to ports and offering the serene luxury.

Premium cruises generally have a refined style in comparison to mainstream cruise lines. Activities are more focused on lifestyles. For example, you may find computer classes or a language-learning class. Besides, these ships still offer resort-style pools, game nights, bingo, spas, gyms, and maybe even a jazz night.

The perks for a premium in comparison to the mainstream is the higher quality of cuisine. Usually offering specialty restaurants and quality chefs, the price may be higher, but the overall quality is higher. The rooms at premium cruise lines are also superior, often offering suites and rooms with balconies.

Examples of Premium Cruise Lines

- Princess Cruises

- Celebrity Cruises

- Holland America Line

The popular audience for Premium cruise lines:

- Older Adults

- Sometimes family-oriented

Source: Fodors

Luxury lines are pricier yet offer the best-selling point, fewer people onboard with a luxurious experience from beginning to end. The more expensive tickets provided to only a few hundred passengers make a profit for the company with the much higher ticket prices.

There are abundant space and a deluxe ship that will greet you as a valued guest from beginning to end for the high price. No doubt, one will fall for such an exquisite experience that starts from fine dining of caviar and foie gras to personal service available at one’s fingertips.

Course meals are offered from a full restaurant menu in your stateroom and served with limitless wine. Most interiors are luxurious and elegant, with rooms that are large and overlooking the sea.

Amenities range from gyms, spas, pools, and low-key entertainment. Generally targeting a niche group, most luxury cruise lines do not allow children.

Examples of luxury cruise lines:

- Windstar Cruises

- Paul Gauguin

- Silversea Cruises

- Crystal Cruises

- Oceania Cruises

Source: Cruise Critic

Many corporations own several of these different targets to make the most profit. Additionally, by corporations owning various cruise types, they can also hand down older ships throughout their other brands.

Logistics throughout the year

In addition to managing several types of cruises, there are numerous ways cruises have to operate to maintain their profits and not waste money through resting and selecting the wrong routes.

For example, cruise lines generally have high sales in November through April by Americans. The cold Americans usually take a warm vacation away from winter for a trip to the Caribbean.

What about other times of the year? Staying on seas without business is a considerable loss in revenue and usually unheard of. So, what do they do? They sell repositioning one-way tickets in April!

Generally, towards the end of April, you will start seeing two-week trips from the Caribbean to Europe. Typically, these trips can range from any state on the Eastern Coast of the United States to European countries.

Switching over/Cleaning

When there are one-way trips, there also needs to be exceptional coordination for a short turnaround between trips. When the cruise ships get to the destination, all hotels, theaters, dining, laundromat, and parks are cleaned and reset for the next people to come on board within half a day!

How do they do it?

During night-time, luggage and bags are ready ashore for passengers to check out. Meanwhile, all the trash is dumped, and the trash containments are cleaned, crew members switch, fuels are refilled, and food is refreshed with new inventory.

Remember the 1 to 2 million gallons of fuel to refill? This process, called bunkering, is a whole-team effort and is completed before the ship is ready to travel again.

A small boat, a “barge,” brings fuel to the 400 ports fueling for ships.

- Barge secures to the side of the cruise ship

- Connects a hose between the ship tanks

- Pumps fuel while watching guard

When passengers load off, then the cleaning crew comes to clean the rooms. While the ship is pampering, they complete paperwork from the first trip, fulfill any necessary maintenance, redecorate rooms, and start preparing and cooking food and lunch for the next set of passengers coming on board.

Soon, the ship is reloaded with happy passengers and starts to move again. They make their profits from when the Casinos start, and food is served.

Crew Members